Cell grabbing device and hot press

A grasping device and grasping mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficulty in multiple manipulators acting in unison, mechanical vibration, and affecting equipment stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, a cell grabbing device is provided. The cell grabbing device is mainly used on a hot press machine to grab and load cells and assist in the production of cell packs. The cell grabbing device can also be used on or in conjunction with other equipment to grab other objects for loading and unloading production.

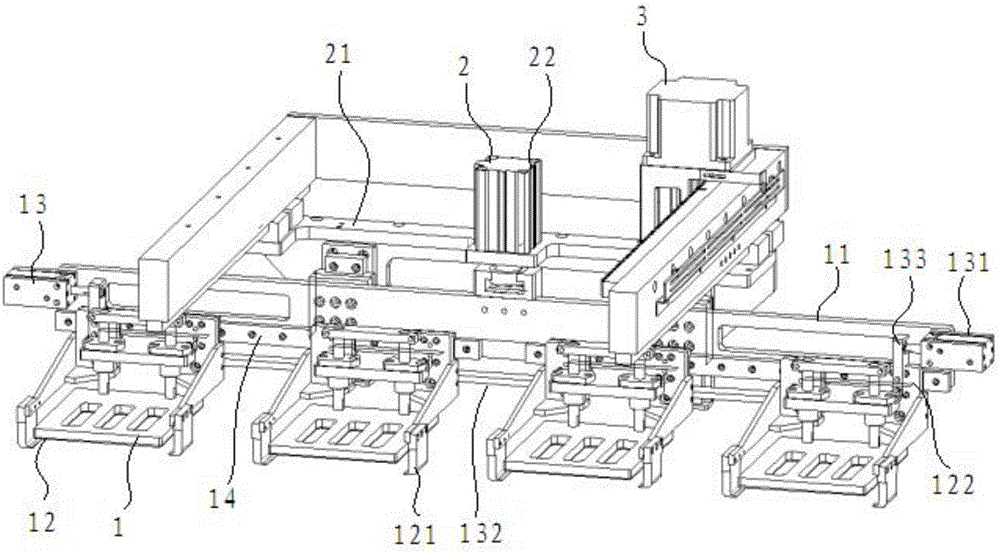

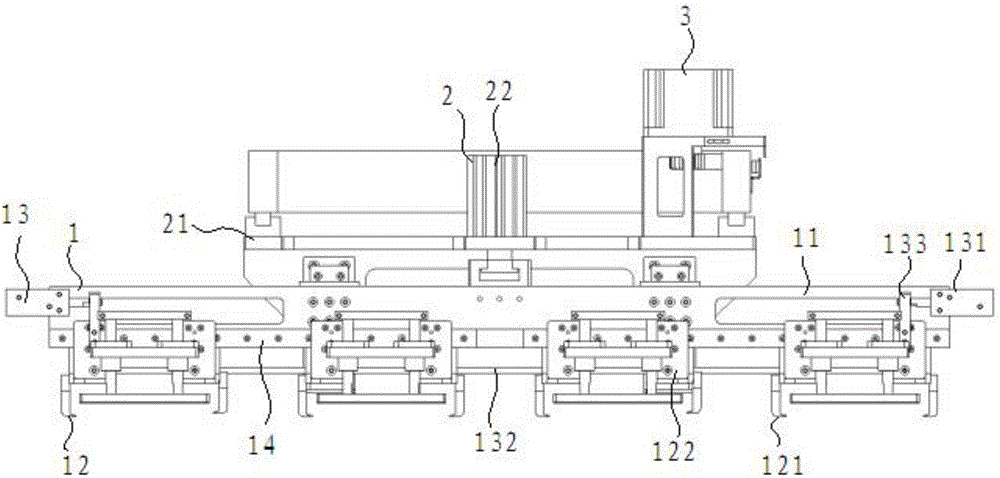

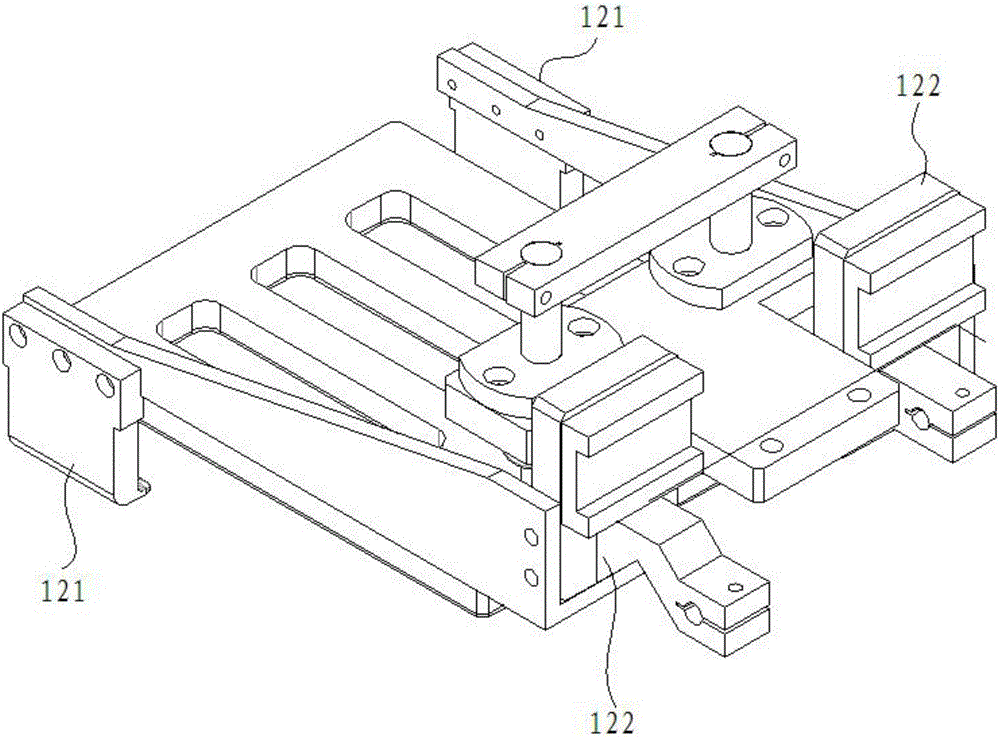

[0023] like figure 1 and figure 2 As shown, the cell grasping device includes a grasping mechanism 1 , a lifting mechanism 2 and a translation mechanism 3 . The lifting mechanism 2 is installed on the translation mechanism 3, and the grasping mechanism 1 is installed on the lifting mechanism 2, so that the translation mechanism 3 drives the lifting mechanism 2 and the grasping mechanism 1 to translate together, and the lifting mechanism 2 drives the grasping mechanism 1 to move up and down. The translation mechanism 3 and the lifting mechanism 2 jointly realize driving the gripping mechanism 1 to move back and forth between the discharging p...

Embodiment 2

[0040] This embodiment provides a heat press machine, which is mainly used for producing and processing lithium battery cells, and the heat press machine includes the cell grasping device of the above embodiment, so that the production and processing stability of the heat press machine And precision are all higher than the equipment in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com