Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Silicene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

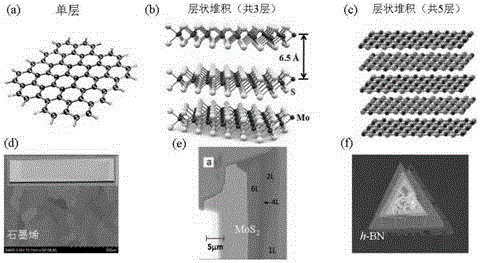

Silicene is a two-dimensional allotrope of silicon, with a hexagonal honeycomb structure similar to that of graphene. Contrary to graphene, silicene is not flat, but has a periodically buckled topology; the coupling between layers in silicene is much stronger than in multilayered graphene; and the oxidized form of silicene, 2D silica, has a very different chemical structure from graphene oxide.

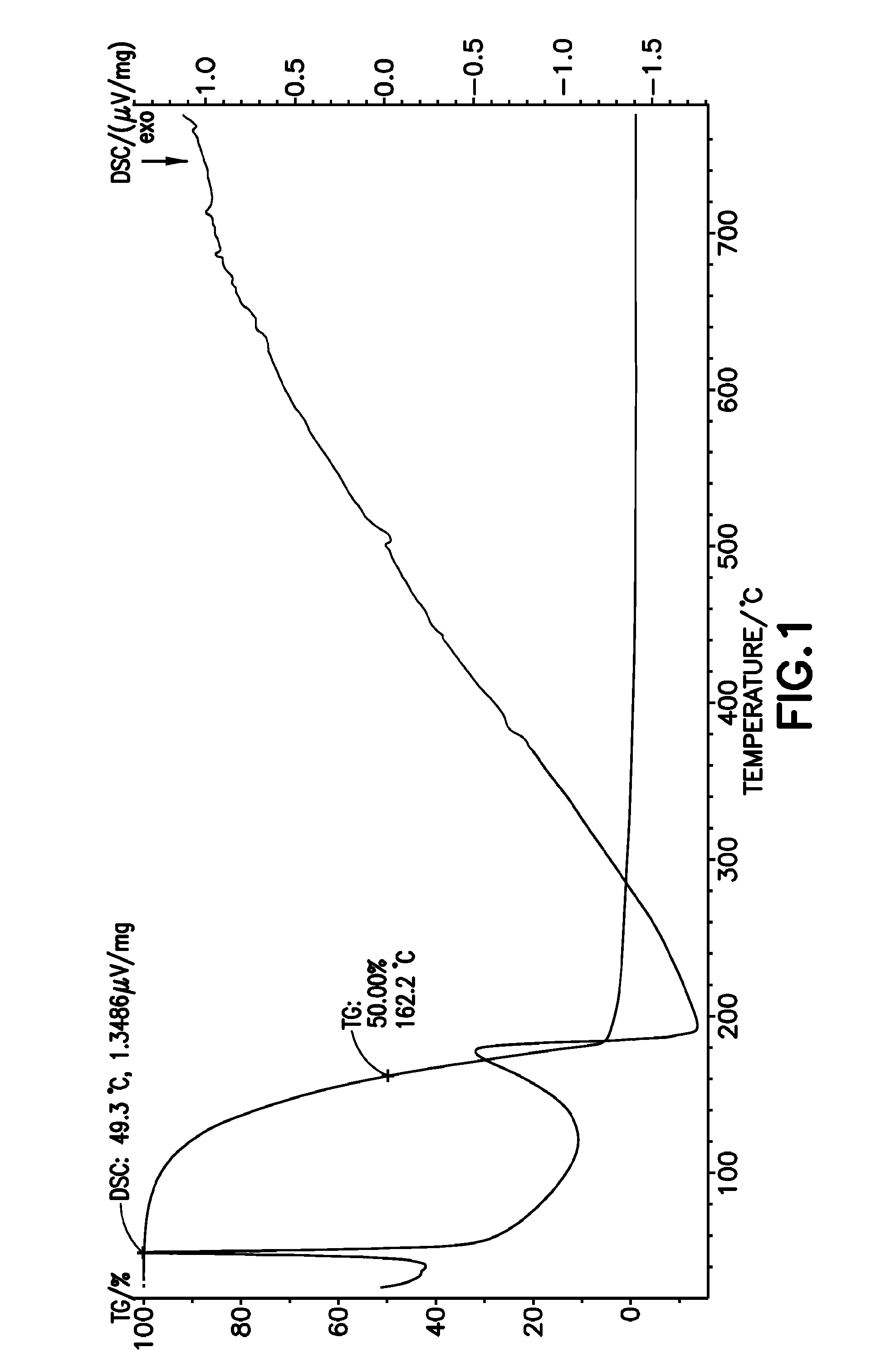

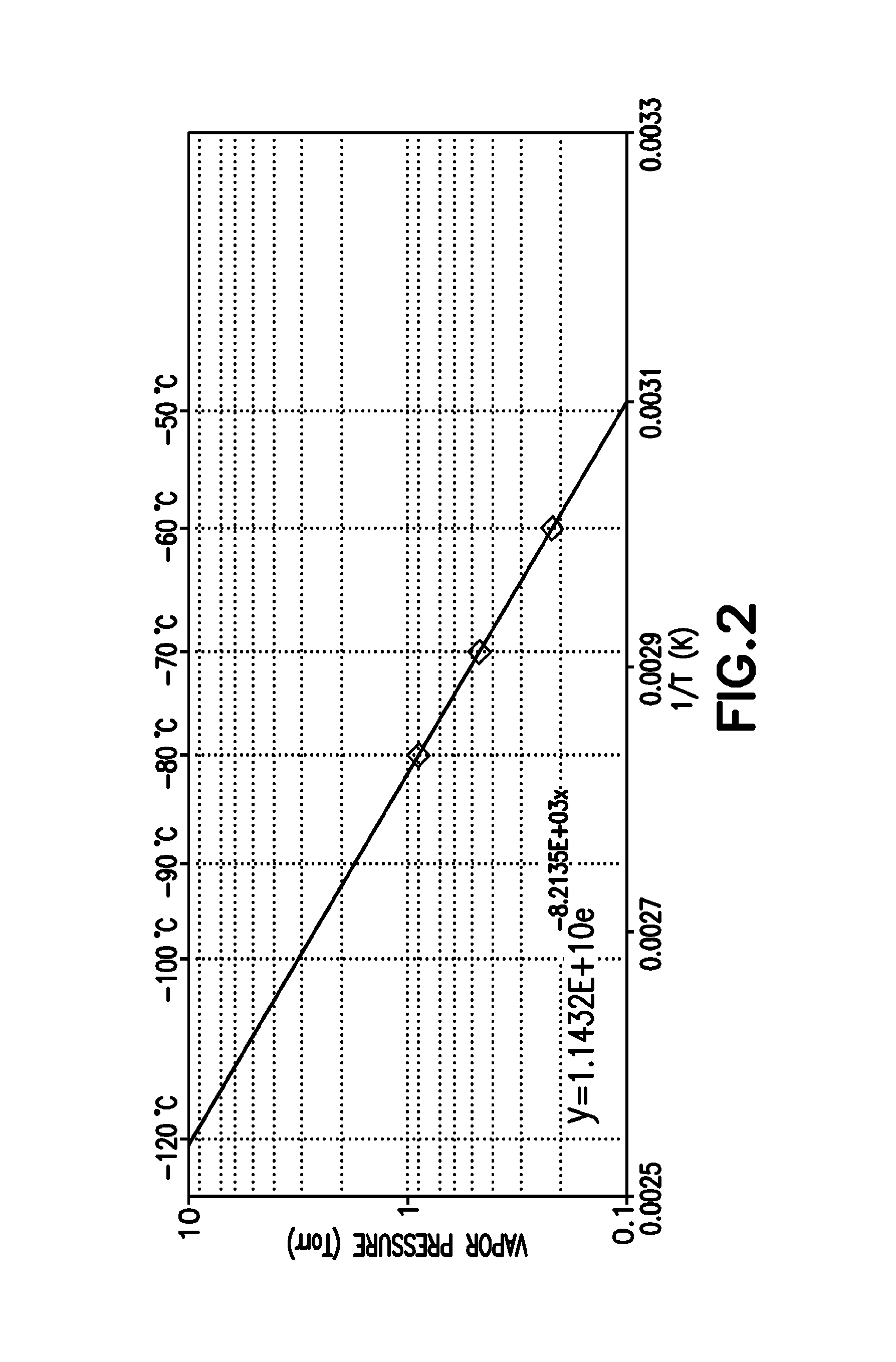

Silicon precursors for low temperature ald of silicon-based thin-films

A silicon precursor composition is described, including a silylene compound selected from among: silylene compounds of the formula: wherein each of R and R1 is independently selected from organo substituents; amidinate silylenes; and bis(amidinate) silylenes. The silylene compounds are usefully employed to form high purity, conformal silicon-containing films of Si02, Si3N4, SiC and doped silicates in the manufacture of microelectronic device products, by vapor deposition processes such as CVD, pulsed CVD, ALD and pulsed plasma processes. In one implementation, such silicon precursors can be utilized in the presence of oxidant, to seal porosity in a substrate comprising porous silicon oxide by depositing silicon oxide in the porosity at low temperature, e.g., temperature in a range of from 50° C. to 200° C.

Owner:ENTEGRIS INC

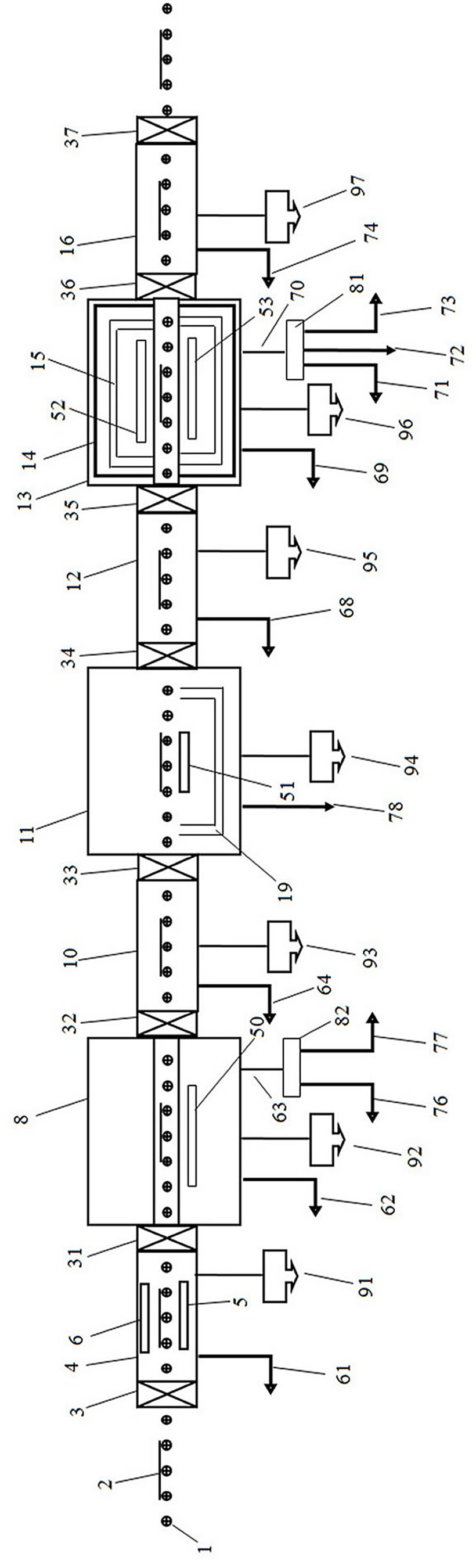

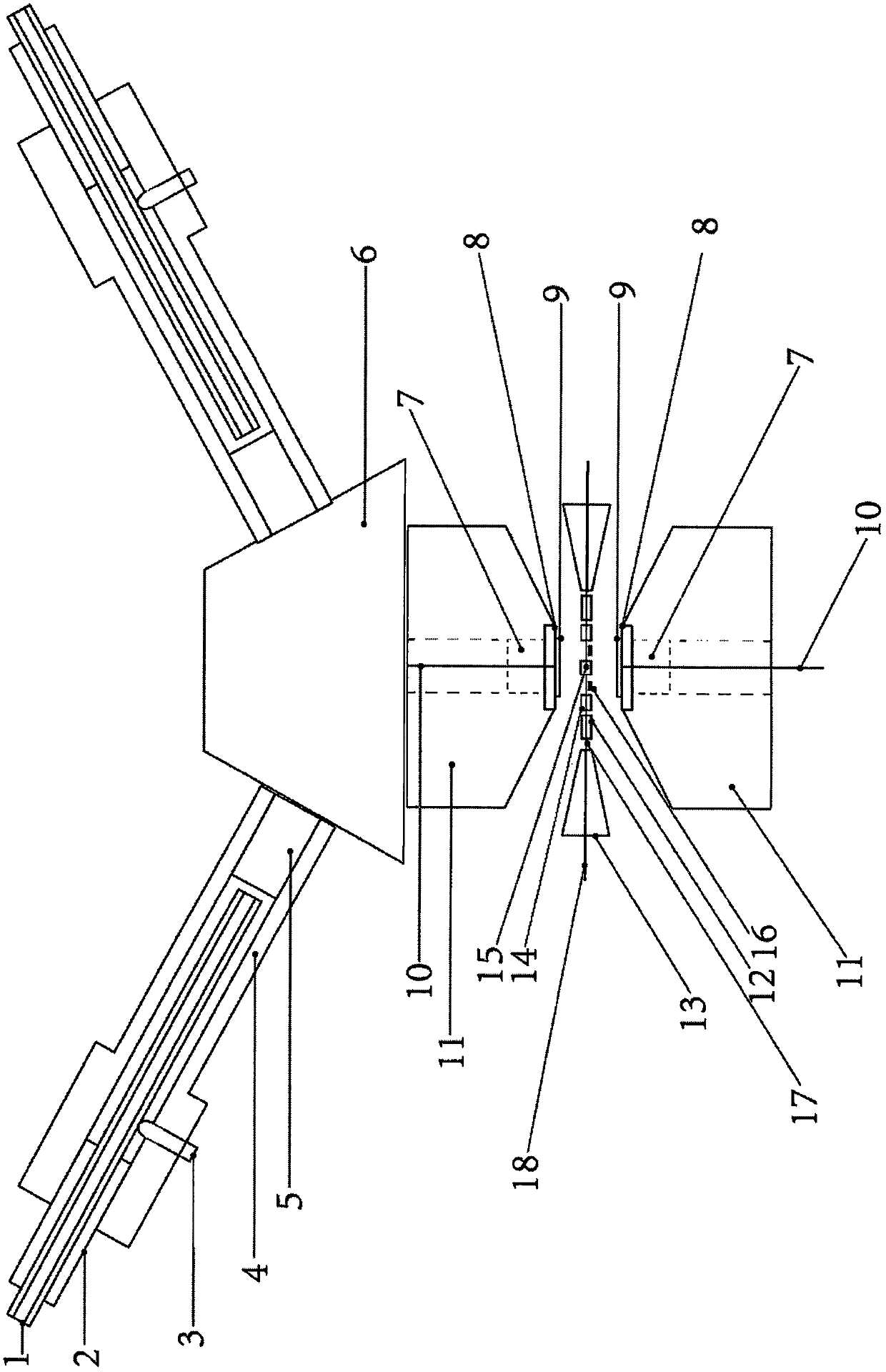

Device for continuously preparing two-dimensional nano films

InactiveCN102618827AAdapt to the development of industrializationRealize industrializationVacuum evaporation coatingSputtering coatingSilyleneThin membrane

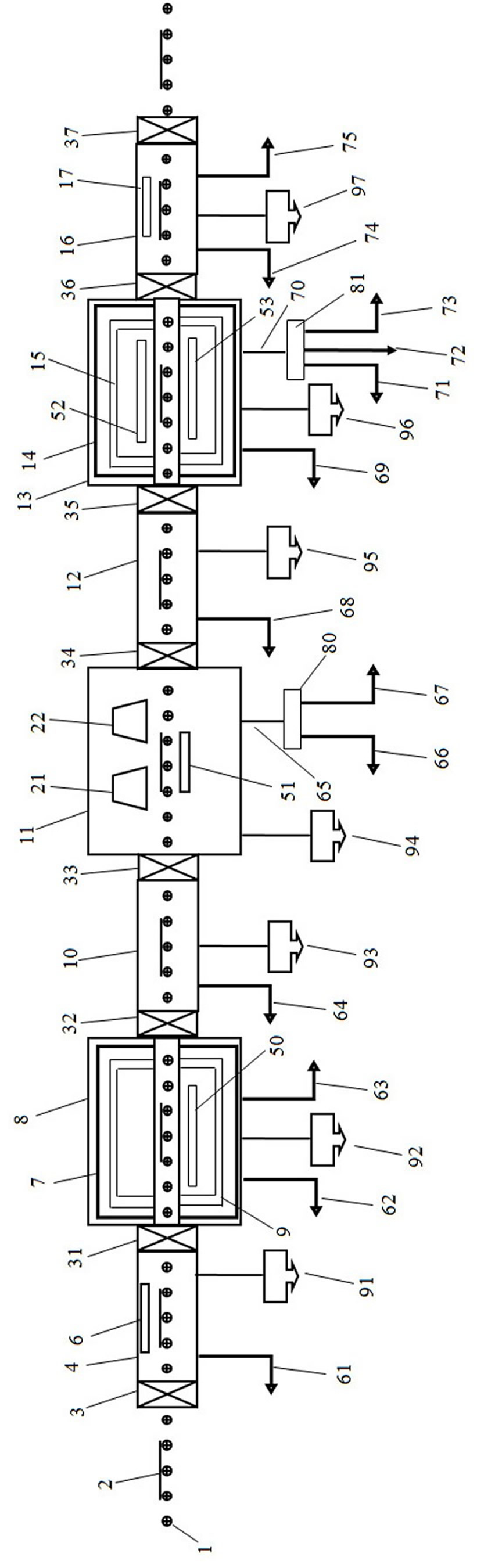

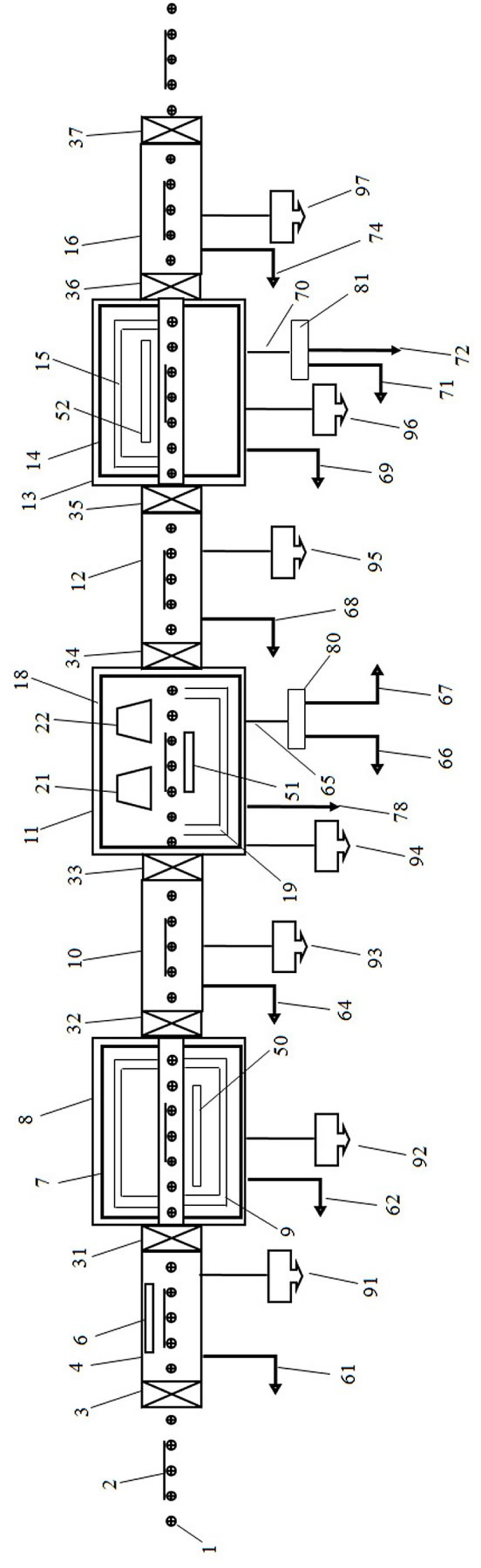

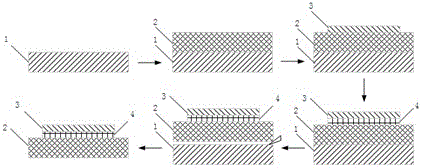

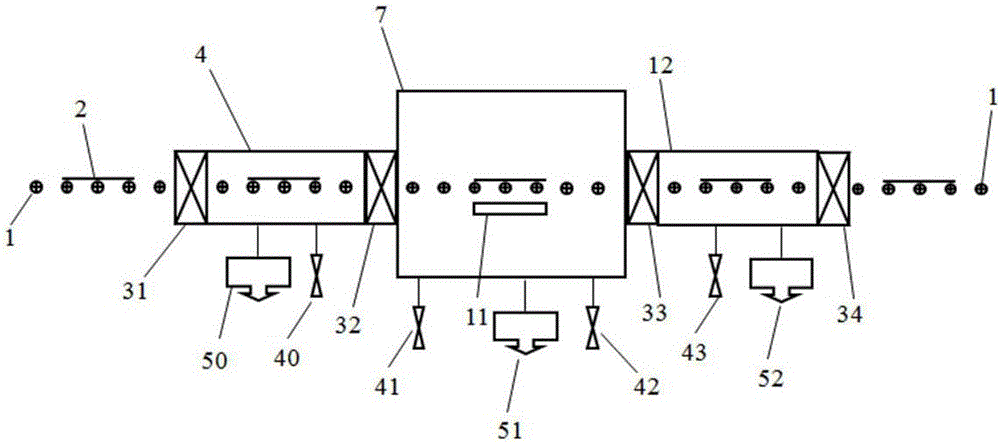

The invention discloses a device for continuously preparing two-dimensional nano films. The device is characterized in that: a feeding chamber, a first treatment chamber, a first balancing chamber, a film preparation chamber, a second balancing chamber, a second treatment chamber and a discharge chamber are sequentially arranged on a production line; a heating device is arranged in at least one of the feeding chamber, the first treatment chamber, the film preparation chamber, the second treatment chamber and the discharge chamber; a valve, a vacuum system and a gas pipeline are arranged between every two chambers, and a sample is transmitted among the chambers through a sample conveying device; and the film preparation chamber is provided with a film deposition system. The device is simple in structure and reliable in work, can be used for continuously preparing uniform two-dimensional nano films of graphene, transition metal sulfides, silylene, germanium alkene or boron nitride and the like in large area, and adapts to industrialized preparation of the two-dimensional nano films.

Owner:徐明生 +2

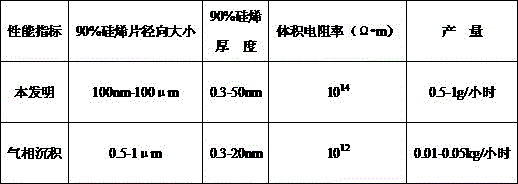

Two-dimensional silylene film and preparation method thereof

ActiveCN103668453ASimple methodEasy to implementPolycrystalline material growthVacuum evaporation coatingSilyleneGas phase

The invention discloses a method for growing a two-dimensional silylene film from a gaseous silicon source. According to the method, the silylene film is prepared through releasing silicon atom groups on a catalytic layer from the gaseous silicon source by adopting a chemical vapor deposition or physical vapor deposition technology, wherein the thickness of the catalytic layer is 25nm to 25mm, and the temperature of the catalytic layer is controlled to be 20-1,600 DEG C. The method disclosed by the invention is simple and easy to implement. The prepared silylene film is a two-dimensional layered film which is formed in a manner that three, four, five or seven silicon atoms serve as repeating units and are connected by covalent bonds, and the number of contained silylene layers is 1-200.

Owner:ZHEJIANG UNIV

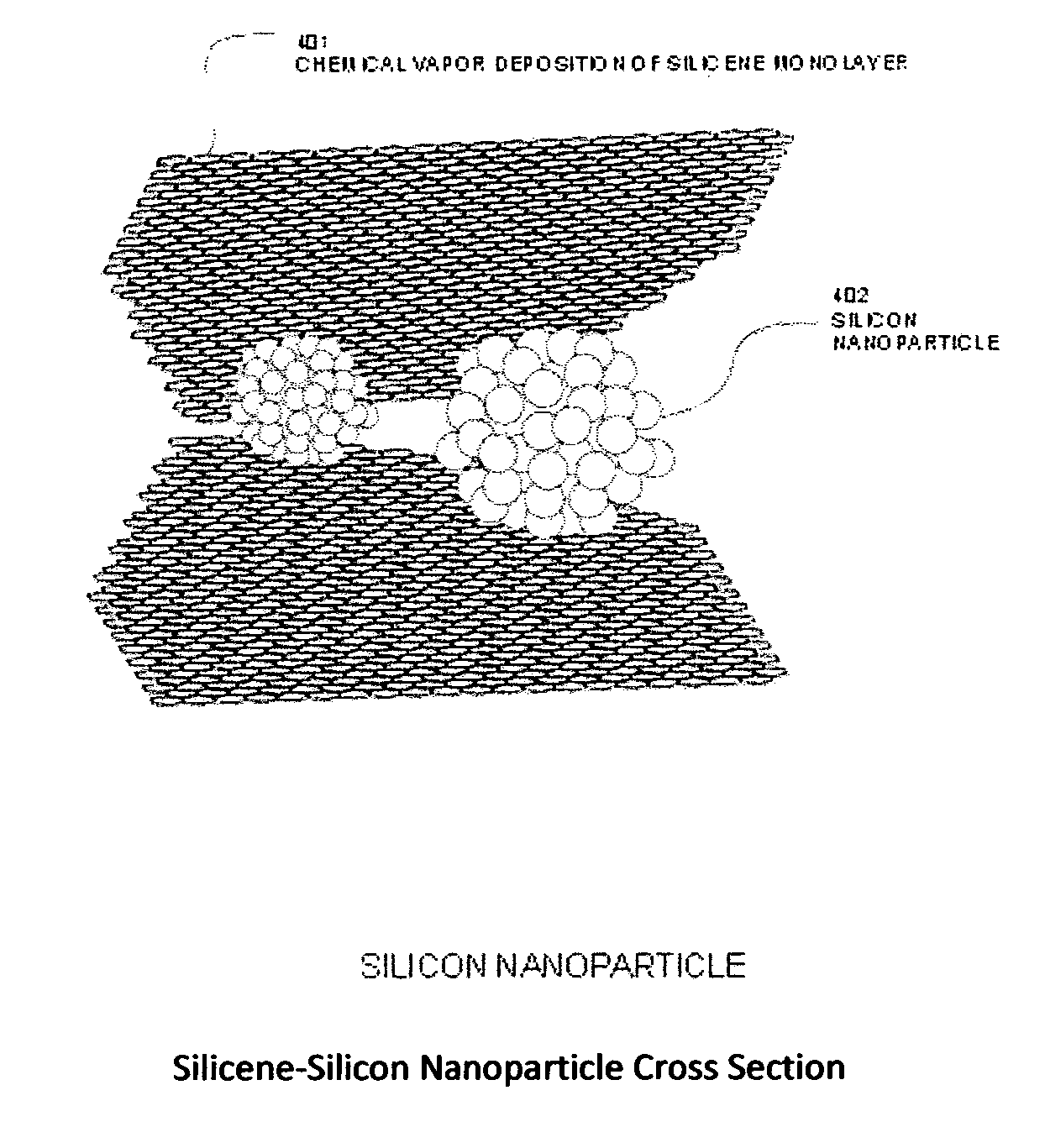

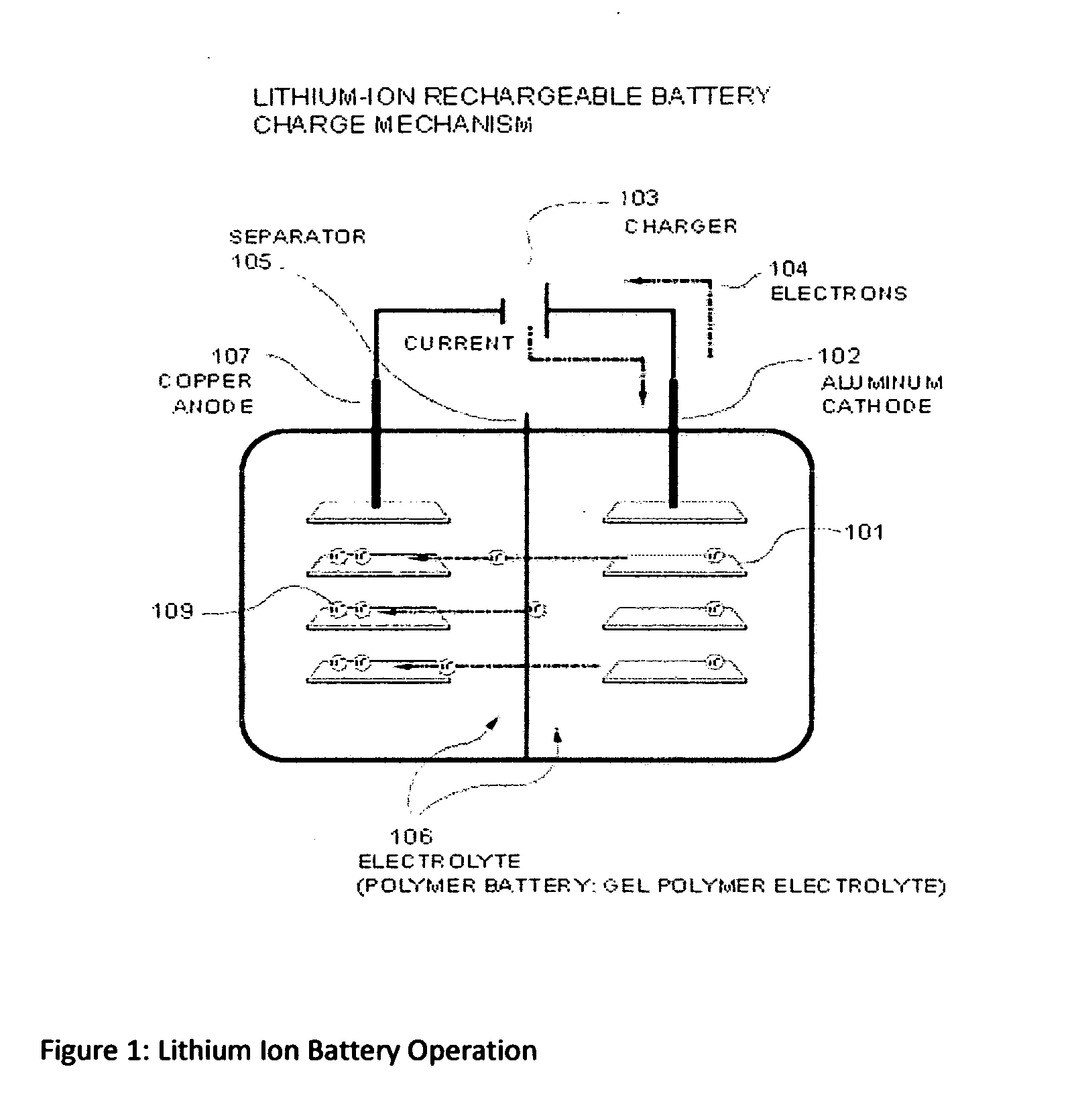

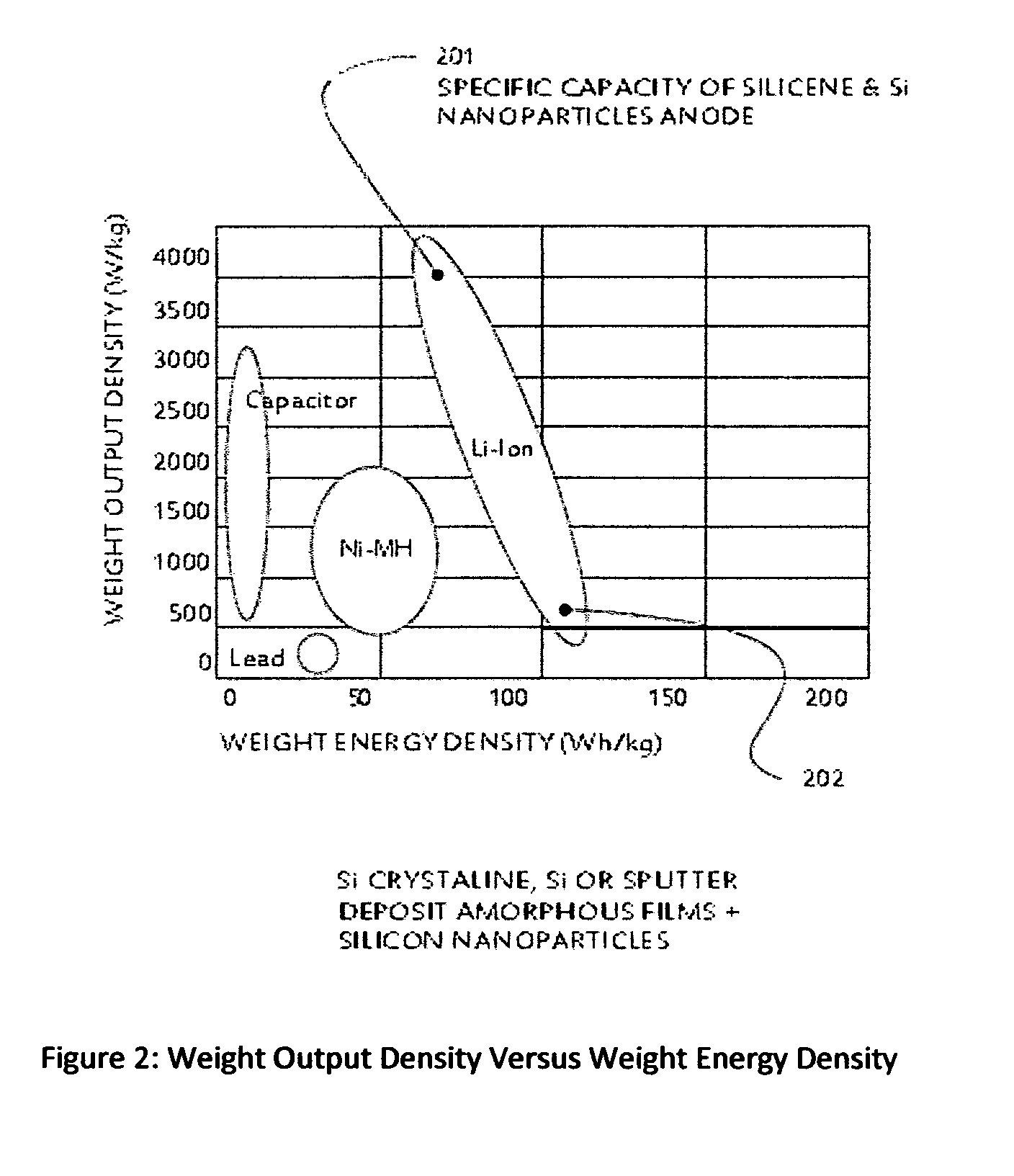

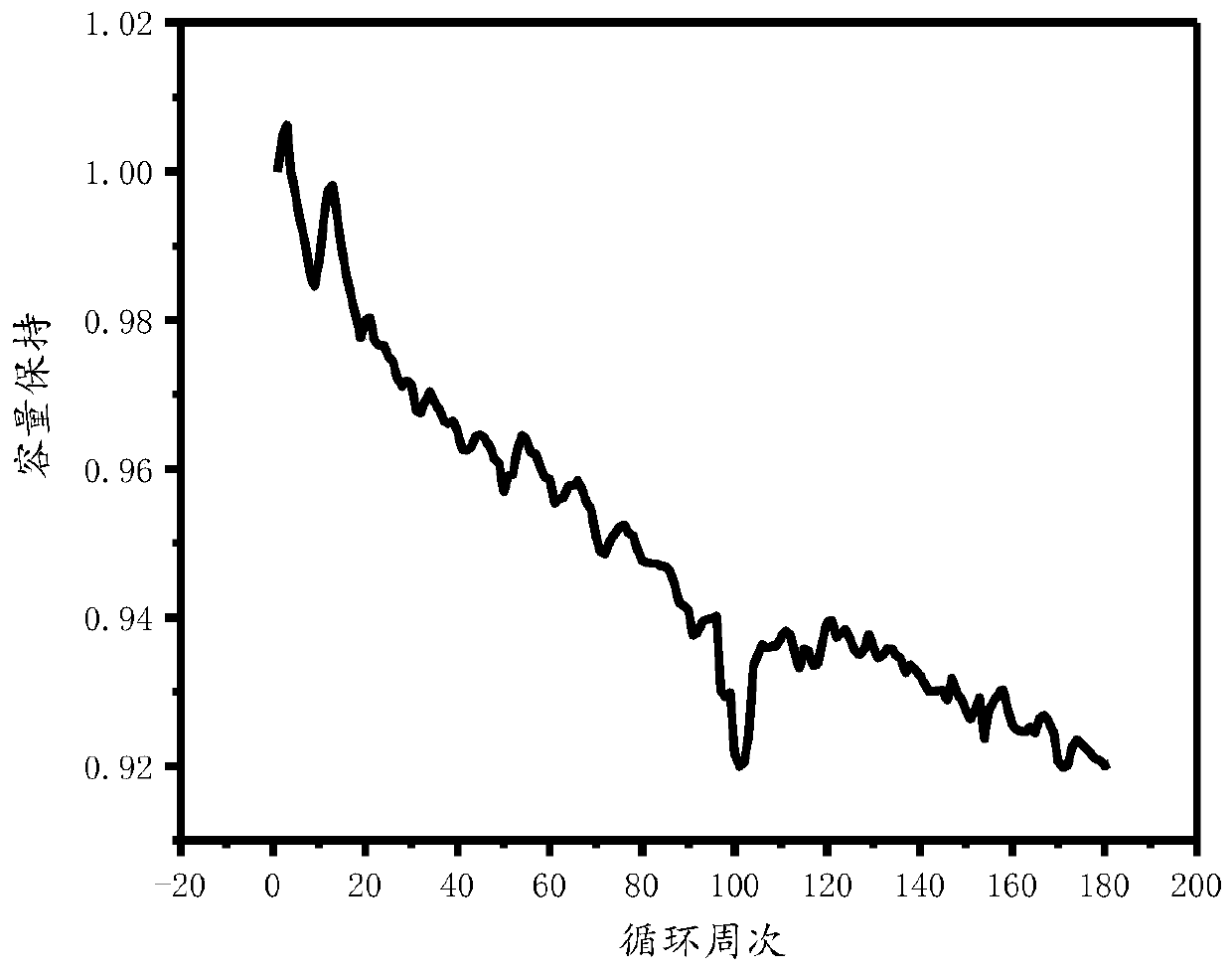

Silicene nanocomposite anode for lithium ion battery

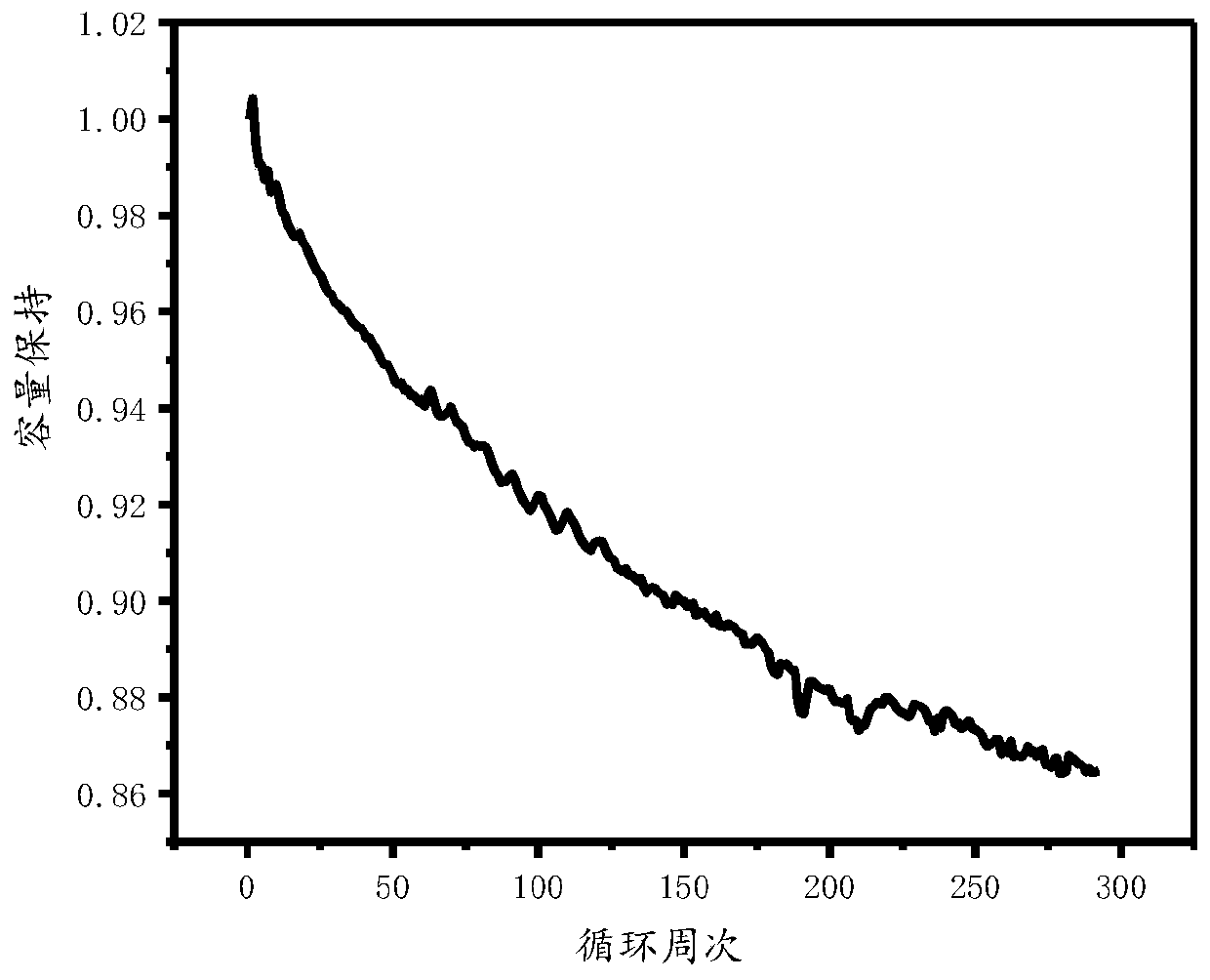

InactiveUS20150364754A1Improves Structural IntegrityMethod is fastMaterial nanotechnologyElectrolysis componentsHigh rateDendrite

A higher capacity silicene thin film structure with alternating layers of silicon nanoparticles which will result in an anode for lithium ion batteries. This nanocomposite structure will increase the specific capacity to 3500 mAh / g-1 versus 350 mAh / g-1 for state of the art lithium batteries. Charge / discharge cycles of 5000 with a maximum of 15% loss are also achievable. This is due to the silicene nanocomposites' capability to accommodate the mechanical expansion of the lithiated silicon species. Reliability defects such as copper cracking and delamination will be minimized using a barrier / adhesion metal layer. This will also reduce copper dendrite formation. Particle cracking and lithium plating will also be reduced by using the silicon based nanocomposite. The silicene nanocomposite can be fabricated using UHV-CVD methods minimizing transition to high rate production and recurring manufacturing product costs.

Owner:PAIDEIA

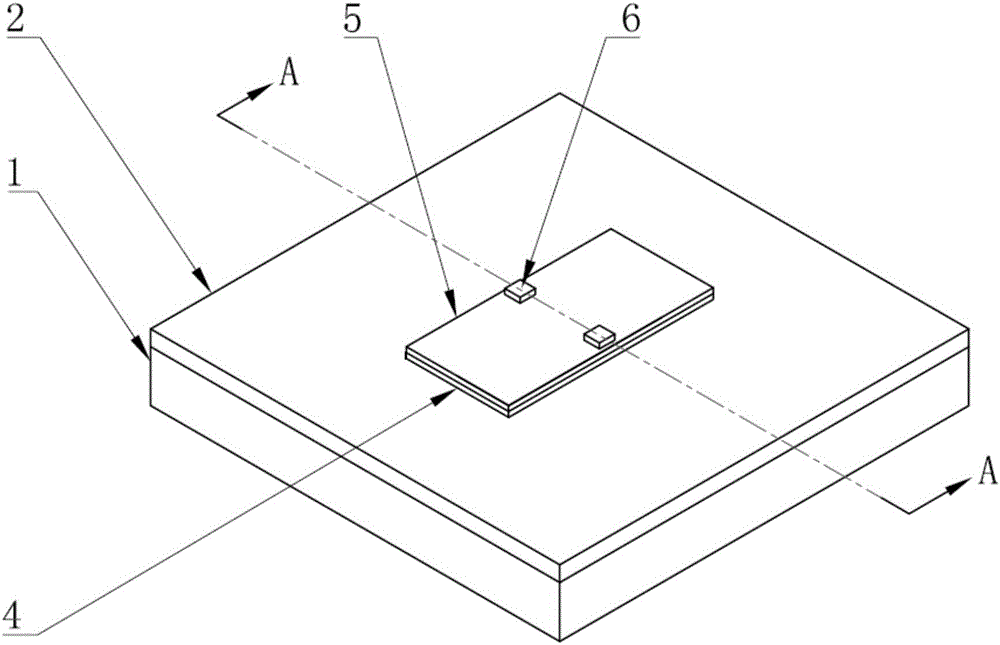

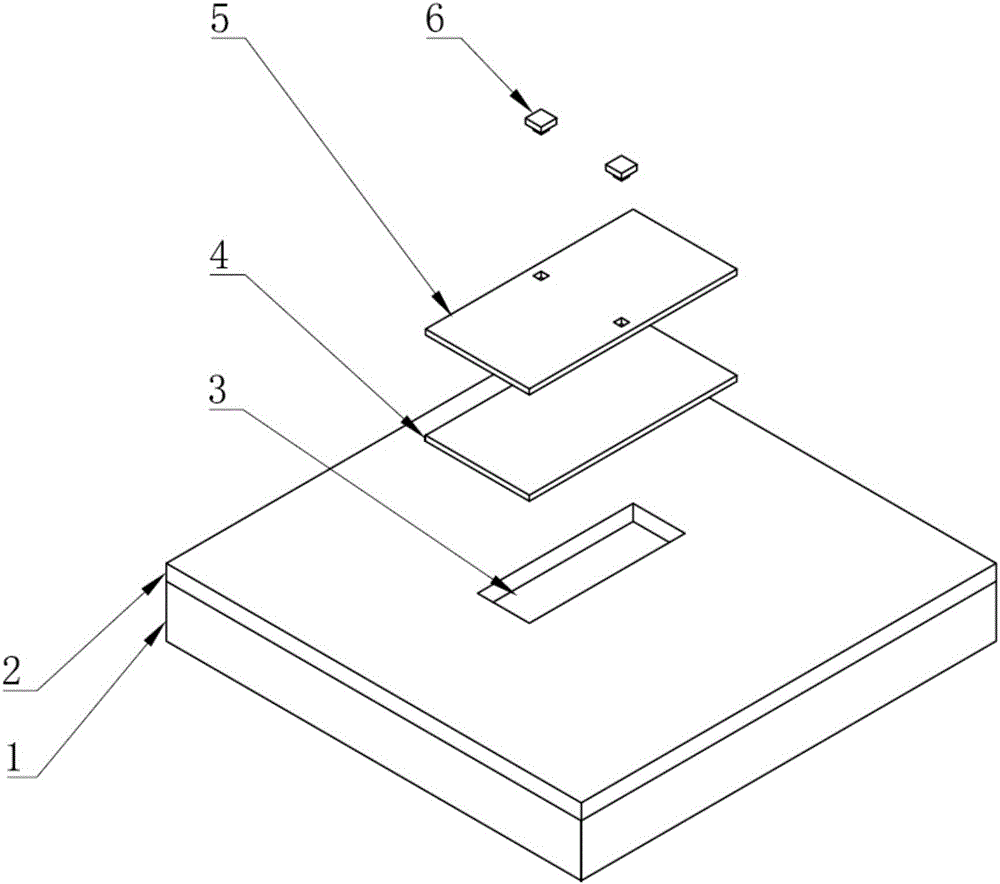

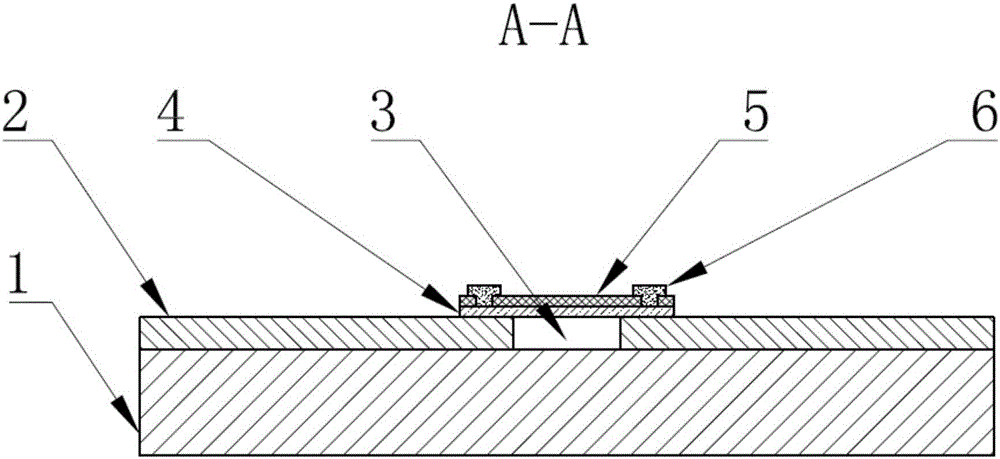

Doping silylene based MEMS piezoresistive pressure sensor and manufacturing method thereof

ActiveCN105841852AAddress reliabilityResolve SensitivityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsSilyleneOxidation resistant

The invention discloses a doping silylene based MEMS piezoresistive pressure sensor and a manufacturing method thereof. According to one method, an insulating layer is deposited at the surface of a substrate based on a surface silicon processing technology, and the insulating layer is etched so as to form a cavity; silylene is deposited on Ag, and the cavity is completely covered; the Ag substrate is peeled off, and then anti-oxidation protection and doping are carried out on a silylene film; and finally, two metal electrodes are deposited at the edge above the film, and each electrode is welded with a wire. According to another method, a mode of a traditional piezoresistive pressure sensor is adopted, wherein the traditional piezoresistive pressure sensor comprises glass, a substrate, an insulating layer, a silylene film, an anti-oxidation protection layer and metal electrodes from the bottom up. The doping silylene based MEMS piezoresistive pressure sensor has the advantages of good compatibility between silylene and the traditional semiconductor technology, simple manufacturing process, higher sensitivity and wider application.

Owner:HUAZHONG UNIV OF SCI & TECH

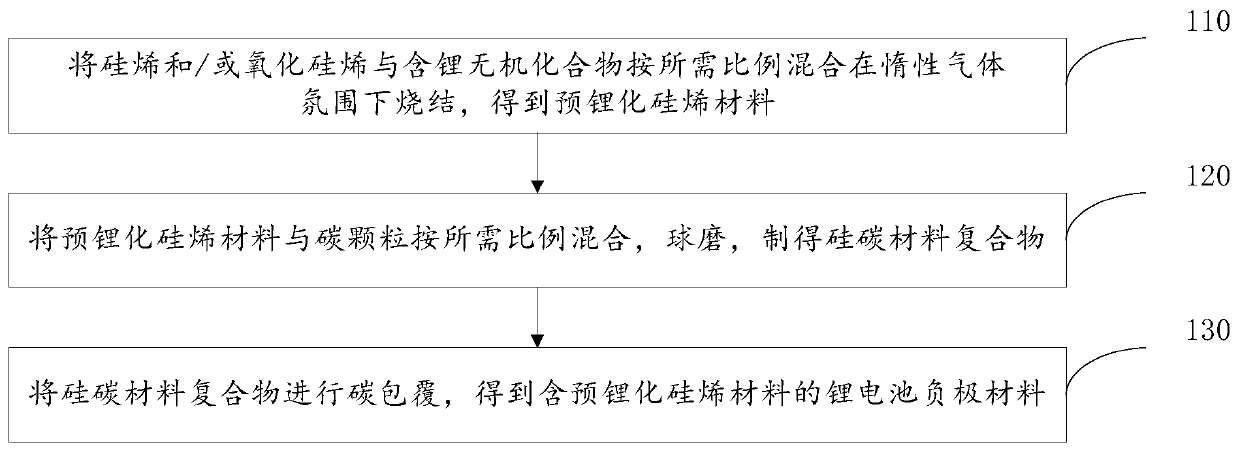

Lithium battery negative electrode material containing pre-lithiated silylene material, preparation method and lithium battery

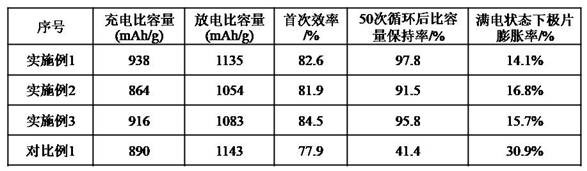

ActiveCN111554910ARelieve swellingImprove the first charge and discharge efficiencyNegative electrodesSecondary cellsCarbon coatingDischarge efficiency

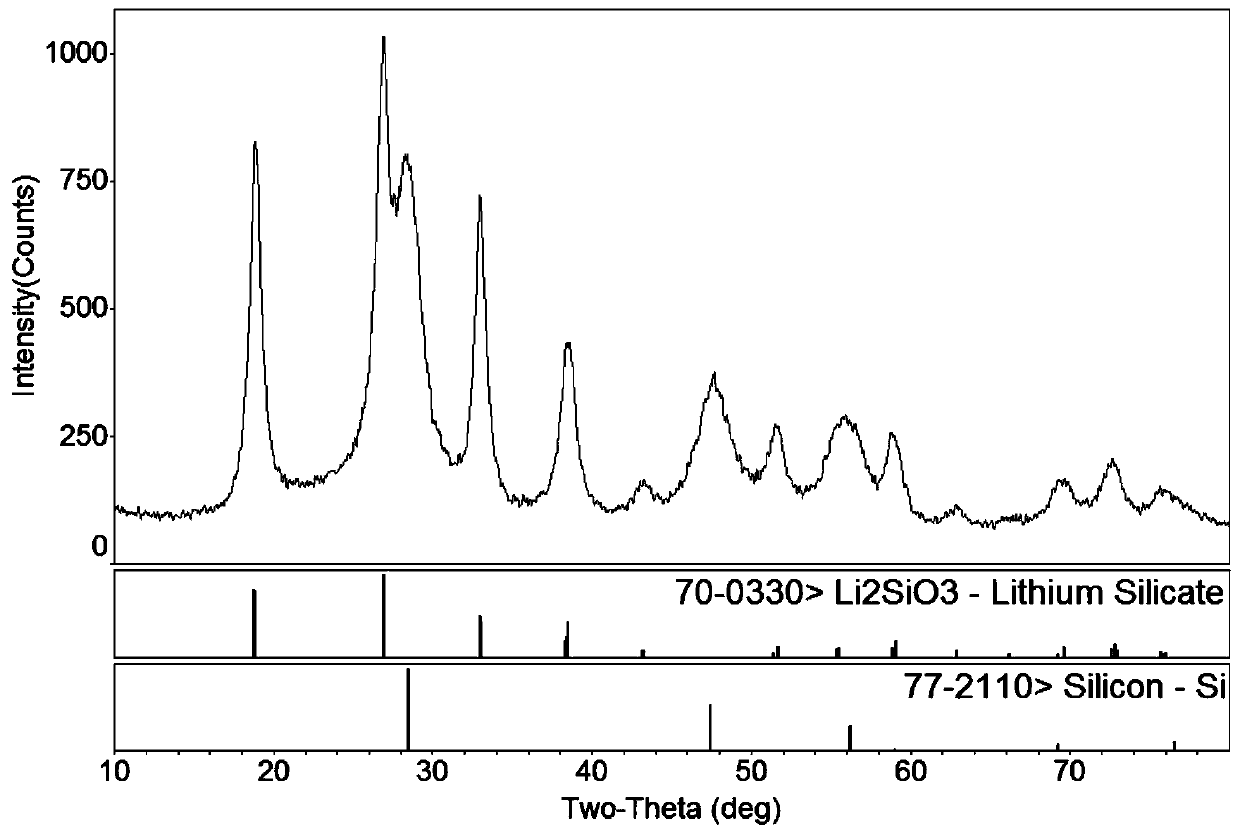

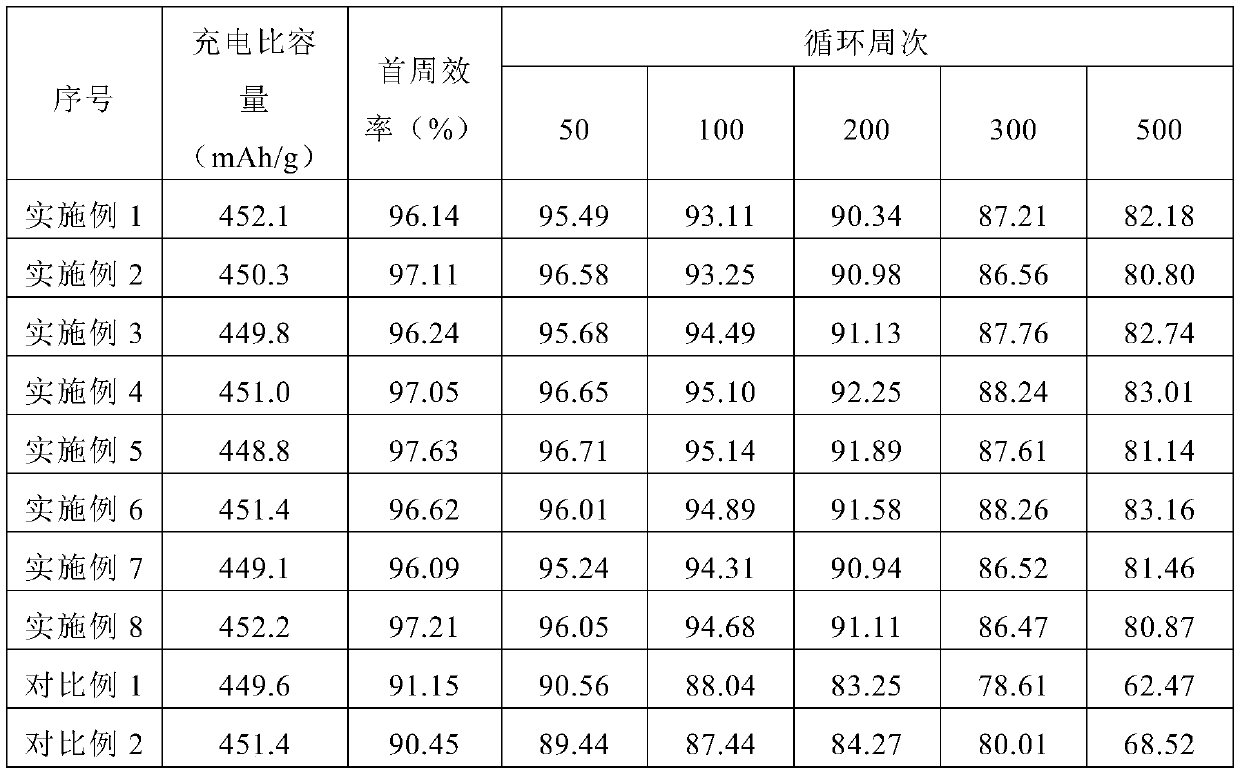

The embodiment of the invention relates to a lithium battery negative electrode material containing a pre-lithiated silylene material, a preparation method and a lithium battery. The negative electrode material has a core-shell structure, wherein an inner core is a mixture of the pre-lithiated silylene material and carbon particles, and an outer shell is one or more carbon-containing layers; the mass ratio of the inner core to the negative electrode material is [80%, 99%]; the mass ratio of the pre-lithiated silylene material in the inner core to the inner core is [10%, 90%]; the mass ratio ofthe outer shell to the negative electrode material [1%, 20%]; the pre-lithiated silylene material is of a sheet structure, and a phase comprises nano silicon and / or silicon oxide and lithium silicate; and the lithium silicate is one or more of Li4SiO4, Li2SiO5 and Li2SiO3. The negative electrode material effectively alleviates the expansion problem of the negative electrode material through the flaky characteristics of silylene or silylene oxide; by lithiating the silylene material in advance, the first charge-discharge efficiency of the negative electrode material is improved; and through carbon coating on the surface layer, the negative electrode material has the advantages of long cycle and high cycle stability.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Silylene/carbon composite negative electrode material and preparation method thereof

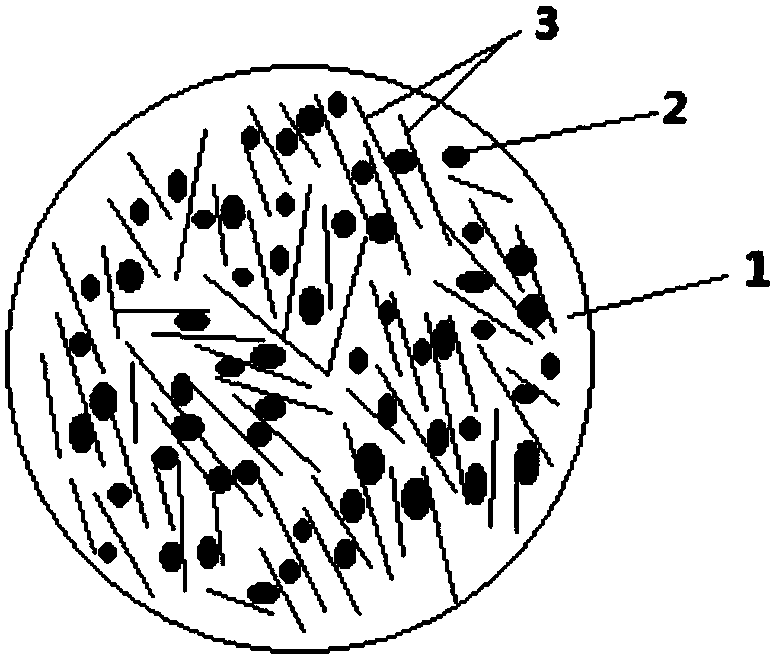

ActiveCN108390028APromote circulationSolve the problem of large volume expansionCell electrodesCarbon compositesSilylene

The invention provides a silylene / carbon composite negative electrode material and a preparation method thereof. The composite negative electrode material comprises a spherical amorphous carbon substrate and silylene and conductive particles dispersed in the carbon substrate. The preparation method of the composite negative electrode material comprises the steps of enabling silylene, the conductive particles and a carbon source to be mixed in a solvent to obtain paste; performing spraying drying on the paste to obtain a silylene / carbon spherical precursor; and performing carbonization processing on the precursor in an non-oxidizing atmosphere to obtain the silylene / carbon composite negative electrode material. The silylene / carbon composite negative electrode material provided by the invention is high in energy density, proper in specific surface area, high in initial coulombic efficiency, excellent in cycle performance and rate capability, and relatively high in application prospect.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

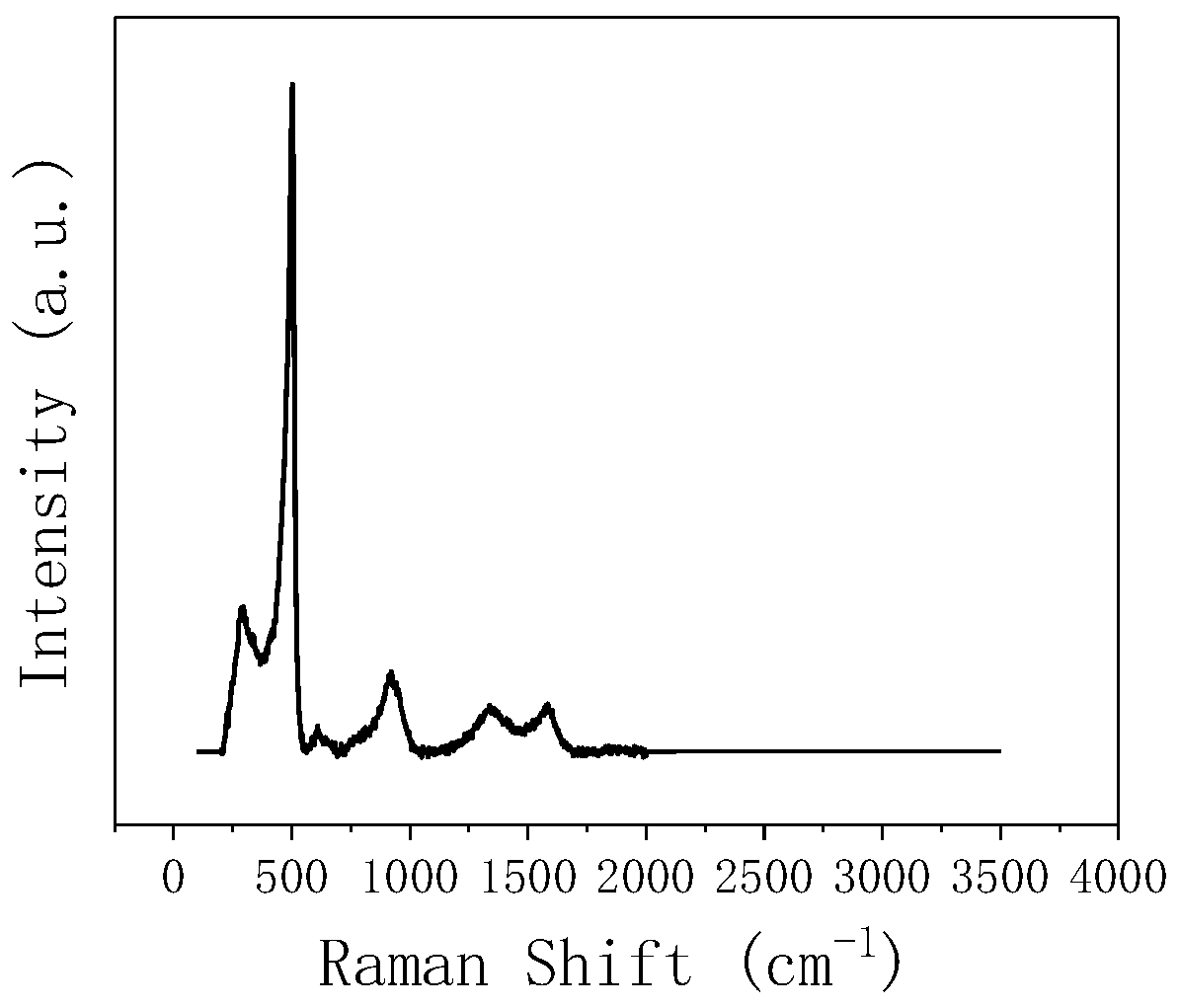

Anode material for lithium battery and lithium battery

ActiveCN110690430AImprove stabilityAlleviate problems caused by volume changesSecondary cellsNegative electrodesCarbon compositesCarbon coating

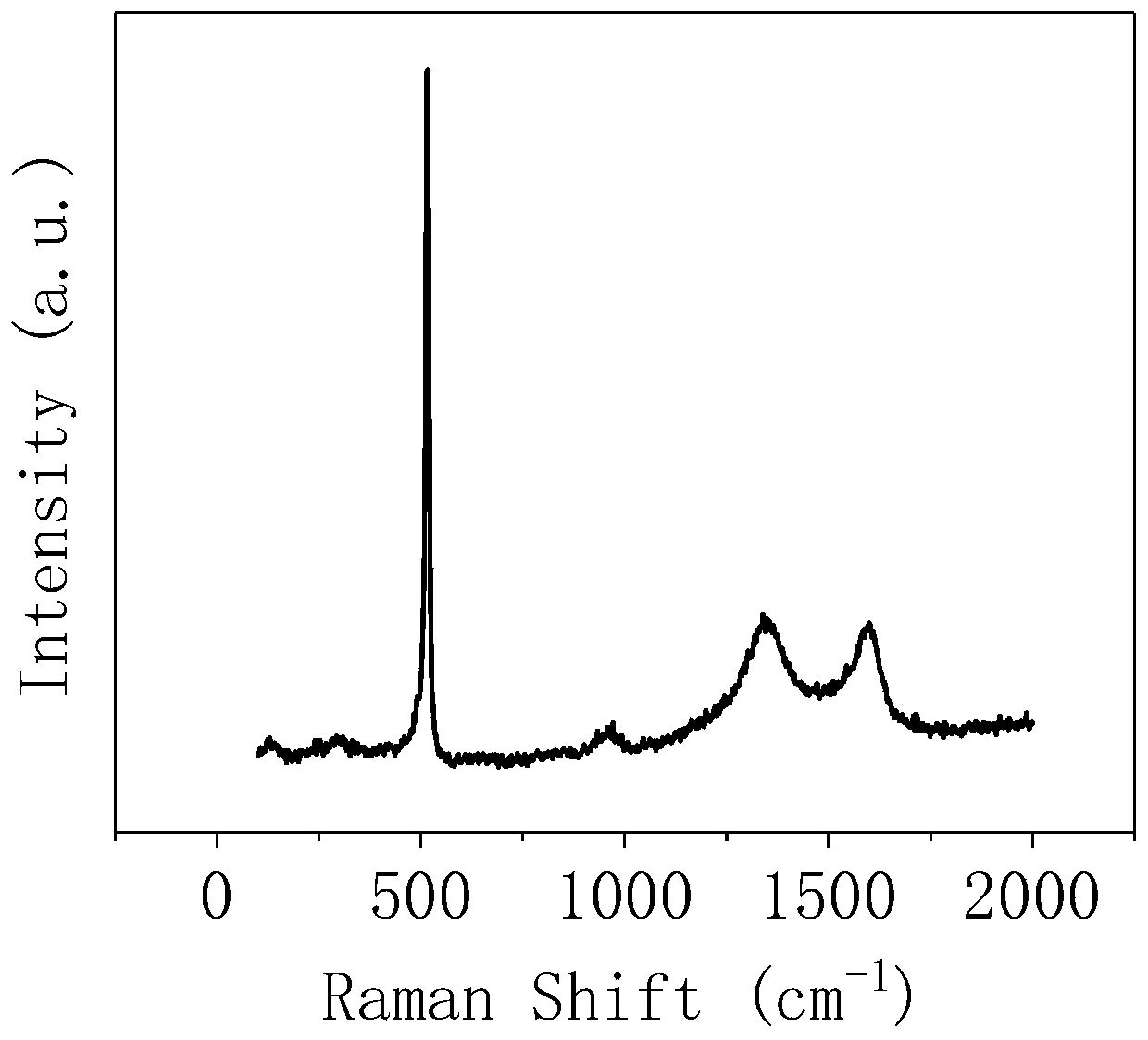

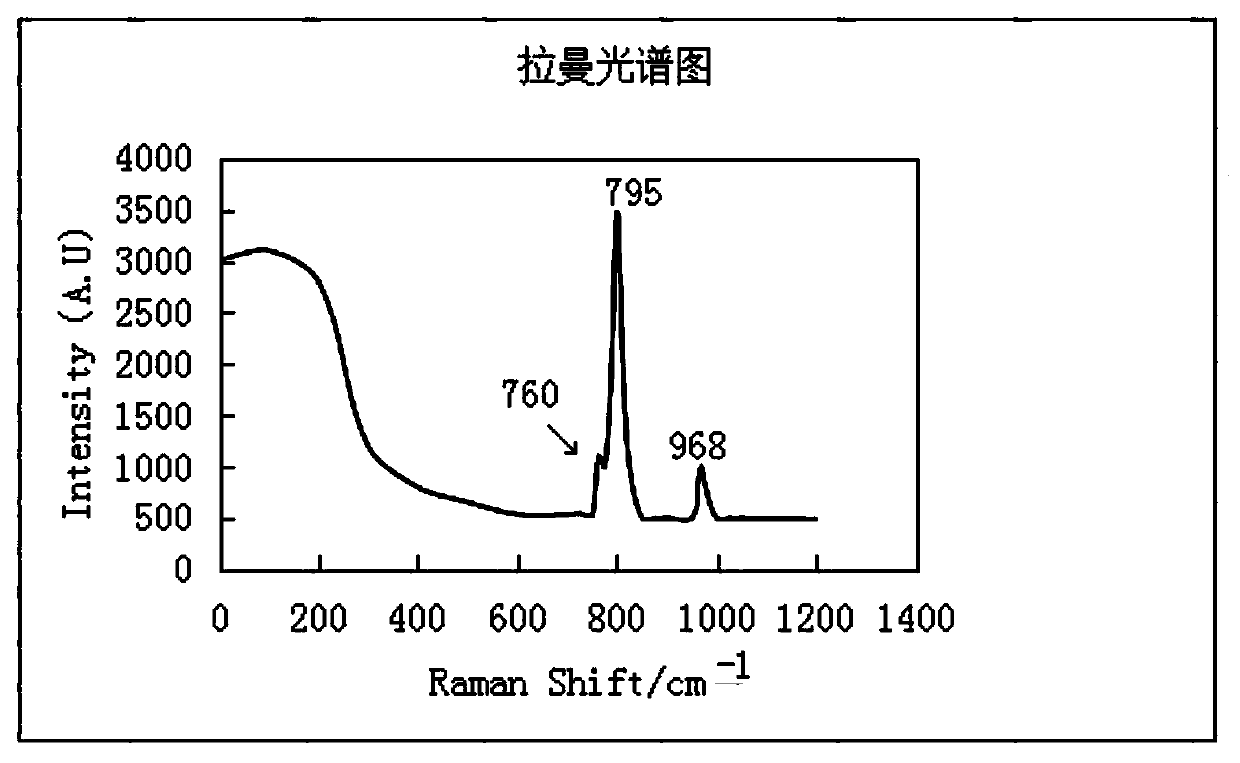

The embodiment of the invention relates to an anode electrode material for a lithium battery and a lithium battery. The anode material is a silicon-carbon composite material with a core-shell structure, wherein the inner core of the anode material is carbon particles, a first coating layer is a coating layer composed of silylene oxide or a composite material of silylene and a buffer material, anda second coating layer is a dot-shaped coated carbon particle layer or a continuously coated carbon coating layer; the mass ratio of the carbon particles of the inner core to the anode material is (0,95%); the mass ratio of the first coating layer to the anode material is [10%, 95%]; the mass ratio of the second coating layer to the anode material is [0, 10%]; in the Raman spectrum of the anode material, the anode material has amorphous bumps at 475+ / -10 cm-1, and / or has crystalline peaks at 510+ / -10 cm-1; and the anode material has characteristic peaks of carbon exist at 1360+ / -20 cm-1 and 1580+ / -20 cm-1.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

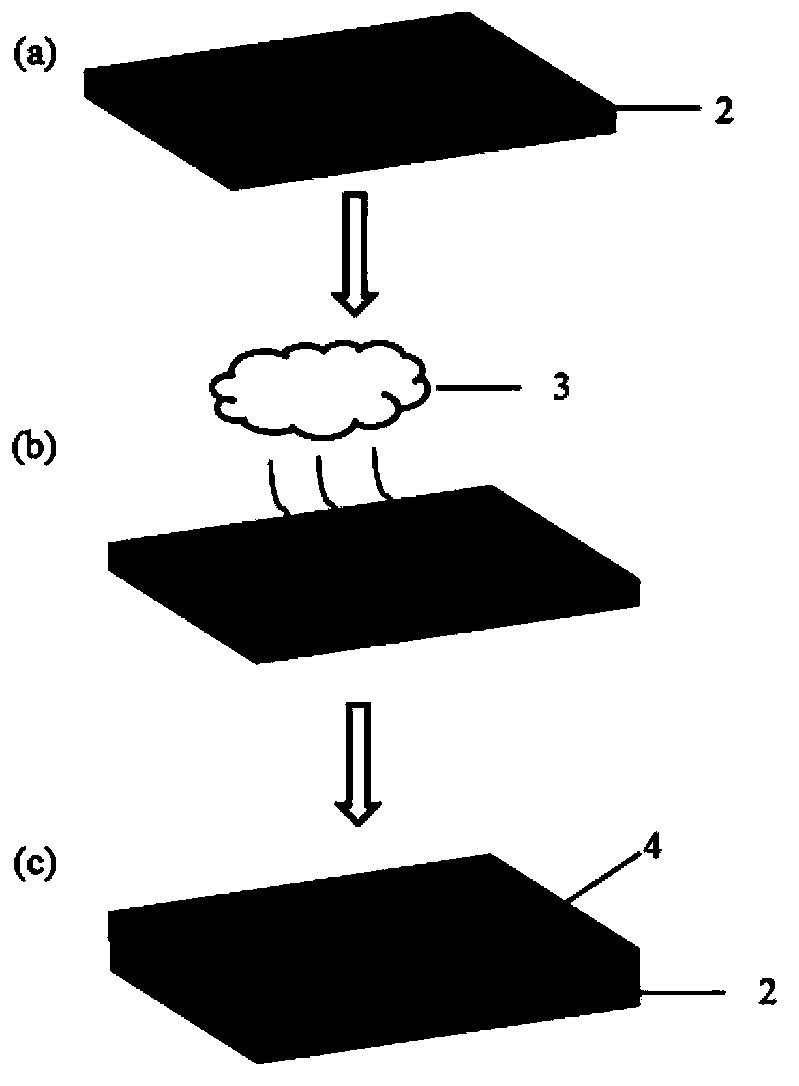

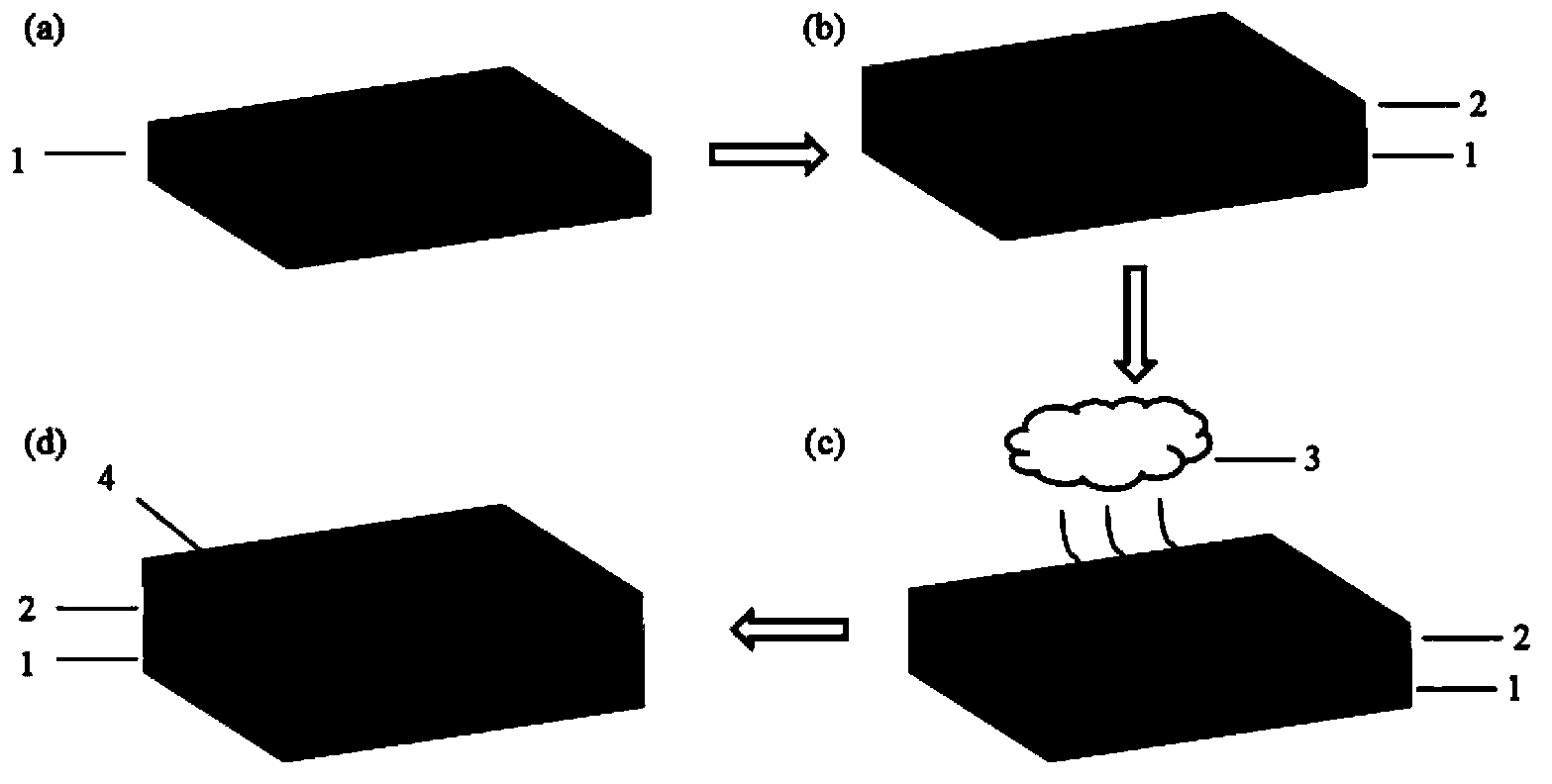

Method for producing silylene film through mechanical stripping, and application of silylene film

ActiveCN106554016APromote mass productionProtect physical propertiesMaterial nanotechnologySolid-state devicesSilyleneWorking environment

The invention discloses a silylene film produced through mechanical stripping, and an application of the obtained silylene film in batteries. A production method of the silylene film comprises the following steps: physically covering the silicon surface of a metal film with a two-dimensional nanomaterial, carrying out high temperature treatment to diffuse the silicon element to the interface of the two-dimensional nanomaterial and the metal film, decreasing the temperature to room temperature, dispersing a sample in a surfactant-containing solvent liquid, allowing polar molecules to easily enter the interface of the metal film and the above substrate material, carrying out ultrasonic stirring to increase friction of the metal film and the substrate material, and stripping the two-dimensional nanomaterial and silylene from the silicon substrate to obtain the silylene film. The silylene film is mechanically stripped from a liquid phase under the physical action, so physical properties of a silylene material are protected, high vacuum and high danger gas working environment is avoided, and use of severely toxic organic reactants is avoided; and the two-dimensional nanomaterial can be used repeatedly, so the cost is reduced, and the silylene film has wide market application values in the field of solar batteries.

Owner:日照东润有机硅股份有限公司

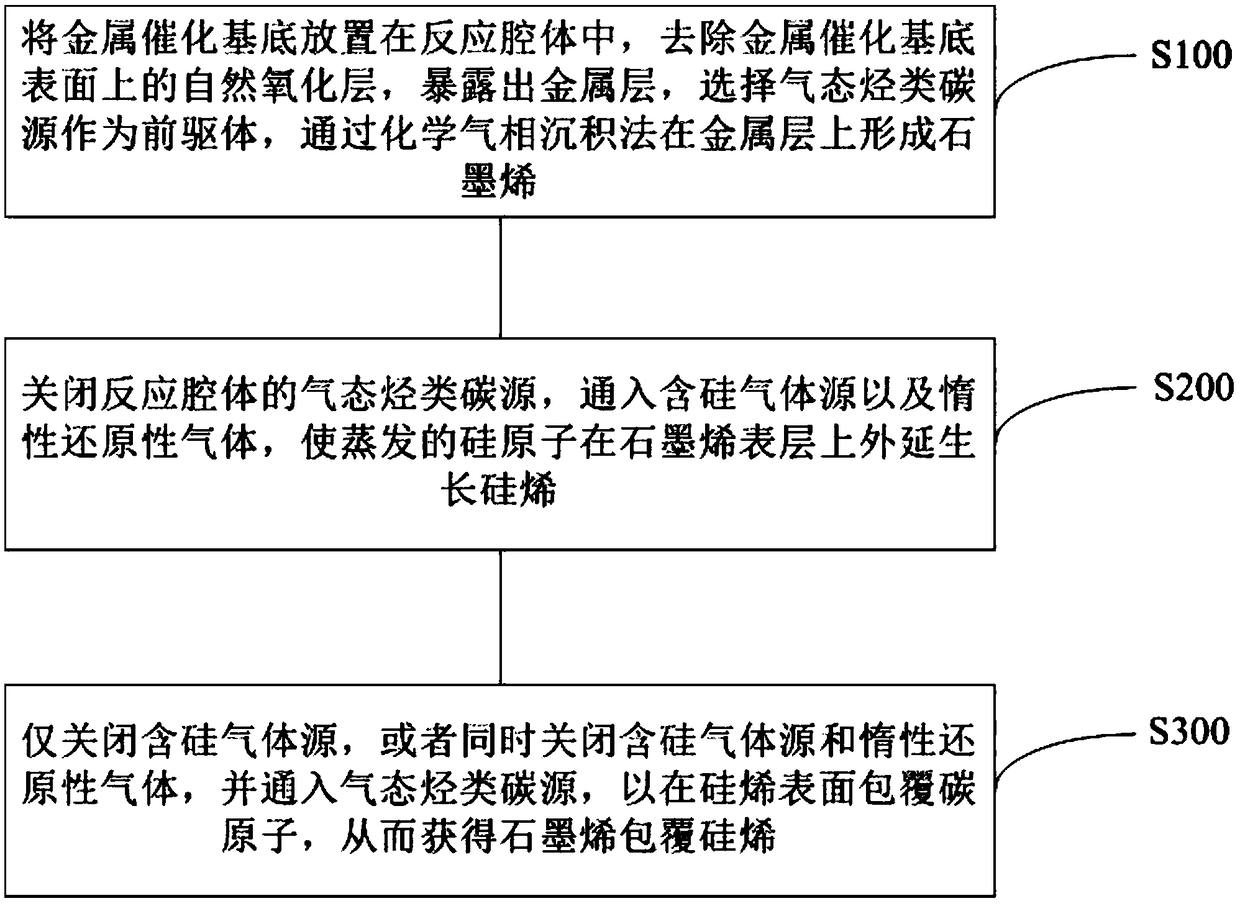

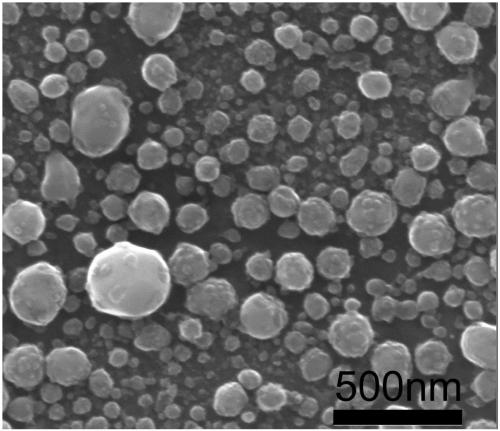

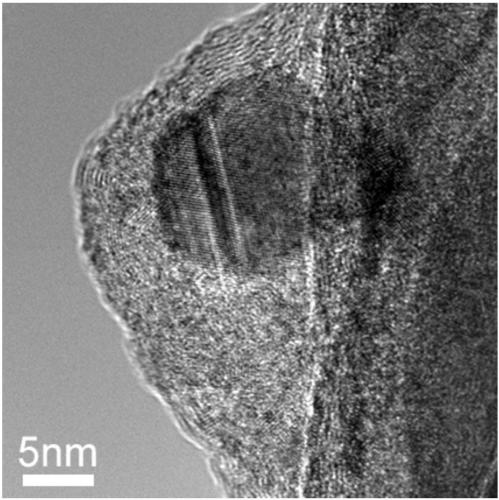

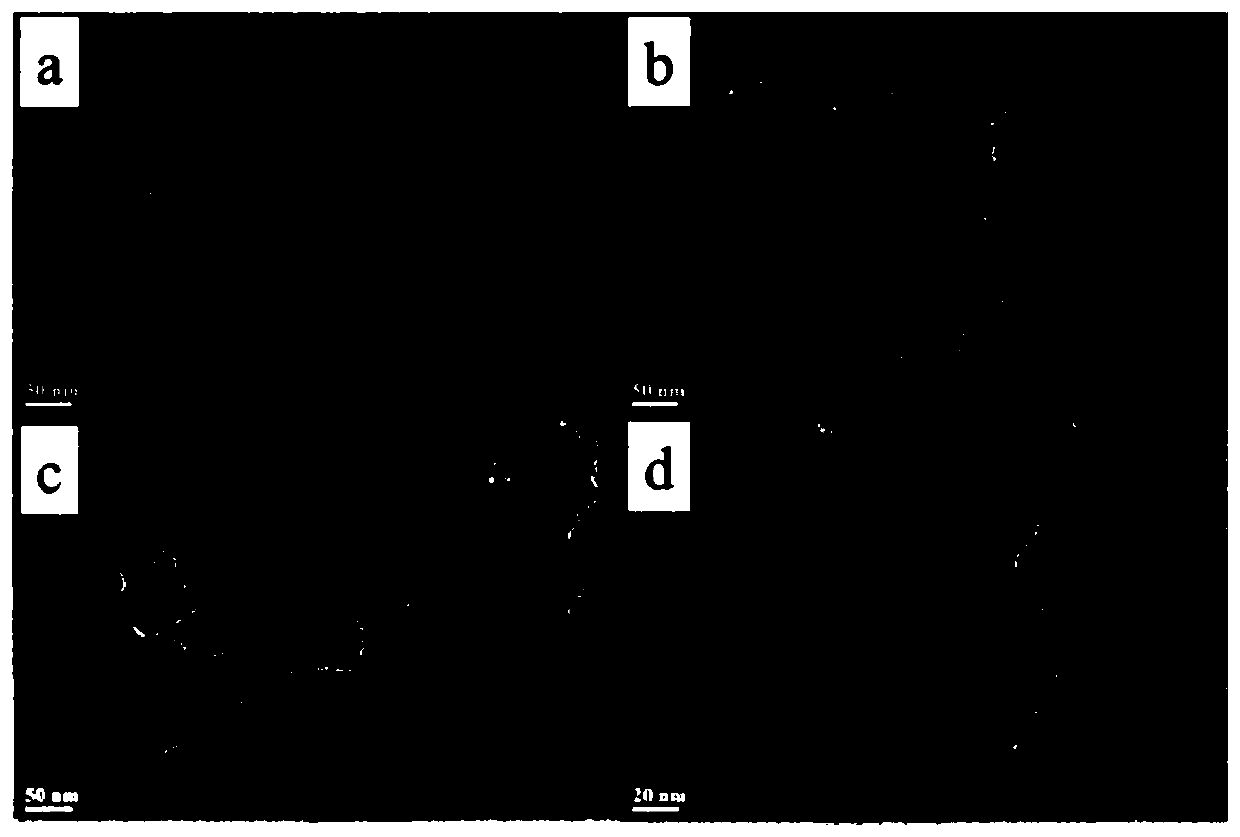

Graphene cladded silylene as well as preparation method and application method thereof

ActiveCN108975318AImprove stabilityPreparation conditions are easy to meetMaterial nanotechnologyGrapheneAutoxidationSilylene

The invention provides graphene cladded silylene as well as a preparation method and an application method thereof. The preparation method comprises the following steps: placing a metal catalysis substrate in a reaction cavity; removing a natural oxidization layer on the metal catalysis substrate and exposing a metal layer; selecting a gas-state hydrocarbon type carbon source as a precursor and forming graphene on the metal layer through a chemical vapor deposition method; closing the gas-state hydrocarbon type carbon source of the reaction cavity and introducing a silicon-containing gas source and reductive gas, so as to form silylene on a surface layer of the graphene through evaporated silicon atoms via epitaxial growth; only closing the silicon-containing gas source or closing the silicon-containing gas source and reductive gas at the same time; introducing the gas-state hydrocarbon type carbon source to clad carbon atoms on the surface of the graphene, so as to obtain the graphenecladded silylene. The silylene obtained by the preparation method can keep an original structure in the air for two or more than two years; the method breaks through a traditional method, and preparation conditions are relatively loose and simple.

Owner:SUZHOU UNIV

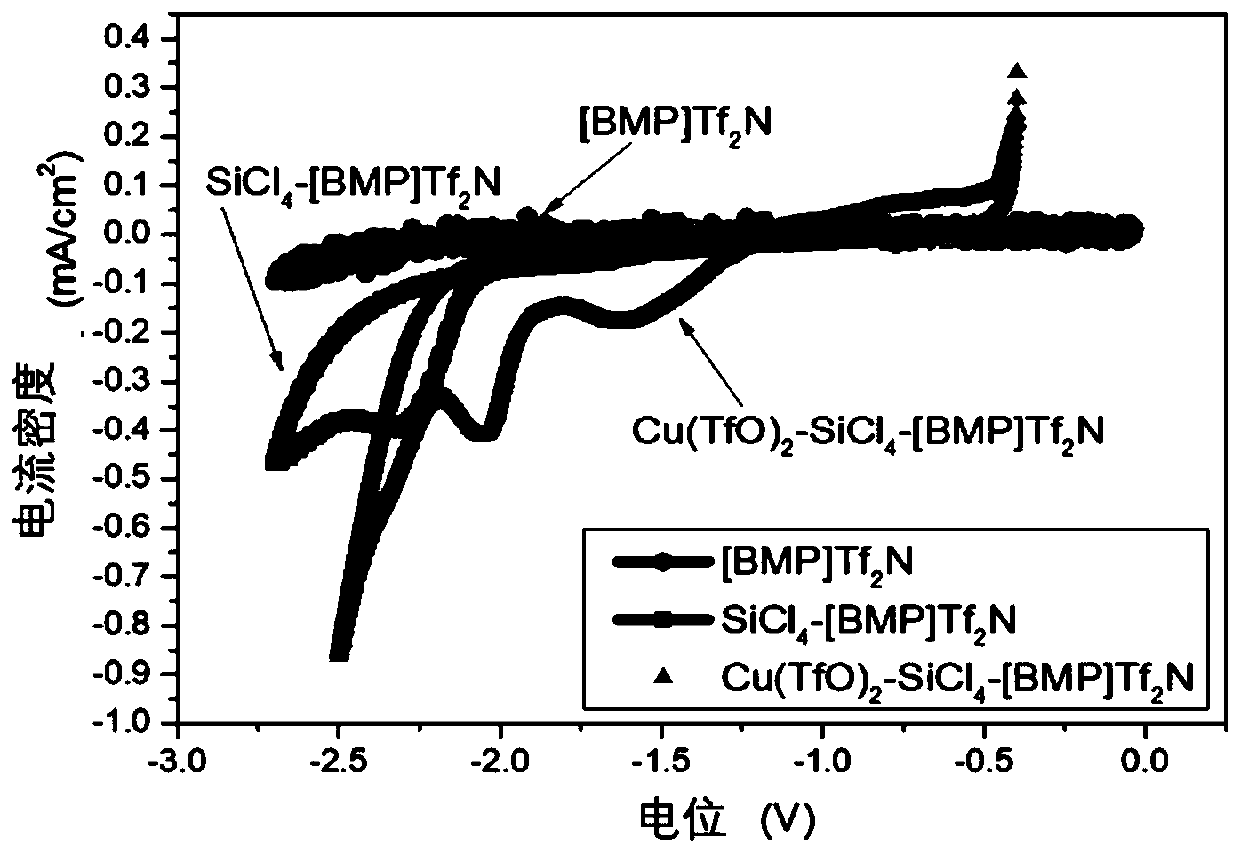

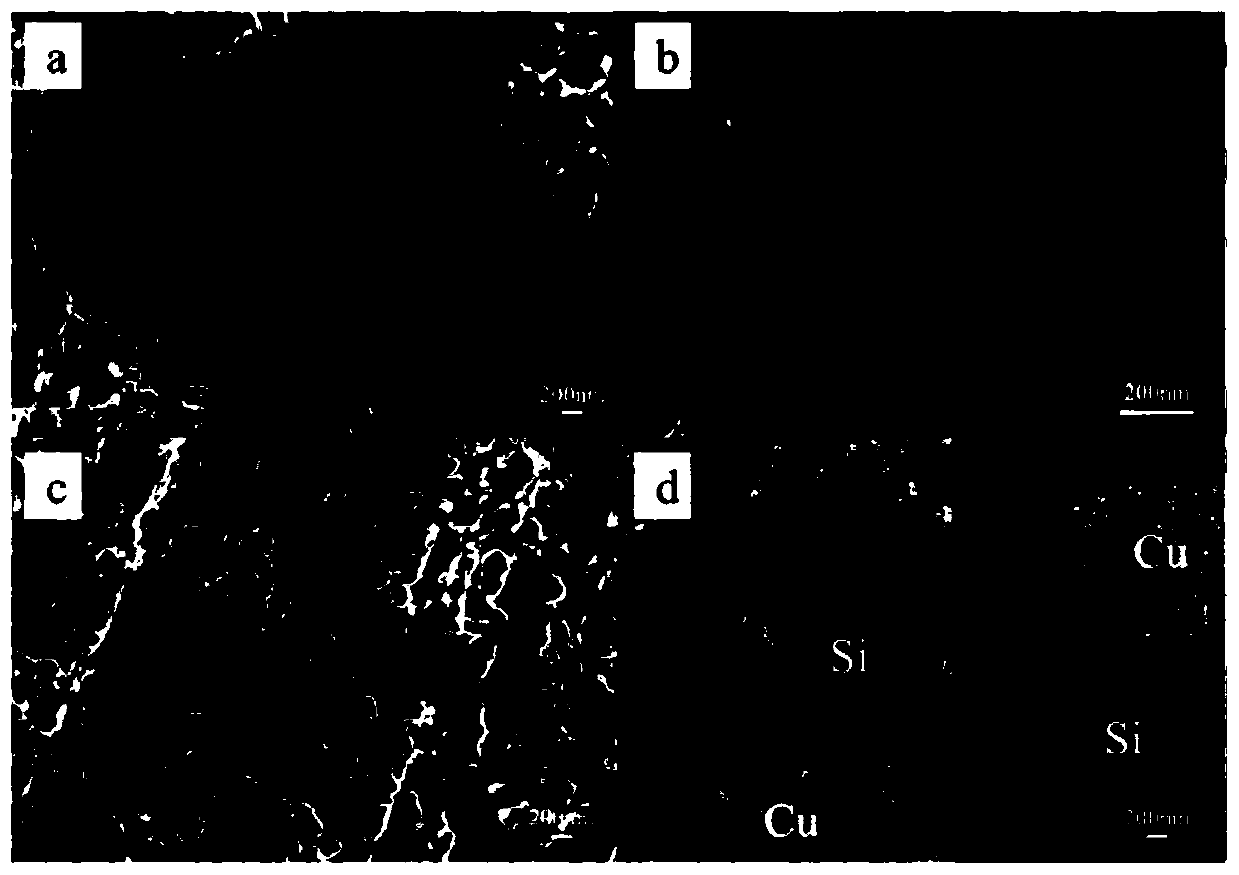

Silylene-copper-silylene composite material, preparation method and application thereof and lithium ion battery

InactiveCN110600688ANo pollution in the processReduce energy consumptionNegative electrodesSecondary cellsSilyleneSodium-ion battery

The invention discloses a silylene-copper-silylene composite material, preparation method and application thereof and a lithium ion battery. The preparation method of the silylene-copper-silylene composite material comprises the following steps of obtaining the silylene-copper-silylene composite material by electro-deposition of a silicon source and a copper source in an ionic liquid, wherein thesilicon source is SiCl4, copper in the copper source is divalent copper, the concentration of the copper source in the ionic liquid is (0.002-0.003)mol / L, and the potential of electro-deposition is (-1.9)-(-2.1) V. The ionic liquid is used as a medium, the silylene-copper-silylene composite material is prepared in one step by an electro-deposition method, and the silylene-copper-silylene compositematerial has the advantages of simple and convenient process, low cost, circulation and no pollution. A silylene piece layer in the prepared silylene-copper-silylene composite material is highly dispersed, and the electrode has favorable conductivity and excellent electrochemical performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Lithium battery anode material with core-shell structure and lithium battery

InactiveCN110690452AImprove stabilityIncrease loopNegative electrodesSecondary cellsCarbon compositesSilylene

The embodiment of the invention relates to a lithium battery anode material with a core-shell structure and a lithium battery. The anode material is a silicon-carbon composite material with a core-shell structure, wherein an inner core of the anode material is silylene oxide or a composite material of silylene and a buffer material, and the shell of the anode material is one or more coating layersor particle layers composed of carbon, carbon particles, carbon fibers or carbon nanotubes with a protective effect; the mass ratio of the silylene oxide to the anode material is 5%-95%; the mass ofthe buffer material is 1-300% of the mass of the silylene oxide; the shell accounts for 0.1%-10% of the mass of the anode material; in the Raman spectrum of the anode material, the anode material hasamorphous bumps at 475+ / -10 cm-1, and / or has crystalline peaks at 510+ / -10 cm-1; and the anode material has characteristic peaks of carbon at 1360+ / -20 cm-1 and 1580+ / -20 cm-1.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

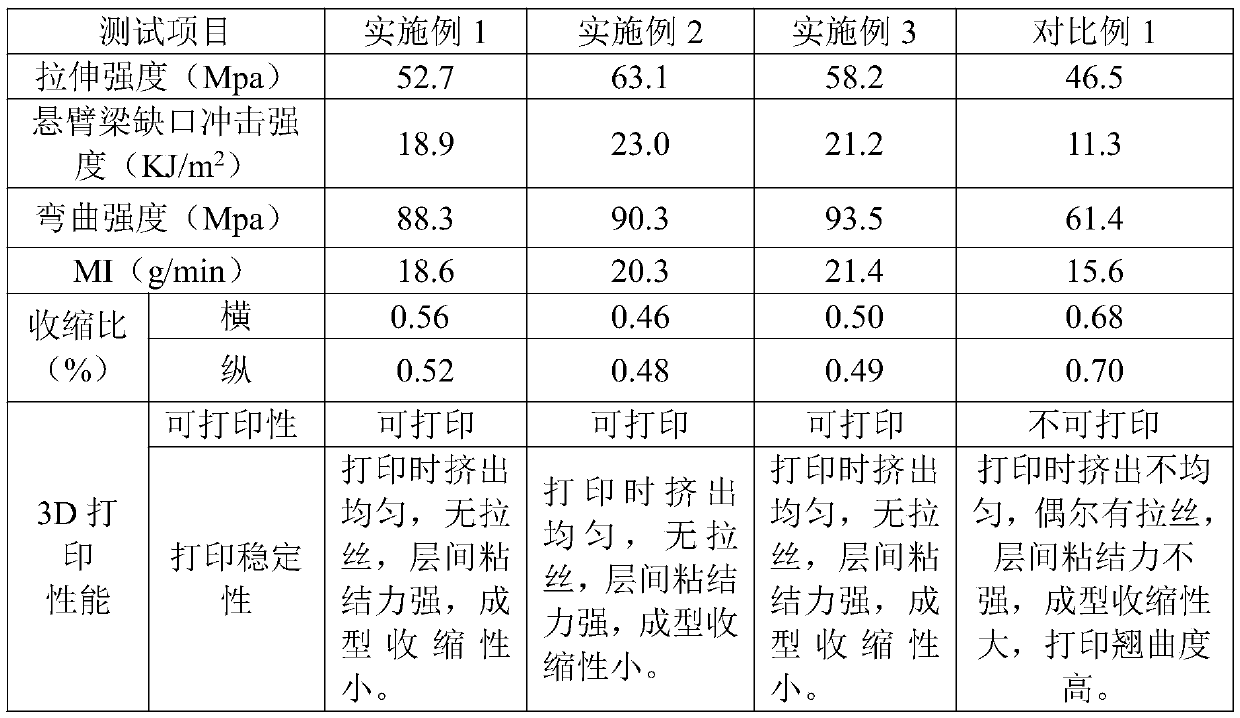

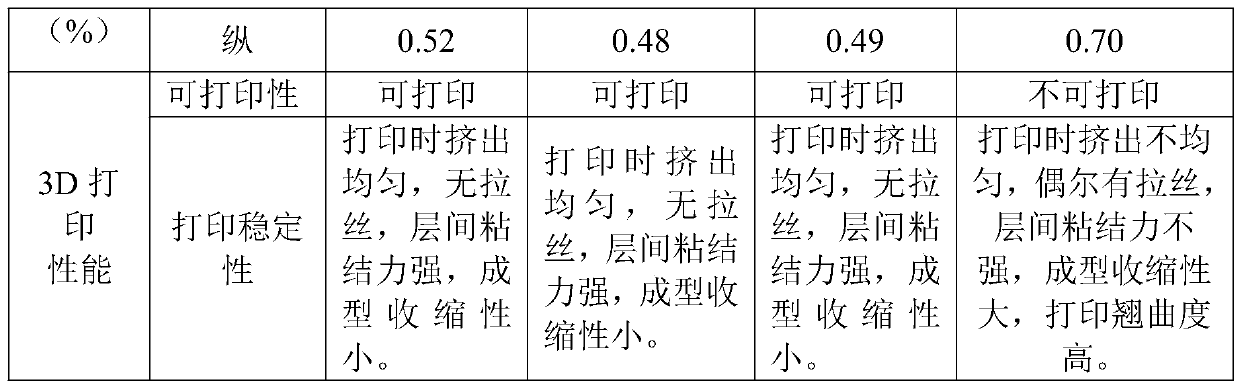

Method for preparing recycled regenerated plastic for 3D printing

InactiveCN110698806AImproved crystallization behaviorImprove mechanical propertiesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a method for preparing a recycled regenerated plastic for printing. The recycled and regenerated plastic for 3D printing, which is disclosed by the invention, comprises 60-70 parts of a recycled plastic, 5-20 parts of glass fibers, 3-10 parts of graphenoid, 1-10 parts of a toughening agent, 2-3 parts of a dispersant, 1-15 parts of biochar, 1-5 parts of a compatibilizer, 0.1-2 parts of a chain extender, 0.5-1 part of a lubricant, 0.1-5 parts of a foaming agent and 1-8 parts of other additives. In addition, recycled and regenerated plastic may also comprise 10-60 parts ofEVA (ethylene vinyl acetate), and the content of VA (vinyl acetate) of EVA is 20-55%. The graphenoid is one of silicene, germanene and molybdenum disulfide surface activity treatment. The chain extender is one or more of pyromellitic dianhydride, dicumyl peroxide and an acrylonitrile-butadiene-styrene copolymer. The recycled and regenerated plastic is one or more of ABS (acrylonitrile butadiene styrene), polypropylene and PET (polyethylene terephthalate).

Owner:泉州龙晟轻工有限公司

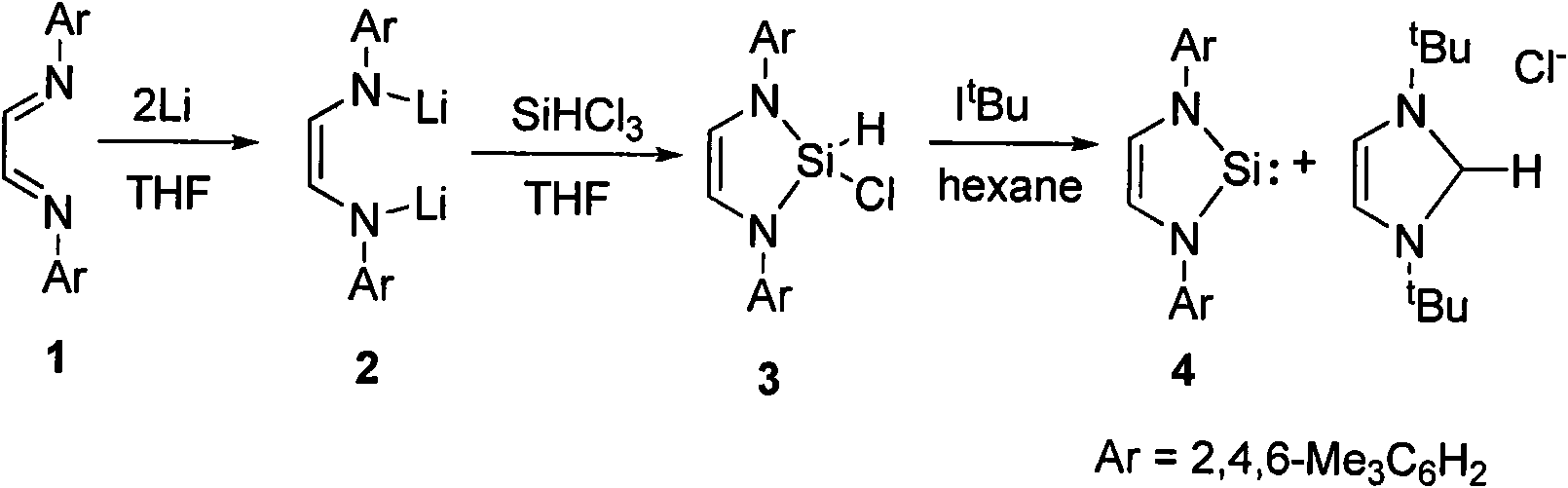

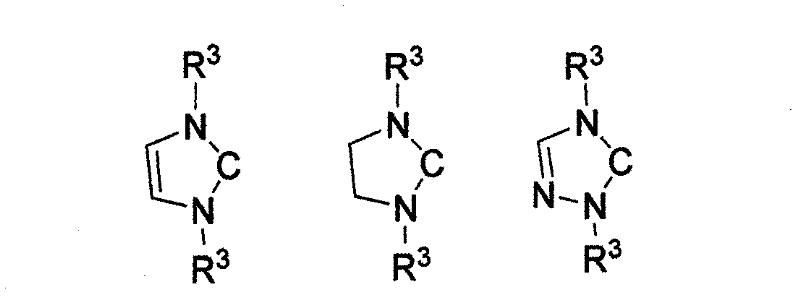

Method for preparing silylene by carbene-induced halogenated silane dehydrohalogenation

The invention discloses a method for preparing silylene by carbene-induced halogenated silane dehydrohalogenation, and relates to a method for synthesizing silylene. Dilithium salt of [NN] bidentate ligand and halogenosilane or substituted halogenosilane organic silicon reagent react to form substituted halogenated silane; and the molar ratio of the substituted halogenated silane to stable carbene is 1:0.5-10, the reaction temperature is between 78 DEG C below zero and 100 DEG C, the substituted halogenated silane and the stable carbene are mixed in a common organic solvent to generate imidazole salt of silylene and carbene, the generated imidazole salt is separated from the solution of a product through filtration after the reaction is finished, and the silylene or derivatives of the silylene are obtained through recrystallization and chromatographic separation. Through the reaction of different organic halogenosilane hydrides and the carbene, the method discovers that the carbene can effectively reduce a silicon compound under the mild condition to generate bivalent silicon intermediate. The imidazole salt as the reaction product can be converted into the carbene more easily so as to realize recycle.

Owner:NANKAI UNIV

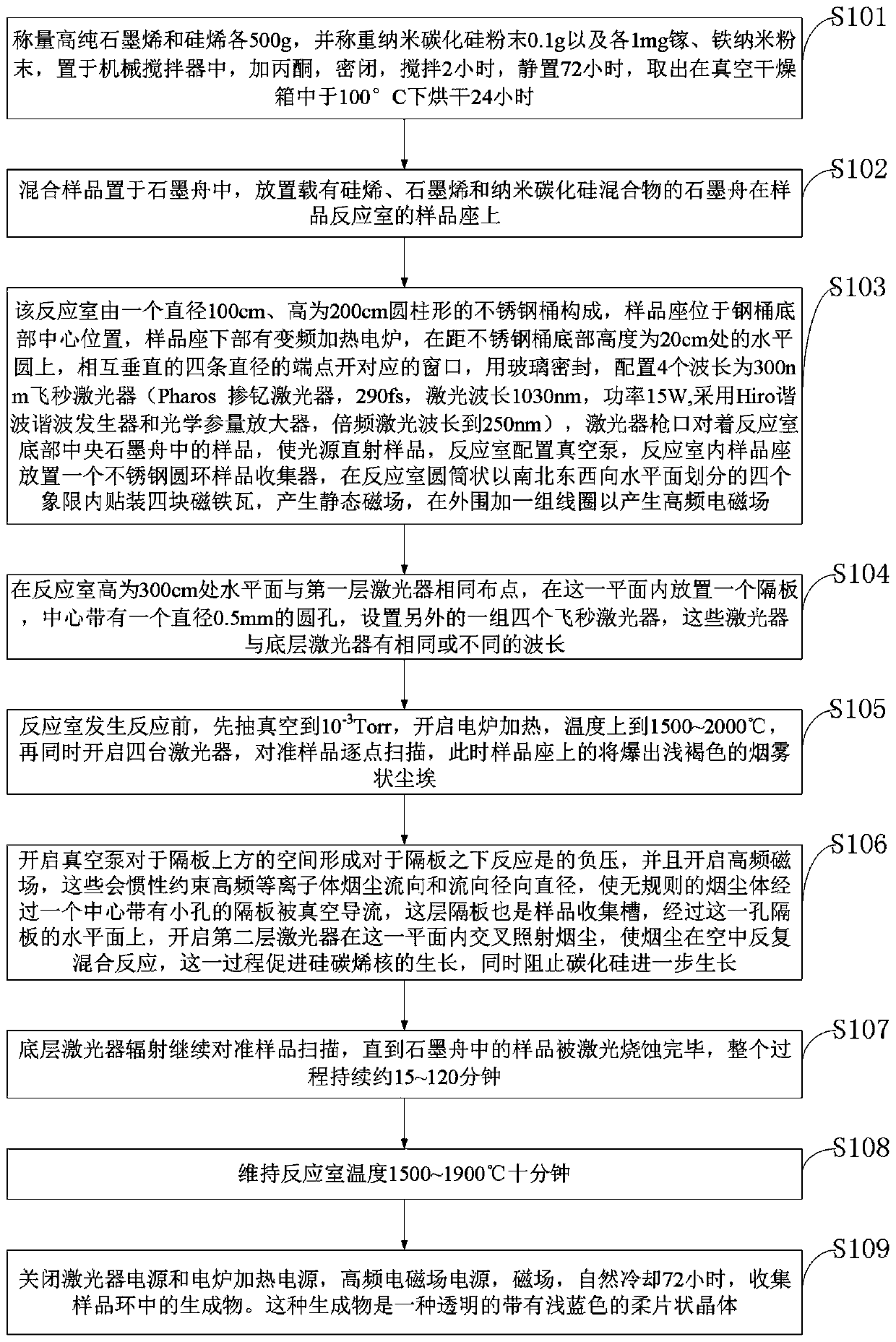

Preparation method of silicon carbene and method for preparing hydrogen by photodecomposition of water vapor

ActiveCN110182808AReduced ability to donate electronsPromote oxidationPhysical/chemical process catalystsCarbon compoundsSemiconductor materialsWater vapor

The invention belongs to the technical field of semiconductors, and discloses a preparation method of silicon carbene and a method for preparing hydrogen by photodecomposition of water vapor. The preparation method of the silicon carbene comprises the following steps: weighing high-purity graphene and silene, placing a mixed sample in a graphite boat, attaching four magnetic tiles to the insides of four quadrants obtained by cylindrical division of a reaction chamber to generate a static magnetic field, and adding a group of coils on the periphery of the static magnetic field to generate a high-frequency electromagnetic field; and after sample reaction is carried out through a sample chamber, switching off a laser power supply, an electric furnace heating power supply and a high-frequencyelectromagnetic field power supply, naturally cooling, and collecting the product of the sample chamber as the silicon carbene. The silicon carbene can grow under the conditions that the silene and the graphene are irradiated by laser at a high temperature, the silicon carbide serves as an induction factor and the silicon carbene further grows through radiation weakening of secondary laser, and the growth is crystal growth of a basic unit layer of the silicon carbide, and the novelty of the semiconductor material shows that the bandwidth changes along with components.

Owner:武汉楚能电子有限公司

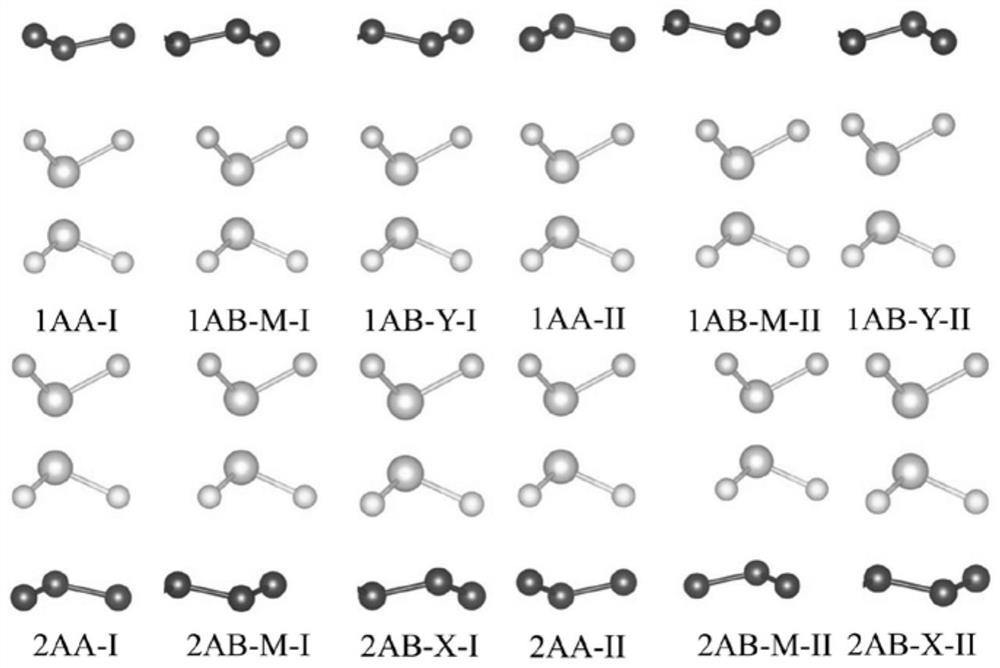

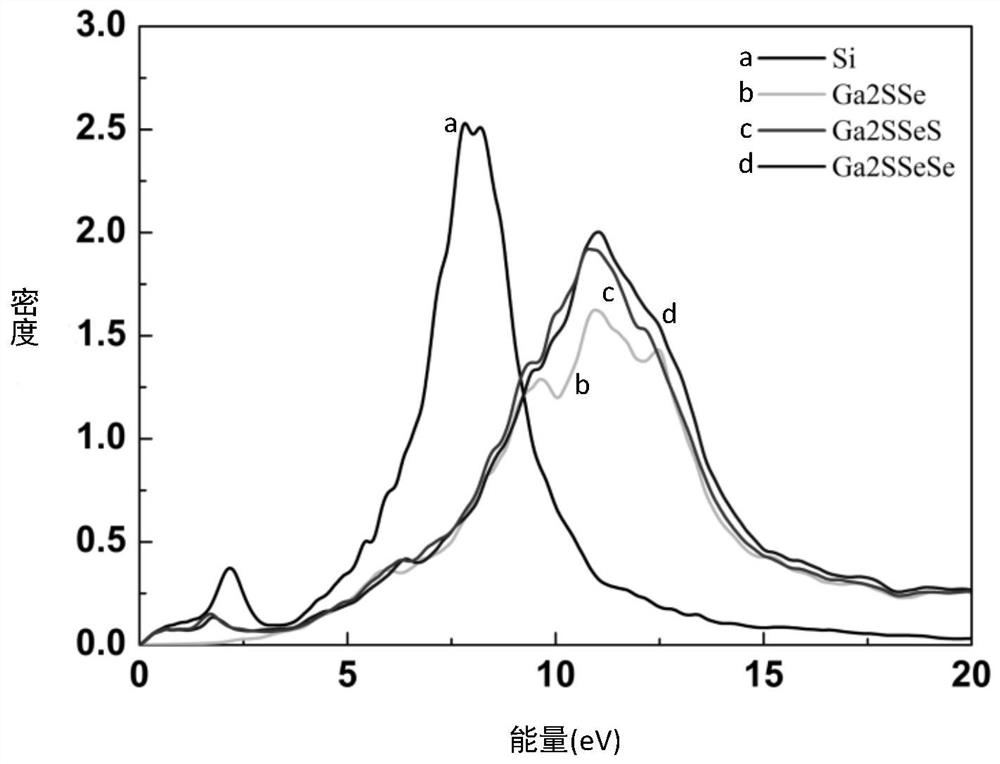

Two-dimensional material heterojunction and performance analysis method and application thereof

ActiveCN111864070AAvoid defectsGood physical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionSilylene

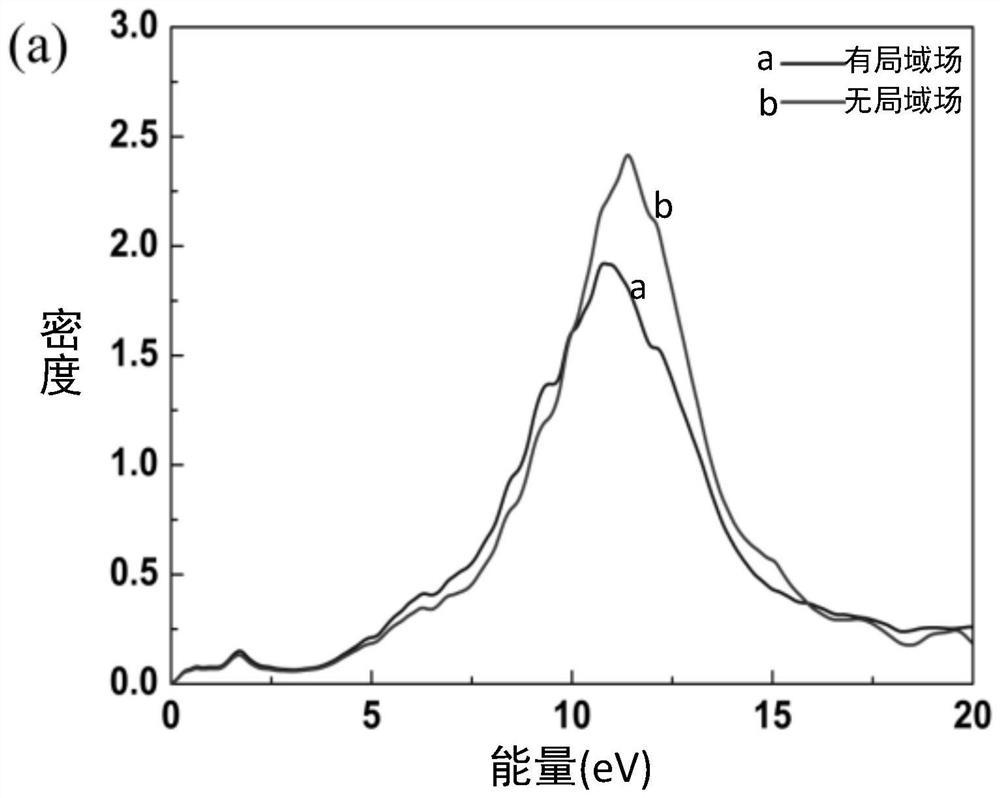

The invention provides a two-dimensional material heterojunction and a performance analysis method thereof, and application of the heterojunction in semiconductor and photoelectric energy conversion.The two-dimensional material heterojunction comprises a first two-dimensional material and a second two-dimensional material, wherein the first two-dimensional material comprises a Janus two-dimensional material; and the second two-dimensional material comprises silylene; and the first two-dimensional material and the second two-dimensional material are longitudinally stacked. According to the heterojunction provided by the invention, the excellent performance of different materials can be utilized; the defect of a single two-dimensional material can be overcome, and the band gap of silylene is opened through the interaction of the Janus two-dimensional material and the silylene, so that the energy spectrum distribution of the two-dimensional material is obviously changed relative to the respective independent properties of the two components forming the two-dimensional material. According to the performance analysis method of the heterojunction, electron energy loss spectrum analysisis carried out based on the time-containing density functional theory and random phase approximation, the steps are simple, operation is easy, and a rapid analysis approach and powerful support are provided for heterojunction design with band gap opening as the purpose.

Owner:HARBIN INST OF TECH

Silylene/graphene composite material, and preparation method and applications thereof

The invention provides a silylene / graphene composite material, and a preparation method and applications thereof. According to the preparation method, a silicon material and a graphene material are mixed, and are processed with high shear stress generated at the interfaces between screw rod engaged screw elements in extruder screw rotating process; the silicon material is taken as a grinding medium of the graphene material; and at the same time, relatively strong Van der Waals bonds are formed between the silicon material and graphene sheets, and rearrangement of silicon atoms on the graphene sheets is realized because of the sheet characteristics of graphene so as to form the silylene / graphene composite material. Mechanical exfoliation and physical shearing are adopted, exfoliation of graphene sheets and growth of silylene are completed via one step operation at the same time, complex high vacuum silylene growth technology is avoided, application of gas materials which are capable of inducing heavy pollution is avoided, cost is reduced, industrial application value is extremely high, and the silylene / graphene composite material is suitable to be taken as a lithium battery anode material.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Recycled regenerated plastic for 3D printing and preparation method of recycled regenerated plastic

InactiveCN110698807AImproved crystallization behaviorImprove mechanical propertiesPolymer sciencePolyethylene terephthalate glycol

The invention relates toa recycled regenerated plastic for 3D printing. The recycled regenerated plastic comprises 60-70 parts of recycled regenerated plastic, 5-20 parts of glass fiber, 3-10 parts ofa graphene-like material, 1-10 parts of a toughening agent, 2-3 parts of a dispersant, 1-15 parts of biochar, 1-5 parts of a compatibilizer, 0.1-2 parts of a chain extender, 0.5-1 part of a lubricant, 0.1-5 parts of a foaming agent and 1-8 parts of other additives. In addition, the recycled regenerated plastic may also comprise 10-60 parts of EVA (an ethylene-vinyl acetate copolymer), and the content of VA (vinyl acetate) inEVA is 20-55%. The graphene-like material is one of silicene, germanene and molybdenum disulfide which are subjected tosurface activity treatment. The chain extender is one or more of pyromellitic dianhydride, dicumyl peroxide and acrylonitrile-butadiene-styrene copolymer grafted oxazoline. The recycled regenerated plastic is one or more of ABS (acrylonitrile butadienestyrene), polypropylene and PET (polyethylene terephthalate).

Owner:泉州龙晟轻工有限公司

High-pressure sample testing table used for measurement of magneto-optical Kerr effect

PendingCN107728084AHigh hardnessImprove conductivityDielectric property measurementsForce measurement by measuring optical property variationFiberCopper wire

The invention relates to the field of high-pressure physical experiments and material physical property measurement, in particular to a high-pressure sample testing table used for measurement of the magneto-optical Kerr effect. Buttress threads specially designed are arranged on the inner side surfaces of sleeves and the outer side surfaces of displacement tubes respectively, and buttress threadsare adopted by the mobile structures of pressing devices used for pressing tungsten carbide anvil cells, so that thermodynamic deformation of optical fibers and the pressing devices of the anvil cellsis relatively consistent in low-temperature environments, and then optical path adjusting is more precise; a conducting glass electrode board with thickness of 100 micrometers is made from indium tinoxide, and the surface of the conducting glass electrode board is coated with a silylene coating; a sample is located at the center of a teflon ring, the outer ring of the teflon ring is sleeved witha stainless steel ring, the outer ring of the stainless steel ring is sleeved with an aluminum gasket composed of an upper portion and a lower portion, axial through holes are formed in the stainlesssteel ring and the teflon ring, a copper thread is placed between the upper portion and the lower portion of the aluminum gasket, a gold thread penetrates the axial through holes of the stainless steel ring and the teflon ring, one end of the gold thread is connected with the sample, the other end of the gold thread is connected with the copper thread, and particles supporting the gold thread arearranged in the area between the teflon ring and the sample.

Owner:JINHUA VOCATIONAL TECH COLLEGE

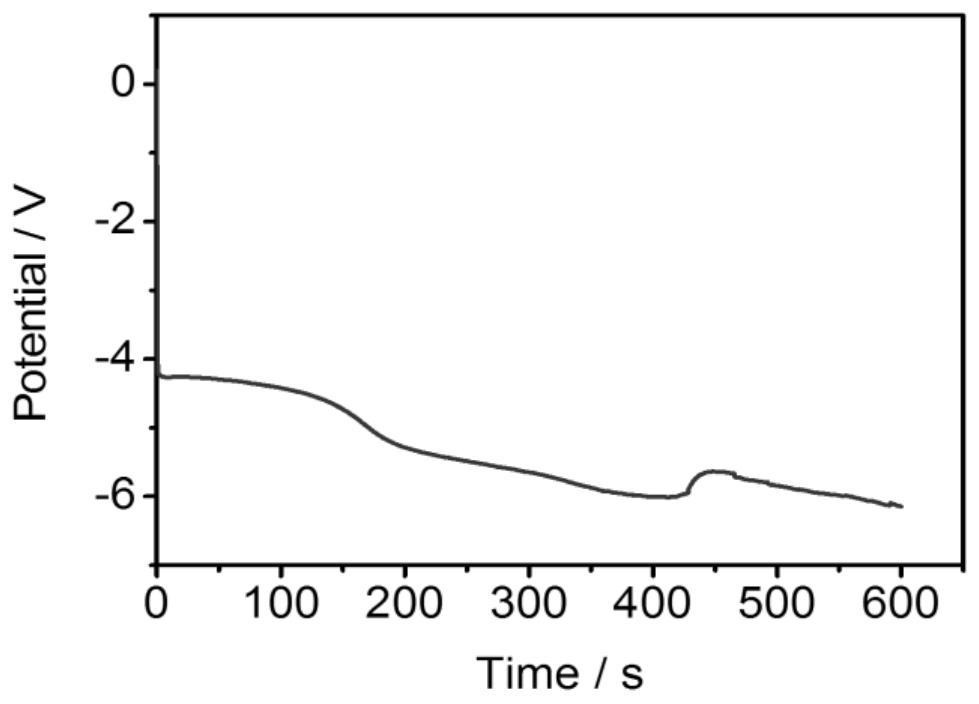

Silylene negative electrode plate capable of being directly used for preparing lithium ion battery and preparation and application of silylene negative electrode plate

ActiveCN113948677ALow costAvoid high temperature and high vacuum reaction conditionsCell electrodesSecondary cellsElectrochemical responseElectrolytic agent

The invention discloses a silylene negative electrode plate capable of being directly used for preparing a lithium ion battery, a preparation method of the silylene negative electrode plate and application of the silylene negative electrode plate in preparation of the lithium ion battery. The preparation method comprises the following steps: (1) mixing and dispersing a silicon precursor, conductive carbon black and a binder in a solvent, performing ultrasonic treatment and stirring to form slurry, coating a current collector with the slurry, and performing vacuum drying to remove the solvent to obtain an electrode plate, wherein the silicon precursor is CaSi2 or MgSi2; and (2) inserting a platinum wire serving as a cathode or an anode into an electrolyte containing inorganic acid and an organic solvent, constructing an electrochemical reaction tank by taking the electrode plate prepared in the step (1) as the anode or the cathode, carrying out electrochemical reaction, cleaning the surface of the electrode plate after the reaction is finished, and carrying out vacuum drying to obtain the silylene negative electrode plate which can be directly used for preparing the lithium ion battery. The electrochemical reaction conditions are as follows: the current density is greater than or equal to 1mA / cm < 2 > and less than or equal to 300mA / cm < 2 >, and the reaction time is greater than or equal to 1min and less than or equal.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

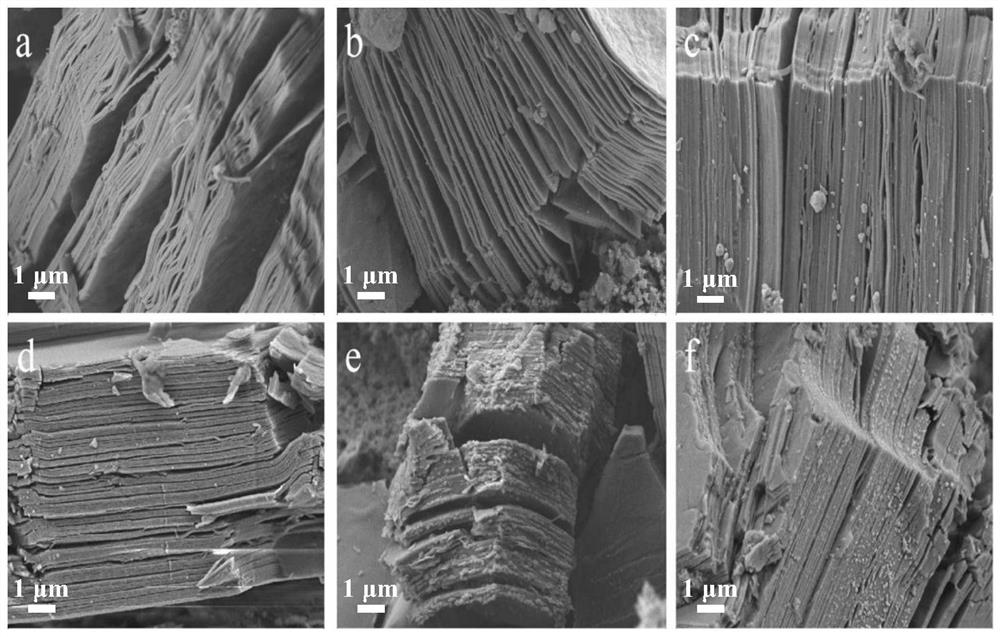

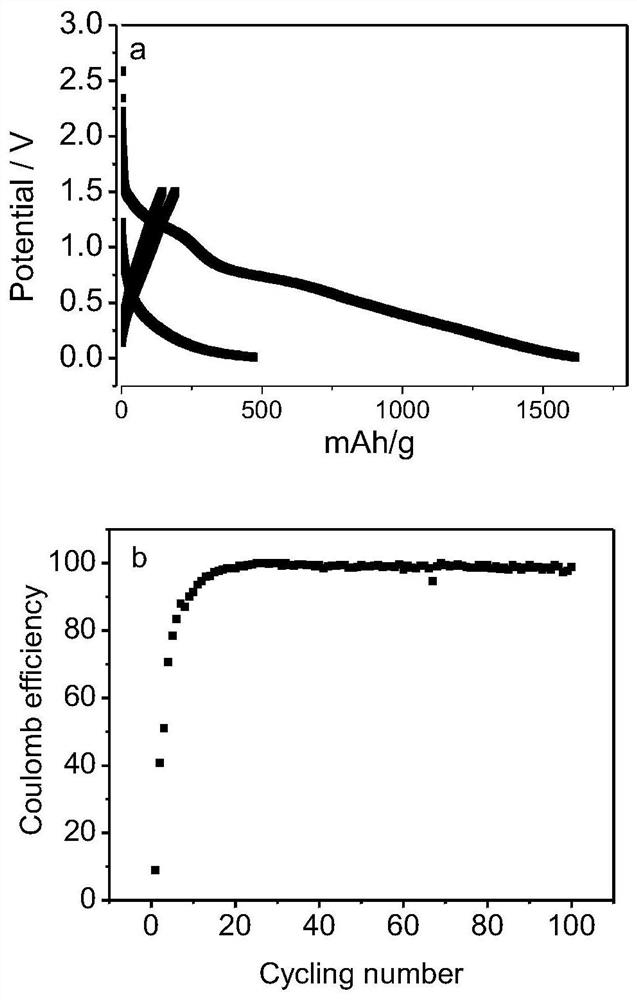

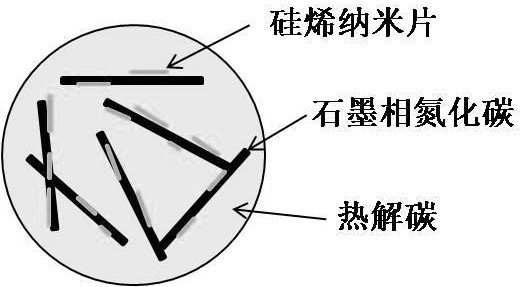

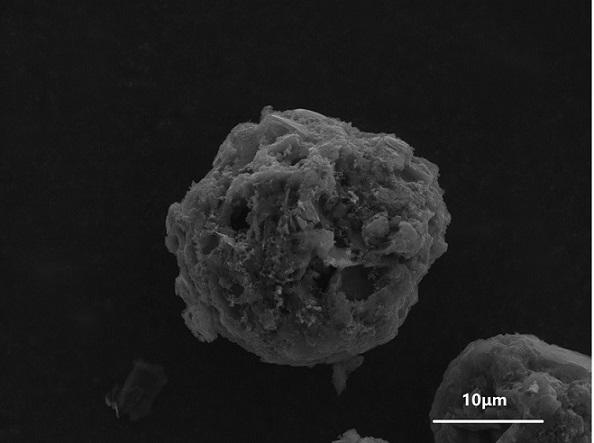

Silylene composite material for lithium ion battery and preparation method of silylene composite material

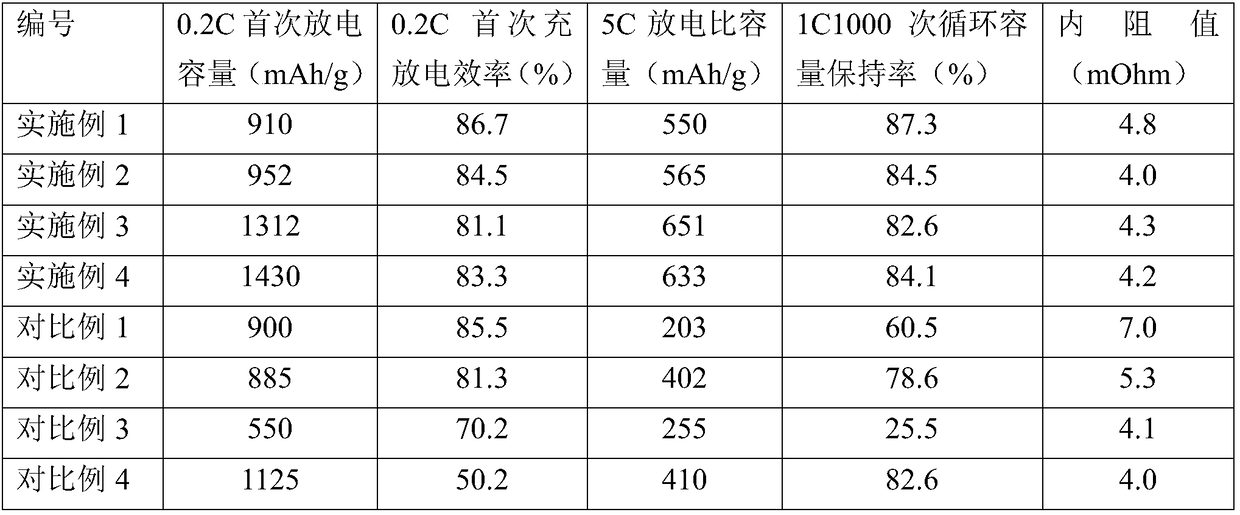

ActiveCN114171717ASolve the bloat problemImprove cycle lifeElectrode thermal treatmentSecondary cellsSilyleneElectrical battery

The invention relates to a composite microsphere based on a two-dimensional nano silylene sheet, graphitized carbon nitride and a coated carbon material and a preparation method of the composite microsphere, the material is of a pomegranate-like core-shell structure, the diameter is 5-20 microns, and the composite microsphere is mainly applied to the field of lithium ion battery negative electrodes. The preparation method comprises the following steps: 1) performing hydrothermal reaction on a carbon-nitrogen-containing organic material in alkali liquor, and calcining to obtain lithiated graphite phase carbon nitride; 2) uniformly and tightly compounding the silylene nanosheet and graphite phase carbon nitride in a solvent environment through an electrostatic self-assembly process; and 3) adding a carbon precursor for coating, and carrying out high-temperature calcining forming. The composite microsphere prepared by the preparation method disclosed by the invention is beneficial to the unique structure and valence bond form of the silylene nanosheet, the defect that the expansion rate of a silicon-based negative electrode material is too high is fundamentally overcome, and the synergistic effect of silylene and graphite-phase carbon nitride is fully utilized, so that the novel negative electrode material has the advantages of high specific capacity, long cycle life and the like; and the preparation process is simple, low in cost and suitable for industrial production.

Owner:陕西晶泰新能源科技有限公司

Low-dimensional material forming method

InactiveCN110010460AReduced material requiredLower requirementSemiconductor/solid-state device manufacturingSilyleneSemiconductor materials

The invention relates to a low-dimensional material forming method, and belongs to the technical field of two-dimensional semiconductor materials. The forming method comprises the following steps of:performing surface treatment on silicon wafers through chemical mechanical planarization and self-limiting oxidation to ensure that one surfaces of the silicon wafers are leveled and the uniformity inthe silicon wafers is smaller than 2nm to obtain the treated silicon wafers; taking one treated silicon wafer, and forming an oxide layer on the other non-flat surface of the silicon wafer; growing or transferring a layer of two-dimensional materials on the top of the oxide layer; taking the other treated silicon wafer, and bonding the flat surface of the other treated silicon wafer with the two-dimensional material layer of the silicon wafer in the step S3 through Van der Waals force; treating the non-flat surface of the obtained silicon wafer through chemical mechanical planarization and self-limiting oxidation to obtain a flat surface; performing etching of an atomic layer and self-limiting oxidation to obtain few layers of flat silylene; and under the catalysis of nitrogen or argon, rearranging crystal lattices of the silylene according to crystal lattices of the lower surface of Si to form the two-dimensional material with a single-layer structure or a few-layer structure and having a large area, uniform few layers and high purity.

Owner:GUIYANG UNIV

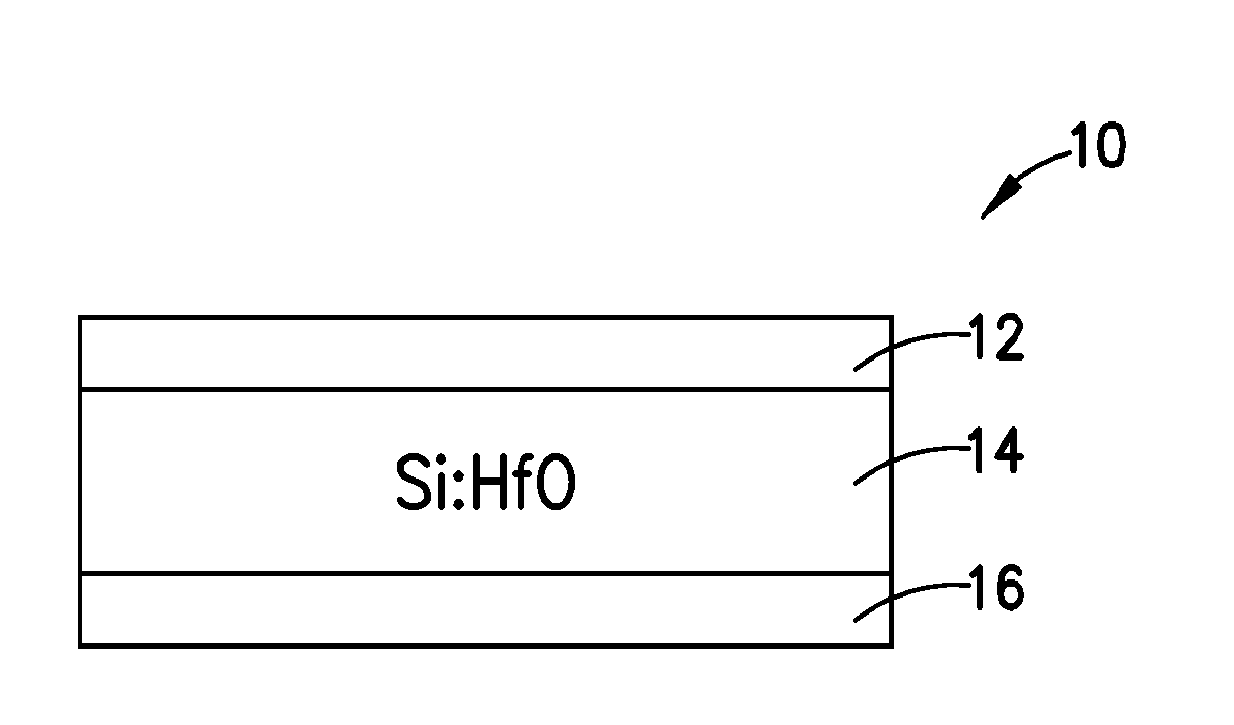

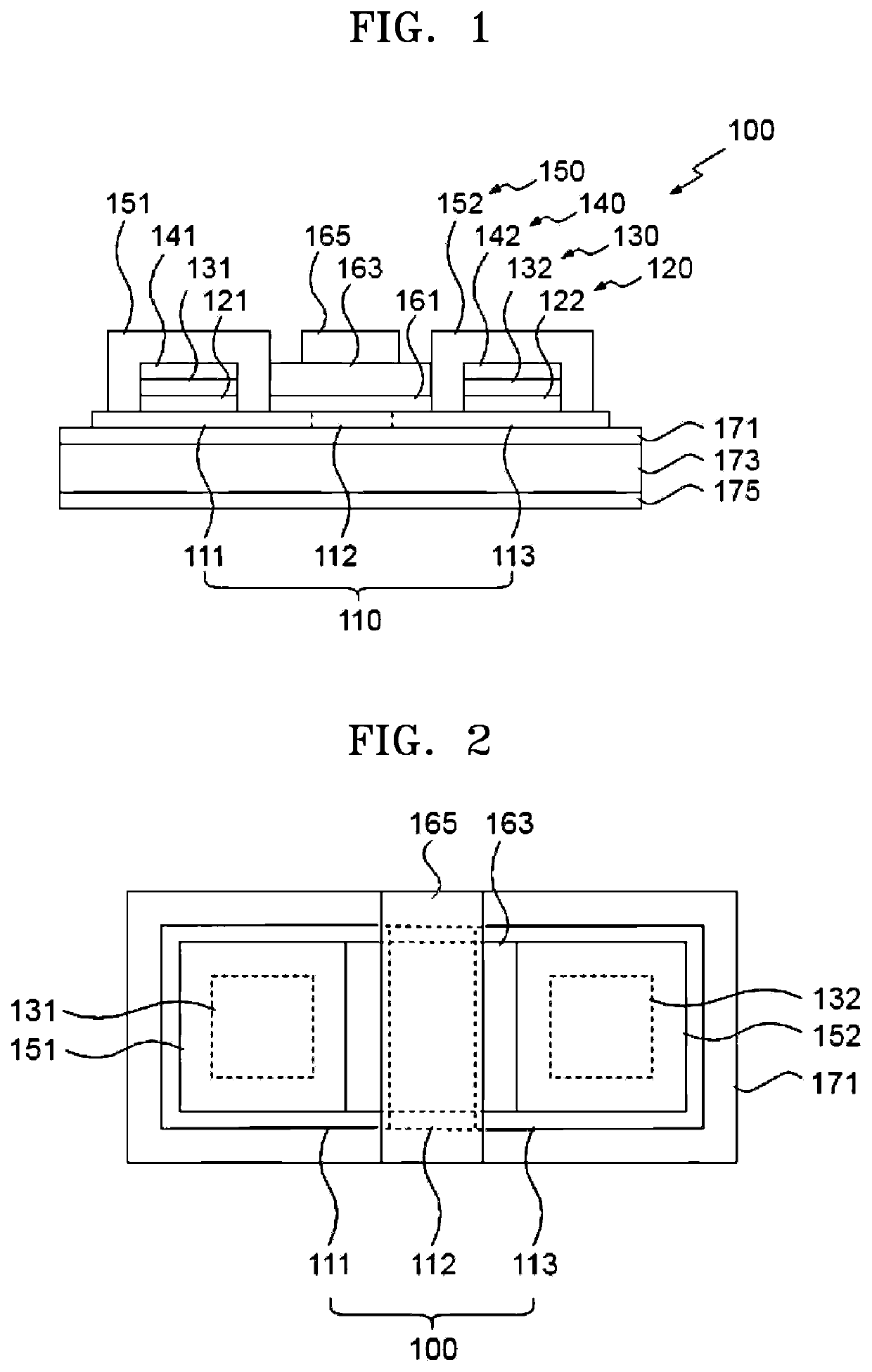

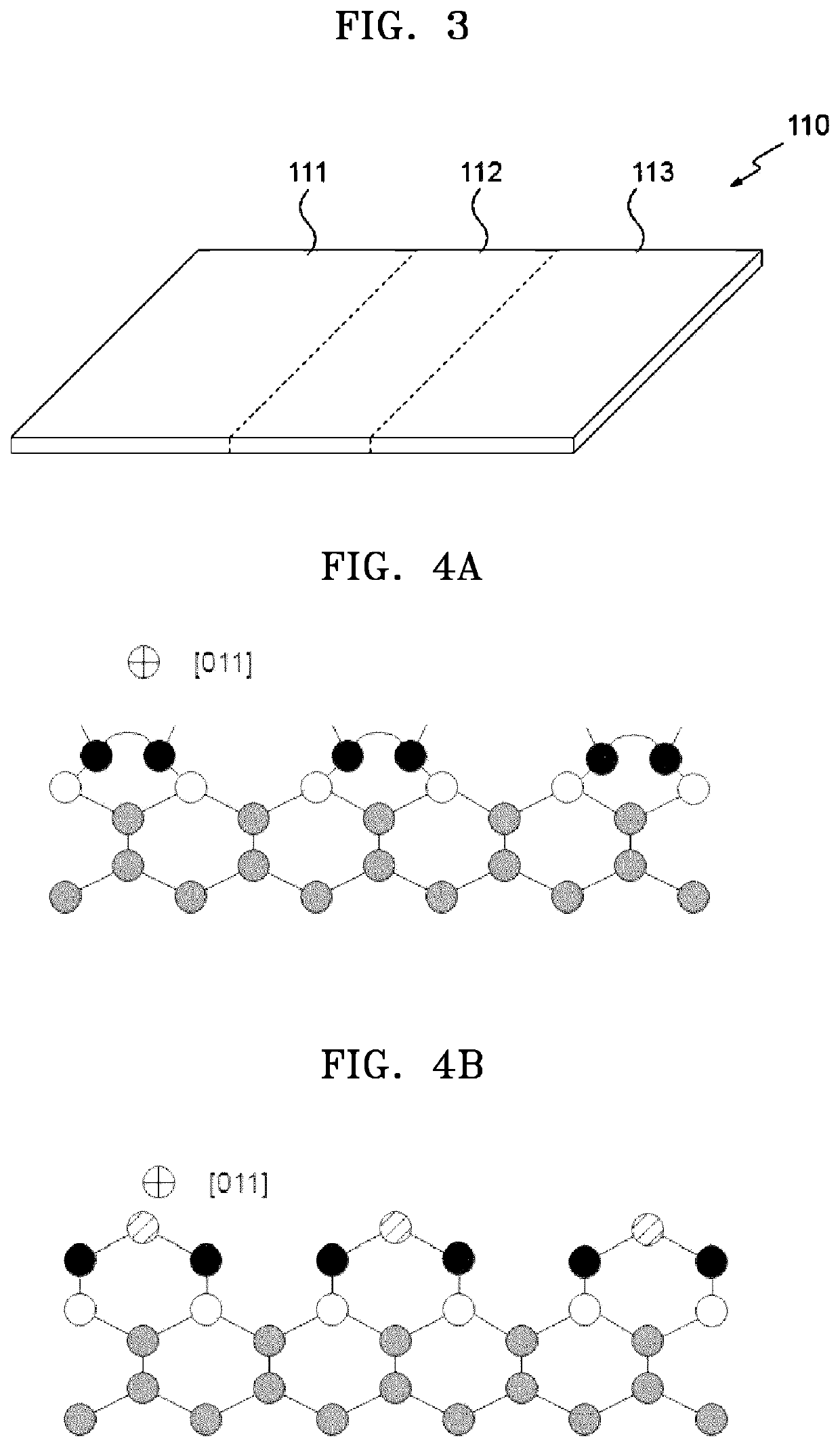

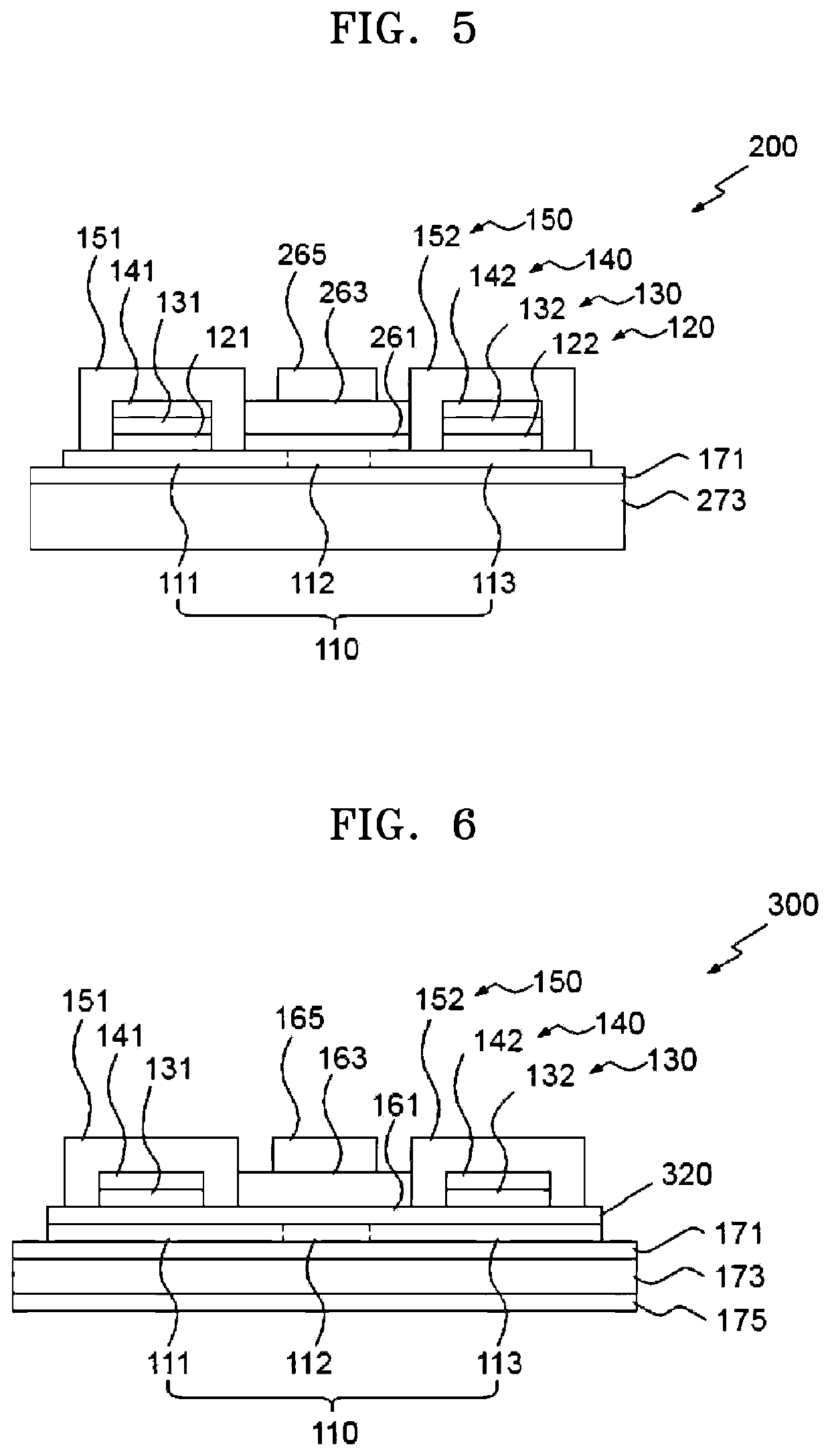

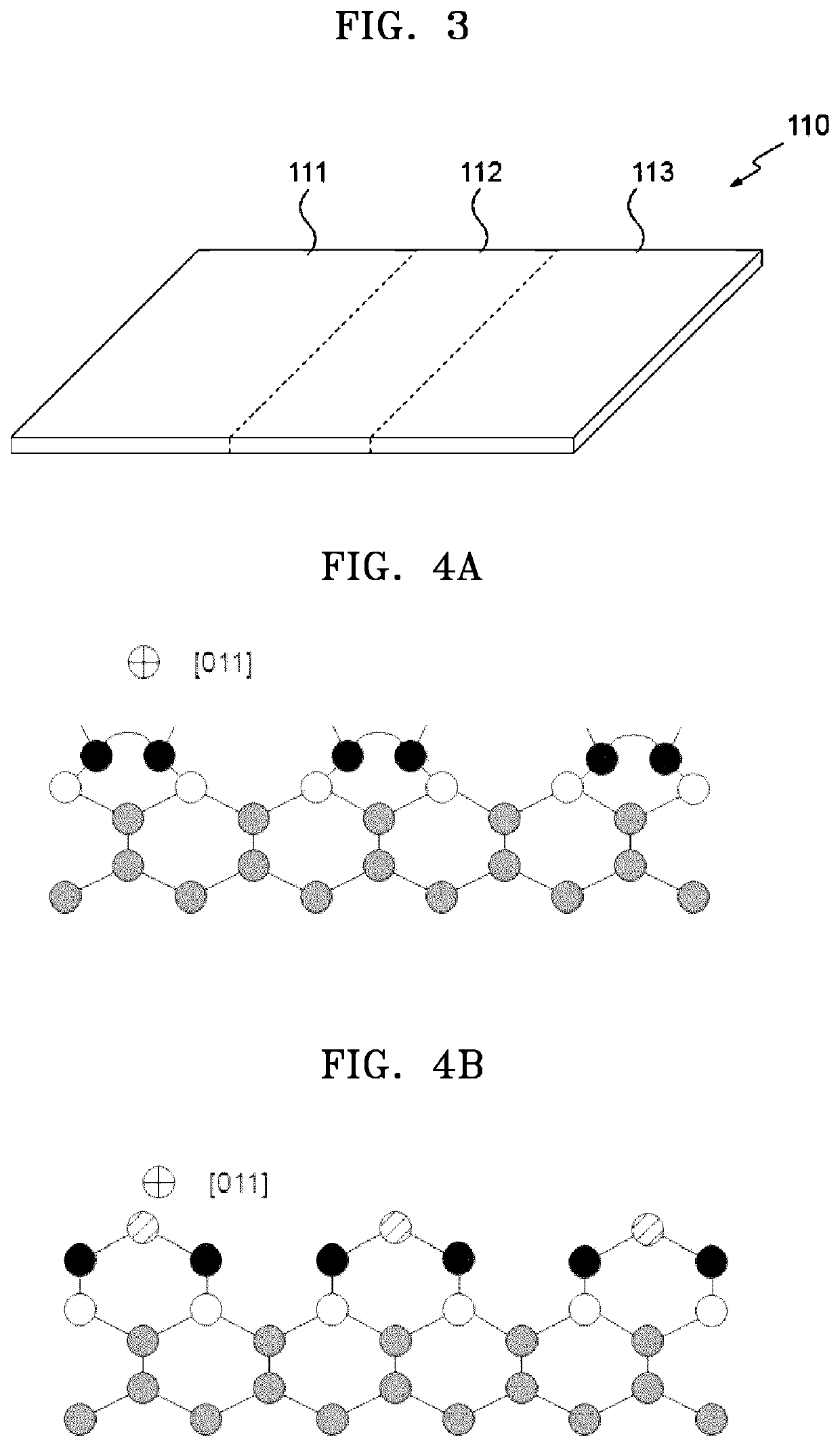

Silicene electronic device

ActiveUS20200135878A1Simple processReducing methodTransistorSemiconductor/solid-state device manufacturingDopantEngineering

A silicene electronic device includes a silicene material layer. The silicene material layer of the silicene electronic device has a 2D honeycomb structure of silicon atoms, is doped with at least one material of Group I, Group II, Group XVI, and Group XVII, and includes at least one of a p-type dopant region doped with a p-type dopant and an n-type dopant region doped with an n-type dopant. An electrode material layer including a material having a work function lower than the electron affinity of silicene is formed on the silicene material layer.

Owner:SAMSUNG ELECTRONICS CO LTD

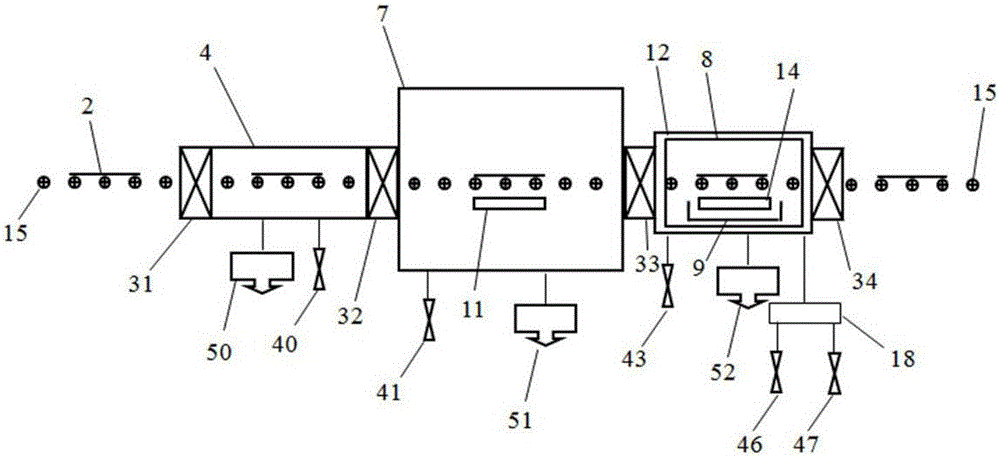

Device for continuously preparing two-dimensional nano tin films

InactiveCN105779961ARealize large-scale productionVacuum evaporation coatingSputtering coatingSilyleneBoron nitride

The invention discloses a device for continuously preparing two-dimensional nano tin films. The device comprises a feed chamber, a sample preparing chamber, a discharge chamber, and the like, wherein valves are arranged among the chambers; samples are conveyed among the chambers through conveying devices such as rollers or conveying belts; each chamber is connected with an independent vacuumizing device and an independent air pipeline; the sample preparing chamber is provided with a physical vapor deposition system, a chemical vapor deposition system, and the like; the feed chamber can be provided with a heating device or a plasma surface treatment system; and the discharge chamber can be provided with a heating device, and the like. According to the device, the whole device is provided with an automated control system for controlling the switching on and switching off of the valves among the chambers, sample transmission, operation of a vacuum system, gas flow, and the like; and the structure is simple, the working is reliable, a uniform graphene, transition metal sulfide, silylene, germylene or boron nitride two-dimensional nano tin film, and the like, can be continuously prepared in a large area, and the device is applicable to industrialized preparation of two-dimensional nano tin films.

Owner:徐明生

Silicene electronic device

ActiveUS10818765B2Simple processReducing methodTransistorSemiconductor/solid-state device manufacturingDopantSilica gel

A silicene electronic device includes a silicene material layer. The silicene material layer of the silicene electronic device has a 2D honeycomb structure of silicon atoms, is doped with at least one material of Group I, Group II, Group XVI, and Group XVII, and includes at least one of a p-type dopant region doped with a p-type dopant and an n-type dopant region doped with an n-type dopant. An electrode material layer including a material having a work function lower than the electron affinity of silicene is formed on the silicene material layer.

Owner:SAMSUNG ELECTRONICS CO LTD

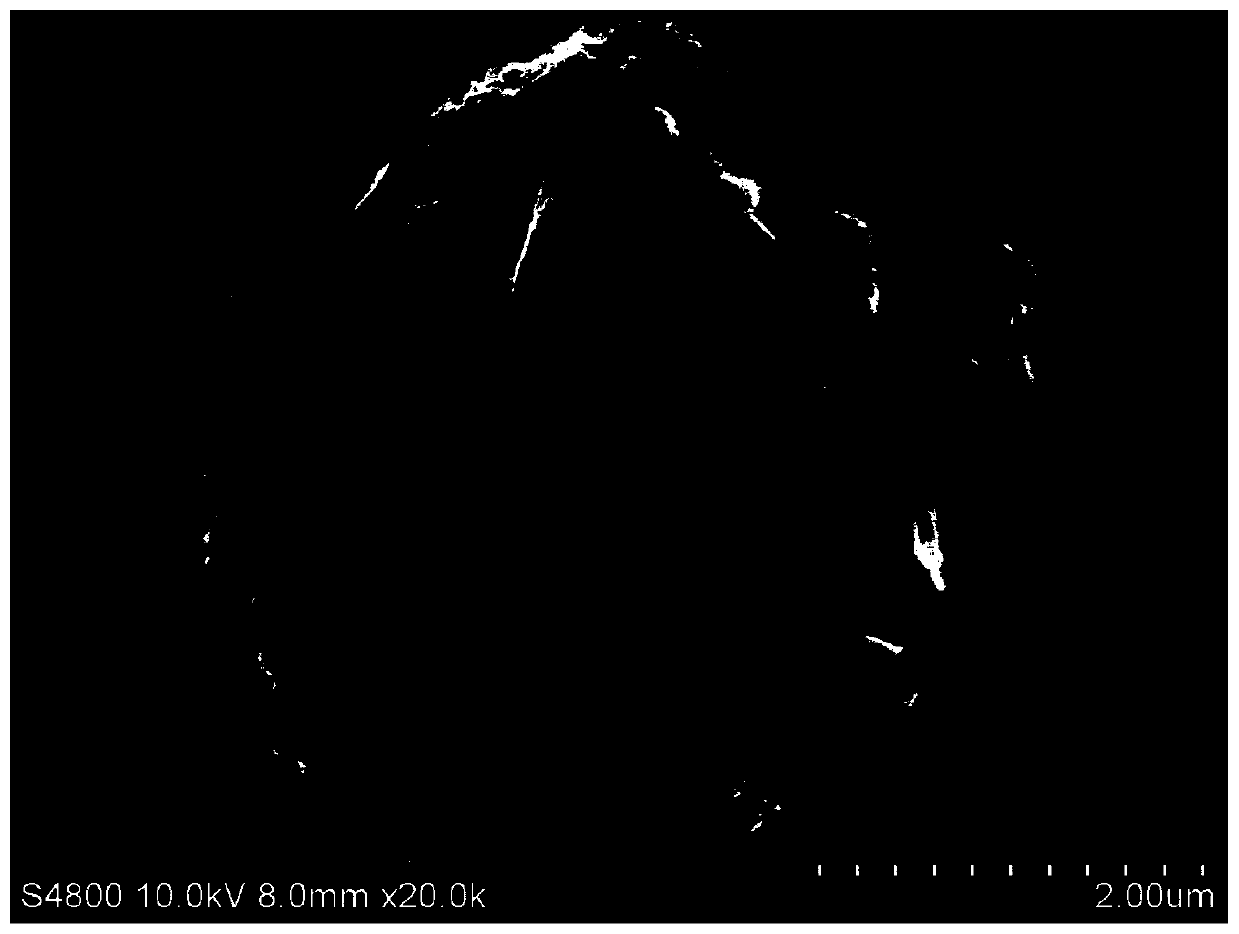

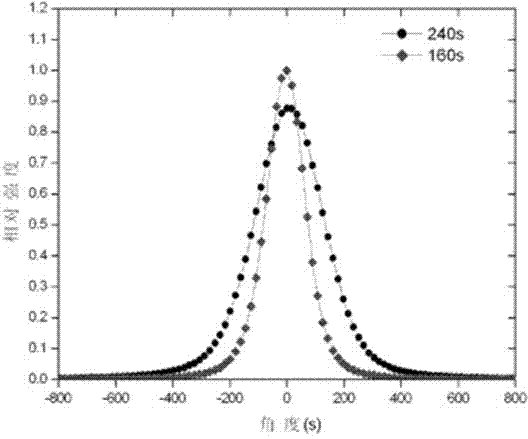

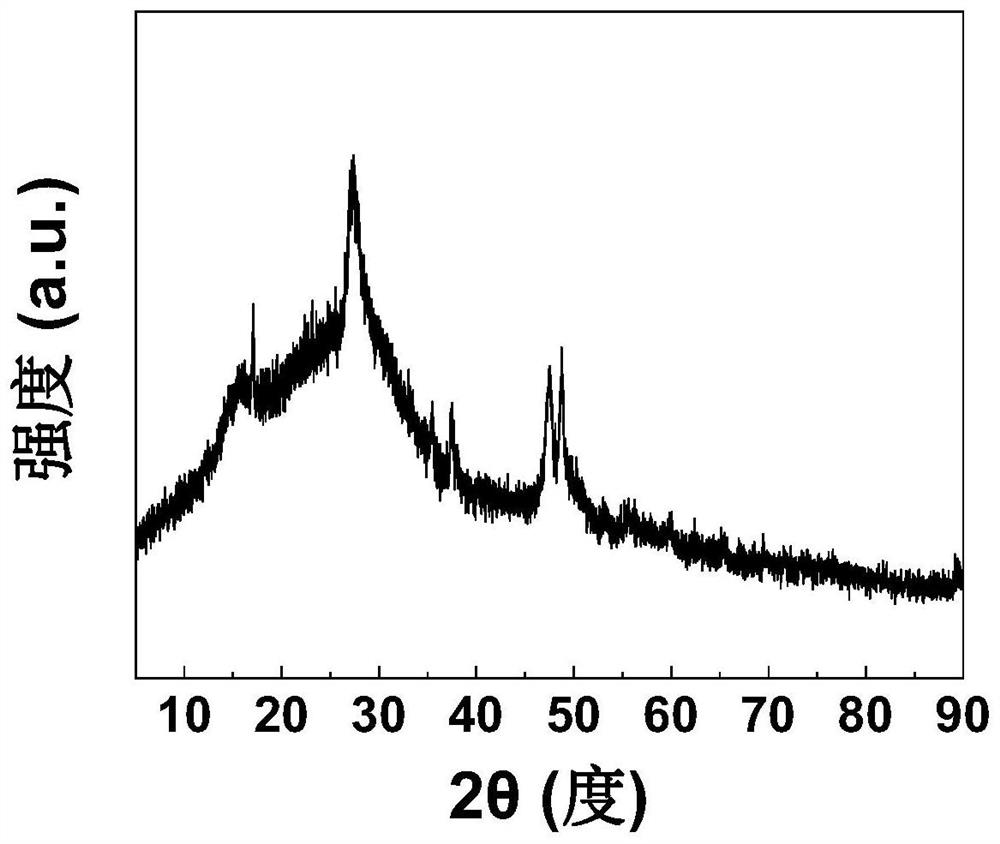

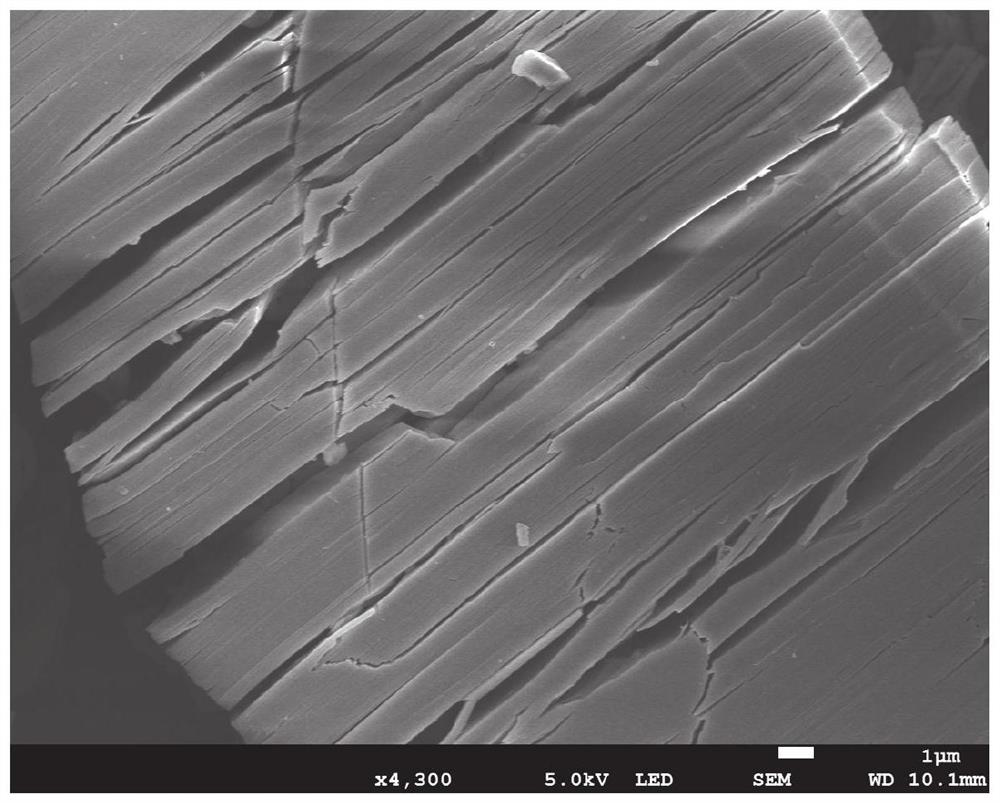

Epitaxial GaN structure with silylene as buffer layer and preparation method thereof

InactiveCN104733580AReduce stressImprove crystal qualitySemiconductor devicesSilyleneElectric capacity

The invention discloses an epitaxial GaN structure with silylene as a buffer layer and a preparation method thereof. The structure comprises the buffer layer and a GaN layer, wherein the buffer layer comprises a silylene layer and a silver droplet layer on the silylene layer, the silylene grows on a substrate, and the silver droplet layer deposits on the silylene layer. The preparation method comprises the following steps that 1, the silylene layer is prepared on the substrate; 2, the silver droplet layer grows on the silylene layer; 3, the GaN layer grows on the sliver droplet layer. The silylene layer is adopted as the buffer layer between the substrate and the GaN epitaxial layer, and the good characteristics of the silylene are combined, namely the silylene has superior electrical conductivity, thermal conductivity and toughness, so that the GaN epitaxial layer with low stress and high crystal quality is obtained; on one hand, the unstable atomic-scale silylene layer is sealed; on the other hand, the connection between the buffer layer and the GaN epitaxial layer is enhanced; the growing GaN epitaxial layer has dislocation with low density, leak current of a device is reduced, and the anti-static electric capacity is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

High-thermal-stability battery diaphragm as well as preparation method and application thereof

PendingCN113540689AImprove thermal stabilityImprove securityMaterial nanotechnologyLi-accumulatorsSilyleneStructural engineering

The invention relates to the technical field of batteries, in particular to a high-thermal-stability battery diaphragm as well as a preparation method and application thereof. The high-thermal-stability battery diaphragm comprises a diaphragm, and the diaphragm is provided with a silylene coating layer. The prepared diaphragm is high in thermal stability and good in safety, and the problem that the diaphragm is poor in thermal stability is solved. And heat preservation is carried out at 120 DEG C, the commercialized diaphragm is deformed and shrunk at high temperature, and the diaphragm with the modified thickness is still kept complete. According to the two-dimensional silylene nanosheet, the diaphragm is coated with a two-dimensional sheet structure, so that heat conduction is facilitated. Besides, the nanosheet structure can also alleviate the problem of increase of ion impedance caused by reduction of the porosity, because the nanosheet structure can provide an ion transmission channel, the ion transmission speed is greatly improved, and the influence of the coating on the porosity of the diaphragm is effectively solved. The preparation method of the diaphragm is simple and easy to implement, low in cost and hopeful for large-scale production.

Owner:SHANDONG UNIV

A method for preparing silicene film by mechanical exfoliation and application of silicene film

ActiveCN106554016BPromote mass productionImprove stabilityMaterial nanotechnologySolid-state devicesActive agentSolar battery

The invention discloses a silicene film prepared by mechanical peeling and the application of the obtained silicene film in batteries. The two-dimensional nanomaterials are physically covered on the passivated silicon surface of the metal film. After high-temperature treatment, the silicon element diffuses into the two-dimensional The interface between the nanomaterial and the metal film is lowered to room temperature, and the sample is dispersed in a solvent liquid with a surfactant. Polar molecules are very easy to enter the interface between the metal film and the substrate material, and the metal film and the substrate are increased by ultrasonic stirring. Material friction, peeling two-dimensional nanomaterials and silicene from silicon substrates to obtain silicene films. The present invention utilizes mechanical stripping to peel off the silicene thin layer in the liquid phase through physical action, which protects the physical properties of the silicene material, avoids the working environment of high vacuum and high-risk gas, and avoids highly toxic organic reactants The use of two-dimensional nanomaterials can be used repeatedly, which reduces the cost and has broad market application value in the field of solar cells.

Owner:日照东润有机硅股份有限公司

A kind of preparation method of silicene

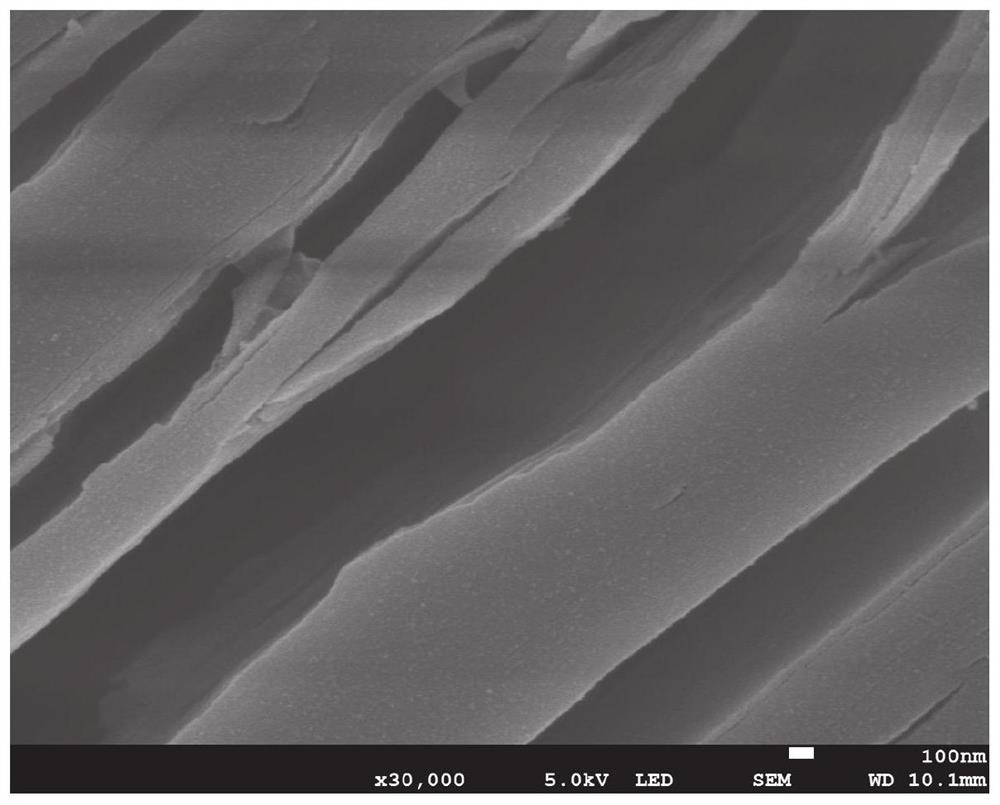

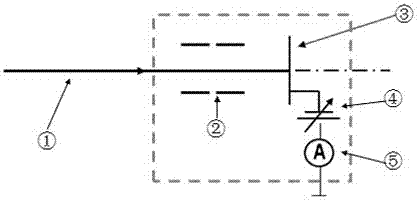

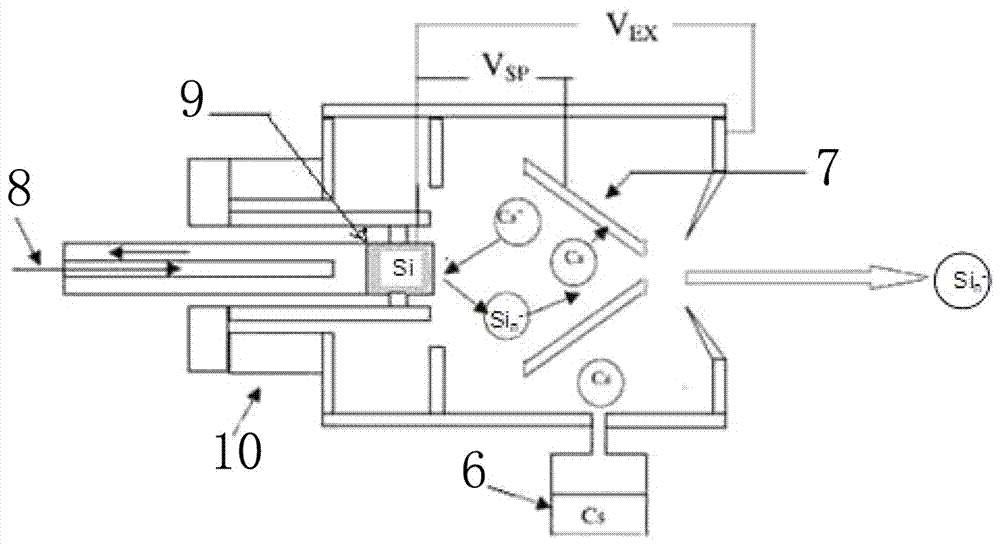

ActiveCN105439148BPrecise and controllable thicknessImprove uniformitySilicon compoundsIon beamSilicene

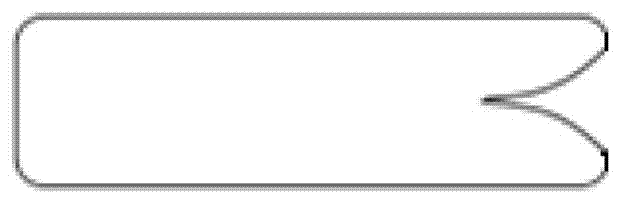

The invention provides a method for preparing silene. The method specifically comprises: processing silicon blocks into a concave tapered silicon target; mounting the silicon target on a sputtering target of a cesium sputtering negative ion source; sputtering the silicon target by using cesium ions; leading out Si<2-> cluster negative ion beams generated by sputtering from extraction electrode extraction holes, wherein Si<2-> cluster negative ions are uniformly deposited on an Ag (111) substrate through scanning electric field after being accelerated by extraction electrode voltage; and putting a sample into a vacuum chamber, sputtering the surface of the sample by Ar<+> ions, and then carrying out annealing treatment on the sample in an ultrahigh vacuum to finish the preparation of silene. According to the preparation method provided by the invention, by using the advantages of low energy of a single atom of low-energy cluster negative ion beams, and an accurate and controllable dose, the silene can be prepared directly by virtue of a direct deposition method.

Owner:武汉纽飞格纳米科技有限公司

Method for preparing silylene by carbene-induced halogenated silane dehydrohalogenation

The invention discloses a method for preparing silylene by carbene-induced halogenated silane dehydrohalogenation, and relates to a method for synthesizing silylene. Dilithium salt of [NN] bidentate ligand and halogenosilane or substituted halogenosilane organic silicon reagent react to form substituted halogenated silane; and the molar ratio of the substituted halogenated silane to stable carbene is 1:0.5-10, the reaction temperature is between 78 DEG C below zero and 100 DEG C, the substituted halogenated silane and the stable carbene are mixed in a common organic solvent to generate imidazole salt of silylene and carbene, the generated imidazole salt is separated from the solution of a product through filtration after the reaction is finished, and the silylene or derivatives of the silylene are obtained through recrystallization and chromatographic separation. Through the reaction of different organic halogenosilane hydrides and the carbene, the method discovers that the carbene can effectively reduce a silicon compound under the mild condition to generate bivalent silicon intermediate. The imidazole salt as the reaction product can be converted into the carbene more easily so as to realize recycle.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com