A kind of preparation method of silicene

A silicene and silicon target technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reduced symmetry, enlarged unit cells, and affecting the performance of silicene film materials, and achieves accurate and reliable thickness. Good control and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

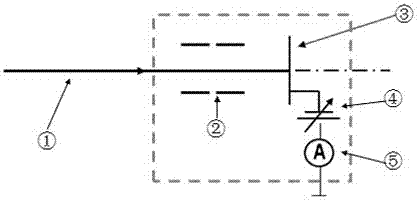

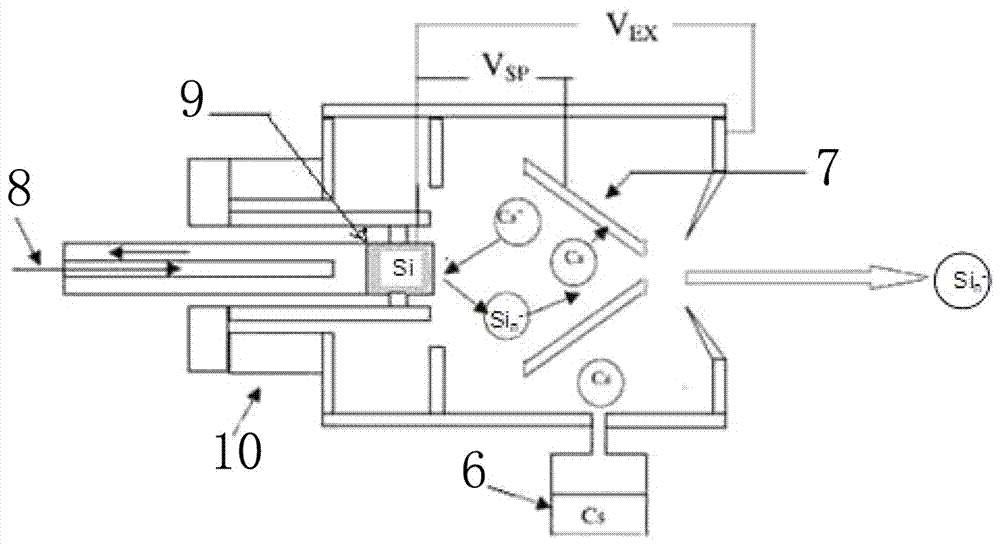

Method used

Image

Examples

Embodiment 1

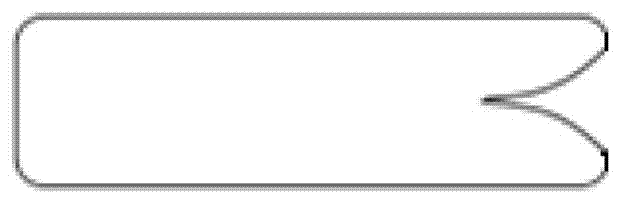

[0035] Since the beam intensity of the extracted negative ions will directly affect the efficiency of ion implantation, it is necessary to optimize the sputtering beam. Ordinary planar targets have a stronger scattering effect on sputtered negative ions, resulting in weaker beam intensity. If the front end of the target is designed with a cone angle of 45-60 o of the concave cone (see attached image 3 ), the scattering effect in the sputtering process is weakened, and the focusing effect is greatly enhanced, thereby increasing the negative ion beam current. Experiments have shown that, under the same conditions as other conditions, using the concave conical sputtering target designed in the present invention, the beam intensity drawn from the deposition target chamber is about an order of magnitude higher than that of a common planar target, which will significantly Improve the efficiency of ion implantation, especially for negative ion implantation of clusters with more th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com