Preparation method of coated thermal battery composite electrode sheet

A composite electrode and thermal battery technology, applied in the electrodes of primary batteries, equipment for manufacturing primary batteries, battery electrodes, etc., can solve the problems of poor powder support, difficult electrode sheet preparation, and low electrode sheet forming rate, etc. Improve toughness and strength, prevent diaphragm melt overflow, and achieve precise and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

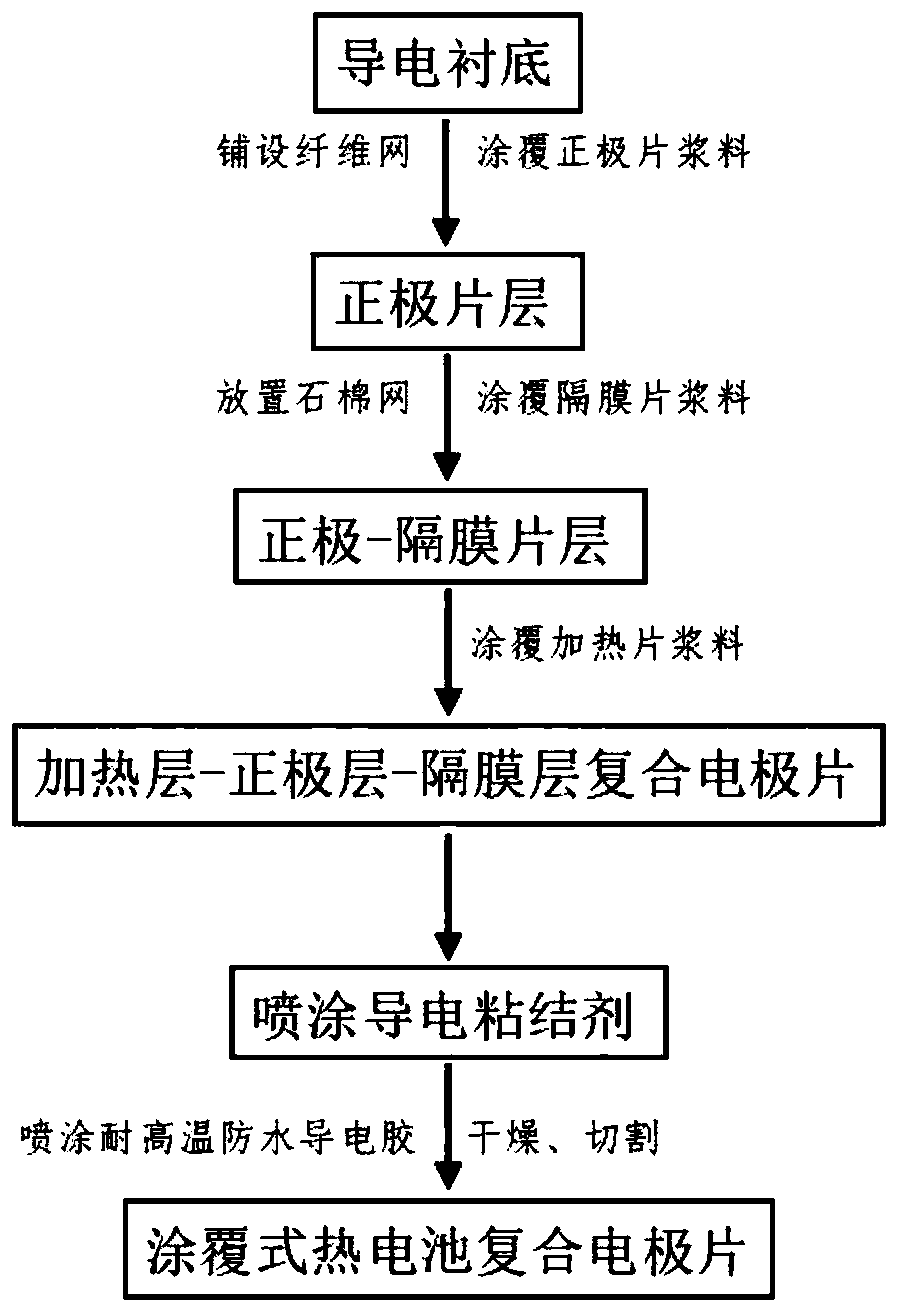

[0040] A method for preparing a coated thermal battery composite electrode sheet, comprising the following steps:

[0041] (1) Preparation of the positive electrode sheet layer: after laying the conductive substrate on the working table of the battery coating machine, lay a layer of fiber mesh on the conductive substrate, and then adjust the height A of the coater scraper according to the thickness of the positive electrode sheet. , place the positive electrode sheet slurry to be coated on the surface of the conductive substrate, then turn on the coating machine to start coating, and place it in a drying oven to dry after coating to obtain the positive electrode sheet;

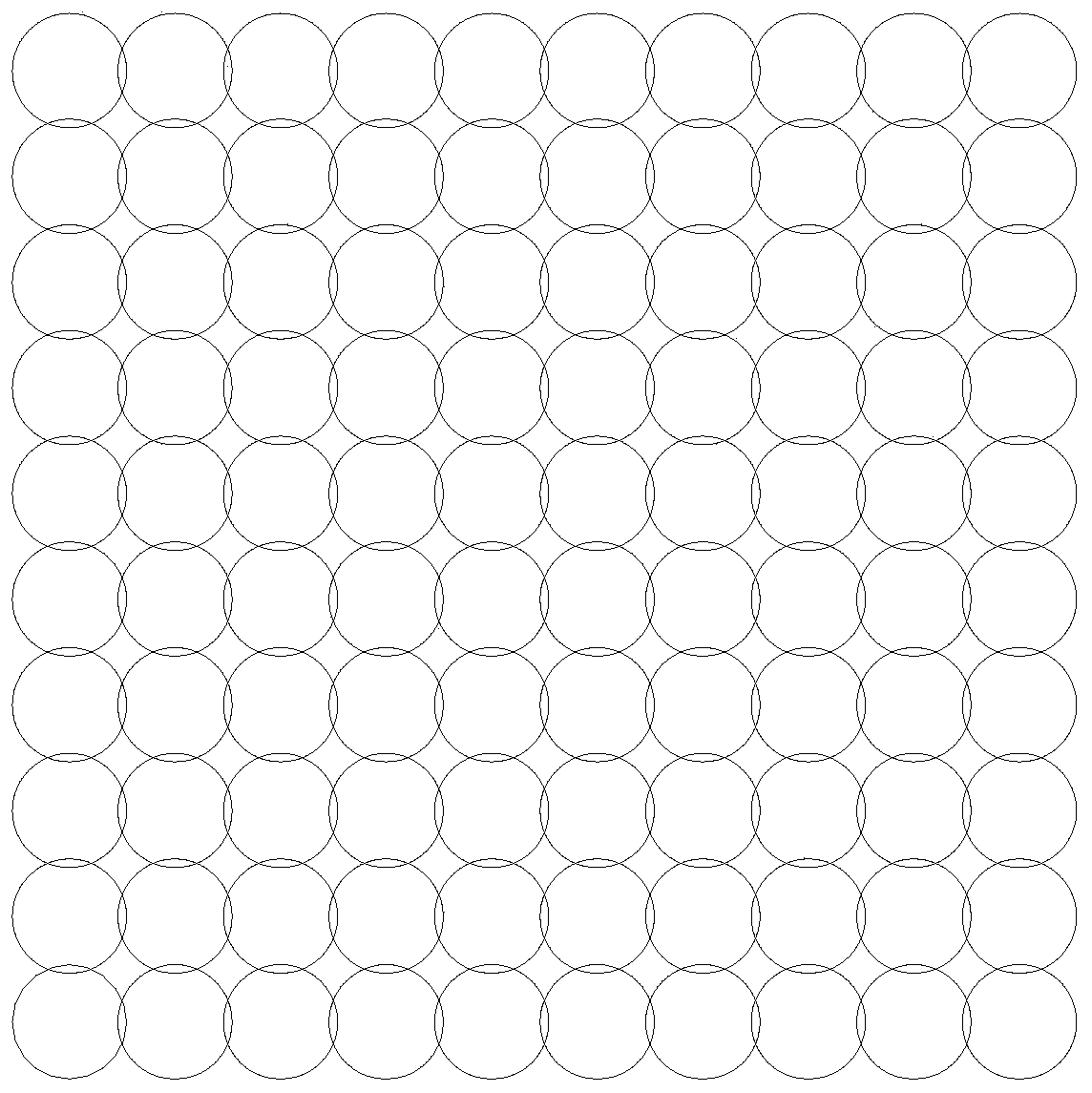

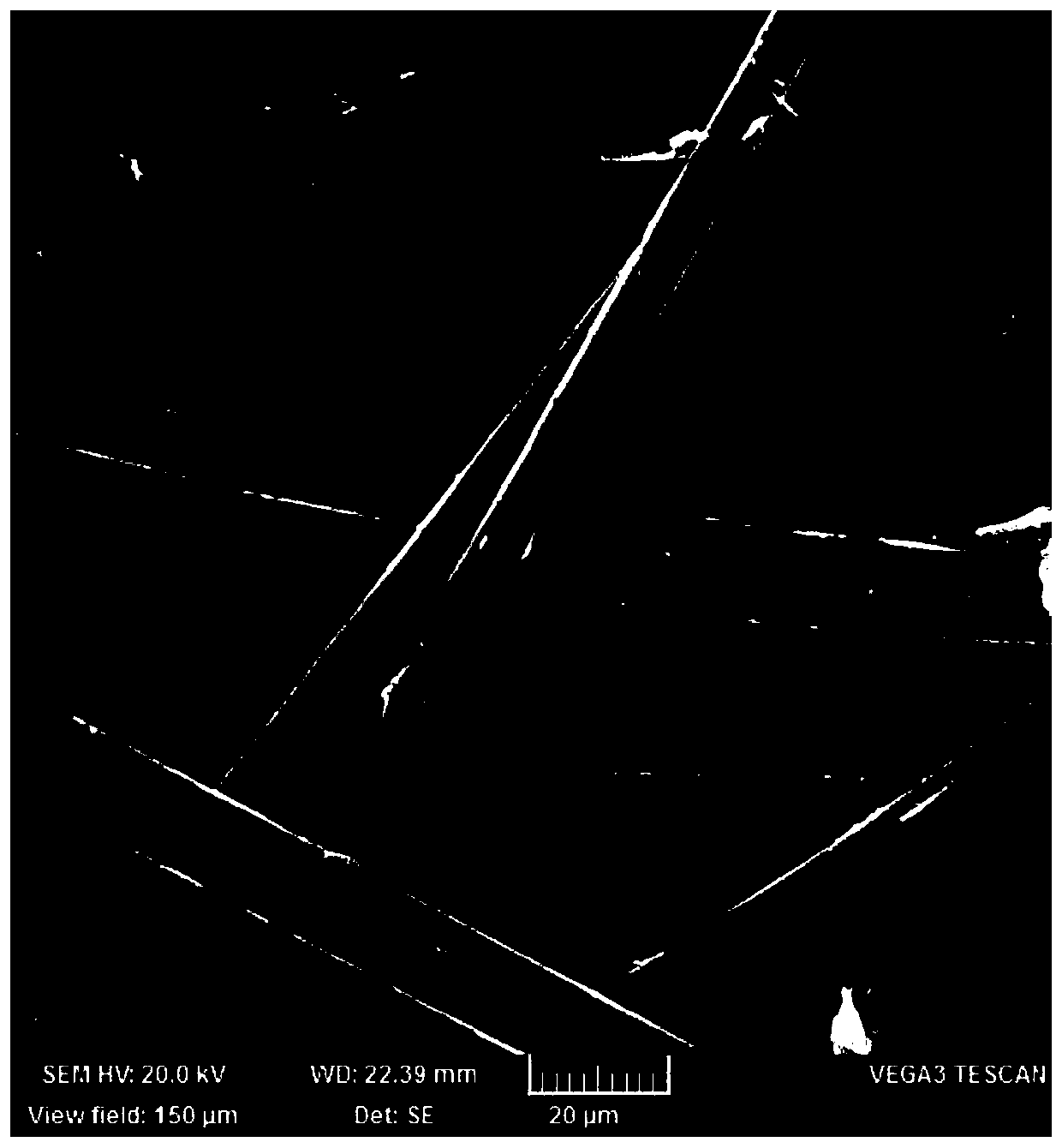

[0042] The conductive substrate is a graphite sheet; the porosity of the fiber web is 85%, and the fiber web is embedded in the positive electrode sheet; the height A of the scraper is adjusted to 0.02mm; the fiber web is carbon fiber felt;

[0043] (2) Prepare the positive electrode-diaphragm sheet: place the...

Embodiment 2

[0050] A method for preparing a coated thermal battery composite electrode sheet, comprising the following steps:

[0051] (1) Preparation of the positive electrode sheet layer: after laying the conductive substrate on the working table of the battery coating machine, lay a layer of fiber mesh on the conductive substrate, and then adjust the height A of the coater scraper according to the thickness of the positive electrode sheet. , place the positive electrode sheet slurry to be coated on the surface of the conductive substrate, then turn on the coating machine to start coating, and place it in a drying oven to dry after coating to obtain the positive electrode sheet;

[0052] The conductive substrate is iron foil; the porosity of the fiber web is 99%, and the fiber web is embedded in the positive sheet; the height A of the scraper is adjusted to 2mm; the fiber web is iron or copper metal fiber felt;

[0053] (2) Prepare the positive electrode-diaphragm sheet: place the posi...

Embodiment 3

[0060] A method for preparing a coated thermal battery composite electrode sheet, comprising the following steps:

[0061] (1) Preparation of the positive electrode sheet layer: after laying the conductive substrate on the working table of the battery coating machine, lay a layer of fiber mesh on the conductive substrate, and then adjust the height A of the coater scraper according to the thickness of the positive electrode sheet. , place the positive electrode sheet slurry to be coated on the surface of the conductive substrate, then turn on the coating machine to start coating, and place it in a drying oven to dry after coating to obtain the positive electrode sheet;

[0062] The conductive substrate is copper foil; the porosity of the fiber web is 86%, and the fiber web is embedded in the positive electrode sheet; the height A of the scraper is adjusted to 0.2mm; the fiber web is beryllium oxide ceramic fiber felt;

[0063] (2) Prepare the positive electrode-diaphragm shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com