Nickel oxide and barium titanate nano composite ferroelectric film material and preparation method and application thereof

A ferroelectric thin film and nanocomposite technology, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of ferroelectric remanent polarization and small dielectric properties, and achieve accurate and reliable film thickness. Control, low production cost, economical and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

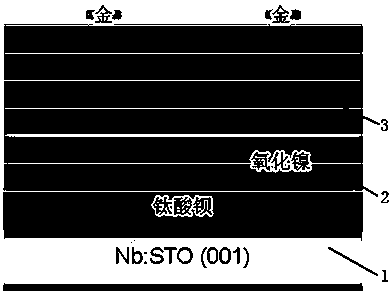

[0069] Such as figure 1 As shown, a nickel oxide-barium titanate nanolayer composite thin film material, which includes Nb:SrTiO 3 (001) single crystal substrate 1, barium titanate thin film 2 and nickel oxide thin film 3, wherein, the volume percentage of NiO is 10%, BaTiO 3 The volume percentage is 90%.

[0070] The preparation method of the nano-layered composite film material comprises the following steps:

[0071] Barium titanate target and nickel oxide target were prepared respectively by solid powder sintering method: mix barium oxide and titanium dioxide powder according to the molar ratio Ba:Ti=1:1, press molding, and heat at 850°C~1350°C sintering at 850°C, 950°C, 1050°C, 1150°C, 1250°C and 1350°C respectively, each time sintering for 20 hours, and sintering for 6 times to obtain pure phase titanium Barium acid target; the nickel oxide powder is pressed into shape, and then sintered at 500-800 °C, the temperature is increased by 100 °C, that is, sintered at 500 °C...

Embodiment 2

[0075] A nickel oxide-barium titanate nano-layered composite film material, which includes Nb:SrTiO 3 (001) single crystal substrate 1, barium titanate thin film 2 and nickel oxide thin film 3, wherein, the volume percentage of NiO is 20%, BaTiO 3 The volume percentage is 80%.

[0076] The preparation method of the nano-layered composite film material is basically the same as that of Example 1, except that the barium titanate target is first bombarded with a laser for 20 seconds, and a barium titanate film is deposited on the substrate; then the nickel oxide target is bombarded with a laser For 100 seconds, a nickel oxide film is deposited on the barium titanate film. Repeat the aforementioned laser bombardment process 30 times, anneal in situ for 30 minutes at an atmospheric pressure, and then cool to room temperature at a rate of 2°C / min to obtain an oxide layer with a volume percentage of 20% NiO and a thickness of 160 nm. Nickel-barium titanate nanocomposite layered film...

Embodiment 3

[0079] A nickel oxide-barium titanate nano-layered composite film material, which includes Nb:SrTiO 3 (001) single crystal substrate 1, barium titanate thin film 2 and nickel oxide thin film 3, wherein, the volume percentage of NiO is 30%, BaTiO 3 The volume percentage is 70%.

[0080]The preparation method of the nano-layered composite film material is basically the same as that of Example 1, the difference is that the barium titanate target is first bombarded with a laser for 10 seconds, and the barium titanate film is deposited on the substrate; then the nickel oxide target is bombarded with a laser For 100 seconds, a nickel oxide film is deposited on the barium titanate film. Repeat the aforementioned laser bombardment process 40 times, anneal in situ for 30 minutes at an atmospheric pressure, and then cool to room temperature at a rate of 2°C / min to obtain an oxide layer with a volume percentage of 30% NiO and a thickness of 150 nm. Nickel-barium titanate nanocomposite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com