Silylene composite material for lithium ion battery and preparation method of silylene composite material

A lithium-ion battery and composite material technology, which is applied in the field of silicene composite materials and its preparation, can solve the problems of high expansion rate, low expansion rate, and high volume expansion rate of the negative electrode, and achieve low production cost, improved stability, and high charge. The effect of discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

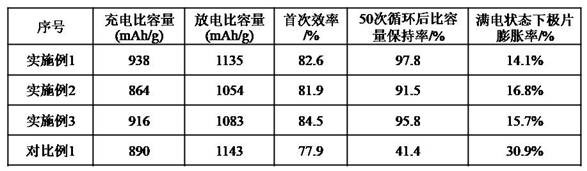

Embodiment 1

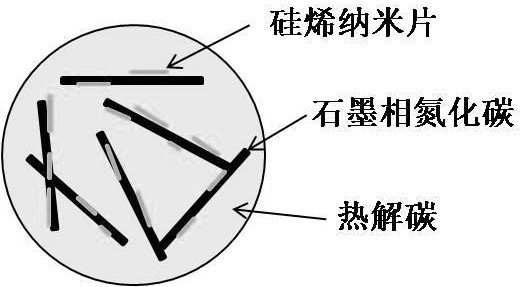

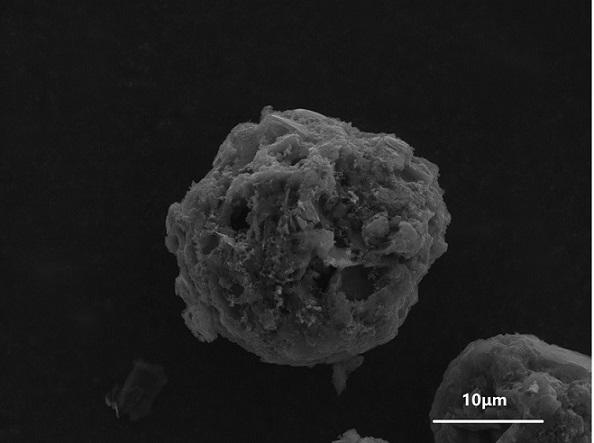

[0031] Preparation of High Performance Composite Anode Materials

[0032] (1) Add 8g melamine and 1.25g LiOH·H to the beaker 2 O and 60 g of deionized water were stirred for 1 h, transferred to a tetrafluoroethylene-lined stainless steel autoclave at 160 ° C for 24 h, the product was washed with de-ionized water for 5 times, and then calcined at 550 ° C under nitrogen to obtain lithiated graphitized carbon nitride ;

[0033] (2) Take 0.6g of graphitized carbon nitride, 0.1g of sodium stearate plus 20ml of ethanol and water (mass ratio 5:1) in the mixed solvent of step 1 and stir for 1h, then ultrasonically disperse for 1h;

[0034] (3) Add 0.8 g of silicene nanosheets and 0.1 g of polydiallyldimethylammonium chloride to a mixed solvent of 20 ml of ethanol and water (mass ratio 5:1), and then sonicate for 1 hour, then slowly add the Post slurry stirring;

[0035] (4) Add 1.2 g of chitosan to the slurry in step 3 and stir for 30 minutes, then spray dry to obtain the negative ...

Embodiment 2

[0042](1) Add 8g of dicyandiamide, 1.25g of lithium carbonate and 60g of deionized water into a beaker and stir for 1 hour, transfer to a tetrafluoroethylene-lined stainless steel autoclave at 160°C for 24 hours, and wash the product with deionized water for 5 times Then calcined at 550°C under air to obtain lithiated graphitized carbon nitride;

[0043] (2) Take 0.6g of lithiated graphitized carbon nitride in step 1, 0.1g of sodium stearate plus 20ml of ethanol and water (mass ratio 5:1) in a mixed solvent and stir for 1h, then ultrasonically disperse for 1h;

[0044] (3) Add 0.8 g of silicene nanosheets and 0.1 g of hexadecyltrimethylammonium bromide to a mixed solvent of 20 ml of ethanol and water (mass ratio 5:1), and then sonicate for 1 h, then slowly add the slurry in step 2 After stirring;

[0045] (4) Add 0.8 g of phenolic resin to the slurry in step 3 and stir for 30 minutes, then stir and dry at 75°C to obtain the negative electrode material precursor;

[0046] (5)...

Embodiment 3

[0050] (1) Add 8g melamine and 1.25g LiOH·H to the beaker 2 O and 60 g of deionized water were stirred for 1 h, transferred to a tetrafluoroethylene-lined stainless steel autoclave at 160 ° C for 24 h, the product was washed with de-ionized water for 5 times, and then calcined at 550 ° C under nitrogen to obtain lithiated graphitized carbon nitride ;

[0051] (2) Take 0.6g of lithiated graphitized carbon nitride, 0.1g of sodium dodecylbenzenesulfonate and 20ml of ethanol in step 1 and stir for 1h, then ultrasonically disperse for 1h;

[0052] (3) Add 0.8 g of silicene nanosheets and 0.1 g of polydiallyldimethylammonium chloride to 20 ml of ethanol, then sonicate for 1 hour, slowly add the slurry in step 2 and stir;

[0053] (4) Add 0.8 g of polyvinylpyrrolidone to the slurry in step 3 and stir for 30 minutes, then spray dry to obtain the negative electrode material precursor;

[0054] (5) The product in step 4 is calcined and carbonized at a high temperature of 700°C for 5h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com