Method for preparing recycled regenerated plastic for 3D printing

A recycled plastic and 3D printing technology, which is applied in the field of recycling recycled plastic and its preparation, can solve the problems of reduced impact strength and achieve the effects of improving impact strength, widening the range, and enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

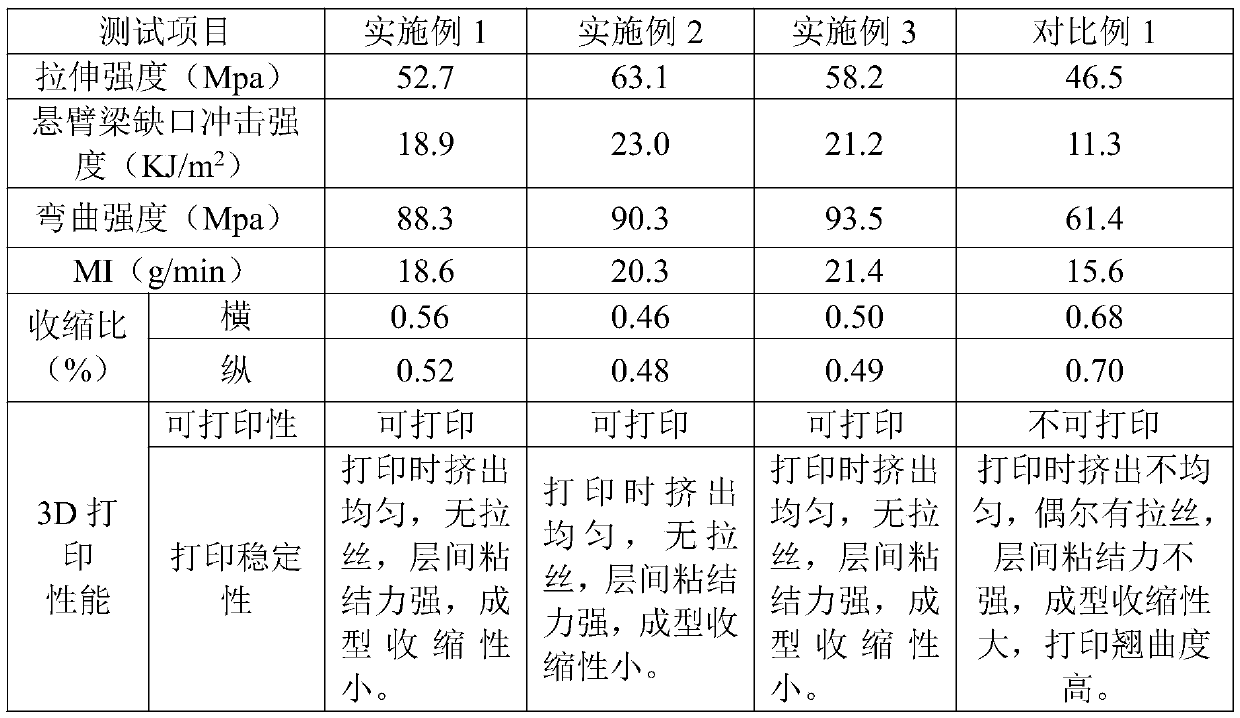

Examples

Embodiment 1

[0046] The recycled plastic used for 3D printing in this embodiment consists of 60 recycled recycled plastics, 5 parts of glass fiber, 3 parts of molybdenum disulfide, 3 parts of maleic anhydride grafted ethylene-octene copolymer, 2 parts of zinc stearate, 3 parts of biochar, 1 part of styrene-maleic anhydride copolymer, 0.5 part of chain extender, 0.5 part of modified ethylene bis fatty acid amide, 0.1 part of azodicarbonamide, 1 part of antioxidant, 1 part of stabilizer agent and UV absorber mixture. Among them, recycled recycled plastics are composed of ABS, polypropylene and PET. The components in parts by weight of the chain extender are: 5-12 parts of pyromellitic anhydride, 6-15 parts of dicumyl peroxide, 7-18 parts of acrylonitrile-butadiene-styrene copolymer grafted oxazoline share.

[0047] The biochar specific surface area of the present embodiment is 300-500m 2 .

[0048] The method for recycling recycled plastics used in this embodiment for 3D printing inclu...

Embodiment 2

[0058] The recycled plastic used for 3D printing in this embodiment consists of 70 parts of recycled plastic, 20 parts of glass fiber, 10 parts of molybdenum disulfide, 10 parts of acrylic acid grafted ethylene-octene copolymer, 3 parts of calcium stearate, 1 -15 parts of biochar, 5 parts of maleic anhydride grafted acrylonitrile-butadiene-styrene copolymer, 2 parts of chain extender, 1 part of pentaerythritol hard fatty acid, 5 parts of azodicarbonamide, 30 parts of EVA (new Material), containing VA content of 40%, and 2 parts of antioxidant, 3 parts of stabilizer and nucleating agent mixture. in:

[0059] The biochar pore diameter of the present embodiment is 50-500nm, specific surface area is 900-1200m 2 . Recycled recycled plastic consists of ABS, polypropylene and PET.

[0060] Then, according to the preparation method of Example 1, recycled plastics for 3D printing were prepared.

Embodiment 3

[0062] The recycled plastic used for 3D printing in this embodiment consists of 65 parts of recycled plastic, 10 parts of glass fiber, 8 parts of molybdenum disulfide, 6 parts of maleic anhydride grafted polypropylene, 3 parts of zinc stearate, and 10 parts of biological Carbon, 3 parts of glycidyl methacrylate grafted ABS, 1 part of chain extender, 1 part of pentaerythritol stearic acid, 2 parts of azodicarbonamide, 10 parts of EVA (recycled material), the content of VA is 35% , 2 parts of antioxidants, 5 parts of stabilizers, nucleating agents, compatibilizers by mass parts 25%: 25%: 50% mixed mixture.

[0063] The biochar pore diameter of this embodiment is 150-300nm, specific surface area is 1100-1300m 2 . Recycled recycled plastic consists of ABS, polypropylene and PET.

[0064] Then, according to the preparation method of Example 1, recycled plastics for 3D printing were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com