Polyethyleneimine functionalized carbon nanotube modified polyformaldehyde composite material and preparation method thereof

A technology of carbon nanotube modification and polyethyleneimine, which is applied in the field of materials, can solve the problems of weak bonding force between carbon nanotubes and polymer matrix interfaces, achieve the effect of improving crystallization behavior and mechanical properties, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

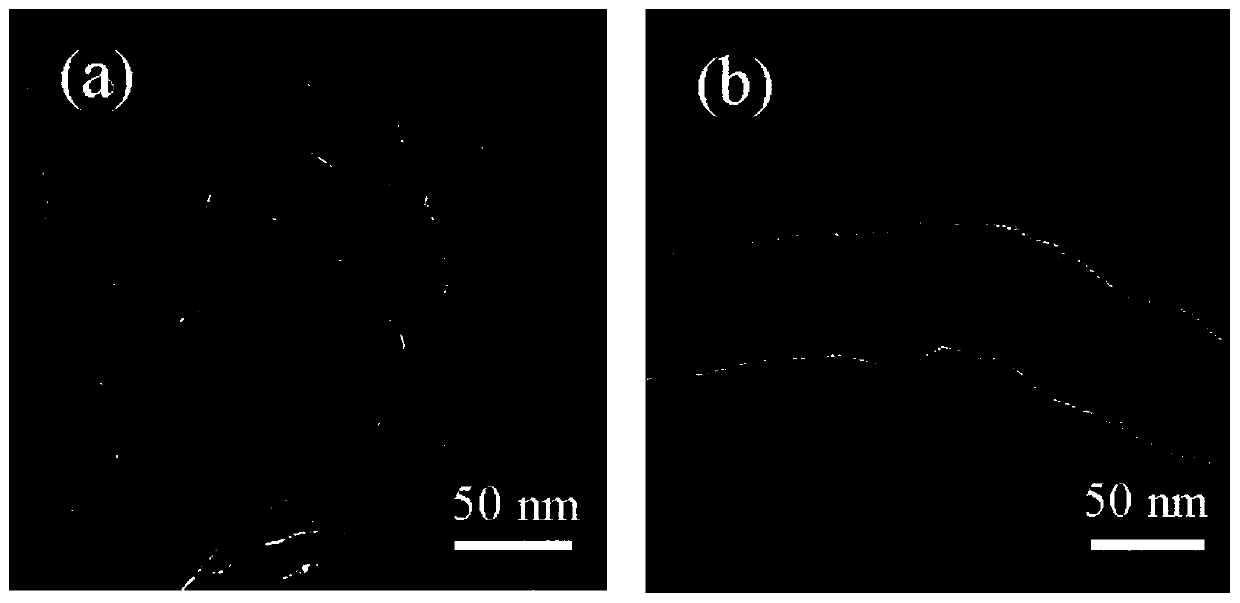

[0028] The invention provides a preparation method of polyethyleneimine functionalized carbon nanotube modified polyoxymethylene composite material, comprising:

[0029] A) carbon nanotubes are mixed with acid to obtain carboxylated carbon nanotubes;

[0030] B) mixing and reacting carboxylated carbon nanotubes and polyethyleneimine in the presence of a condensing agent to obtain polyethyleneimine functionalized carbon nanotube products;

[0031] C) react polyoxymethylene and polyethylenimine functionalized carbon nanotube product, and form it to obtain the product.

[0032] The preparation method of the polyethyleneimine functionalized carbon nanotube-modified polyoxymethylene composite material provided by the invention firstly mixes the carbon nanotube with acid to obtain the carboxylated carbon nanotube.

[0033] Preferably, carbon nanotubes are subjected to ultrasonic treatment and oxidation treatment in a mixed acid solution to obtain carboxylated carbon nanotubes (MWNT...

Embodiment 1

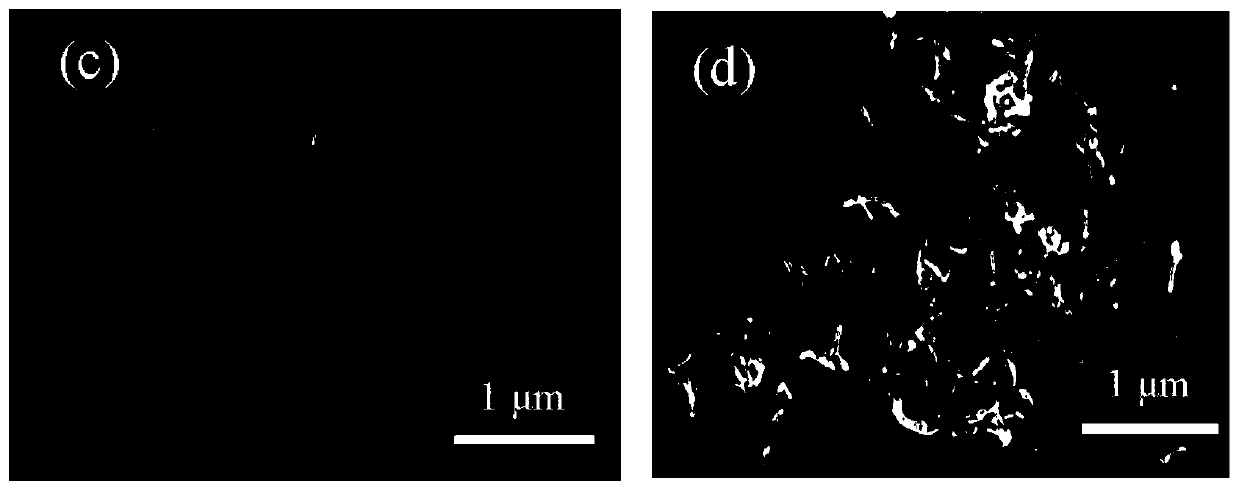

[0058] Carbon nanotubes were oxidized by ultrasonic treatment in a mixed acid solution (volume ratio of concentrated sulfuric acid and concentrated nitric acid 3:1) for 1 to 10 hours to obtain carboxylated carbon nanotubes (MWNTs-COOH), and the product was washed with distilled water until neutral. dry;

[0059] Take the dried MWNTs-COOH and deionized water to form a solution in a flask, then place the flask in a water bath at a certain temperature and perform the following operations: first add 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC·HCl), add N-hydroxysuccinimide (NHS) after a period of time, react under stirring for 3h, then choose to add polyethyleneimine with a molecular weight of 2000, in Stir at room temperature for 8h. The polyethyleneimine functionalized carbon nanotube product was obtained, which was successively washed by centrifugation with distilled water several times, and dried;

[0060] Completely dissolve an appropriate amount of pol...

Embodiment 2

[0067] Carbon nanotubes were oxidized by ultrasonic treatment in a mixed acid solution (volume ratio of concentrated sulfuric acid and concentrated nitric acid 3:1) for 1 to 10 hours to obtain carboxylated carbon nanotubes (MWNTs-COOH), and the product was washed with distilled water until neutral. dry;

[0068] Take the dried MWNTs-COOH and deionized water to form a solution in a flask, then place the flask in a water bath at a certain temperature and perform the following operations: first add 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC·HCl), add N-hydroxysuccinimide (NHS) after a period of time, react under stirring for 6h, then choose to add polyethyleneimine with a molecular weight of 5000, in Stir at room temperature for 9h. The polyethyleneimine functionalized carbon nanotube product was obtained, which was successively washed by centrifugation with distilled water several times, and dried;

[0069] Add polyethyleneimine functionalized carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com