A nano-composite high-wax heavy oil pour point and viscosity depressant and preparation method thereof

A technology of nano-composite material and viscosity reducer, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of poor low temperature fluidity of heavy oil, and achieves simple and easy control of production process, good effect, and easy acquisition of raw materials. Effect

Active Publication Date: 2022-06-03

SOUTHWEST PETROLEUM UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the above-mentioned deficiencies in the prior art, the present invention provides a nanocomposite high-wax heavy oil pour point and viscosity reducer and a preparation method thereof. Improve the low-temperature fluidity of crude oil, the production process is simple and easy to control, effectively solve the problems that the pour point depressant and viscosity depressant cannot be taken into account at the same time, and the low-temperature fluidity of heavy oil is poor, and has broad application prospects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

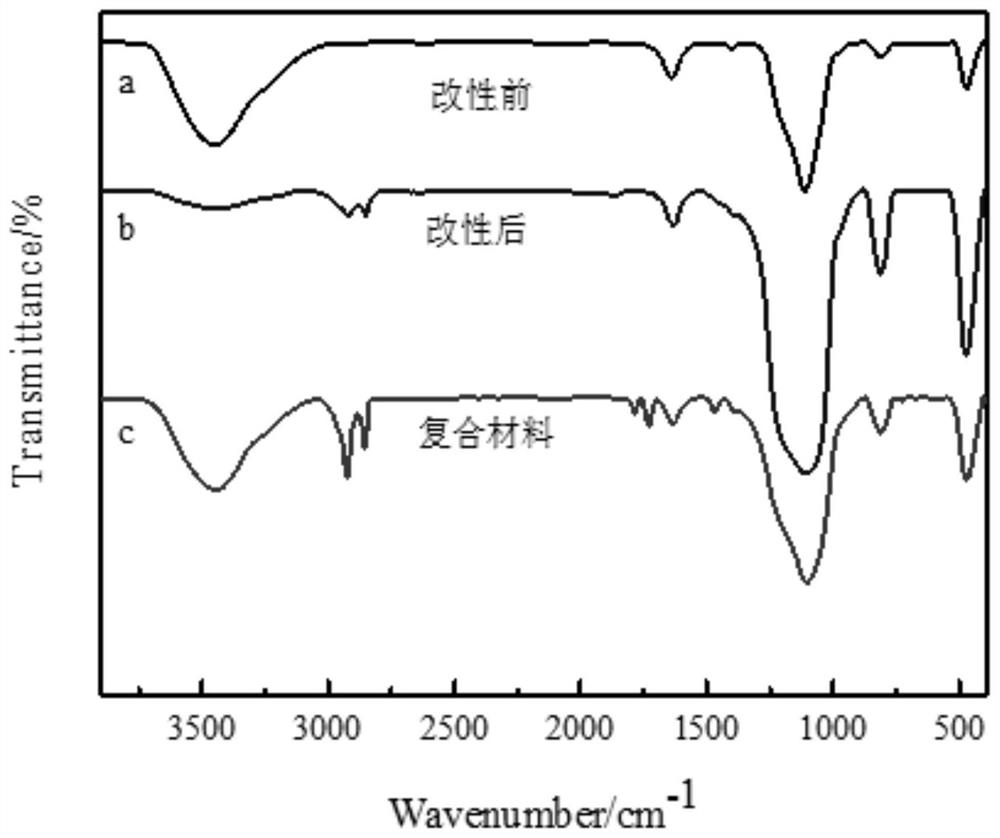

The invention provides a nano-composite high-wax heavy oil pour point and viscosity reducer and a preparation method thereof. The pour point and viscosity reducer includes the following components: nano silicon dioxide, silane coupling agent, stearyl methacrylate, Maleic anhydride, styrene and acrylamide; the mass volume ratio of nano-silica to silane coupling agent is 2-3:1g / mL, and the molar ratio of octadecyl methacrylate, maleic anhydride, styrene and acrylamide is 3-8:1:2:1; the molar volume ratio of octadecyl methacrylate to silane coupling agent is 3-8:1mol / mL. The invention also provides a preparation method of the pour point and viscosity reducer. The pour point depressant and viscosity depressant of the present invention has the effect of depressing the pour point and viscosity at the same time, and the effect is good, the low temperature fluidity of crude oil is improved, the production process is simple and easy to control, and it effectively solves the problem that the pour point depressant and the viscosity depressant cannot be taken into account at the same time. Problems such as poor fluidity at low temperature have broad application prospects.

Description

A kind of nano composite material high wax heavy oil pour point and viscosity reducer and preparation method thereof technical field The present invention relates to pour point depressant and preparation technical field thereof, be specifically related to a kind of nano composite material high wax heavy oil pour point depressant Viscosity reducer and preparation method thereof. Background technique With the continuous exploitation of petroleum resources, the reserves of light crude oil are rapidly decreasing, and unconventional oil and gas resources such as heavy oil are rapidly decreasing. sources are getting more and more attention. Heavy oil is an important part of the world's oil and gas resources. The complex composition makes heavy oil density, viscosity and viscosity. At room temperature, heavy oil is solidified and has extremely poor fluidity. Therefore, the exploitation of heavy oil and Shipping is a huge problem. How to effectively transport heavy oil wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/588C08F220/18C08F222/08C08F212/08C08F220/56

CPCC09K8/588C08F220/18C09K2208/10

Inventor 毛金成亢智杨小江林冲毛金桦

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com