Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "High viscosity reduction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidative thinner for heavy oil exploitation via steam injection and preparation thereof

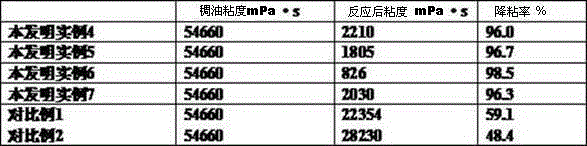

ActiveCN101440275AHigh viscosity reduction rateLow viscosityDrilling compositionHydrolysateAcid substances

The invention relates to an oxidization viscosity reducer for viscous oil recovery by steam injection and a preparation method thereof. The oxidization viscosity reducer comprises components by weight percentage: 0.5 to 10 percent of component A, 0.5 to 10 percent of component B, 0.1 to 8 percent of component C, 0.1 to 5 percent of component D, and the balance being water, wherein the component Ais peroxide, the component B is transition metal salt of an organic acid, the component C is inorganic salt with the acidity shown in a hydrolysate, and the component D is an alkaline substance. The oxidization viscosity reducer can oxidize gelatine and asphaltine in viscous oil, reduce the viscosity of crude oil by changing a structure of the viscous oil through chain termination, oxidize to generate an acid substance at the same time, ensure that the viscous oil becomes a substance with the effect of a surfactant by adding the alkaline substance, and also play a role in viscosity reduction.The experiments show that the viscosity reduction rate can reach 99.9 percent when the viscosity reducer reacts with the crude oil for 24 hours at the temperature of 100 DEG C. The viscosity reducer has higher viscosity reduction rate, is applicable to the viscosity reduction of oil well stratums with high steam injection temperature, and also has good effect under relatively lower temperature conditions.

Owner:中国石化集团河南石油勘探局有限公司

Preparation method of depolymerized and dispersed viscosity reducer of heavy oil

InactiveCN101560380ADepolymerization, dispersion and viscosity reduction remain unchangedUse low concentrationDrilling compositionSolventBenzyl chloride

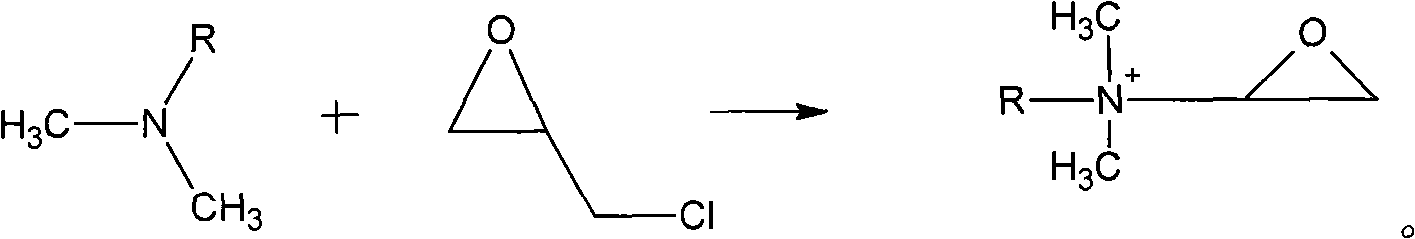

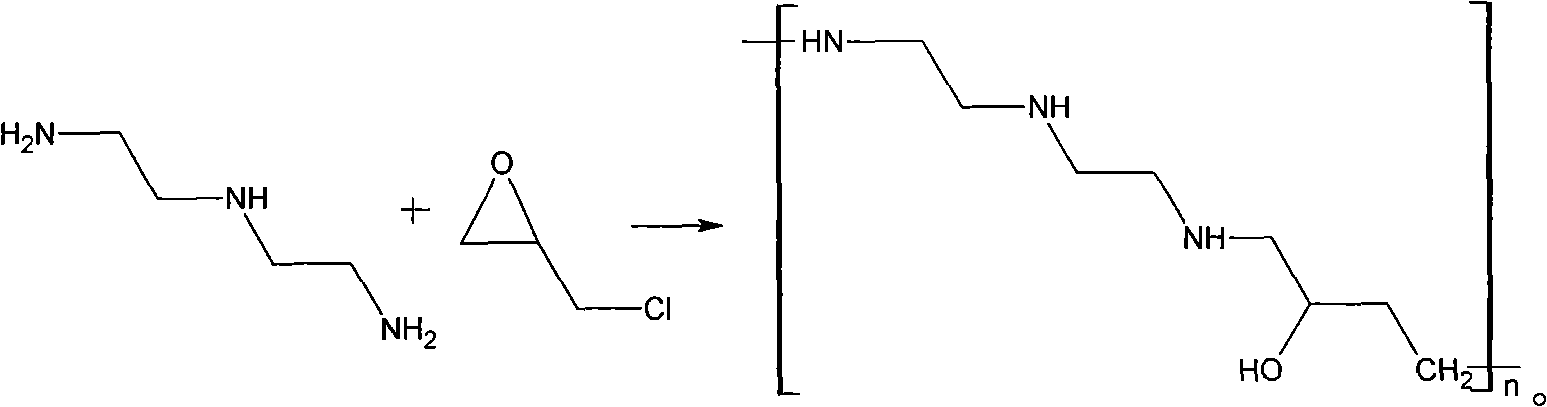

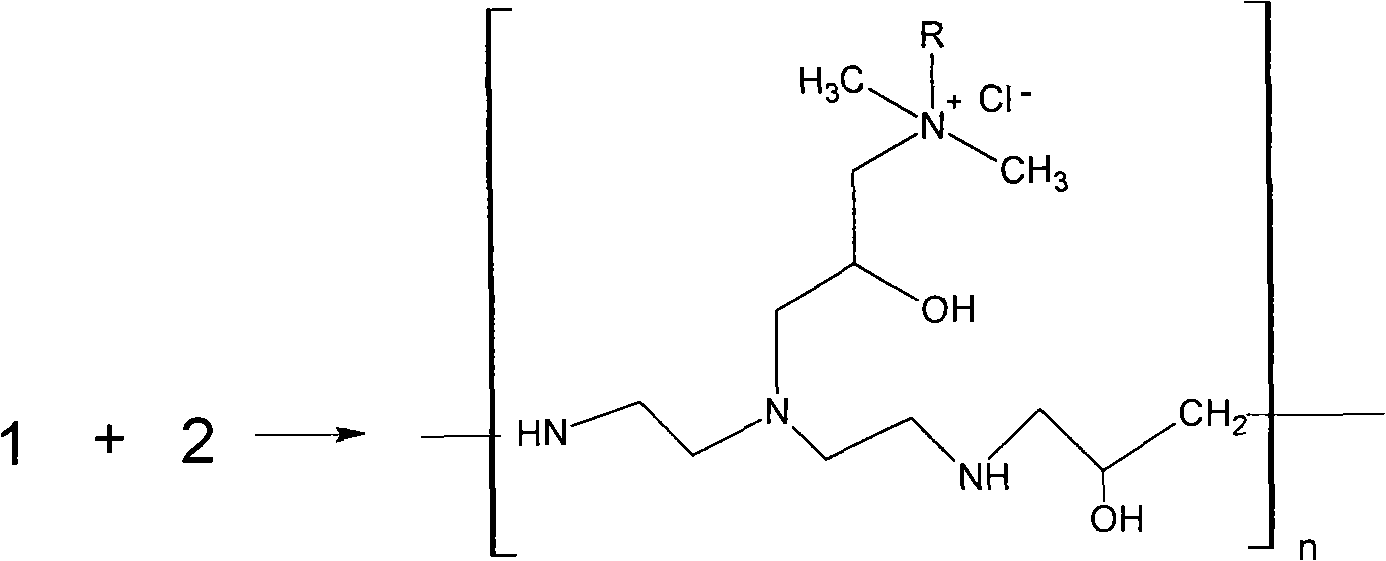

The invention discloses a preparation method of a depolymerized and dispersed viscosity reducer of heavy oil. The preparation method comprises selecting N,N-Dimethyloctadecylamine as a hydrophobic group monomer, and diethylene triamine, epoxy chloropropane and benzyl chloride as hydrophilic group monomers, and ethanol as a solvent. The preparation method sequentially comprises the following steps: (1) adding the N,N-Dimethyloctadecylamine (N,N-Dimethylhexadecylamine) and the ethanol to a reaction vessel with a stirring device, evenly mixing and keeping the mixture at constant temperature for 0.5h; (2) slowly dripping the epoxy chloropropane with a dropping funnel to the reaction vessel, heating to 70 DEG C-75 DEG C, and reacting for 1-4h to generate HDI-1; (3) dripping the epoxy chloropropane to the diethylene triamine at room temperature to generate HDI-2; (4) allowing reaction products in (3) and (2) to react to generate HDI-3; and (5) dripping the benzyl chloride with the dropping funnel to the HDI-3, evenly stirring the mixture, and reacting at increased temperature of 90-95 DEG C for 2-5h to obtain the target product HD.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

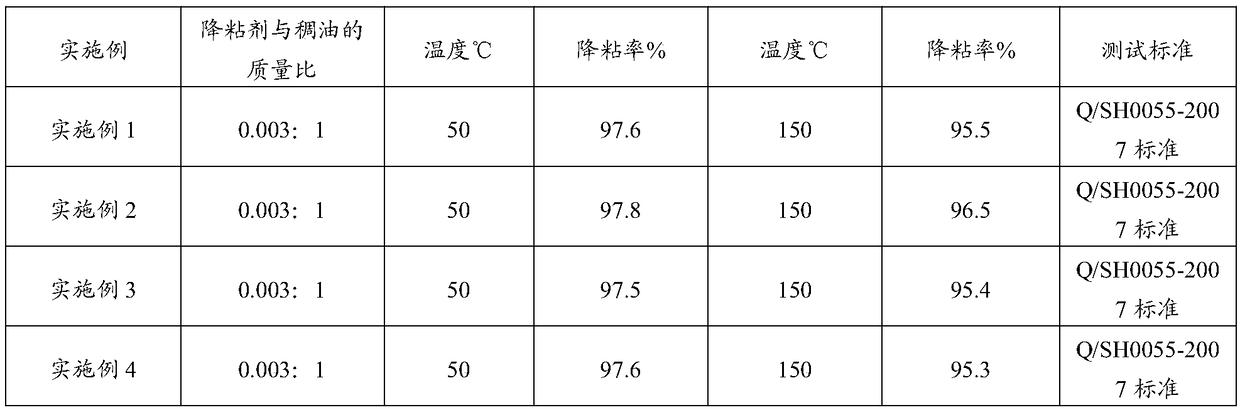

Temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer and preparation method thereof

ActiveCN110041462AImprove temperature resistanceImprove salt toleranceDrilling compositionTemperature resistanceChemistry

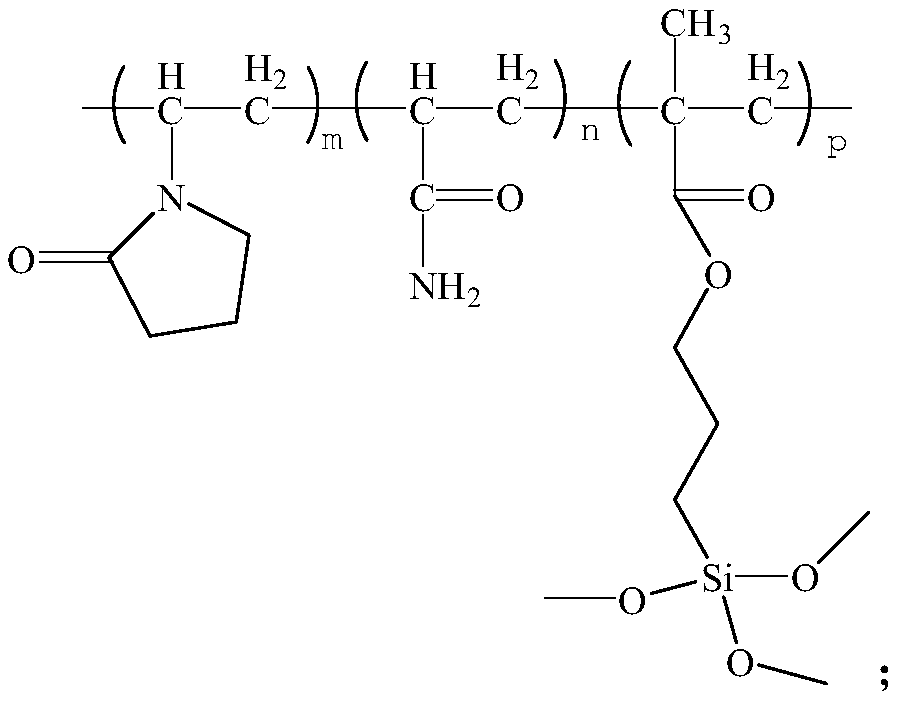

The invention relates to a polymer type viscosity reducer used in a heavy oil recovery process, concretely to a temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducerand a preparation method thereof. The viscosity reducer is generated by 1-vinyl-2-pyrrolidone, acrylamide and methacryloxypropyltrimethoxysilane under the action of an initiator. A mol ratio of the 1-vinyl-2-pyrrolidone, the acrylamide and the methacryloxypropyltrimethoxysilane is 1:0.05-10:0.05-20, preferably 1:1.2:2.3. The heavy oil viscosity reducer of the invention has good temperature resistance and salt resistance, the temperature resistance is above 220 DEG C, and the mineralization resistance is above 100000 mg / L. The heavy oil viscosity reducer of the invention has the characteristics of good universality, low use concentration and high viscosity reduction rate, and can reduce more than 98% of the viscosity of heavy oil within 1000-10000 mPa.s under the condition that the use concentration is 200 ppm. Therefore, the temperature-resistant and salt-resistant amphiphilic polymer heavy oil viscosity reducer and the preparation method thereof can be widely applied to heavy oil recovery.

Owner:北京安德兴石油技术有限公司

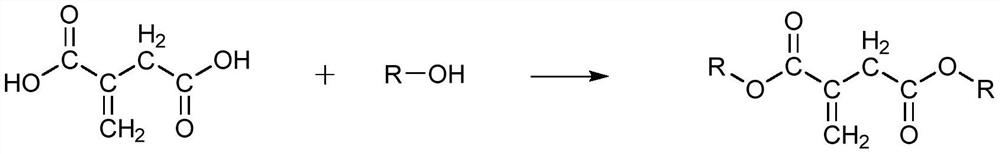

Polymeric surfactant heavy oil viscosity reducer and preparation method

The invention discloses a polymeric surfactant heavy oil viscosity reducer and a preparation method, and mainly solves the problem of poor viscosity reduction effect of existing heavy oil viscosity reducers. The preparation method includes: firstly reacting maleic anhydride with nonylphenol polyoxyethylene ether to obtain an intermediate product, and then reacting the intermediate product with a certain amount of acrylamide to prepare the polymeric surfactant. The surfactant has the advantages of reliable preparation process, low cost and low use concentration, and has the ability of significantly reducing the heavy oil viscosity.

Owner:SOUTHWEST PETROLEUM UNIV

Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN107955592AImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityRaw material

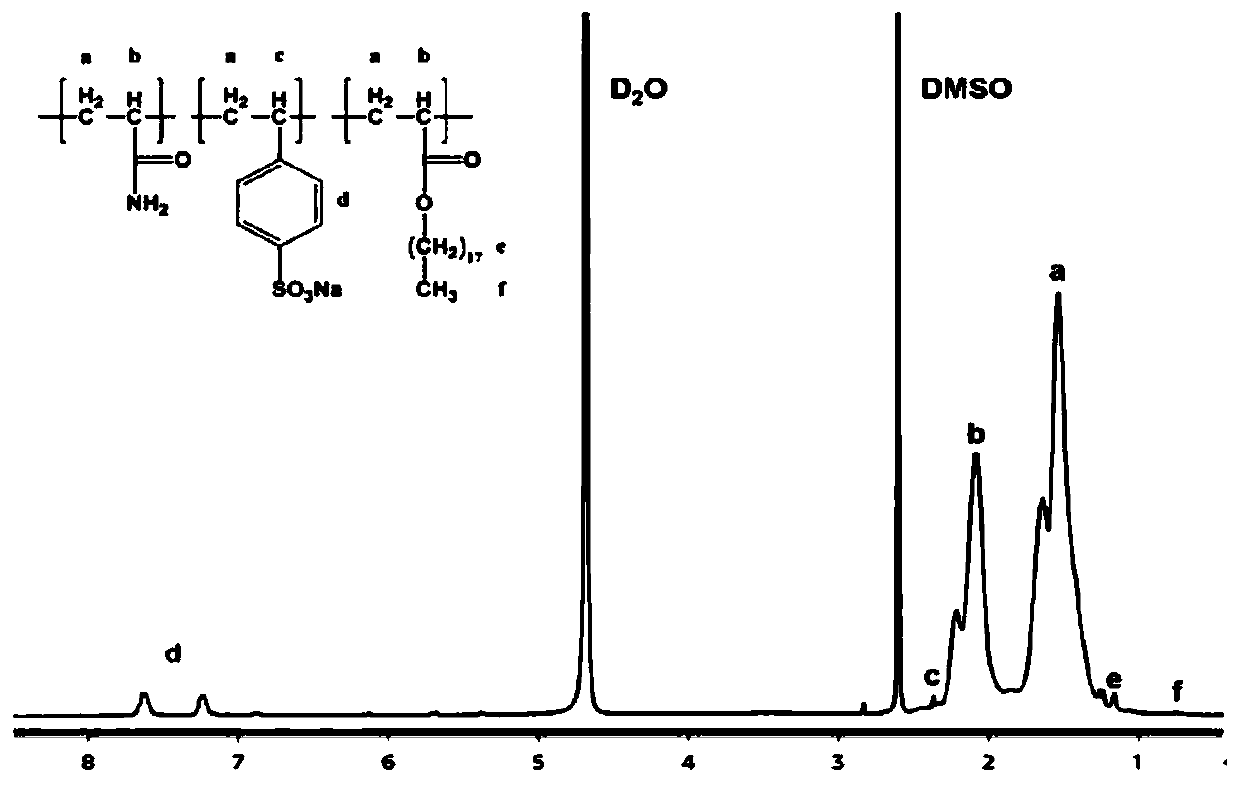

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Heavy oil viscosity reducer and preparation method thereof

ActiveCN105647502AGood sensitivity to viscosity reductionHigh viscosity reduction rateDrilling compositionOil viscosityPolymer

The present invention belongs to the technical field of organic chemical industry, and relates to a heavy oil viscosity reducer and a preparation method thereof, the viscosity reducer is prepared by ternary polymerizationof fluorocarbon alcohol ether (methyl) acrylate, maleic anhydride and styrene, the preparation method comprises the following stesp: synthesis of fluorocarbon alcohol ether; synthesis of fluorocarbon alcohol ether acrylate, synthesis of a ternary polymer, and preparation of the viscosity reducer. The advantages are as follows: the viscosity reducer can significantly reduce the viscosity of a variety of heavy oil especially cycloalkyl heavy oil, can prevent wax from forming a network structure, also can make asphaltene and colloid highly dispersed. The viscosity reducer can make the colloid stabile in property, the heavy oil may not be layered by placing for long time, and the viscosity reducer is remarkable in viscosity reduction effect, low in cost, and facilitates oil transport and application.

Owner:PETROCHINA CO LTD

Preparation method and application of catalyst for visbreaking behavior of heavy oil by aquathermolysis

InactiveCN109675561AReduce gelatinLow asphaltene contentCatalytic crackingDrilling compositionReaction temperatureSolvent

The invention belongs to the field of catalyst synthesis, and particularly relates to a preparation method and an application of a catalyst for visbreaking behavior of heavy oil by aquathermolysis. The method comprises specific steps as follows: ferric chloride is weighed and added to a three-neck beaker, ethanol, water, n-hexane and oleic acid are added to the three-neck beaker in sequence, magnetic stirring is performed, NaOH is added, heating and reflux condensation are performed, after a ferric oleate compound and an oleic acid mixture are synthesized and added to sodium alkylbenzene sulfonate, a mixture is dissolved in octyl ether, 1-octadecene or 1-eicosylene, a mixed solution is subjected to temperature programming and then cooled to the room temperature, ethanol is added to the solution, centrifugal separation is performed, and the target product, namely, the catalyst for visbreaking behavior of the heavy oil by aquathermolysis is obtained. The target product is cheap and easily available and has low energy consumption and excellent visbreaking effect, and physical properties and nanoscale can be set by selecting correct reaction temperature, reaction solvent or reaction time.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Anti-waxing agent special for heavy crude well thermal recovery

The invention relates to a special wax-proof agent for the thermal recovery of a heavy oil well which belongs to the technical field of oil field chemical product. The technical scheme thereof consists of the materials with the following weight portions: 20 to 30 portions of sherwood oil, 35 to 45 portions of dimethylbenzene, 5 to 10 portions of bottom oil, 3 to 5 portions of alkyl phenol polyoxyethylene ether, 2 to 5 portions of alkanolamides of fatty acid, 10 to 15 portions of fatty acid, 5 to 10 portions of alkaline liquid with a concentration of 25 to 35 as well as 100 to 150 portions of water. The special wax-proof agent has the advantages of high wax-dissolving speed, high viscidity reducing rate, good wax-proof effect, and the like. The efficiency and productivity for the thermal recovery of the heavy oil well can be greatly improved through adding wax-proof agent into the oil well periodically and being matched with a hot water thermal recovery technology; the construction is convenient.

Owner:赵芳

Styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer as well as preparation method and application thereof

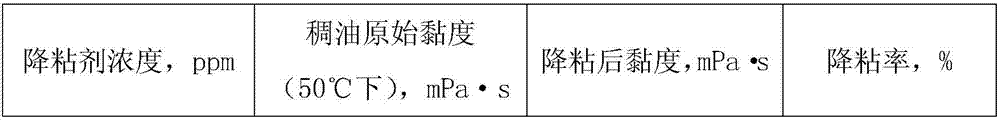

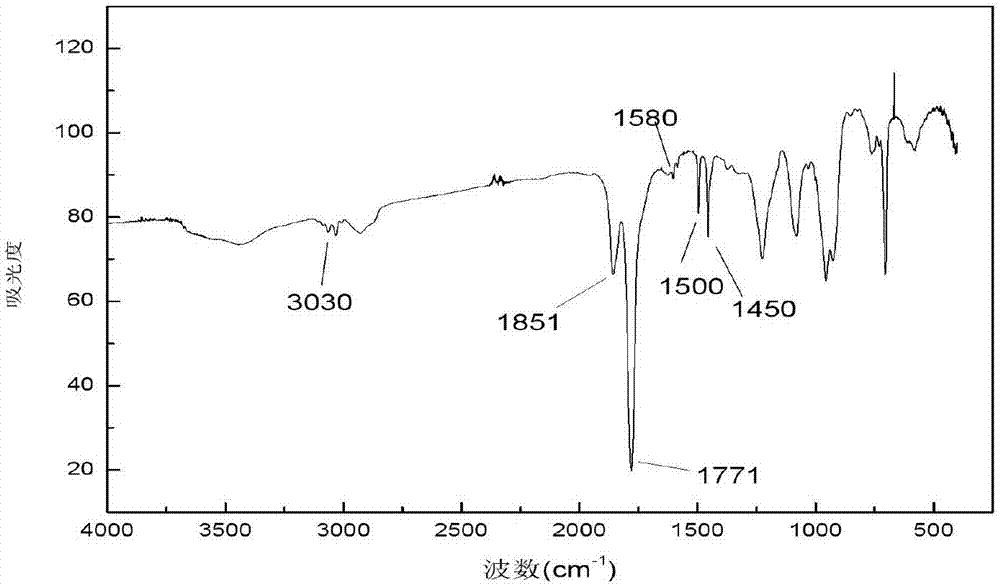

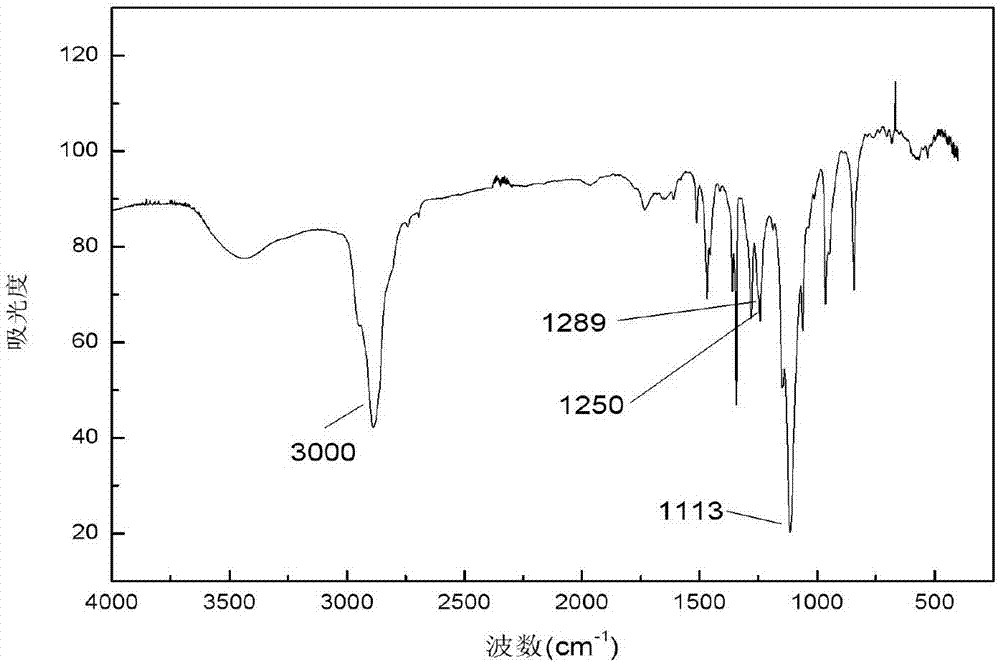

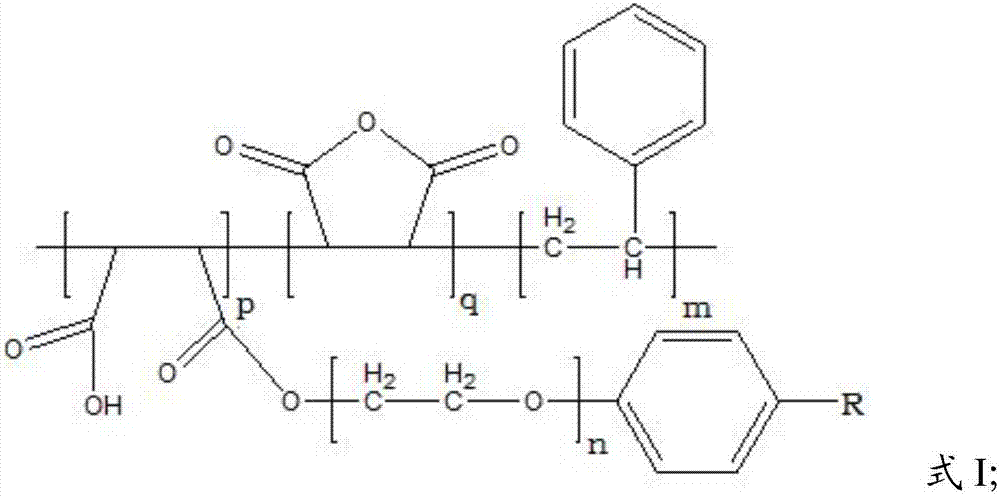

ActiveCN107325293ALow viscosityNo impact on qualityPipeline systemsDrilling compositionReduction rateAlkylphenol

The invention provides styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer which has a structure shown as a formula I. The copolymer disclosed by the invention has better compatibility with high-colloid asphalt, can be used as a high-colloid asphaltene heavy oil viscosity reducer, has effects of dispersing asphaltene and enhancing colloid stable asphaltene, can effectively reduce heavy oil viscosity and has higher viscosity reduction rate. In an application process, the copolymer can be directly added into heavy oil, has convenience in application and low cost and further has no effect on oil quality. Embodiment results show that the styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer disclosed by the invention can be utilized as the viscosity reducer to be applied into the heavy oil; when an adding amount is 0.4% of the mass of the heavy oil, the viscosity reduction rate at 50 DEG C can reach 76% or more.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Siloxane quaternary ammonium salt modified amphiphilic polymer ultra-heavy oil viscosity reducer and preparation method and application thereof

ActiveCN107880213AThe synthesis process is simpleEasy to controlDrilling compositionEnvironmental resistanceSalt resistance

The invention provides a siloxane quaternary ammonium salt modified amphiphilic polymer ultra-heavy oil viscosity reducer and a preparation method and an application thereof. Firstly, two kinds of double bond-containing siloxane-based quaternary ammonium salt monomers with different structural features are synthesized, and the viscosity reducer is obtained through radical solution polymerization of the double bond-containing siloxane-based quaternary ammonium salt monomers with cationic monomers and acrylamide respectively. The viscosity reducer is used for ultra-heavy oil and has good viscosity reducing effects, temperature resistance and salt resistance, excellent viscosity reducing effects and the like for high-mineralization ultra-heavy oil. The ultra-heavy oil is easy to be demulsified and dehydrated after being subjected to emulsification and viscosity reduction treatment. The synthetic process of the method is simple and easy to control, the obtained viscosity reducer can be used alone and does not need to be compounded and used together with other additives, and the viscosity reducer is excellent in comprehensive performance, green and environmentally friendly.

Owner:SHANDONG UNIV

Method for preparing drilling diluter of TARA sulfonated tannin

InactiveCN101092555AHigh viscosity reduction ratePromote incomeSugar derivativesOrganic compound preparationHigh densityWell drilling

This invention provides a method for preparing well drilling thinner tara sulfonated tannin. The method comprises: mixing tara powder and water, leaching at 20-80 deg.C for 2-5 times (2-8 h each time), filtering, incorporating the filtrates, separating, concentrating, adding an alkali solution to adjust the pH value to 8-12, adding a sulfonating agent, sulfonating at 60-120 deg.C for 1-4 h, adding a complexant, complexing at 60-120 deg.C for 0.5-3 h to obtain a complex, concentrating, spray-drying, and packaging to obtain tara sulfonated tannin thinner. The tara sulfonated tannin thinner has such advantages as renewable raw material, stable output and low cost. The method has such advantages little discharge of wastewater, exhaust gas and waste residue, easy treatment, and little pollution. The tara sulfonated tannin thinner is an environmentally friendly chrome-free thinner, and is suitable for high-temperature (180-220 deg.C) and high-density oil wells with a viscosity reduction ratio higher than 90%.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY +1

Active catalytic viscosity reducer for viscous oil recovery, and preparation method and application thereof

ActiveCN104830305AHigh viscosity reduction rateGood viscosity reduction effectOrganic compound preparationEther preparation from oxiranesCu2 ionsZinc ion

The invention relates to the technical filed of viscosity reducers, and relates to an active catalytic viscosity reducer for viscous oil recovery, and a preparation method and an application thereof. The structural general formula of the active catalytic viscosity reducer for viscous oil recovery is [R-O-(EO)mCH2CO2]2M, wherein R is a C12-18 linear or branched alkyl group, EO is an oxyethylene group, m is the number of the oxyethylene group, and m is an integer between 2 and 6; and M is a nickel ion or a manganese ion or a copper ion or a zinc ion. The viscosity reduction rate of the active catalytic viscosity reducer for viscous oil recovery obtained in the invention is greatly higher than that of viscosity reducers in the prior art, so the viscosity reduction effect of the active catalytic viscosity reducer for viscous oil recovery is good; and the active catalytic viscosity reducer for viscous oil recovery is suitable for viscosity reduction of stratum of well steam injection wells, and is also suitable for high temperature steam catalytic oil displacement.

Owner:YANGTZE UNIVERSITY +1

Heavy oil emulsifying viscosity reducer and preparation method thereof

ActiveCN109207133AHigh viscosity reduction rateHigh natural dehydration rateDrilling compositionReduction rateReducer

The invention discloses a heavy oil emulsifying viscosity reducer and a preparation method thereof. The heavy oil emulsifying viscosity reducer comprises a nonionic surfactant, an anionic surfactant,a small molecule penetrant and water. The emulsifying viscosity reducing agent is mixed and stirred with heavy oil to form an oil-in-water emulsion of the heavy oil, thereby achieving the purpose of emulsification and viscosity reduction of the heavy oil. The emulsifying viscosity reducer has the characteristics of high viscosity reduction rate, long emulsion stability time, high natural dehydration rate and superior salt tolerance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

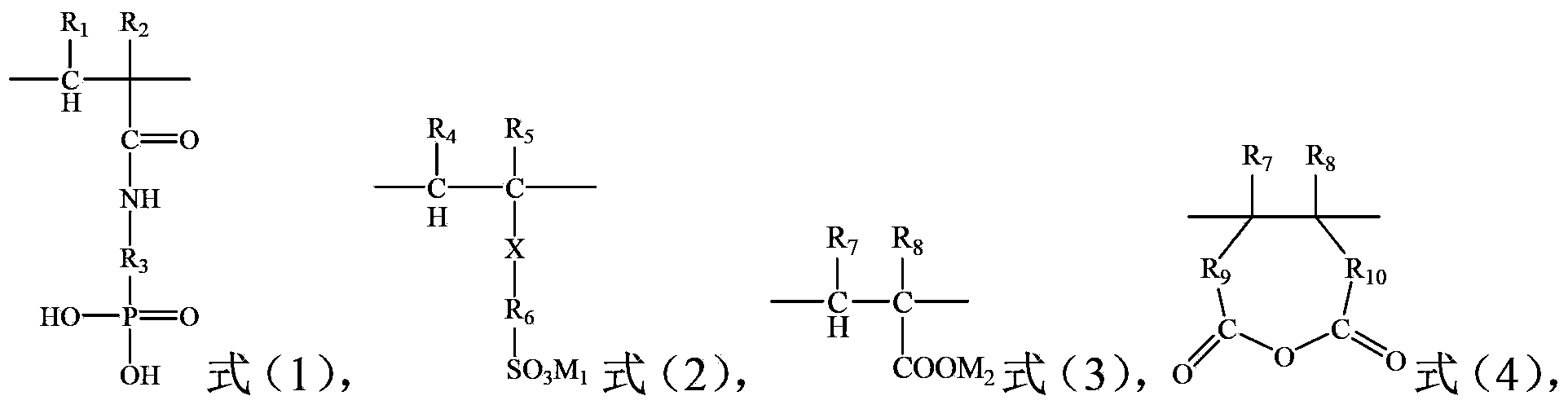

Phosphonic acid base containing polymer and application thereof as well as phosphonic acid base containing polymer drilling fluid viscosity reducer

ActiveCN103665263AGood viscosity reductionGood temperature and salt resistanceDrilling compositionHigh densityPolymer science

The invention provides a phosphonic acid base containing polymer and an application thereof as well as a phosphonic acid base containing polymer drilling fluid viscosity reducer. The phosphonic acid base containing polymer contains a structural unit shown as a formula (1), a structural unit shown as a formula (2), a structural unit shown as a formula (3) and / or a structural unit shown as a formula (4). The ratio of the mole number of the structural unit shown as the formula (1), the mole number of the structural unit shown as the formula (2) and the total mole number of the structural unit shown as formulae (3) and (4) is (10-85):(10-75):(5-55). The phosphonic acid base containing polymer aged at high temperatures in saline drilling fluids and high density drilling fluids still has a more excellent viscosity reducing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN109504360AGood solubilityGood high temperature resistanceFluid removalDrilling compositionChemistrySolubility

The invention provides a heavy oil viscosity reducer as well as a preparation method and an application thereof, and belongs to the technical field of heavy oil recovery. The heavy oil viscosity reducer is prepared from components in percentage by weight as follows: 2.5%-6.5% of dodecyl dimethyl benzyl ammonium chloride, 2.4%-3.4% of isopropanol, 0.31%-6.7% of nonylphenoxypoly(ethyleneoxy)ethanol,2%-5.81% of 2-butoxyethanol, 1%-3% of EDTA-2Na, 4%-7% of 2-(2-[4-(1,1,3,3-tetramethylbutyl)phenoxy]ethoxy)ethanol and the balance of water. The heavy oil viscosity reducer has good solubility in water, a formed viscosity reducing solution is transparent, good in resistance to high temperature and high in viscosity reduction rate at low and high temperature, and the application range is wide.

Owner:KARAMAY SANDA NEW TECH

Lignosulfonate for drilling fluid and lignosulfonate preparation method

InactiveCN104892955AGood mud performanceImprove mud performanceDrilling compositionLignosulfonatesSodium lignosulfonate

The invention provides lignosulfonate for drilling fluid and a lignosulfonate preparation method. The lignosulfonate is obtained by mixed reaction of a complexing agent and sodium lignin sulfonate prepared from liquid glucose. By selection of special sodium salt of lignosulfonate and taking of the sodium lignin sulfonate prepared from liquid glucose as a starting material, the prepared lignosulfonate for drilling fluid has an excellent mud property no matter at the normal temperature or the high temperature, and generation of harmful waste residues in a preparation process is avoided.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

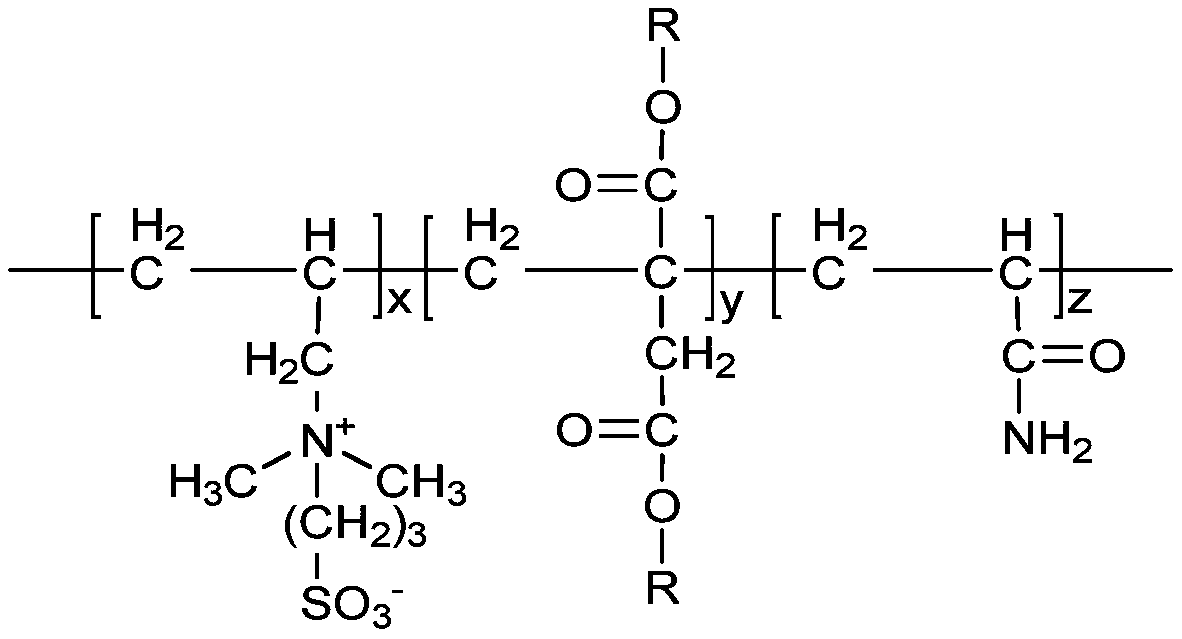

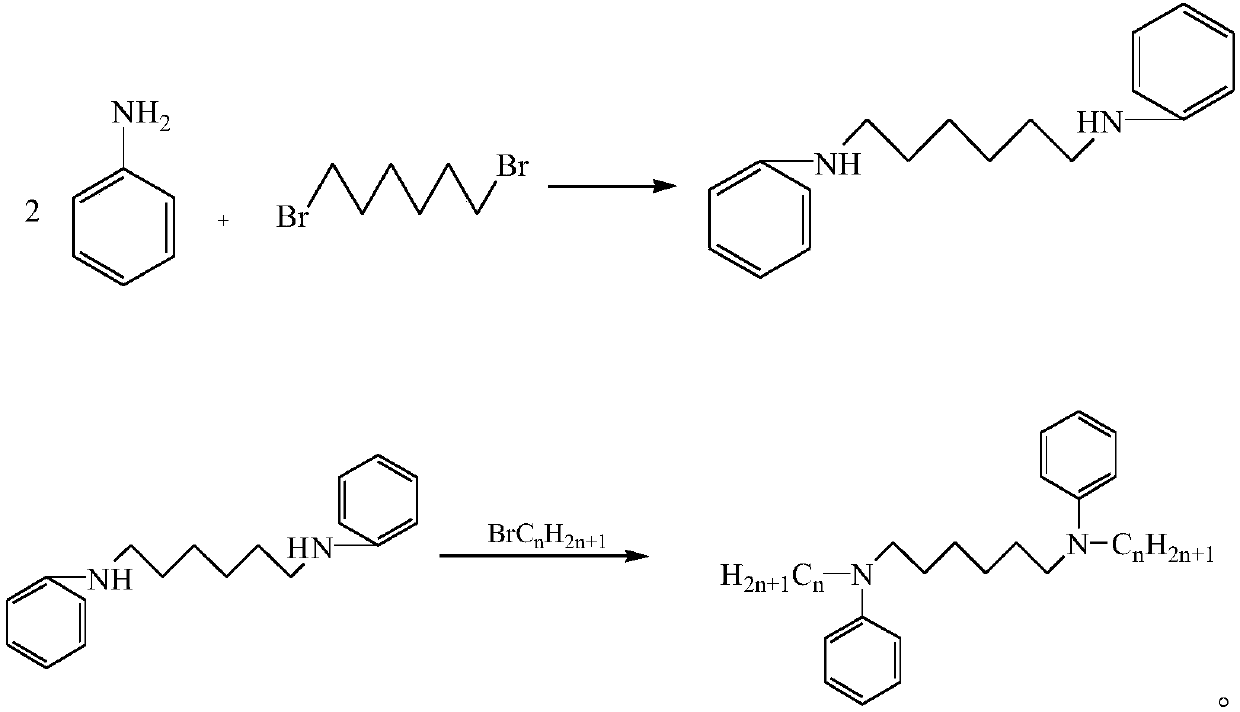

Polymer heavy oil emulsifying viscosity reducer and preparation method and application thereof

The invention provides a polymer heavy oil emulsifying viscosity reducer and a preparation method and application thereof. The polymer heavy oil emulsifying viscosity reducer comprises the following components: acrylamide, a sulfobetaine monomer and an itaconic acid double-long-chain ester monomer, wherein the molar ratio of the acrylamide to the sulfobetaine monomer to the itaconic acid double-long-chain ester monomer is (65-70): (30-45): (1-5). The polymer heavy oil emulsifying viscosity reducer disclosed by the invention contains a quaternary ammonium type cation structure, so that the foaming capacity is relatively strong, heavy oil can be effectively emulsified, the preparation method is simple and easy to control in process and few in byproducts, and the problems of poor viscosity reduction effect, relatively poor temperature resistance and salt resistance, poor emulsifying effect and the like are effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV

A self-demulsifying heavy oil viscosity reducer and its preparation method and application

ActiveCN107955592BImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityReducing agent

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Chemical reservoir oil displacement method suitable for super-high water-sensitive heavy oil reservoir

The invention belongs to the field of petrochemistry and relates to a chemical reservoir oil displacement method for heavy oil, in particular to a chemical reservoir oil displacement method suitable for a super-high water-sensitive heavy oil reservoir. The chemical reservoir oil displacement method comprises the following steps that a clay stabilizer and a heavy oil viscosity reduction oil displacement agent are selected; the selected clay stabilizer is injected, and the injection period is 20-40 days; water is injected, and the injection period is 10-20 days; and the selected heavy oil viscosity reduction oil displacement agent is injected, the injection period is 180 days or above, or the clay stabilizer is injected in a switching mode according to the sand production condition of an oilwell. Through the chemical reservoir oil displacement method, the problem of difficult oil extraction of the super-high water-sensitive heavy oil reservoir is solved, and the effect that the oil extraction quantity of the super-high water-sensitive heavy oil reservoir can be increased through the chemical reservoir oil displacement method is proved by practical application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient composite viscosity reduction agent for viscous oil recovery

InactiveCN108865096AIncreased mining recoveryImprove displacementDrilling compositionAlkylphenolOil production

The invention relates to the technical field of oil production, and particularly relates to an efficient composite viscosity reduction agent suitable for viscous oil reservoir recovery. The compositeviscosity reduction agent is prepared from the following raw materials in percentage by mass: 10 to 15% of sodium lauryl sulfate, 5 to 10% of sodium dodecylbenzene sulfonate, 13 to 15% of alkylphenolethoxylate, 15 to 30% of polyacrylate and the balance of water. The alkylphenol ethoxylate is a condensation compound of alkylphenol and ethylene oxide. The polyacrylate is a segmented copolymer of ethyl acrylate and butyl acrylate, which has a molecular weight of 50 to 300 thousand. The efficient composite viscosity reduction agent disclosed by the invention is high in viscosity reduction rate; the viscous oil viscosity reduction rate can reach 98% in a range of 30 to 70 DEG C; the efficient composite viscosity reduction agent can be widely applied to viscous oil recovery.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

Temperature-resistant salt-resistant heavy oil emulsifying viscosity reducer and preparation method thereof

ActiveCN110835524AWide variety of sourcesThe synthesis process is simpleOrganic compound preparationDrilling compositionSalt resistanceViscosity

The invention discloses a temperature-resistant salt-resistant heavy oil emulsifying viscosity reducer and a preparation method thereof, wherein the molecular formula of the emulsifying viscosity reducer is defined in the specification, and n is a natural number and is more than or equal to 10 and less than or equal to 16. According to the invention, the emulsifying viscosity reducer has characteristics of simple synthesis process, small dosage, low cost and remarkable economic benefit, further has advantages of remarkable temperature resistance, strong salt resistance, strong emulsifying anddispersing capacity and high viscosity reduction rate, and can resist a temperature of more than 120 DEG C, resist calcium and magnesium ion concentration of 10000 mg / L and resist the total ion concentration of 200000 mg / L; the viscosity of heavy oil at 50 DEG C can be reduced by more than 95.0% at a dosage of 100 ppm; and the temperature-resistant salt-resistant heavy oil emulsifying viscosity reducer can be widely applied to on-site high-temperature and high-salt heavy oil recovery and transportation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and application method of surfactant

InactiveCN104399404AIncrease productionLarge applicable spaceTransportation and packagingMixingActive agentAcrylonitrile

The invention belongs to the field of treating heavy oil, and relates to a preparation and application method of a surfactant. The surfactant is characterized by comprising the following components: 10-20% of phosphatide, 5-20% of tween-80, 5-20% of diethanolamine, 5-20% of AES (acrylonitrile), and the balance of water. The preparation method comprises the following steps: pouring the water into a reaction kettle, adding the quantitative diethanolamine and phosphatide to the reaction kettle at the same time, raising the temperature to 80 DEG C, and stirring the mixture for 2 hours at a constant temperature until the diethanolamine and the phosphatide are fully dissolved; adding the quantitative AES, raising the temperature to the range of 75 DEG C to 85 DEG C, and stirring for an hour at the constant temperature; then adding the tween-80, stirring for an hour at the constant temperature of 80 DEG C, reducing the temperature to 40 DEG C, and loading finished products into packing buckets according to measurement so as to obtain the finished products of the surfactant. The surfactant can be used as a thick oil viscosity-reducing agent, an asphalt emulsifying agent or an oil mixing agent for use. The surfactant has good emulsifiability and is wide in application field, heavy oil can be easily emulsified into the water through the surfactant, the viscosity reducing rate is as high as 99.99%, and the oil-water interfacial tension can be greatly reduced.

Owner:刘国清 +1

Emulsifying viscosity-reducing oil-displacing agent, preparation method and thick oil viscosity-reducing oil-displacing fracturing method

PendingCN111944508AStrong emulsificationHigh viscosity reduction rateFluid removalDrilling compositionPhosphoric Acid EstersAlkylphenol

The invention relates to the technical field of oil-displacing agents and preparation and use methods thereof, in particular to an emulsifying viscosity-reducing oil-displacing agent, a preparation method thereof and a thick oil viscosity-reducing oil-displacing fracturing method. The emulsifying viscosity-reducing oil-displacing agent comprises the following components: heavy alkylphenol polyoxyethylene phosphate, polyalkyl polyoxyethylene benzene sulfonate, ethoxylated sodium alkyl sulfate, octyl phenol polyoxyethylene ether, fatty alcohol dimethyl betaine, fatty alcohol polyoxyethylene ether and the like. The emulsifying viscosity-reducing oil-displacing agent has the characteristics of low shear external force (static) emulsifying capacity, long emulsion stabilization time, high viscosity reduction rate and the like; meanwhile, when the emulsifying viscosity-reducing oil-displacing agent is applied to volume fracturing or temporary plugging diversion fracturing, the development anduse degree of thickened oil can be greatly improved, and effective use of the thickened oil is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oxidative thinner for heavy oil exploitation via steam injection and preparation thereof

ActiveCN101440275BHigh viscosity reduction rateLow viscosityDrilling compositionHydrolysateAcid substances

The invention relates to an oxidization viscosity reducer for viscous oil recovery by steam injection and a preparation method thereof. The oxidization viscosity reducer comprises components by weight percentage: 0.5 to 10 percent of component A, 0.5 to 10 percent of component B, 0.1 to 8 percent of component C, 0.1 to 5 percent of component D, and the balance being water, wherein the component A is peroxide, the component B is transition metal salt of an organic acid, the component C is inorganic salt with the acidity shown in a hydrolysate, and the component D is an alkaline substance. The oxidization viscosity reducer can oxidize gelatine and asphaltine in viscous oil, reduce the viscosity of crude oil by changing a structure of the viscous oil through chain termination, oxidize to generate an acid substance at the same time, ensure that the viscous oil becomes a substance with the effect of a surfactant by adding the alkaline substance, and also play a role in viscosity reduction. The experiments show that the viscosity reduction rate can reach 99.9 percent when the viscosity reducer reacts with the crude oil for 24 hours at the temperature of 100 DEG C. The viscosity reducer has higher viscosity reduction rate, is applicable to the viscosity reduction of oil well stratums with high steam injection temperature, and also has good effect under relatively lower temperature conditions.

Owner:中国石化集团河南石油勘探局有限公司

Viscosity reducer for heavy oil and its application and method for viscosity reduction of heavy oil

ActiveCN106318357BHigh viscosity reduction rateLess targetedDrilling compositionReduction ratePolymer science

The invention relates to a thick-oil viscosity reducer. The thick-oil viscosity reducer contains an alkene amide polymer, an alkylaryl sulfonic acid and lower alcohol, wherein the weight ratio of the alkene amide polymer to the alkylaryl sulfonic acid to the lower alcohol is 1 to (0.5 to 3) to (1 to 5), and the carbon atom number of the lower alcohol is 1 to 4; and the thick-oil viscosity reducer is applied to the viscosity reduction of thick oil with high metal content, the viscosity of the thick oil with high metal content at the temperature of 30 DEG C is not lower than 10,000mPa.s, the content of asphaltenes is not lower than 10%, and the content of metals, i.e., Ni and V is not lower than 260mg / kg. The invention further relates to an application of the thick-oil viscosity reducer in the viscosity reduction of the thick oil with high metal content. The invention further relates to a thick-oil viscosity reduction method. The thick-oil viscosity reducer and the thick-oil viscosity reduction method, disclosed by the invention, have relatively high viscosity reduction rate to the thick oil with high metal content, and particularly, the viscosity reduction rate can reach up to 75% to 95%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-soluble nano material and preparation method and application thereof

ActiveCN113416286AImprove temperature resistanceGood viscosity reductionDrilling compositionHydrophilic monomerPolymer science

The invention discloses a water-soluble nano material. The water-soluble nano material is obtained by grafting a viscosity-reducing monomer, a hydrophilic monomer and an active monomer on a double-bond modified nano material. The preparation method of the water-soluble nano material comprises the following steps: deoxidizing a solution containing a double-bond modified nano material, a viscosity-reducing monomer, a hydrophilic monomer and an active monomer, adding an oxidizing agent, and uniformly mixing; and dropwise adding a reducing agent, and reacting to obtain the water-soluble nano material. The invention also provides application of the water-soluble nano material as a viscosity-reducing and oil-displacing agent for thickened oil. The water-soluble nano material not only retains good temperature resistance of the nano material, but also has a good viscosity reduction effect and an excellent capability of reducing interfacial tension. The temperature resistance is improved through the rigidity of the nano material, and a large number of active groups are grafted by virtue of the small-size effect of the nano material so that the interfacial activity and emulsifying capacity are improved, and the purpose of reducing the viscosity of the thickened oil is achieved.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST CO LTD

Preparation method for oil-soluble thickened oil hydrothermal catalytic cracking viscosity breaking agent

InactiveCN102093869AImprove qualityReduce the interaction forceDrilling compositionGallic acid esterNickel salt

The invention relates to a preparation method for oil-soluble thickened oil hydrothermal catalytic cracking viscosity breaking agent, which is characterized by comprising the following steps of: 1) choosing raw materials at the following ratio: 3-5g of gallic acid, 5-10ml of halogenated hydrocarbon, 10-100ml of organic solvent, 8-15g of anhydrous carbonate, 80-100ml of aqueous alkali with the concentration of 2-5mol / L, 100ml of absolute methanol and 3-7g of nickel salt for later use; 2) preparing oil-soluble catalyst viscosity breaking agent: respectively adding the gallic acid, the halogenated hydrocarbon and the anhydrous carbonate into a round bottom flask; then adding the organic solvent; introducing nitrogen into the round bottom flask; carrying out thermal stirring and backflow for 12-24h at the temperature of 50-70 DEG C; filtering the obtained product; carrying out reduced pressure distillation to obtain transparent oily liquid; dissolving the product into the absolute methanol; adding aqueous alkali; carrying out backflow for 3h at the temperature of 30-50 DEG C; hydrolyzing the product; carrying out reduced pressure distillation to obtain methyl alcohol; slowly dipping diluted hydrochloric acid into the solution until the pH value of the solution is 7-8; then, slowly dipping nickel salt solution; stirring for full reaction and filtering and drying to obtain nattier blue powder, i.e. the oil-soluble catalyst viscosity breaking agent. The viscosity breaking agent has the characteristics of good viscosity breaking effect, strong popularity and simple preparation process.

Owner:SHANGHAI UNIV

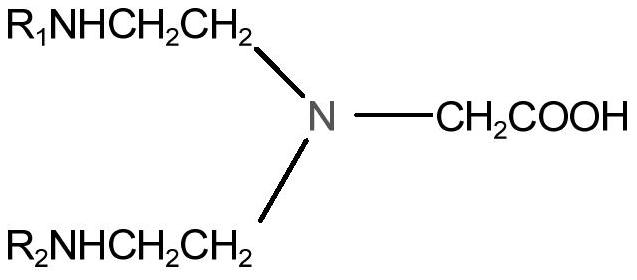

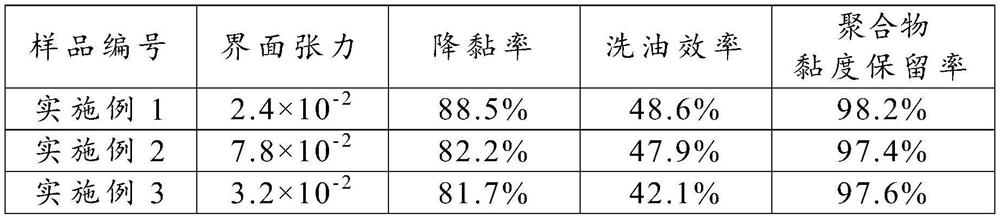

Thickened oil viscosity reduction oil washing agent for synergistic polymer flooding as well as preparation method and application of thickened oil viscosity reduction oil washing agent

ActiveCN114774098AImprove oil washing efficiencyHigh viscosity reduction rateFluid removalDrilling compositionActive agentOil viscosity

The invention provides a thickened oil viscosity-reducing oil washing agent for synergistic polymer flooding as well as a preparation method and application thereof, and belongs to the technical field of oil exploitation. The thickened oil viscosity-reducing oil washing agent for synergistic polymer flooding provided by the invention comprises the following components in percentage by mass: 25%-35% of an anionic surfactant, 10%-20% of a zwitterionic surfactant, 10%-20% of a nonionic surfactant, 10%-20% of low-carbon alcohol and the balance of water. When the viscosity-reducing oil washing agent provided by the invention is applied to the recovery of heavy oil with the formation temperature of 70 DEG C and the crude oil viscosity of 1314 mPa.s, the interfacial tension is less than or equal to 8.9 * 10 <-2 >, the viscosity reduction rate is greater than or equal to 81.7%, the oil washing efficiency is greater than or equal to 42.1%, the polymer viscosity retention rate is greater than or equal to 97.4%, the effect is remarkable, and the preparation process is simple, low in cost and green and environment-friendly.

Owner:SHANDONG XINGANG CHEM

Preparation method of oil-soluble aquathermolysis catalytic viscosity reducer for thickened oil

InactiveCN104194760AImprove qualityReduce the interaction forceDrilling compositionNickel saltGallic acid ester

The invention relates to a preparation method of an oil-soluble aquathermolysis catalytic viscosity reducer for thickened oil. The preparation method is characterized by comprising the following steps: 1) selecting the following raw materials in proper proportions: 3-5g of gallic acid, 5-10mL of halogenated hydrocarbon, 10-100mL of an organic solvent, 8-15g of anhydrous carbonate, 80-100mL of 2-5mol / L aqueous alkali, 100mL of absolute methanol and 3-7g of nickel salt; 2) adding gallic acid, halogenated hydrocarbon and anhydrous carbonate to a round-bottom flask respectively, next, adding the organic solvent, introducing nitrogen and performing heating and stirring reflux at a temperature of 50-70 DEG C for 12-24 hours, filtering the obtained product, and performing reduced-pressure rotary evaporation to obtain a transparent oily liquid, next, dissolving the product in the absolute methanol, adding the aqueous alkali, and hydrolyzing the product by virtue of reflux at a temperature in the range of 30-50 DEG C for 3 hours, performing reduced-pressure rotary evaporation to separate out the methanol, slowly and dropwise adding diluted hydrochloric acid to the solution until the pH value is in the range of 7-8, next, slowly and dropwise adding a nickel salt solution, stirring for reacting thoroughly, and then filtering and drying to obtain bluish powder, namely the oil-soluble aquathermolysis catalytic viscosity reducer.

Owner:NABAI KECHUANG BEIJING TECH DEV

A kind of polymer heavy oil emulsification viscosity reducer and its preparation method and application

The invention provides a high molecular weight oil emulsification viscosity reducer and its preparation method and application. The high molecular weight oil emulsification viscosity reduction agent comprises the following components: acrylamide, sulfobetaine monomer and itaconic acid double long chain Ester monomer; the molar ratio of acrylamide, sulfobetaine monomer and itaconic acid double long-chain ester monomer is 65-70:30-45:1-5. The polymer heavy oil emulsifying viscosity reducer of the present invention contains a quaternary ammonium cationic structure, so that the foaming ability is strong, and the heavy oil can be effectively emulsified, and the preparation method is simple and easy to control, with few by-products, effectively solving the problem of viscosity reduction. Poor effect, poor temperature and salt resistance, and weak emulsifying effect.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com