Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

A thick oil viscosity reducer and demulsification technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problem of hydrolysis of amide groups and changes in molecular form, molecular weight reduction, unfavorable viscosity Oil viscosity reduction and other issues, to achieve the effect of simple synthesis method, large molecular weight, and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

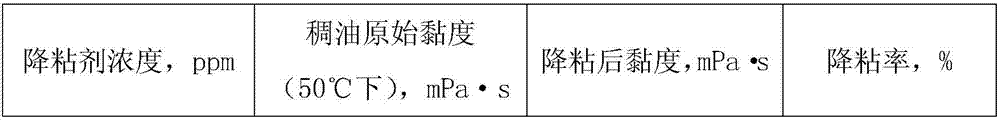

Image

Examples

Embodiment 1

[0062] A self-demulsifying heavy oil viscosity reducer, which is obtained by copolymerizing the following monomers:

[0063] Acrylamide 97.8 mol%

[0064] Sodium p-styrene sulfonate 2 mol%

[0065] Octadecyl acrylate 0.2 mol%.

[0066] The preparation method of the above-mentioned self-demulsifying heavy oil viscosity reducer comprises steps:

[0067] (1) Weigh 13.90g of acrylamide, 0.82g of sodium p-styrenesulfonate and 0.13g of stearyl acrylate into a container, add 66.20mL of dimethyl sulfoxide, stir at 50°C for 5min, and wait until the raw materials are completely Dissolve; after the raw material is completely dissolved, inject nitrogen gas, stir at 50°C for 30 minutes, and make it completely in the nitrogen atmosphere to obtain the raw material solution;

[0068] (2) Under nitrogen atmosphere, heat up to 70°C, then add 0.0743g of initiator azobisisobutyronitrile, and react for 7h at 70°C under nitrogen protection; after the reaction, the product is precipitated and was...

Embodiment 2

[0085] A self-demulsifying heavy oil viscosity reducer, which is obtained by copolymerizing the following monomers:

[0086] Acrylamide 97.6 mol%

[0087] Sodium p-styrene sulfonate 2 mol%

[0088] Octadecyl Acrylate 0.4 mol%.

[0089] The preparation method of the above-mentioned self-demulsifying heavy oil viscosity reducer comprises steps:

[0090] (1) Weigh 13.87g of acrylamide, 0.82g of sodium p-styrene sulfonate and 0.26g of stearyl acrylate into a container, add 66.20mL of dimethyl sulfoxide, stir at 50°C for 5min, and wait until the raw materials are completely Dissolve; after the raw material is completely dissolved, inject nitrogen gas, stir at 50°C for 30 minutes, and make it completely in the nitrogen atmosphere to obtain the raw material solution;

[0091] (2) Under nitrogen atmosphere, heat up to 70°C, then add 0.0747g of initiator azobisisobutyronitrile, and react for 7h at 70°C under nitrogen protection; after the reaction, precipitate and wash the product w...

Embodiment 3

[0107] A self-demulsifying heavy oil viscosity reducer, which is obtained by copolymerizing the following monomers:

[0108] Acrylamide 97.5 mol%

[0109] Sodium p-styrene sulfonate 2 mol%

[0110] Octadecyl acrylate 0.5 mol%.

[0111] The preparation method of the above-mentioned self-demulsifying heavy oil viscosity reducer comprises steps:

[0112] (1) Weigh 13.85g of acrylamide, 0.82g of sodium p-styrenesulfonate and 0.325g of stearyl acrylate into a container, add 66.20mL of dimethyl sulfoxide, stir at 50°C for 5min, and wait until the raw materials are completely Dissolve; after the raw material is completely dissolved, inject nitrogen gas, stir at 50°C for 30 minutes, and make it completely in the nitrogen atmosphere to obtain the raw material solution;

[0113] (2) Under a nitrogen atmosphere, heat up to 70°C, then add 0.0750 g of initiator azobisisobutyronitrile, and react for 7 hours at 70°C under nitrogen protection; after the reaction, the product is precipitated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com