Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198results about How to "Good viscosity reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110AGood viscosity reductionReduce dosageDrilling compositionSalt resistanceTemperature resistance

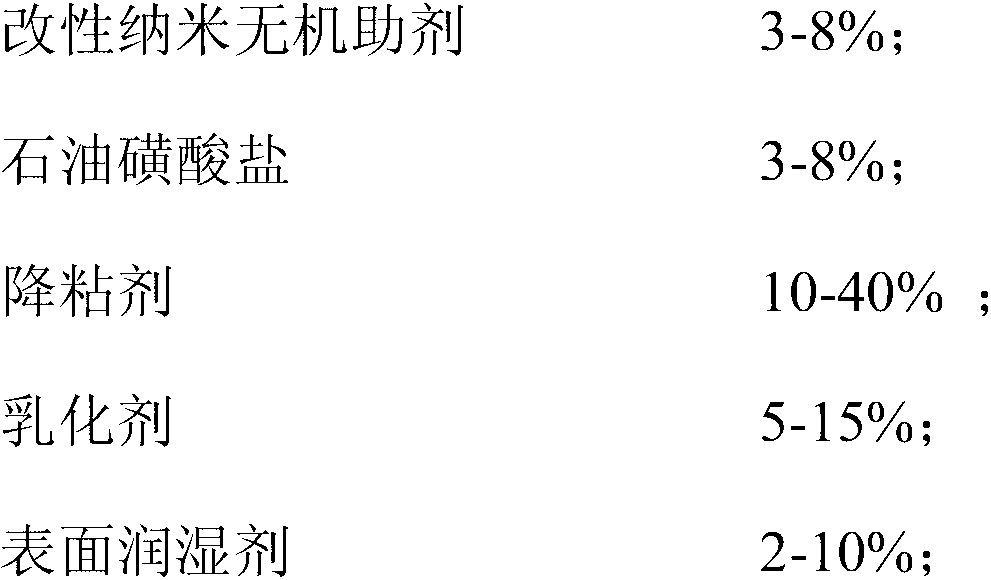

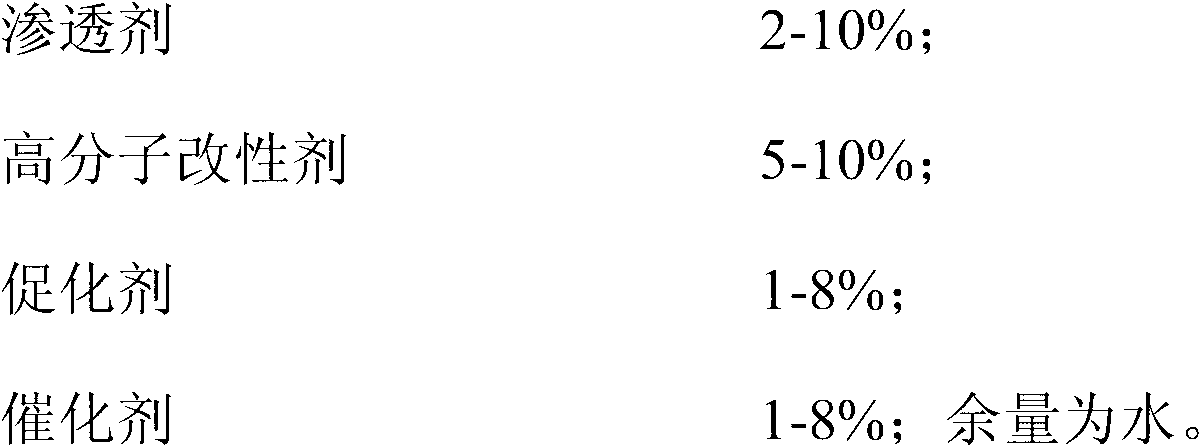

The invention discloses a nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery. The nano composite high-temperature-resistant extraction aid is prepared from 3-8 weight percent of modified nano-silica, 3-8 weight percent of petroleum sulfonate, 10-40 weight percent of a viscosity reducer, 5-15 weight percent of an emulsifier, 2-10 weight percent of a surface wetting agent, 2-10 weight percent of a penetrating agent, 5-10 weight percent of a high polymer modifier, 1-8 weight percent of a catalyst and the balance of water. The preparation method comprises the following steps: polymerizing the petroleum sulfonate, viscosity reducer, a promoting agent and the catalyst at the temperature of 60-150 DEG C for 2-6 hours according to a ratio, adding the modified nano inorganic aid, and uniformly mixing; and finally, adding the emulsifier, surface wetting agent, penetrating agent, high polymer modifier and water according to the ratio, and mixing for 1-2 hours. The nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery has high high-temperature resistance and excellent emulsification and salt resistance, the production efficiency can be greatly improved, and the recovery rate is reduced.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

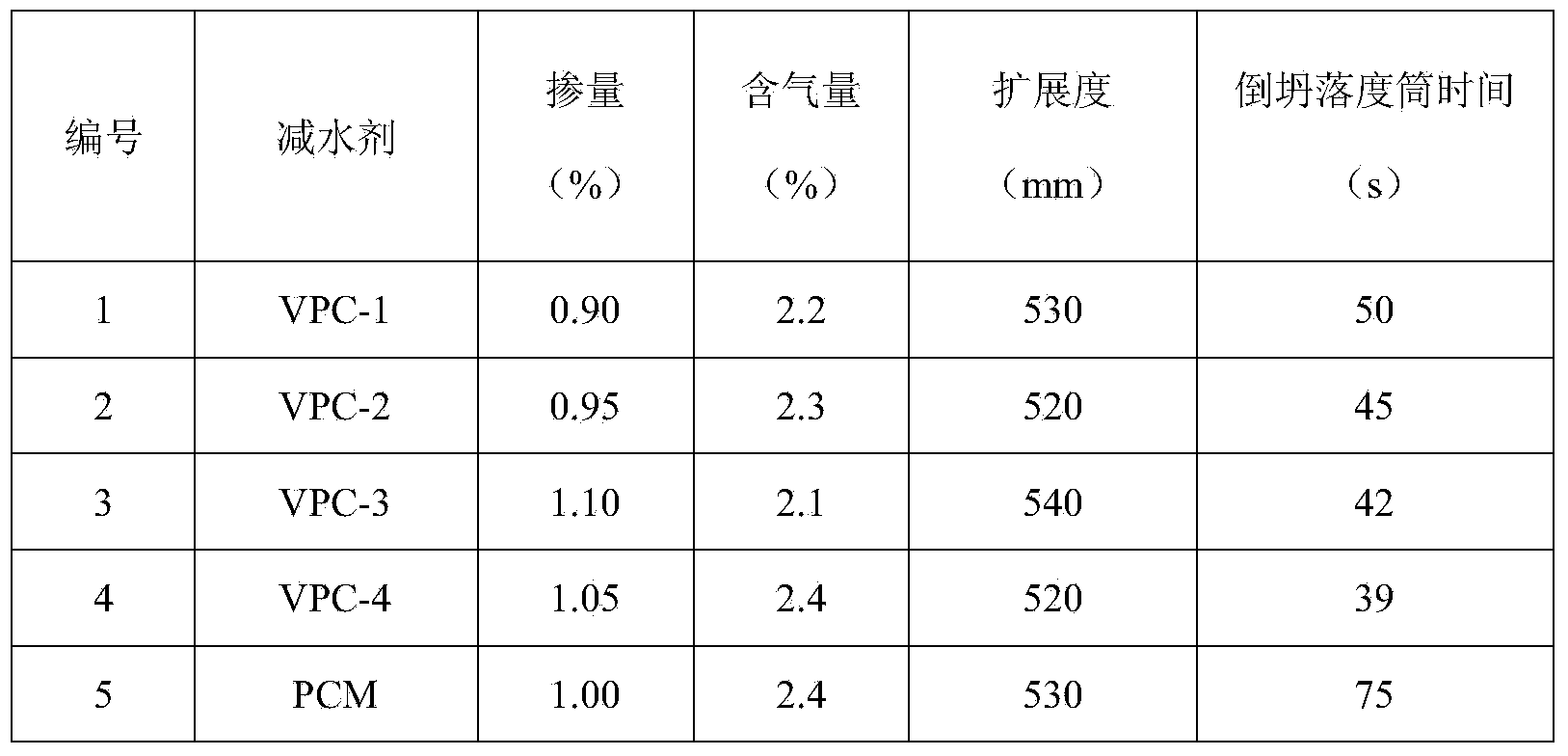

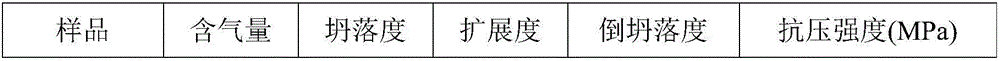

Preparation method of viscosity-reduction type polycarboxylate water reducer

InactiveCN103865007AGood viscosity reduction effectImprove dispersionChemistryHigh strength concrete

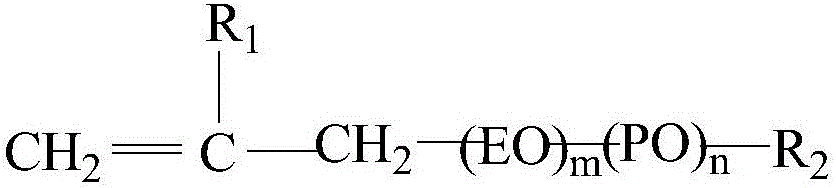

The invention discloses a preparation method of a viscosity-reduction type polycarboxylate water reducer, which belongs to the field of concrete admixtures. The water reducer is prepared from random polyoxyalkyl ether unsaturated acid ester, unsaturated modified polyoxyethylene ether, unsaturated acid alkyl ester, and (methyl) acrylic acid, by means of copolymerization with an aqueous solution and then adding alkali for neutralization, under the presence of an initiator and a molecular weight regulator. By a certain quantity of hydrophobic units and hydrophobic groups which are introduced into and controlled in carboxylic acid copolymer molecule structures, the viscosity of a cement-based material is reduced under the presence of the water reducer. The water reducer prepared by the method has the advantages of high viscosity reducing effect, high dispersibility, good adaptability to cement, and the like; the water reducer is especially applicable to preparation of high-strength concrete, self-compacting concrete, low-water-binder-ratio high-dosage mineral admixture concrete, and the like.

Owner:NANJING RUIDI HIGH TECH

Hydraulic composition dispersant

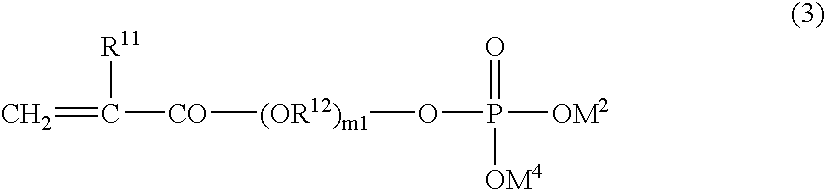

The present invention relates to a hydraulic composition dispersant containing a polycarboxylic acid-based polymer A having a carboxylic acid group and an oxyalkylene group and / or an oxystyrene group such as polymers obtained by copolymerizing a specified monomer 1 such as an ethylenic unsaturated carboxylic acid derivative having a polyoxyalkylene group with a specified monomer 2 such as a (meth)acrylic acid, and a polymer B obtained by copolymerizing the monomer 1, a monophosphate-based monomer 3 and a diphosphate-based monomer 4.

Owner:KAO CORP

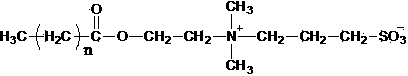

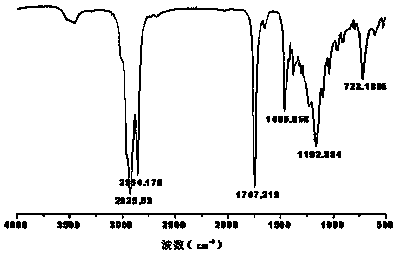

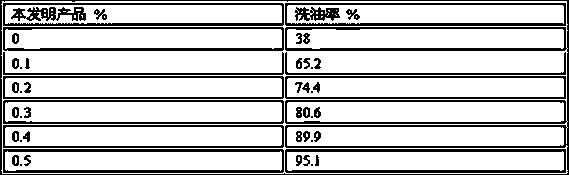

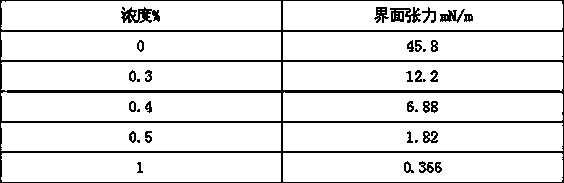

Surface active agent and oil-soluble viscosity reducer for crude oil as well as preparation method of surface active agent

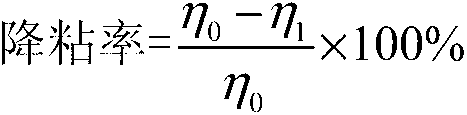

InactiveCN103468228AEasy to operateLow costSulfonic acids salts preparationDrilling compositionLong chain fatty acidReduction rate

The invention provides a surface active agent and an oil-soluble viscosity reducer for crude oil as well as a preparation method of the surface active agent. The surface active agent is fatty acid ester ethyl sulphobetaine; and the oil-soluble viscosity reducer for crude oil comprises the following components in percentage by mass: (1) 40%-70% of mixed aromatics solvent, (2) 20%-55% of mutual solvent and (3) 2%-10% of surface active agent. The oil-soluble viscosity reducer for crude oil has the advantages that the fatty acid ester ethyl sulphobetaine type surface active agent obtained by the reaction of propane sultone and long-chain fatty acid-2-(dimethylamino) ethyl ester is firstly adopted in the oil-soluble viscosity reducer for the crude oil, the viscosity reducing effect is obvious, the using amount of the oil-soluble viscosity reducer does not exceed 5%, and the viscosity reduction rate of the oil-soluble viscosity reducer is above 90%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

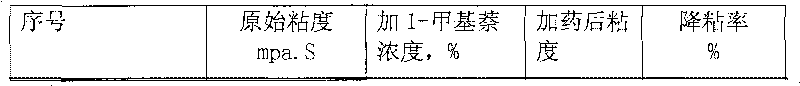

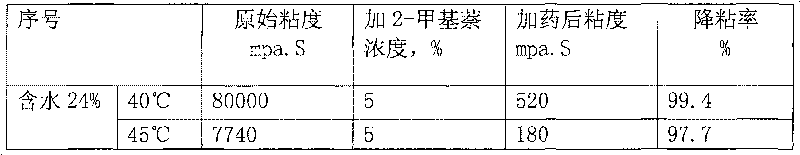

Application of methylnaphthalene in lowering viscosity of thickened oil

ActiveCN101717626ALow viscositySpeed up the flowFluid dynamicsFluid removalOil viscosityHigh surface

The invention discloses application of methylnaphthalene in lowering viscosity of thickened oil, which comprises application of 1-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps, 2-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps and mixed methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps. The invention enlarges the application method of methylnaphthalene, clearly demonstrates the specific application method of using methylnaphthalene to lower viscosity of thickened oil, solves the problems of great load and power consumption, frequent machinery accidents, high surface line return pressure, and the like of an oil extractor during extracting and outwards transporting thickened oil in the background art, and can effectively lower viscosity of thickened oil and reduce extraction and outward transportation cost of thickened oil.

Owner:盘锦河升大地石油科技有限公司

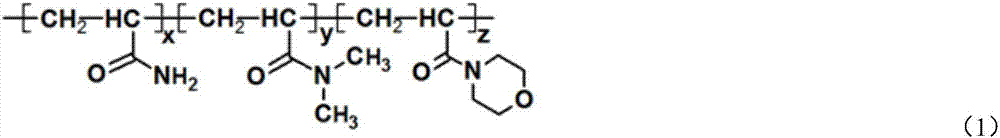

Preparation method of water-soluble anion polymer-type thickened oil viscosity reducer

ActiveCN107880214ARaw materials are cheap and easy to getSimple processDrilling compositionReduction rateEnd-group

The invention relates to a preparation method of a water-soluble anion polymer-type thickened oil viscosity reducer. The thickened oil viscosity reducer comprises a component A and a component B; thecomponent A is an acrylamide copolymer containing acryloyl morpholine blocks; the component B is an acrylamide copolymer containing active end groups. A thickened oil viscosity reducer solution is mixed with thickened oil; it is proved through viscosity reduction tests that when the dosage reaches 0.2 mg / mL, the viscosity reducer can achieve high-temperature stirred emulsification and viscosity reduction in pure water and salt water, the viscosity reduction rate is greater than 93%, and stirred demulsification is stopped at room temperature. The thickened oil emulsification viscosity reducer is obvious in viscosity reduction effect and high in environmental adaptability, the emulsification and viscosity reduction behaviors of the thickened oil viscosity reducer have temperature and shearing responsiveness, and convenience is provided for application and post-treatment in oil fields.

Owner:CHINA NAT OFFSHORE OIL CORP +2

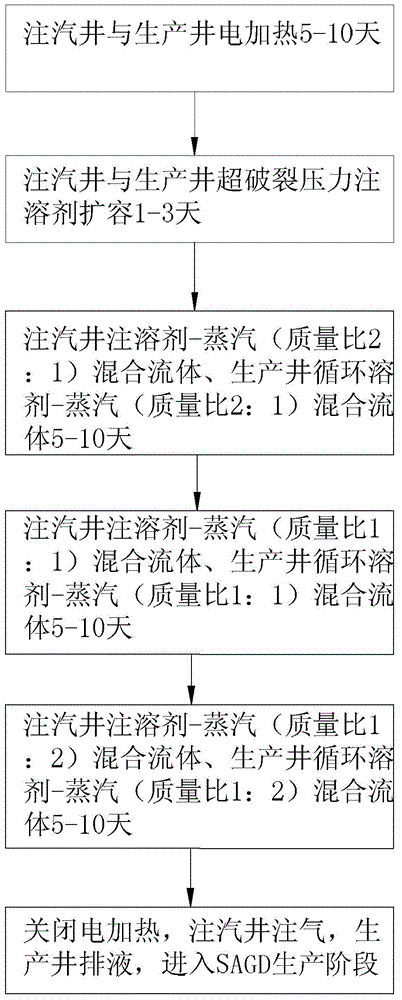

Rapid start method for heavy oil reservoir steam assisted gravity drainage

ActiveCN104453805ABuild pressure connectionIncrease the range of viscosity reductionFluid removalSolventInjection well

The invention discloses a rapid start method for heavy oil reservoir steam assisted gravity drainage. The rapid start method for heavy oil reservoir steam assisted gravity drainage comprises the following steps that (1) a steam injection well and a producing well are electrically heated at a large power; (2) a solvent is injected into a long oil pipe and a short oil pipe of the steam injection well and a long oil pipe and a short oil pipe of the producing well at the same time; (3) a solvent and steam liquid mixture is injected into the long oil pipe and the short oil pipe of the steam injection well at the same time, the solvent and steam liquid mixture is injected into the long oil pipe of the producing well, and the short oil pipe of the producing well discharges liquid; (4) electric heating is stopped, pure steam is injected into the long oil pipe of the steam injection well and the short oil pipe of the seam injection well at the same time, and the long oil pipe and the short oil pipe of the producing well discharge liquid at the same time. Compared with a conventional preheating start method, time is shortened by over two thirds, so that the heat energy utilization rate is greatly increased, rapid preheating start of SAGD can be achieved, and the production speed of SAGD is increased. In addition, through rapid solvent volume expansion and super fracture pressure injection, an even oil drainage channel can be established, and the purposes of increasing the yield and the recovery rate are achieved.

Owner:PETROCHINA CO LTD

Preparation method of high-polymer viscosity reducer for heavy oil production

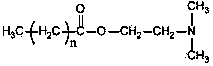

ActiveCN110372816ARaw materials are easy to getThe production process is simple and safeDrilling compositionCysteamineFunctional monomer

The invention relates to a preparation method of a high-polymer viscosity reducer for heavy oil production. According to the preparation method, by utilizing cysteamine as a chain transfer agent, a macromolecule functional monomer containing various functional groups such as nitrogen heterocyclic rings, benzene rings and ethylene oxide chain segments is prepared, then the macromolecule functionalmonomer, acrylamide, vinyl pyrrolidone, acrylic acid and a 2-acrylamide-2-methylpropanesulfonic acid water-soluble monomer are taken as raw materials, and a water-soluble polymer with a comb-shaped functional structure is prepared through aqueous solution polymerization. The product has the good dissolving property in an aqueous solution, and the viscosity of heavy oil can be lowered significantly. In addition, oil-water separation is easy under still standing of a heavy oil viscosity-reducing sample, and produced liquid is convenient to treat.

Owner:CHINA NAT OFFSHORE OIL CORP +2

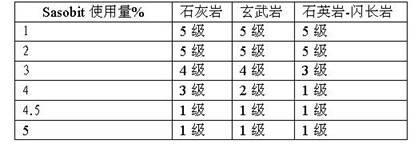

Color asphalt warm-mixing agent and preparation process thereof

ActiveCN102093731AEasy to useReduce the temperatureClimate change adaptationBuilding insulationsSilicon dioxideAsphalt

The invention relates to a color asphalt warm-mixing agent, in particular relating to a warm-mixing agent for color asphalt and a preparation process of the warm-mixing agent. The color asphalt warm-mixing agent is prepared by mixing, melting, extruding and granulating the following components by weight percent: 48-48% of polyethylene wax, 48-49% of calcium stearate and 2-4% of silica. The color asphalt warm-mixing agent has the advantages that the construction cost is saved, and the construction temperature is reduced.

Owner:河南金欧特实业集团股份有限公司

Viscosity reduction type polycarboxylate concrete admixture and preparation method thereof

The invention discloses a viscosity reduction type polycarboxylate concrete admixture and a preparation method thereof. The polycarboxylate concrete admixture contains the following synthetic raw materials: low molecular weight segmented modified unsaturated polyoxyethylene ether comonomer A, an unsaturated carboxylic acid comonomer B, alkylphenol ethoxylate C, an initiator, a reducing agent, a chain transfer agent, caustic soda liquid and water, wherein the mass ratio of the synthetic raw materials is as follows: a ratio of the low molecular weight segmented modified unsaturated polyoxyethylene ether comonomer A to the unsaturated carboxylic acid comonomer B to the alkylphenol ethoxylate C to the initiator to the reducing agent to the chain transfer agent to the caustic soda liquid to the water is (320-420):(24-36):(3-10):(1-5):(0.5-3):(0.5-4):(20-50):(400-500). The viscosity reduction type polycarboxylate concrete admixture disclosed by the invention has the characteristics of excellent dispersion property, obvious viscosity reduction effect, and excellent cement adaptability, and the product is simple in process, safe, reliable and stable in performance, does not contain any chloride ion, does not have any Corrosion damage on reinforcement and is environment-friendly.

Owner:广东瑞安科技实业有限公司

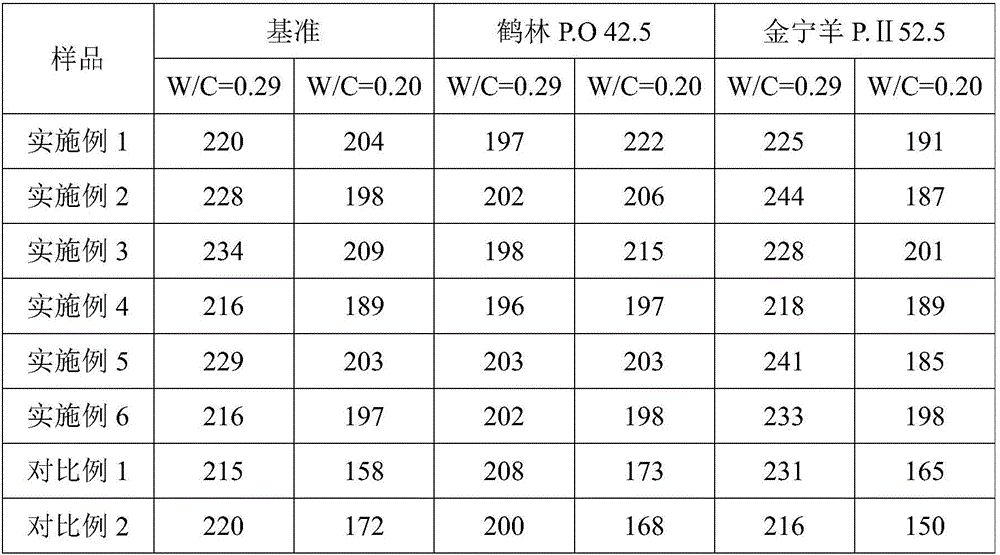

Viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete

The invention relates to a viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete and a preparing method thereof, and belongs to the field of cement concrete water reducing agents. The preparing method includes the following steps that polyethylene polyamine and alkyl acrylate are used for preparing a comonomer A; the comonomer A, polyoxyethylene-polyoxypropylene comonomer B, a vinyl aromatic compound C and an unsaturated carboxylic monomer are subjected to water-phase free radical polymerization reaction under the action of initiator and a chain transferring agent, and the pH value is adjusted after the reaction is completed to prepare the viscosity reducing polycarboxylate-type water reducing agent. The viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete has the advantages of being high in dispersing performance, obvious in viscosity reducing effect, high in adaptability to cement and particularly suitable for preparing high-strength and ultrahigh-strength concrete and self-compaction concrete. The viscosity reducing polycarboxylate-type water reducing agent is low in requirement for production equipment and simple in process, operation is convenient, which is beneficial for industrial production, and the product is free of chloridion, and does not corrode rebars in the concrete.

Owner:NANJING HYDRAULIC RES INST

Viscous oil viscosity reducer

The invention relates to a viscous oil viscosity reducer. The viscous oil viscosity reducer comprises hydrocarbon oil, beta-cyclodextrin, fatty alcohol polyoxyethylene ether and a hydrophilic component, wherein the mass of the hydrocarbon oil accounts for 0.25-2.5 of the mass of the hydrophilic component, the mass of the beta-cyclodextrin accounts for 0.006-0.33 of the mass of the hydrophilic component, and the mass of the fatty alcohol polyoxyethylene ether accounts for 0.0006-0.033 of the mass of the hydrophilic component; the hydrophilic component comprises one or more of C1-C4 monocarboxylic acid, C1-C4 monohydric alcohol, C1-C4 monoamine and C1-C4 amide; and the fatty alcohol polyoxyethylene ether is polyoxyethylene ether obtained through treating fatty alcohol as an initiator, the fatty alcohol treated as the initiator is C4-C20 straight-chain or branched-chain fatty alcohol, and the polymerization degree of oxyethylene is 2-10. The viscous oil viscosity reducer is a solution or a micro-emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-based drilling cutting treatment method

InactiveCN104804759AGood viscosity reductionHigh ignition pointLiquid hydrocarbon mixture productionHydrocarbon oils treatmentSolventHigh pressure

The invention discloses an oil-based drilling cutting treatment method. The oil-based drilling cutting treatment method comprises oil-based drilling cutting extraction, separation of an extract liquor, recycling of a switchable solvent, repeated separation and extraction, oil-based drilling cutting component analysis and the like. The method can be performed under a mild condition without high temperature, high pressure and other additional conditions, and changes of hydrophilic performance of the solvent can be intelligently controlled under the stimulus-response of CO2; the viscosity reduction effect on oil-based drilling cuttings is good, the separation capacity for mineral oil in the oil-based drilling cuttings is good, the recovery rate of oil can be up to 95% or higher, the ignition point of the switchable solvent CyNMe2 is high, the method does not have a biological accumulation effect, the recovery rate of the solvent can be up to 85% or higher, and the recovery efficiency can be further improved with methods such as infrared heating, addition of chemical agents and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Heavy oil aquathermolysis catalytic viscosity reducer and preparation method thereof

The invention provides a heavy oil aquathermolysis catalytic viscosity reducer and a preparation method thereof. The heavy oil aquathermolysis catalytic viscosity reducer comprises o-phenylenediamine, dodecylbenzene sulfonic acid and a transition metal sulfate in a mass mole ratio of 1:0.5-1.5:0.5-1.5. The heavy oil aquathermolysis catalytic viscosity reducer is prepared by the steps of: dissolving dodecylbenzene sulfonic acid in water to obtain a dodecylbenzene sulfonic acid solution with a concentration of 0.5mol / L-1.2mol / L; at 70-110DEG C, adding o-phenylenediamine into the dodecylbenzene sulfonic acid solution to obtain an intermediate product; dissolving the transition metal sulfate in water to obtain a transition metal sulfate solution with a concentration of 0.5mol / L-0.9mol / L; and adding the transition metal sulfate solution into the intermediate product, carrying out reaction at 70DEG C-110DEG C for 2h-4h, and performing vacuum drying to obtain the heavy oil aquathermolysis catalytic viscosity reducer. The heavy oil aquathermolysis catalytic viscosity reducer provided by the invention has better temperature resistance, and can reach more excellent cracking viscosity reducing effect.

Owner:PETROCHINA CO LTD

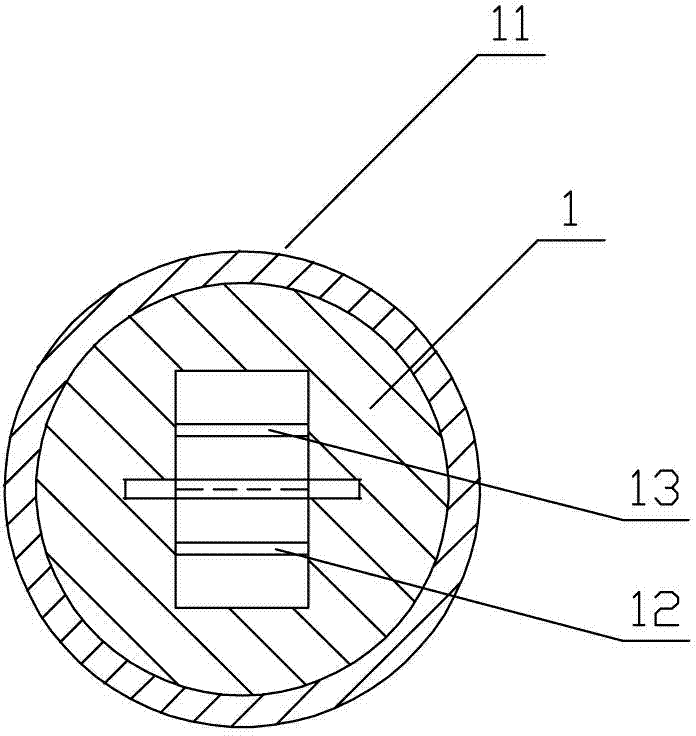

Ultrasonic-electromagnetic combined action based viscosity-reducing and paraffin-control device for crude oil and viscosity-reducing and paraffin-control method of device

The invention discloses an ultrasonic-electromagnetic combined action based viscosity-reducing and paraffin-control device for crude oil and a viscosity-reducing and paraffin-control method of the device, relates to the field of petroleum industry, and aims to solve the problems that the existing methods for reducing the viscosity of crude oil in the processes of being gathered and transported are poor in viscosity-reducing effect and large in energy consumption, and pollute the environment, and the like. According to the invention, a control system respectively sends a frequency signal with a frequency of 25 KHz to two ultrasonic transducers, so that the two ultrasonic transducers generate ultrasonic waves, the control system sends a pulse signal to an inductance coil, so that the inductance coil generates a magnetic field in an oil pipe, a high-frequency oscillation generated by an oscillating circuit is transferred to the two ultrasonic transducers, so that the two ultrasonic transducers and the oscillating circuit generate a high-frequency resonance, and the two ultrasonic transducers generate superposed ultrasonic waves in a middle pipe, so that the crystallization of paraffin molecules is prevented; and due to an induced magnetic field generated by the inductance coil, the liquidity of crude oil is enhanced under the action of the magnetic field, thereby achieving the viscosity reduction of the crude oil. The device and method disclosed by the invention are applied to the viscosity reduction of crude oil.

Owner:HARBIN INST OF TECH

Surfactant complex-based high temperature-resistant solvent

InactiveCN103992783AImprove liquidityImprove permeabilityDrilling compositionInorganic saltsThermodynamics

The invention discloses a surfactant complex-based high temperature-resistant solvent. The surfactant complex-based high temperature-resistant solvent is used for unconventional energy thickened oil steam-injection thermal recovery and through the surfactant complex-based high temperature-resistant solvent, a steam-chemical assistant combined exploitation method is formed. The surfactant complex-based high temperature-resistant solvent comprises a dispersant, a surfactant complex and an inorganic salt, and concretely, the surfactant complex-based high temperature-resistant solvent comprises, by mass, 5-10 parts of the dispersant, 10-30 parts of the surfactant complex, 5-10 parts of the inorganic salt and 80-50 parts of water. Through compounding of a fluorocarbon surfactant and a hydrocarbon surfactant, the surfactant complex-based high temperature-resistant solvent can resist a temperature of 300 DEG C and can improve steam transmission efficiency and stripping, viscosity reduction and displacement effects on thickened oil in thickened oil steam-injection recovery and especially in thickened oil steam assisted gravity drainage (SAGD).

Owner:KARAMAY XINRONG TECH

Method for preparing cement dispersant with both high water reduction effect and viscosity reduction effect

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Easily-degradable alkali-free viscosity reducer for thick oil and preparation method thereof

ActiveCN102732241AEasy to degradeImprove surface activityFluid removalPipeline systemsAlkali freeReducer

The invention relates to an easily-degradable alkali-free viscosity reducer for thick oil and a preparation method thereof. The viscosity reducer consists of propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol, a penetrating agent and water; and in terms of the total mass of the viscosity reducer, the sum of mass percent of propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol and the penetrating agent is 45 to 60 wt%. The invention also provides the preparation method for the viscosity reducer, and the method comprises the following steps: successively adding propylene glycol block polyether, fatty alcohol ammonium sulfate, fatty alcohol and the penetrating agent into water at a temperature of 50 to 80 DEG C under normal pressure, wherein a mass ratio of the four above-mentioned raw materials to water is 15: 15: 5: 10: 55 to 25: 25: 4: 6: 40; and carrying out continuous stirring for 60 to 90 min at a rotating speed of 60 to 120 r / min while adding the four raw materials so as to obtain the easily-degradable alkali-free viscosity reducer for thick oil. Surfactant used in the viscosity reducer is nonionic and anionic surfactant, the structure of benzene rings is not included in a molecule, and therefore, the characteristics of easy degradability, no toxicity, greenness and environment friendliness are obtained.

Owner:PETROCHINA CO LTD

Integrated method for thin oil blending, viscosity reduction, extraction and transportation of thickened oil

InactiveCN102116144AAdaptableSave thin oil consumptionFluid removalPipeline systemsSolventDistillation

The invention relates to an integrated method for thin oil blending, viscosity reduction, extraction and transportation of thickened oil, which is used for extracting, gathering and transporting the thickened oil of an oil field. By using the method, the viscosity of the thickened oil can be reduced, the flowing resistance can be reduced, and the output of the thickened oil can be improved. The method adopts the technical scheme that firstly, an organic solvent is blended into a pit shaft and automatically mixed with the thickened oil according to a mass ratio of 1.0 to 1.5 of the solvent to the thickened oil, so as to reduce the viscosity of the thickened oil; secondly, the thickened oil blended with the organic solvent is output to the outside of the pit shaft, is heated to a temperature of 50 DEG C to 150 DEG C through a heat exchanger and a heating furnace, and then enters a distillation tower fractionally distilled, and the organic solvent is output from the tower top, cooled to 0 DEG C to 30 DEG C through the heat exchanger, and transported back to the pit shaft for cycle use by using a pipe; and thirdly, the fractionally distilled thickened oil is output from the tower bottom and cooled through the heat exchanger, then thin oil is blended into the thickened oil to be mixed with the thickened oil according to a mass ratio of 0.3 to 0.4 of the thin oil to the thickened oil, and the oil is directly transported out after the viscosity is reduced. According to the method, the organic solvent blended into the pit shaft can be completely recycled for use; the method is suitable for ordinary thickened oil, special thickened oil and super thickened oil, and has high adaptability; and besides, by using the method, the use amount of the thin oil is greatly reduced, the utilization rate of the thin oil is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

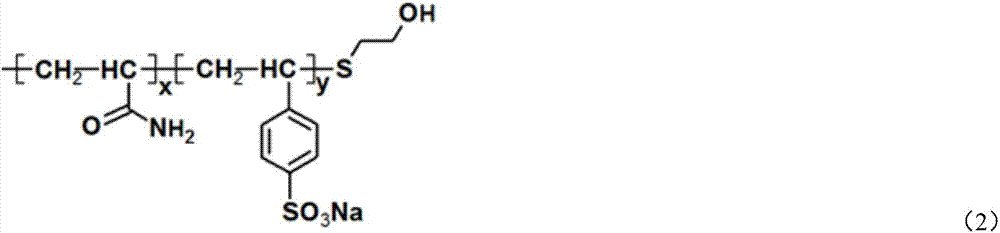

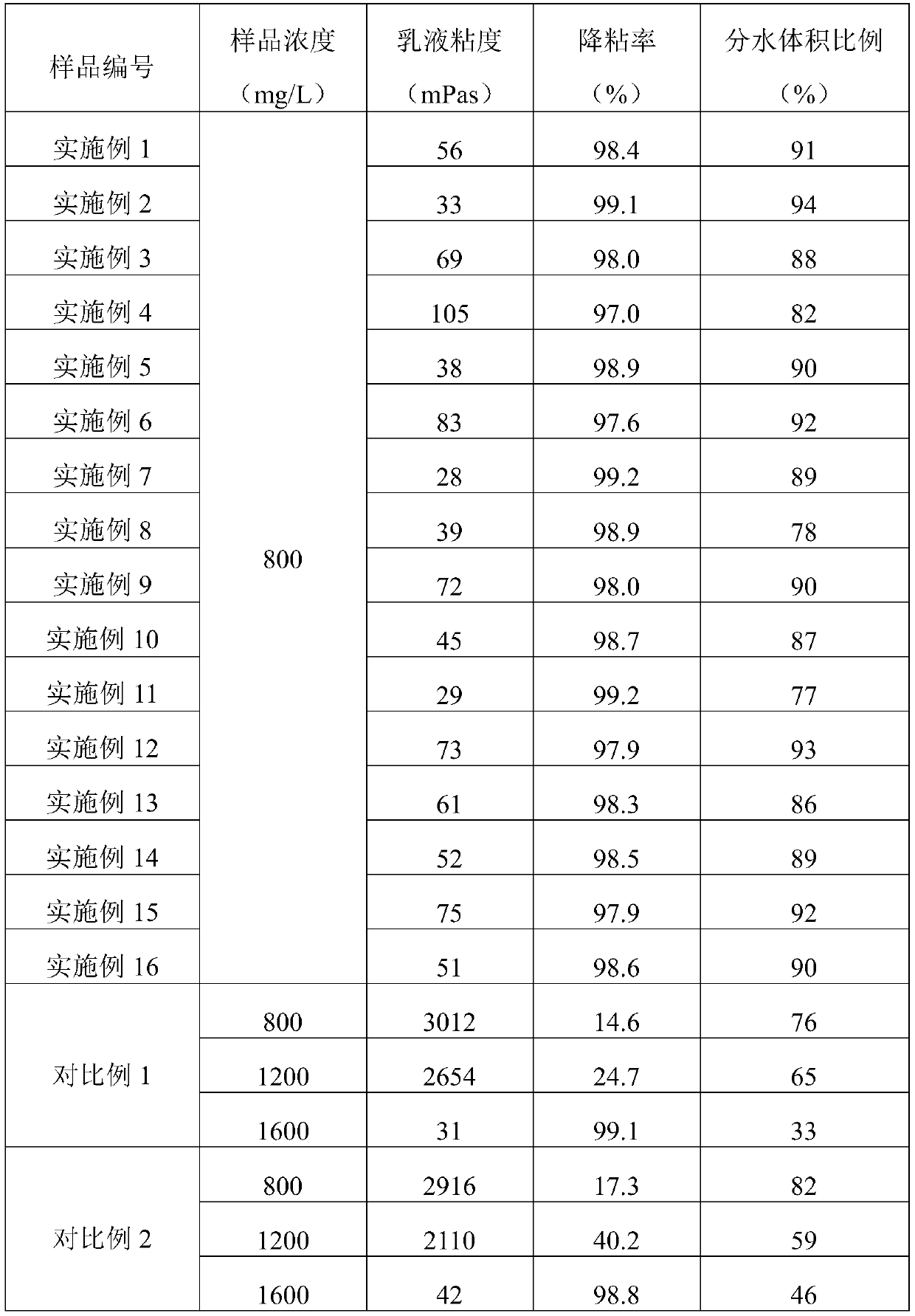

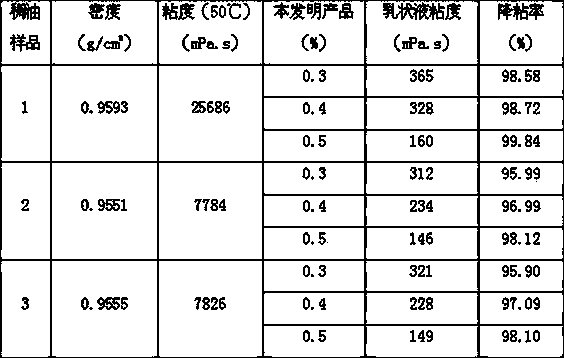

Self-demulsification heavy oil viscosity reducer as well as preparation method and application thereof

ActiveCN107955592AImprove surface activityHigh molecular weightFluid removalDrilling compositionOil viscosityRaw material

The invention relates to a self-demulsification heavy oil viscosity reducer as well as a preparation method and application thereof. The preparation method is characterized in that the self-demulsification heavy oil viscosity reducer is prepared by taking acrylamide, sodium p-styrenesulfonate and octadecyl acrylate as main raw materials; the selected raw materials have low cost and can be preparedinto the self-demulsification heavy oil viscosity reducer by adopting a simple traditional preparation process; meanwhile, an obtained product has high yield and has great advantages in a productionlink of a product; besides, the self-demulsification heavy oil viscosity reducer disclosed by the invention has the advantages of excellent viscosity reduction capability, good temperature and salt resisting effects, more outstanding viscosity reduction effect of extra-heavy oil and self-demulsification performance; integration of viscosity reduction and demulsification can be realized, and efficient oil extraction is realized.

Owner:SHANDONG UNIV

Highly environment-friendly multipurpose two-component adhesive

PendingCN110551477AFast curingQuick drying and early curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterSilanes

The invention discloses a highly environment-friendly multipurpose two-component adhesive, and relates to a water glass-polyurethane two-component environment-friendly adhesive capable of bonding various hard base materials. The technical problem to be solved comprises that an adhesive with good thixotropy and bonding performance is prepared. The technical problems of foaming, precipitation and the like caused by adding more fillers into a water glass-polyurethane system can be effectively inhibited; the adhesive is characterized in that in a component A, the ratio of modified water glass to polyether polyol to a filler is (2.6-5):1:(1.7-3.3), or (3.5-4.5):1:(2.0-3.3), the modified water glass is prepared by adding a silane coupling agent into water glass, or adding a silane coupling agentand polyol ester or polyol ether into water glass, and the filler is a substance suitable for being matched with the water glass; in a component B, the ratio of polyester polyol to polyether polyol to a plasticizer to polyisocyanate is 1:(1-1.5):(0.5-1.2):(5.5-12), and the ratio of the component A to the component B is (1-1.2):(1-1.2), or the ratio of polyester polyol to polyether polyol to a plasticizer to polyisocyanate is 1:(1-1.5):(0.5-1.2):(6.5-10), and the ratio of the component A to the component B is (1-1.5):(1-1.5). The adhesive can achieve quick-drying early strength without a catalyst at a low temperature, can effectively inhibit foaming so as to achieve good adhesion strength on a plurality of hard substrates such as steel and iron, and has the advantages of long storage life,a certain antirust flame-retardant effect, low cost, green environmental protection, low carbon and energy saving.

Owner:重庆津竹缘创新科技有限公司

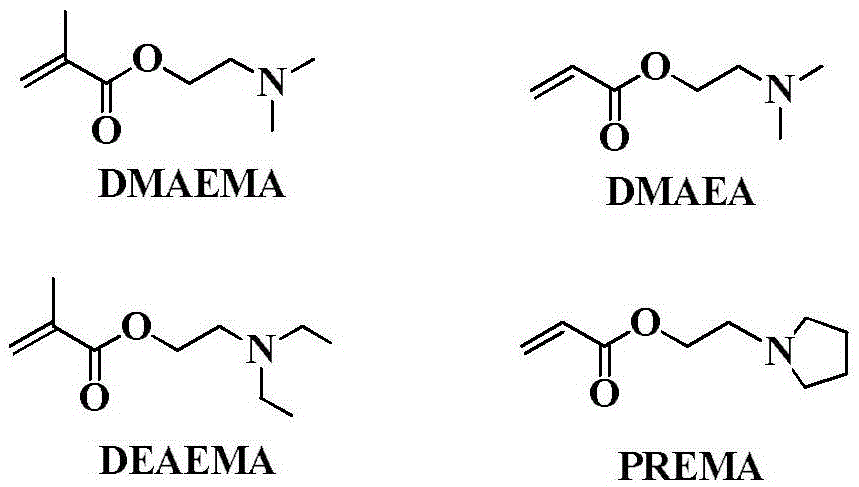

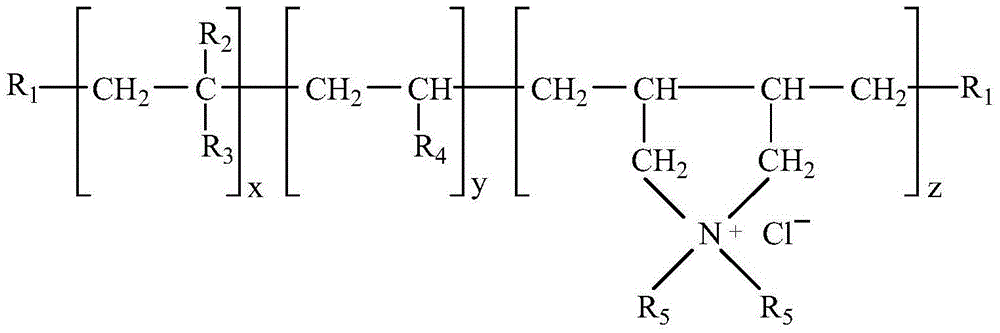

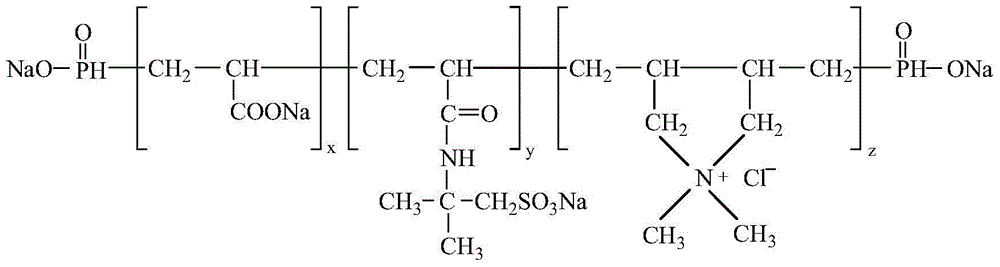

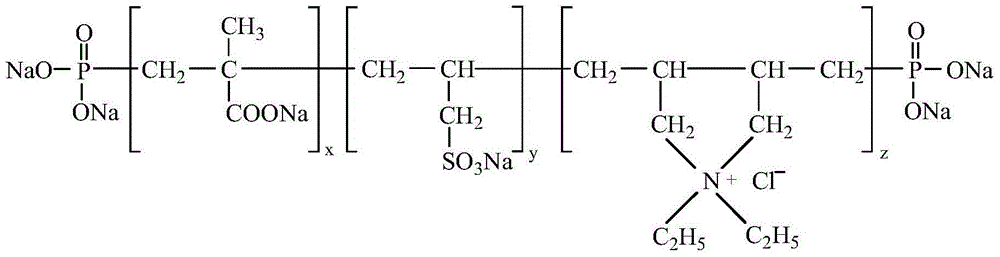

Phosphorus-containing high-temperature-resistant drilling-fluid viscosity reducer and preparation method thereof

The invention relates to a phosphorus-containing high-temperature-resistant drilling-fluid viscosity reducer and a preparation method thereof. The reducer is obtained by mixing a carboxyl monomer A, a sulfo-group-containing monomer B, a phosphorus-containing compound C and a cation monomer D according to the mass ratio of 10:5-10:0.5-2:1-3 and performing free radical polymerization. The average molecular mass of the viscosity reducer is 3000-20000. The obtained viscosity is capable of resisting the temperature up to 240 DEG C or more, is strong in salt and calcium pollution resistance, has good viscosity reducing effect under the conditions of high temperature and salt and calcium pollution compared with conventional drilling-fluid viscosity reducers, is capable of effectively improving the rheological property of a drilling fluid, is relatively low in cost, and is beneficial for large-scale application.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of thickened oil viscosity reducer with dual structure of hydrogen donor and catalytic center

InactiveCN102516969AShorten development timeLow viscosityCatalytic crackingDrilling compositionOil viscosityToluene

The invention relates to a preparation method of aquathermolysis catalysis viscosity reducer for thickened oil recovery, in particular to a preparation method of thickened oil viscosity reducer with a dual structure of hydrogen donor and catalytic center, which is characterized by comprising the following steps: (1) selecting the following raw materials in parts by weight: 17-19 parts of p-toluenesulfonic acid, 4-5 parts of cupric oxide powder and 40-60 parts of water; and (2) dissolving the p-toluenesulfonic acid in the water, heating to 40-60 DEG C, adding the cupric oxide powder, stirring for 0.5-1 hour at the temperature of 80-90 DEG C, filtering while hot, putting filtrate in an oven for drying at the temperature of 50-70 DEG C for 10-12 hours, and obtaining the thickened oil viscosity reducer with the dual structure of hydrogen donor and catalytic center. The viscosity reducer prepared by the method has favorable viscosity reducing effect at the temperature below 200 DEG C, and the preparation process is simple.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

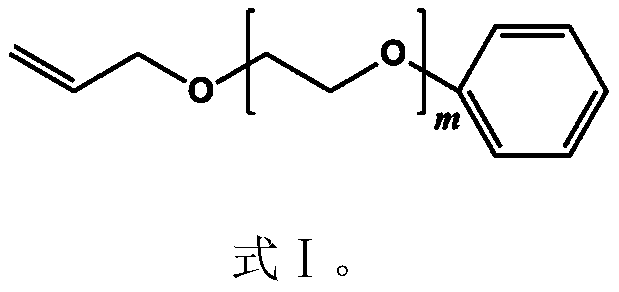

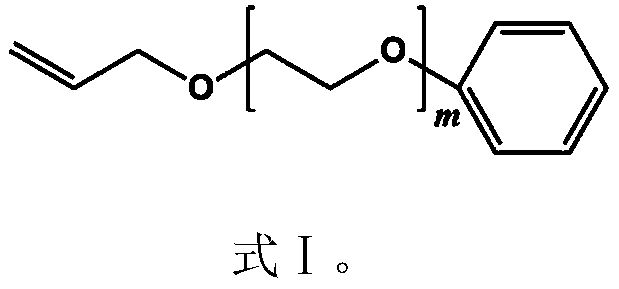

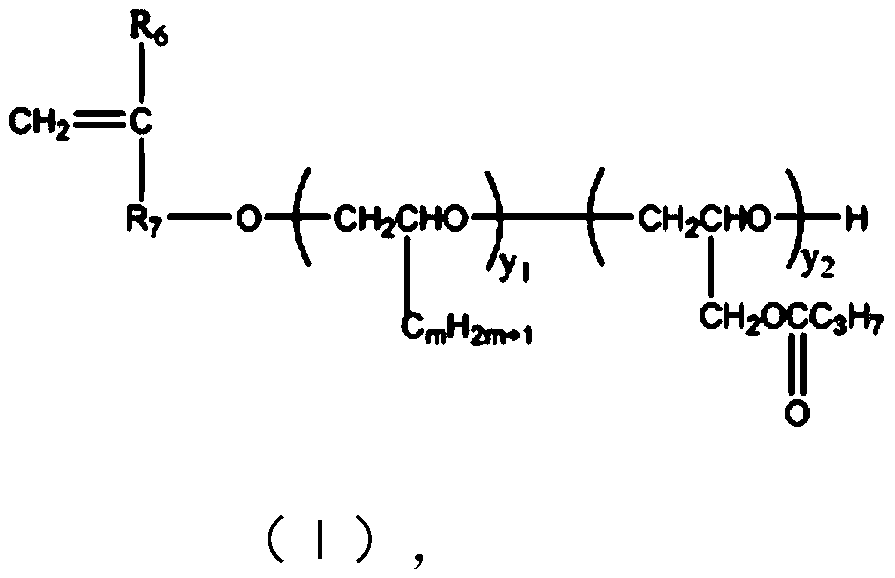

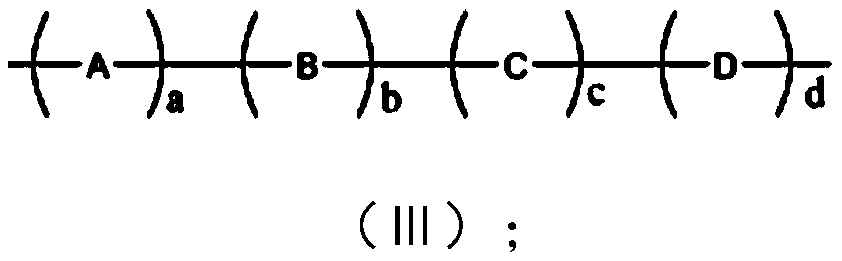

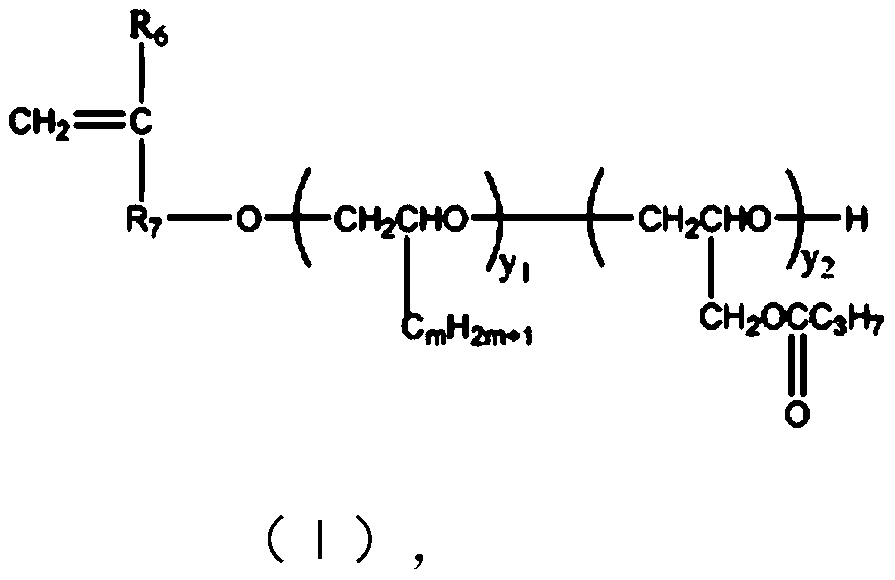

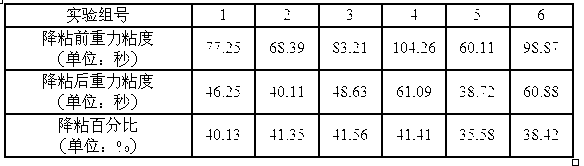

Viscosity reduction type polycarboxylic acid water reducer containing dual viscosity reduction functional groups, preparation method for viscosity reduction type polycarboxylic acid water reducer and use of viscosity reduction type polycarboxylic acid water reducer

The invention provides a viscosity reduction type active macromonomer. The invention further provides a viscosity reduction type polycarboxylic acid water reducer. According to the viscosity reductiontype polycarboxylic acid water reducer provided by the invention, all ingredients and all functional groups are in mutual synergism; compared with viscosity reduction type polycarboxylic acid water reducers synthesized in the prior art, the viscosity reduction type polycarboxylic acid water reducer has the advantages that the viscosity reduction effect is superior, and the water reducing rate isnot affected; meanwhile, a large number of hydrophobic alkyl groups and ester groups are introduced into a PEG lateral chain, so that the HLB value is lowered, the surfactivity effect is enhanced, andthe viscosity reduction type polycarboxylic acid water reducer has a good reduction effect; and concrete doped with the product provided by the invention is low in shrinkage and does not crack. The viscosity-reduction hydrophobic functional groups are located on the lateral chain, the viscosity reduction effect of the water reducer can be regulated through the content of the viscosity-reduction functional groups, however, the content of dispersion groups is not affected, the dispersion effect on cement particles is not affected, and the dispersion and water reduction effects of the water reducer are not affected.

Owner:惠州市红墙化学有限公司

Formula for viscosity reducer

ActiveCN102786245AImprove liquidityLow viscosityDrilling compositionSodium bicarbonateEconomic benefits

The invention provides a formula for a viscosity reducer which is prepared from the following components: aluminum potassium sulfate dodecahydrate, sodium hexametaphosphate, sodium bicarbonate and sodium citrate. The viscosity reducer accounting for 0.13 to 0.3% of the weight of slurry is added into shield and drilling engineering slurry for viscosity adjustment. The above-mentioned aluminum potassium sulfate, sodium hexametaphosphate, sodium bicarbonate and sodium citrate are all industrial products, cost little, have stable physical and chemical properties and are harmless to the environment. The formula for the viscosity reducer provided by the invention can effectively reduce the viscosity of high-viscosity engineering slurry; and the viscosity reducer is convenient to blend, transport, store and use and has obvious economic benefits.

Owner:三川德青工程机械有限公司 +1

High-temperature resistant viscosity reducer for drilling fluids and preparation method for viscosity reducer

InactiveCN102899007ASimple preparation processLow costDrilling compositionMaleic anhydrideAdverse effect

The invention provides a high-temperature resistant viscosity reducer for drilling fluids and a preparation method for the viscosity reducer. The preparation method comprises the following steps of: adding lignin, acrylic acid, maleic anhydride and a part of iron powder into water, and reacting at 60 to 75 DEG C for 1 to 2 hours; cooling to 48 to 52 DEG C, adding initiator, adding acrylonitrile, and reacting at 50 to 70 DEG C for 1 to 3 hours; and adding alkali to neutralize, adding formate and the rest of iron powder, and stirring for 30 minutes to obtain the high-temperature resistant viscosity reducer. By the method, the process is simple, and the cost is low; the obtained viscosity reducer has a good viscosity reducing effect in a low-density drilling fluid and a high-density drilling fluid, can be applied to deep wells and ultra deep wells, and is resistant to high temperature of 180 DEG C; and the viscosity reducer has good compatibility with the drilling fluids, and does not have adverse effect on drilling fluid performance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Parallel-connection type double-sound-wave-vortex viscosity reducing and oil enhancing device

InactiveCN104763378AIncrease flow ratePrevent reaccumulationCleaning apparatusVibration devicesCavitationOil production

The invention relates to a petroleum production auxiliary device, and discloses a parallel-connection type double-sound-wave-vortex viscosity reducing and oil enhancing device for downhole oil pumping. The viscosity reducing and oil enhancing device is formed by connecting a jet flow ultrasonic vibrator with a vortex flow guide ejector in a butt joint mode. A cavitation cabin is arranged between the jet flow ultrasonic vibrator and the vortex flow guide ejector. The viscosity reducing and oil enhancing device is characterized in that the jet flow ultrasonic vibrator comprises a shell, a jet flow head is arranged in the shell, two parallel wedge-shaped through holes are formed in the jet flow head, the small opening ends of the two wedge-shaped through holes are opposite to the cavitation cabin and provided with an outwards-extending support, and the positions, corresponding to the two wedge-shaped through holes, of the support are each provided with a vibration elastic piece to form two parallel ultrasonic vibrators. By means of the viscosity reducing and oil enhancing device, the problems that the wax content is high, blockage is prone to happening, the viscosity of crude oil is high, and mobility is poor are better solved, especially the problem that other existing viscosity reducing devices can not adapt to low deep oil well oil pumping is solved, the oil pumping yield is greatly increased, and the viscosity reducing and oil enhancing device is widely applied to oil well oil production of different types, different wax contents and different water contents.

Owner:HUANGSHI KEWEI PETROLEUM EQUIP CO LTD

Biological enzyme fracturing outlet liquid recovery oil displacement and plugging relief technology

InactiveCN101608542AEnhanced overall recoveryImprove protectionWaste water treatment from quariesFluid removalOil waterSuspended matter

The invention relates to a biological enzyme fracturing outlet liquid recovery oil displacement and a plugging relief technology comprising the following steps: (1) after biological enzyme fracturing outlet liquid is subjected to gel breaking, a flocculating agent or an adhesive mud removing agent or a bactericide is added into the biological enzyme fracturing outlet liquid to accumulate suspended matters and sterilize the fracturing outlet liquid; (2) the sterilized biological enzyme fracturing outlet liquid is initially filtered and recovered by a well cleanout truck with a filtering function or a precise filter; (3) the recovered biological enzyme fracturing outlet liquid is finely filtered again from 2 microns to 150 microns by the precise filter according to requirements; and (4) after the recovered biological enzyme fracturing outlet liquid is finely filtered, a chemical agent is added into or compositely prepared with the biological enzyme fracturing outlet liquid. The recovery rate of the biological enzyme fracturing outlet liquid processed by the technology can reach more than 70 percent, the invention thoroughly solves the problem of the environment pollution of the biological enzyme fracturing outlet liquid, enhances the recovery ratio of crude oil by more than 6-18 percent, prevents incrustations being accumulated again and reduces the oil-water interfacial tension.

Owner:SUNCOO PETROLEUM TECH

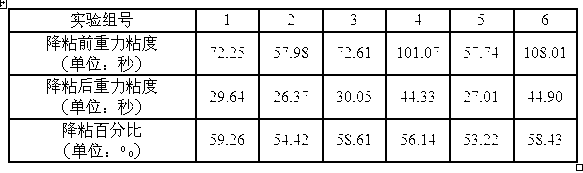

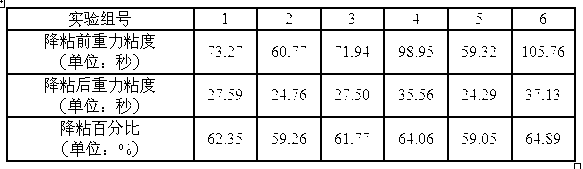

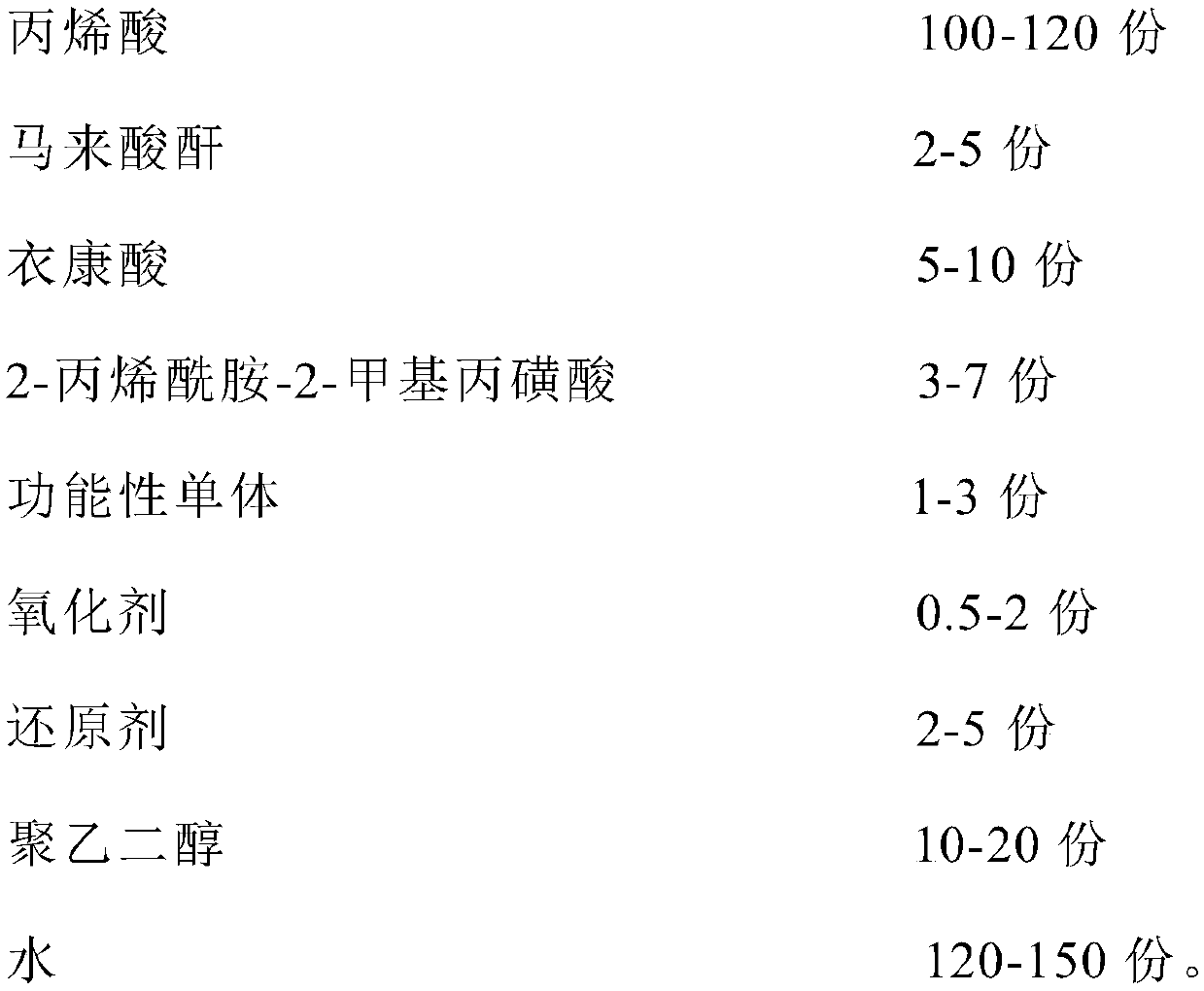

Preparation method and application of novel viscosity reducing rheological agent for papermaking coating

ActiveCN107840964AViscosity reduction stabilityEvenly dispersedPaper coatingCoatingsEnvironmental resistanceFunctional monomer

The invention relates to a preparation method of a novel viscosity reducing rheological agent for a papermaking coating. The novel viscosity reducing rheological agent comprises acrylic acid, maleic anhydride, itaconic acid, 2-acrylamide-2-methyl propanesulfonic acid and functional monomer mixed liquid, wherein polyethylene glycol, water, an oxidizer, a reducer and liquid alkali 48% are also addedin the reaction. The preparation method comprises the following steps: dropwise adding the functional mixed monomer slowly into a backing material; adjusting the temperature to 70-95 DEG C; initiating copolymerization by means of an oxidizing and reducing system; carrying out a dropwise reaction for 60-120min; carrying out insulating reaction for 20-50min; then adding polyethylene glycol to reactfor about 30-50min; after reaction, reducing the temperature to be below 40 DEG C; and carrying out neutralization with liquid alkali as needed to obtain the novel viscosity reducing rheological agent. According to the preparation method provided by the invention, the production process is simple, no waste is discharged and an environment-friendly effect is achieved, the shearing viscosity can bereduced greatly in the coating application process, the dosage of a disperser is reduced, and the cost is lowered; by adopting a precise molecular weight control and main chain rigidity structural design, the viscosity of the coating is reduced, the solid content of the coating is improved, and therefore, the vehicle speed is improved and the energy consumption is reduced.

Owner:ZHEJIANG JIUBEN BIOCHEM

Composite lignin-base viscosity breaker for drilling fluid and preparation method thereof

ActiveCN102888212AStrong temperature resistanceGood synergyDrilling compositionLignosulfonatesEnvironmental geology

The invention discloses a composite lignin-base viscosity breaker for a drilling fluid and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out sulfonation reaction to obtain lignosulfonate; (2) preparing ferrimanganic salt; and (3) preparing ferrimanganic lignosulfonate. In the composite lignin-base viscosity breaker for a drilling fluid, the water-insoluble substance content is at most 0.5%, the calcium sulfate content is at most 1.0%, the iron content is 3-5%, the complexation degree is at least 75%, and the relative molecular weight Mn is 5000-20000. The method has the advantage of low production cost; and the prepared viscosity breaker can display favorable viscosity breaking effect of the inorganic viscosity breaker, and also has favorable temperature resistance and salt resistance of the lignin viscosity breaker, thereby having favorable synergistic action. The preparation technique is simple and does not generate secondary pollution.

Owner:FUZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com