Rapid start method for heavy oil reservoir steam assisted gravity drainage

A rapid start-up and gravity-assisted technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of slow production speed, large steam consumption, and long SAGD warm-up time, so as to prevent single point The effect of breaking through and improving the oil drainage capacity and the uniformity of oil drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for quick start-up of SAGD in heavy oil reservoirs. First, a long oil pipe extending into the toe of the horizontal section is run in both the SAGD steam injection well and the production well, and a long oil pipe extending into the heel of the horizontal section and A short oil pipe parallel to the long oil pipe, an electric heating pipe, and a thermocouple temperature monitoring pipe.

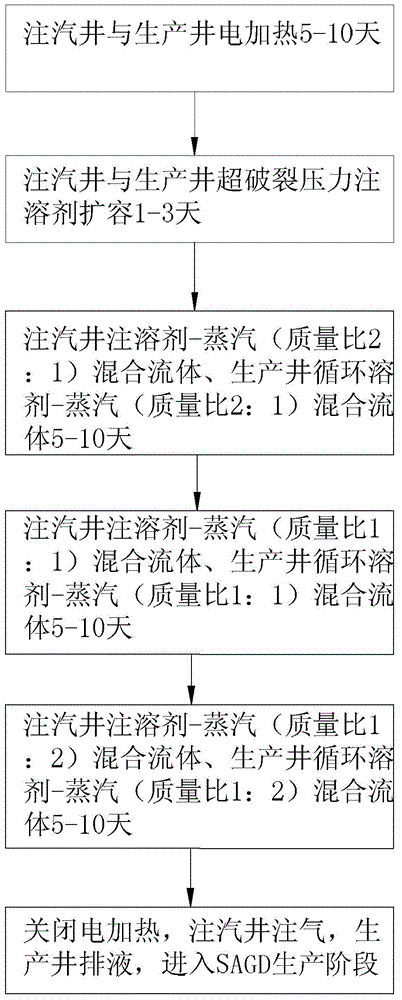

[0044] The SAGD rapid start-up method for heavy oil reservoirs includes the following specific steps:

[0045] (1) High-power electric heating for steam injection wells and production wells, using resistance heating, the maximum resistance power is 1000KW / unit length of horizontal section (m), and the maximum temperature is the saturated steam temperature corresponding to the pressure of the oil layer, which can be flexibly adjusted through the ground Control the power, thereby controlling the maximum heating temperature, and the heating time is 10 day...

Embodiment 2

[0051] The well pattern structure of this embodiment is the same as that of the first embodiment, and the difference lies in the following specific steps:

[0052] (1) High-power electric heating of steam injection wells and production wells, using resistance heating, the maximum resistance power is 1500KW / unit length of horizontal section (m), and the maximum temperature is the saturated steam temperature corresponding to the pressure of the oil layer, which can be flexibly adjusted through the ground Control the power, thereby controlling the maximum heating temperature, and the heating time is 7 days.

[0053] (2) Simultaneously inject solvent into the long tubing and short tubing of the steam injection well and production well. The solvent type is alkane solvent with carbon number 10, and the solvent temperature is the saturated steam temperature under the pressure of the oil layer. The high temperature viscosity test results show that all The selected solvent is that unde...

Embodiment 3

[0058] The well pattern structure of this embodiment is the same as that of the first embodiment, and the difference lies in the following specific steps:

[0059] (1) High-power electric heating for steam injection wells and production wells, using resistance heating, the maximum resistance power is 2000KW / unit length of horizontal section (m), and the maximum temperature is the saturated steam temperature corresponding to the pressure of the oil layer, which can be flexibly adjusted through the ground Control the power, thereby controlling the maximum heating temperature, and the heating time is 5 days.

[0060] (2) Simultaneously inject solvent into the long tubing and short tubing of the steam injection well and the production well. The solvent type is alkane solvent with carbon number 20, and the solvent temperature is the saturated steam temperature under the pressure of the oil layer. The high temperature viscosity test results show that the The selected solvent is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com