Viscosity reduction type polycarboxylate concrete admixture and preparation method thereof

A viscous polycarboxylic acid, high-performance technology, applied in the field of viscosity-reducing polycarboxylic acid high-performance water reducing agent and its preparation, can solve the problem of molecular structure hydrophilicity and hydrophobicity and viscosity reduction effect. Economic problems, complex preparation methods, etc., to achieve the effects of excellent cement adaptability, significant viscosity reduction effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

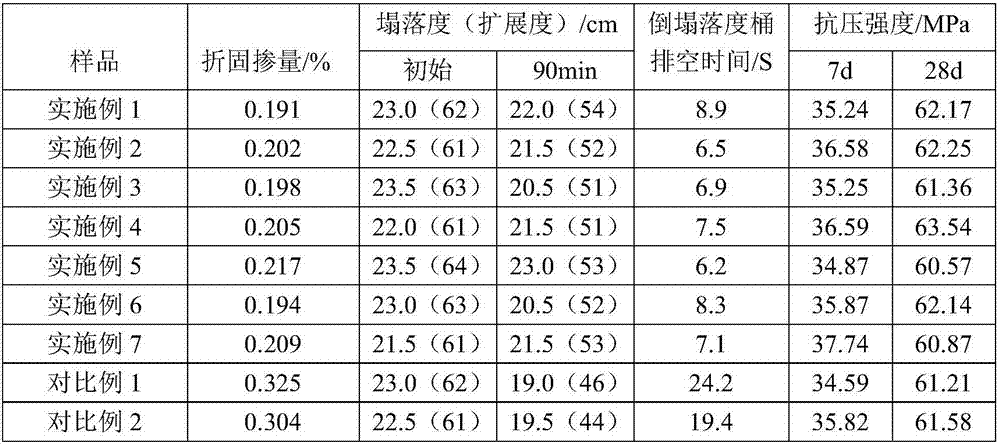

Examples

Embodiment 1

[0023] A viscosity-reducing polycarboxylate high-performance water reducer, the synthetic raw materials are: low molecular weight block modified unsaturated polyoxyethylene ether comonomer A, unsaturated carboxylic acid comonomer B, alkylphenol polyoxyethylene Ether C, initiator, reducing agent, chain transfer agent, liquid alkali and water; the mass ratio of synthetic raw materials is, unsaturated polyoxyethylene ether comonomer A: unsaturated carboxylic acid comonomer B: alkylphenol polyoxygen Vinyl ether C: initiator: reducing agent: chain transfer agent: liquid caustic soda: water is (320~420): (24~36): (3~10): (1~5): (0.5~3): ( 0.5~4): (20~50): (400~500).

[0024] Among them, the low-molecular-weight block-modified unsaturated polyoxyethylene ether comonomer has a molecular structure composed of propylene oxide or butylene oxide segments embedded in the middle of ethylene oxide segments, and its chemical structural formula is as follows Show: CH 2 =C(CH 2 CH 3 )CH 2 ...

Embodiment 2

[0032] In a four-necked flask equipped with a stirrer and a thermometer, put 324.1 parts of low molecular weight block-modified unsaturated polyoxyethylene ether CH with a molecular weight of 500 2 =C(CH 2 CH 3 )CH 2 O-(CH 2 CH 2 O) 2 -(CH 2 CH 2 CH 2 O) 2 -(CH 2 CH 2 O) 5 OH () and 4.8 parts of nonylphenol polyoxyethylene ether NP-4, add 250.5 parts of water, start stirring and heat up to 35 ° C ~ 40 ° C, after the monomer in the flask is completely dissolved, add 1.2 parts of ammonium persulfate, and stir for 5 minutes After ~10min, add material I and material II dropwise at the same time, material I (a solution prepared by stirring 34.7 parts of acrylic acid and 40 parts of water) dropwise for 3h to 4h, material II (2.1 parts of sodium bisulfite, 1.8 parts Thioglycollic acid and 58.7 parts of water were stirred evenly to form a solution) added dropwise for 3.5h to 4.5h, and then continued to keep warm at 40°C to 45°C for 1h to 2h after the completion of the reac...

Embodiment 3

[0034] In a four-necked flask equipped with a stirrer and a thermometer, put 359.4 parts of low molecular weight block-modified unsaturated polyoxyethylene ether CH with a molecular weight of 800 2 =C(CH 2 CH 3 )CH 2 O-(CH 2 CH 2 O) 3 -(CH 2 CH 2 CH 2 CH 2 O) 4 -(CH 2 CH 2 O) 7 OH and 5.7 parts of nonylphenol polyoxyethylene ether NP-10, add 254.3 parts of water, start stirring and heat up to 35 ° C ~ 40 ° C, after the monomer in the flask is completely dissolved, add 1.9 parts of sodium persulfate, and stir for 5 min ~ 10 min Then add material I and material solution dropwise at the same time, material I (a solution prepared by stirring 25.4 parts of acrylic acid and 30 parts of water uniformly) is added dropwise for 3h to 4h, material II (made of 1.8 parts of L-ascorbic acid, 1.6 parts of mercaptoethanol and 72.4 parts of water (mixed evenly to make a solution) dropwise for 3.5h~4.5h, continue to keep warm at 40°C~50°C for 1h~2h after dropping, after the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com