Preparation method of high-polymer viscosity reducer for heavy oil production

A technology of polymer and viscosity reducer, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high production cost and large amount of viscosity reducer surfactant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] A preparation method of a polymer viscosity reducer for heavy oil development, comprising the following steps:

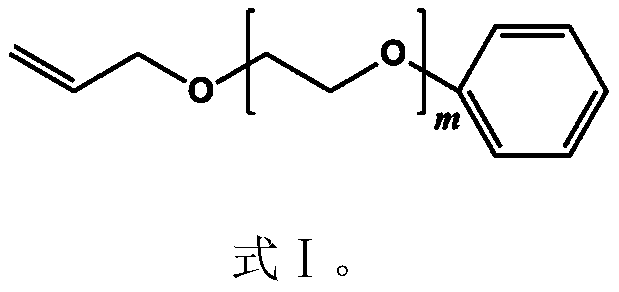

[0013] Preparation steps of macromolecular functional monomers: azobisisobutyronitrile, nitrogen-containing heterocyclic monomers, styrene, monomers containing ethylene oxide segments, acrylamide, and dimethylformamide under the action of chain transfer agents A polymerization reaction occurs, and then triethylamine and acryloyl chloride are added to carry out a modification reaction to obtain a macromolecular functional monomer;

[0014] The preparation steps of the polymer viscosity reducer: the macromolecule functional monomer, the non-ionic aqueous solution monomer, and the anion water-soluble monomer, under the action of an initiator, polymerize the polymer viscosity reducer through aqueous solution.

[0015] Preferably according to the present invention, the specific preparation method of macromolecular functional monomer is as follows:

[0016] After ...

specific Embodiment approach

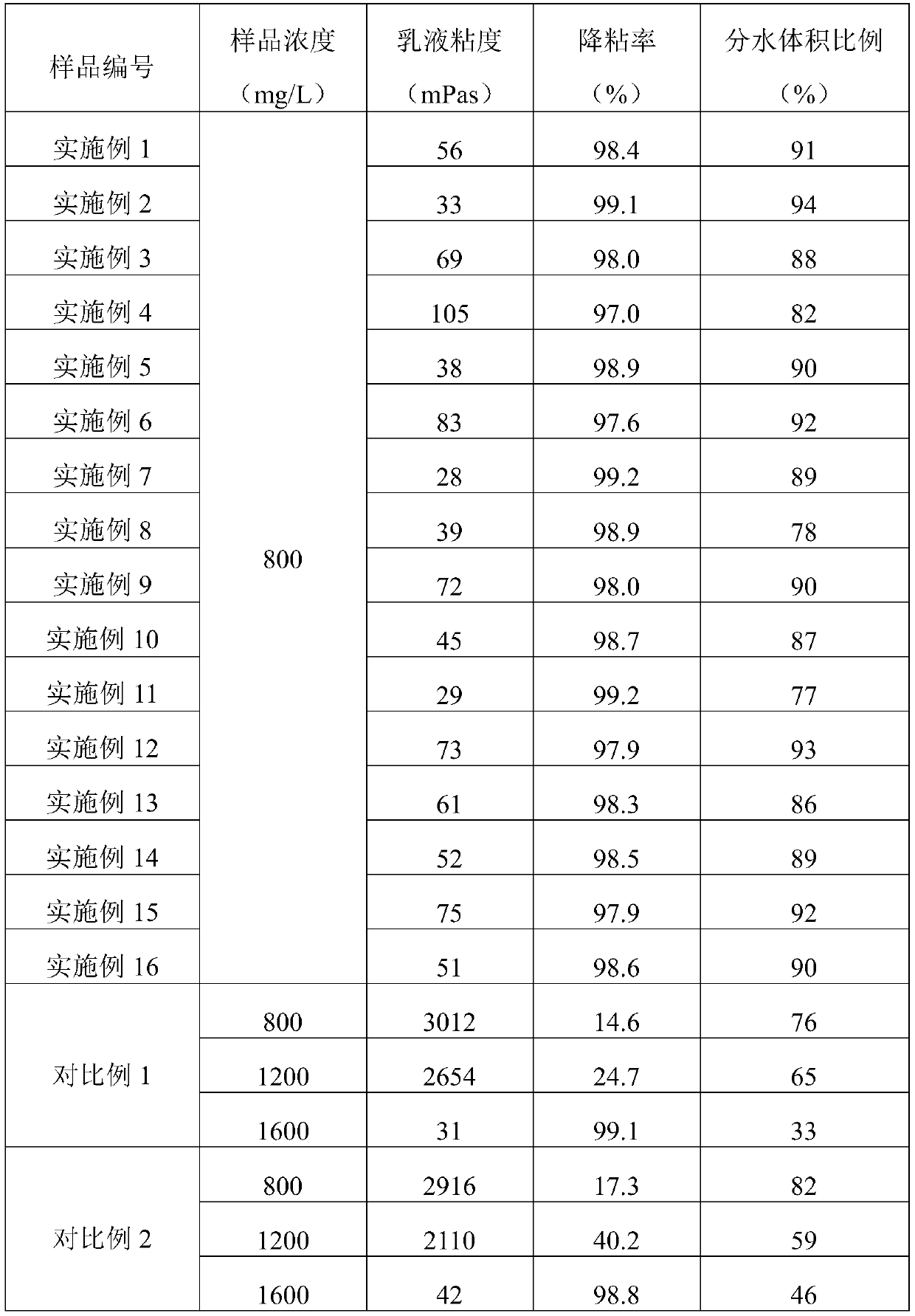

[0042] In order to better understand the present invention, it will be further described below in conjunction with specific examples.

[0043] The experimental methods used in the examples are conventional methods unless otherwise specified.

[0044] The materials and reagents used in the examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0046] A kind of preparation method of polymer viscosity reducer for heavy oil development, the steps are as follows:

[0047] (1) Preparation of macromolecular functional monomers

[0048] 4g of azobisisobutyronitrile, 1g of mercaptoethylamine, 4g of 1-vinylimidazole, 6g of styrene, 10g of ethylene oxide-containing segment monomers (m is 5), 5.5g of acrylamide, and 100g of dimethyl Formamide was added to a four-neck glass bottle equipped with a stirrer, a nitrogen pipe, a spherical condenser and a thermometer, stirred until all the raw materials were dissolved, then nitrogen gas was introduced for 30 minutes, and the temperature was raised to 60°C for polymerization for 6 hours; then the system temperature Control the temperature at 0-5°C, add 6.5g triethylamine and 5g acryloyl chloride, modify the reaction for 12h under stirring, precipitate the product with ether, and distill the volatile components under reduced pressure at 50°C to obtain macromolecular functional monolaye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com