Styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer as well as preparation method and application thereof

The technology of acid anhydride alkylphenol polyoxyethylene ether and alkylphenol polyoxyethylene ether is applied in the field of styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer and its preparation, and can solve the problem of high application cost and mixed use. The problems of large water volume and complex process can achieve the effect of easy industrial production, reducing the viscosity of heavy oil and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

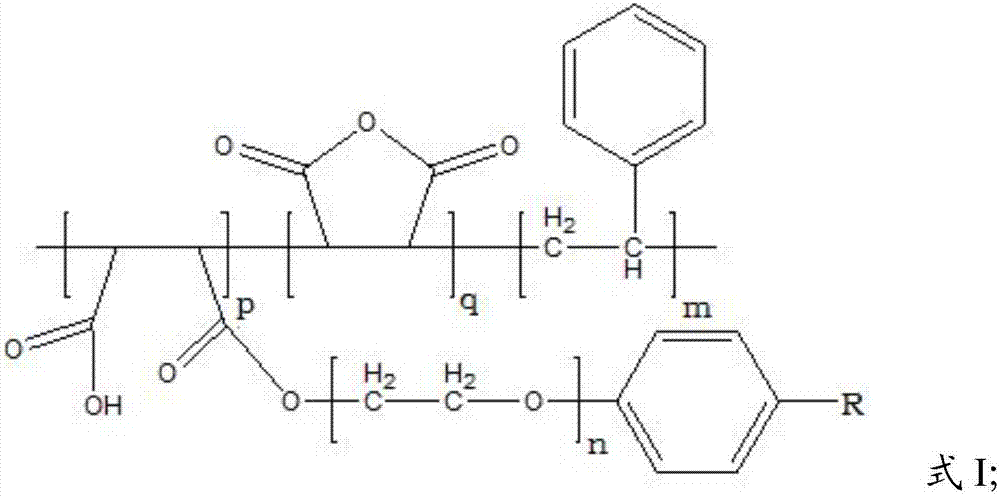

[0034] The present invention provides a preparation method of the styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer according to the above scheme, which includes the following steps:

[0035] Under the action of a catalyst, the styrene-maleic anhydride copolymer and alkylphenol polyoxyethylene ether are esterified in a polar aprotic solvent to obtain styrene-maleic anhydride alkylphenol polyoxyethylene ether copolymer Things.

[0036] In the present invention, the styrene-maleic anhydride copolymer is preferably obtained by a method including the following preparation steps:

[0037] Under the protection of inert gas and the effect of initiator, styrene and maleic anhydride are polymerized in a solvent to obtain styrene-maleic anhydride copolymer.

[0038] In the present invention, the molar ratio of styrene and maleic anhydride is preferably 1 to 999:1 to 999, more preferably 5 to 800:5 to 800, and most preferably 20 to 600:20 to 600; The initiator is preferably a...

Embodiment 1

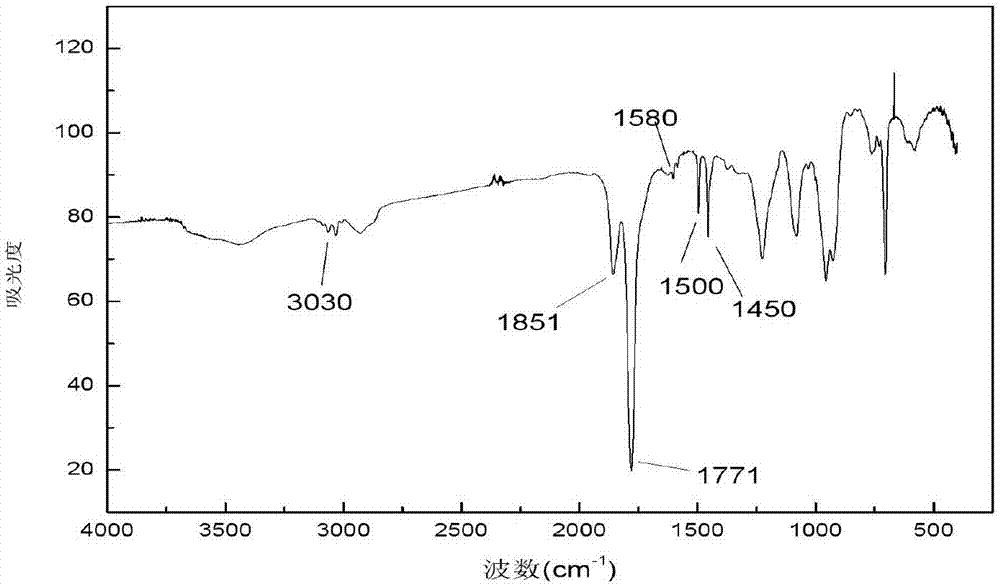

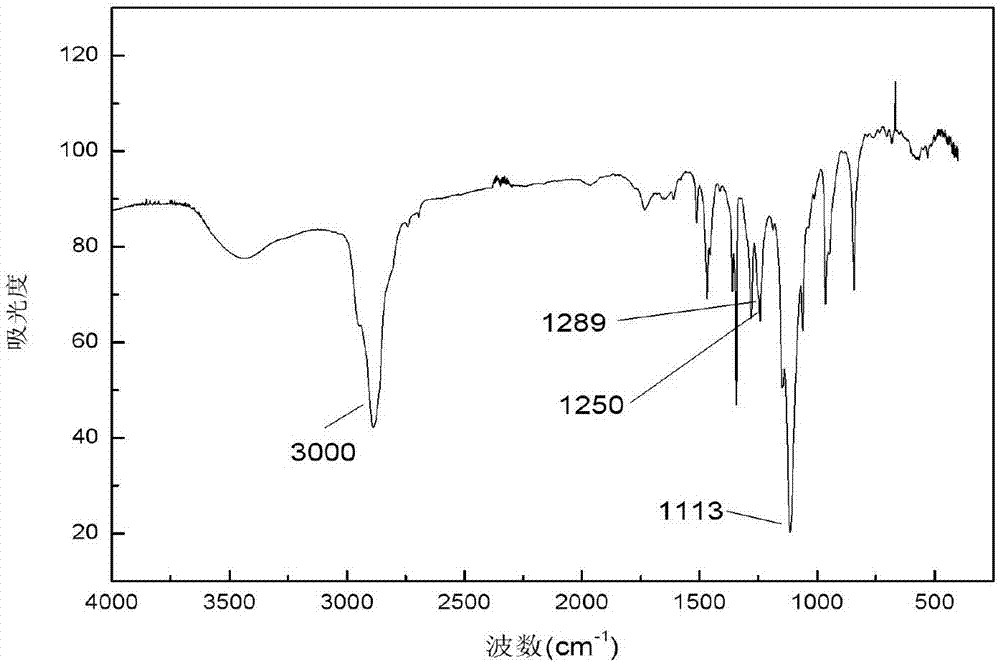

[0069] Accurately weigh 1 mol of styrene and 0.5 mol of maleic anhydride, add maleic anhydride and toluene (the mass ratio of toluene to maleic anhydride is 10:1) into the reactor, heat and stir to dissolve at 55°C, pass in N 2 After 15 minutes, add dropwise toluene-dissolved benzoyl peroxide (the mass of benzoyl peroxide is 1% of the total mass of styrene and maleic anhydride) and styrene. 2 Slowly increase the temperature under protection (heating rate 3°C / min), the reaction is carried out under stirring, the reaction temperature is controlled at 75°C, and the polymerization inhibitor hydroquinone is added after the constant temperature reaction for 4 hours to complete the reaction. 2 Cooled to room temperature under the atmosphere, the reaction solution was added dropwise to methanol for precipitation, vacuum filtration, and then the white precipitate was vacuum dried at 50° C. for 4 hours to obtain a white powdery product, which is a styrene-maleic anhydride copolymer.

[0070] ...

Embodiment 2

[0075] Accurately weigh 1 mol of styrene and 1 mol of maleic anhydride, add maleic anhydride and toluene (the mass ratio of toluene to maleic anhydride is 10:1) into the reactor, heat and stir to dissolve at 60°C, and pass in N 2 After 20 minutes, add dropwise azobisisobutyronitrile dissolved in toluene (the mass of azobisisobutyronitrile is 1% of the total mass of styrene and maleic anhydride) and styrene, in N 2 Slowly increase the temperature under protection (heating rate 3°C / min), the reaction is carried out under stirring, the reaction temperature is controlled at 50°C, and the polymerization inhibitor p-benzoquinone is added to complete the reaction after 7 hours of constant temperature reaction 2 After cooling to room temperature under atmosphere, the reaction solution was added dropwise to methanol for precipitation, vacuum filtration, and then the white precipitate was vacuum dried at 55° C. for 5 hours to obtain a white powdery product, which is a styrene-maleic anhydrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com