Anode material for lithium battery and lithium battery

A negative electrode material, lithium battery technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of low coulombic efficiency in the first week

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This example provides a method for preparing a silicon-carbon composite material with a multilayer core-shell structure, including:

[0048] Step 1: Take 100mL of a mixed solvent of ethanol and water (volume ratio 1:4), add 20g of glucose to form a glucose solution. Take 10 g of a silicon oxide sample and add it to the glucose solution, and stir to form a uniform slurry. Add 30 g of spherical graphite (average particle size: 10 μm) to the slurry and continue to stir evenly.

[0049] The second step: drying the above slurry at 120° C. for 12 hours to remove the solvent. The resulting product was heated in a tube furnace at 600°C with high-purity N 2 Under pyrolysis for 8 hours, after cooling, grind and sieve (400 mesh).

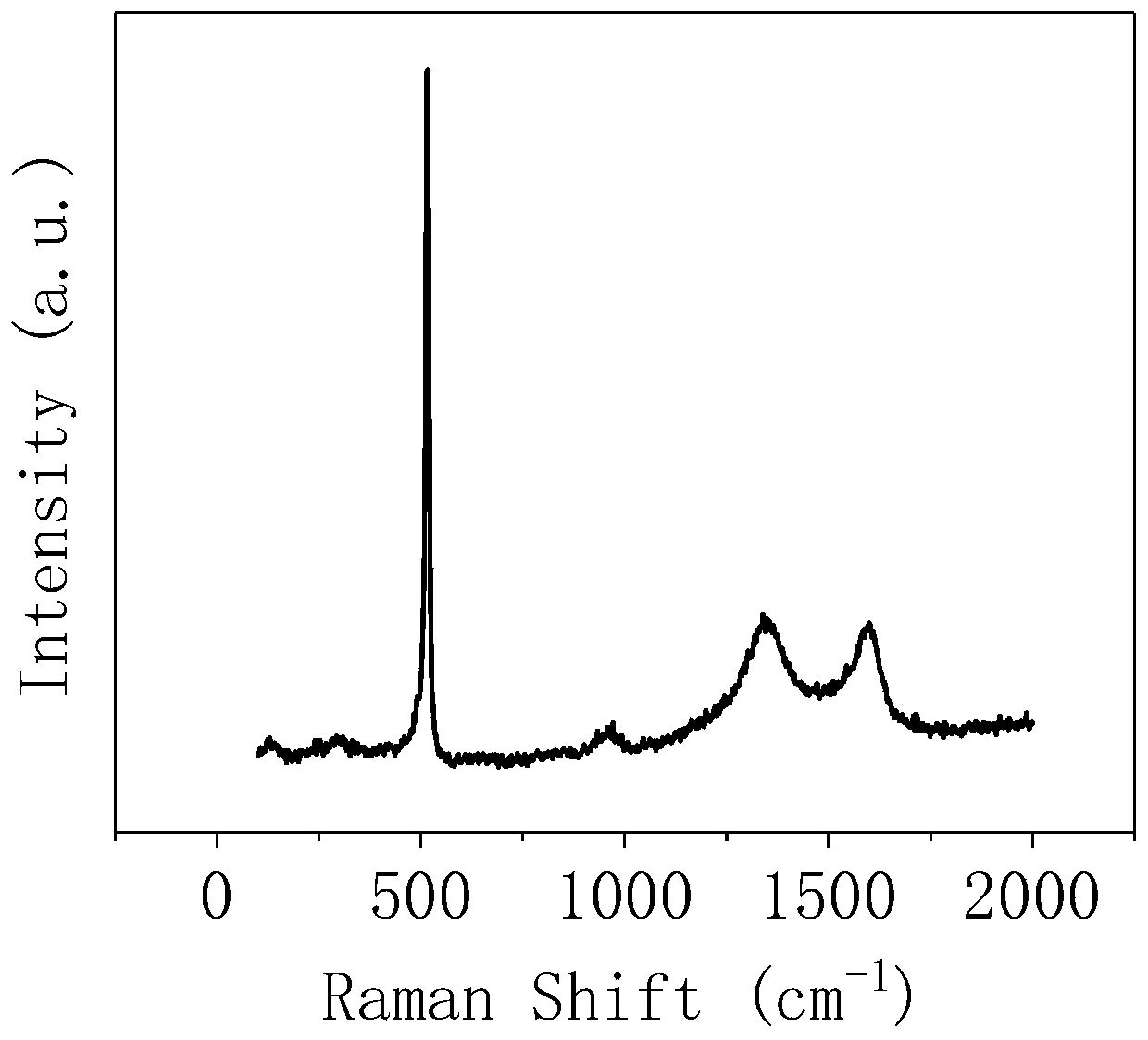

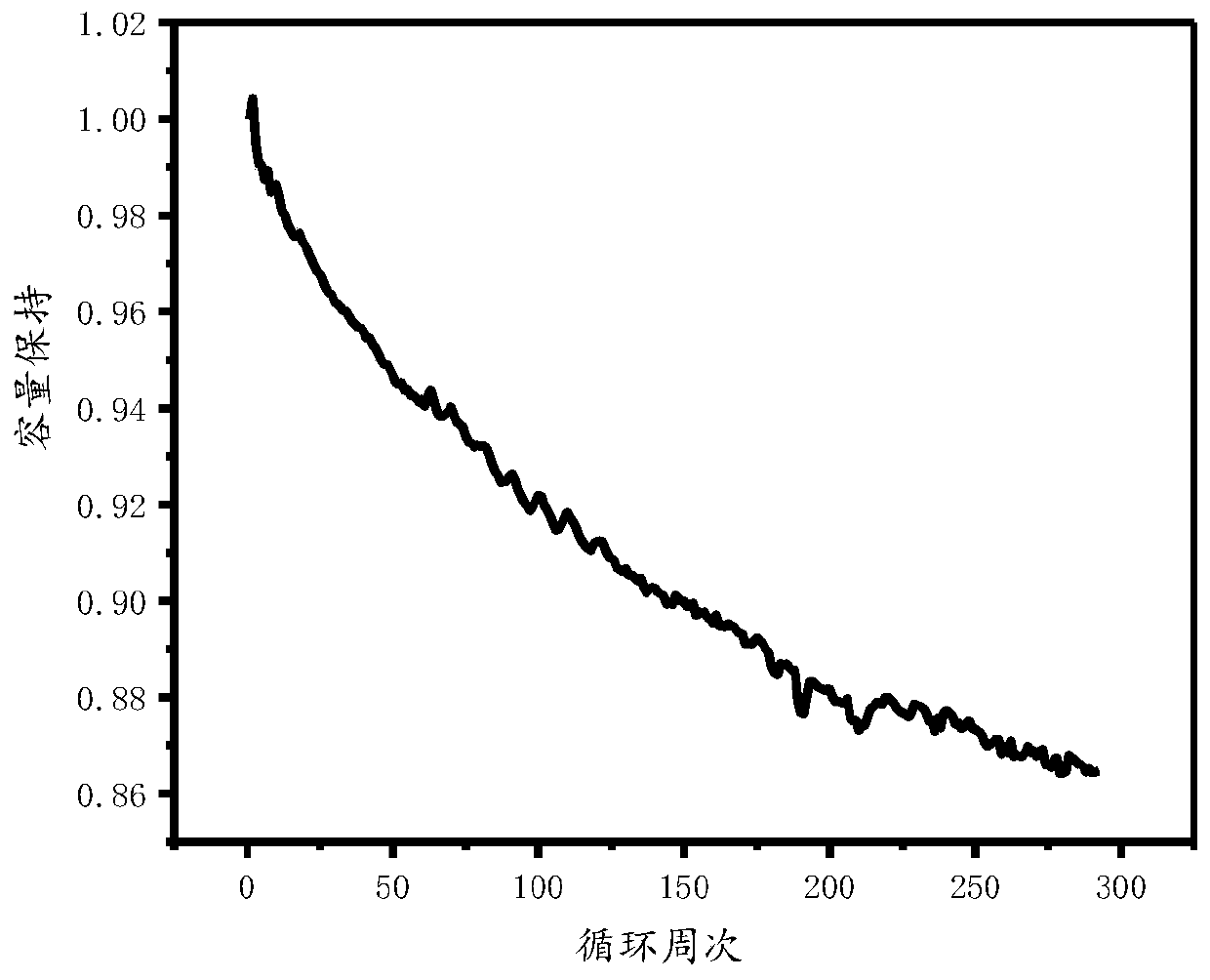

[0050] Step 3: Put the sieved sample into a tube furnace with argon gas and heat it up to 900°C, then switch the argon gas to a gas mixed with argon and natural gas (volume ratio is 2:1), at 700°C After heating for 12 hours, the composite material w...

Embodiment 2

[0057] This example provides a method for preparing a silicon-carbon composite material with a multilayer core-shell structure, including:

[0058] Step 1: Take 100mL of a mixed solvent of ethanol and water (volume ratio 1:4), add 30g of dextrin to form a starch solution. Take 10g of siloxane sample and 1g of acetylene black (average particle size: 30nm) into the starch solution, and stir for 2 hours to form a uniform slurry. Add 30 g of spherical graphite (average particle size: 10 μm) to the slurry and continue to stir evenly.

[0059] Step 2: Dry the above slurry at 120° C. for 8 hours to completely remove the solvent. The obtained product was heated in a tube furnace at 600 °C with high-purity N 2 Under pyrolysis for 5 hours, after cooling, grind and sieve (400 mesh).

[0060] Step 3: put the sieved sample into a tube furnace with argon and heat up to 900°C, then switch the argon to a gas mixed with argon and toluene (volume ratio is 4:1), at 900°C The composite materi...

Embodiment 3

[0062] This example provides a method for preparing a silicon-carbon composite material with a multilayer core-shell structure, including:

[0063] Step 1: Take 8g of siloxane sample, 5g of carbon hard balls (average particle size of 5μm) and 1g of asphalt, and ball mill for 2 hours.

[0064] The second step: the mixture after ball milling is put in a tube furnace at 600°C, high-purity N 2 Under pyrolysis for 5 hours, after cooling, grind and sieve (400 mesh).

[0065] Step 3: Put the sieved sample into a tube furnace with argon gas and heat it up to 900°C, then switch the argon gas to a gas mixed with argon and acetylene (volume ratio is 2:1), at 900°C The composite material with multi-layer core-shell structure of the present invention was obtained by heating at low temperature for 8 hours. The data are recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com