Device for continuously preparing two-dimensional nano films

A two-dimensional nano-film technology, applied in the direction of ion implantation plating, gaseous chemical plating, coating, etc., can solve the problem of large differences, restrict the development of two-dimensional nano-film, uneven distribution of carbon-containing gas source graphene film and other issues to achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

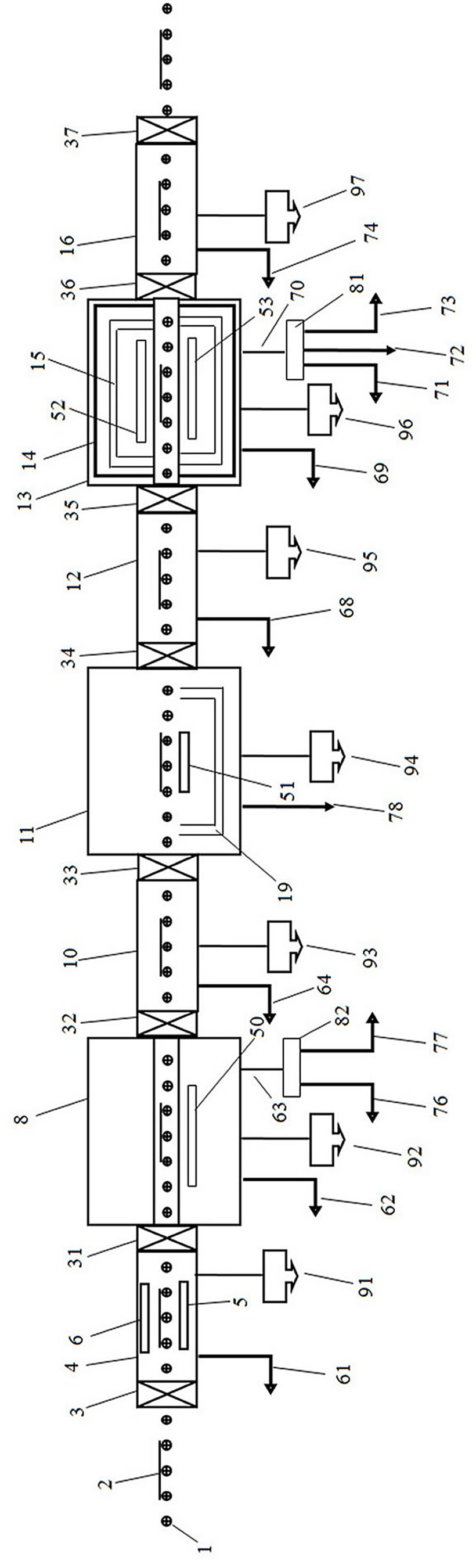

Embodiment 1

[0035] see figure 1 , the equipment for continuously preparing two-dimensional nano-films of the present invention includes that a feed chamber 4, a first processing chamber 8, a first balance chamber 10, a thin film preparation chamber 11, and a second balance chamber are sequentially arranged on the production line 12. The second processing chamber 13 and the discharge chamber 16; the feeding chamber 4 is provided with a valve 3 communicating with the atmosphere, and a valve 31 is arranged between the feeding chamber 4 and the first processing chamber 8, and the first A valve 32 is provided between the processing chamber 8 and the first balance chamber 10, a valve 33 is provided between the first balance chamber 10 and the film preparation chamber 11, and a valve 33 is provided between the film preparation chamber 11 and the second balance chamber 12. A valve 34 is provided between the second balance chamber 12 and the second processing chamber 13, a valve 35 is provided ...

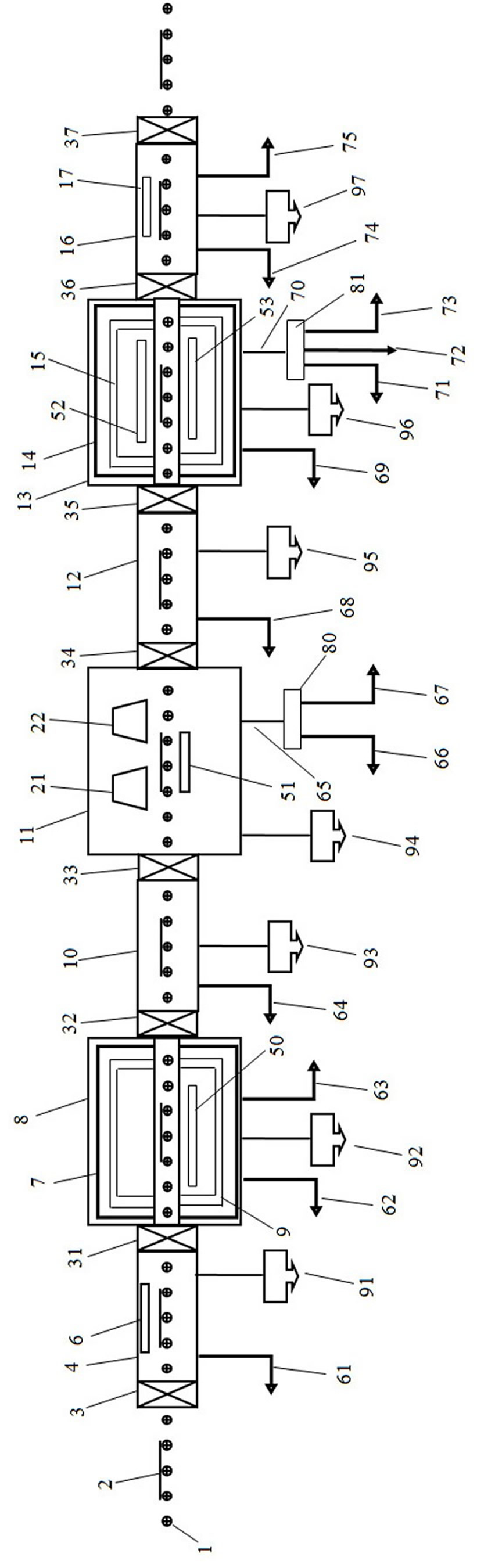

Embodiment 2

[0044] see figure 2 , the equipment for continuously preparing two-dimensional nano-films of the present invention includes that a feed chamber 4, a first processing chamber 8, a first balance chamber 10, a thin film preparation chamber 11, and a second balance chamber are sequentially arranged on the production line 12. The second processing chamber 13 and the discharge chamber 16; the feeding chamber 4 is provided with a valve 3 communicating with the atmosphere, and a valve 31 is arranged between the feeding chamber 4 and the first processing chamber 8, and the first A valve 32 is provided between the processing chamber 8 and the first balance chamber 10, a valve 33 is provided between the first balance chamber 10 and the film preparation chamber 11, and a valve 33 is provided between the film preparation chamber 11 and the second balance chamber 12. A valve 34 is provided between the second balance chamber 12 and the second processing chamber 13, a valve 35 is provided ...

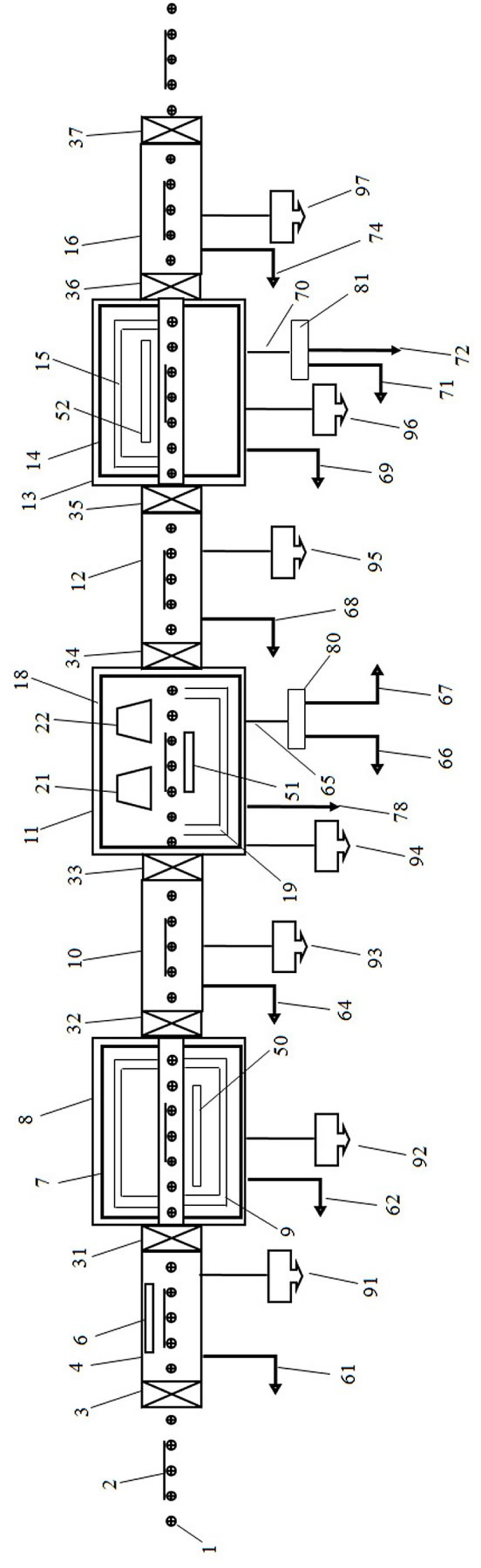

Embodiment 3

[0054] see image 3 , the equipment for continuously preparing two-dimensional nano-films of the present invention includes that a feed chamber 4, a first processing chamber 8, a first balance chamber 10, a thin film preparation chamber 11, and a second balance chamber are sequentially arranged on the production line 12. The second processing chamber 13 and the discharge chamber 16; the feeding chamber 4 is provided with a valve 3 communicating with the atmosphere, and a valve 31 is arranged between the feeding chamber 4 and the first processing chamber 8, and the first A valve 32 is provided between the processing chamber 8 and the first balance chamber 10, a valve 33 is provided between the first balance chamber 10 and the film preparation chamber 11, and a valve 33 is provided between the film preparation chamber 11 and the second balance chamber 12. A valve 34 is provided between the second balance chamber 12 and the second processing chamber 13, a valve 35 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com