Information sensing and storing device and fabrication method thereof

A storage device and sensing technology, applied in the field of sensors and memories with non-volatile characteristics, can solve problems such as increased sensitivity, unfavorable system integration, structural redundancy, etc., to save integrated circuit area, solve large power consumption, reduce The effect of device power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

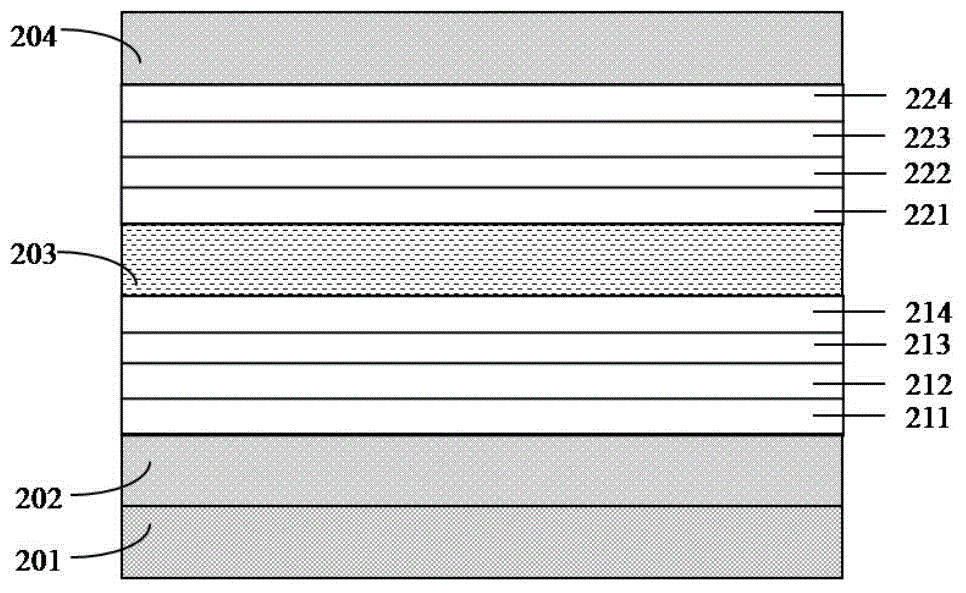

[0058] See image 3 , the present invention comprises a kind of preparation method of information sensing and storage device, and the concrete steps of this method are as follows:

[0059] Step 1, as shown in FIG. 2( a ), a magnetic multilayer film material is deposited on the substrate 201 . As shown in Figure 2(b)-(e), in some embodiments, they are deposited sequentially from bottom to top: bottom electrode 202, pinning layer 211, reference layer 212, oxide barrier layer 213, free layer 214, non-ferromagnetic Metal isolation layer 203 , free layer 221 , oxide barrier layer 222 , reference layer 223 , pinning layer 224 , and top electrode 204 .

[0060] In some embodiments, the reference layers 212, 223 and the free layers 214, 221 include mixed metal materials CoFe, CoFeB or NiFe, and the composition ratio of each element in the mixed metal materials may be different, and the thickness ranges from 0 to 20 nm. The oxide barrier layers 213, 222 include MgO or Al 2 o 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com