Two-dimensional silylene film and preparation method thereof

A silicene and thin film technology, applied in the field of two-dimensional silicene thin film and its preparation, can solve the problems of lack of silicene preparation technology, hindering experimental research progress, lack of silicene preparation technology and characterization technology, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

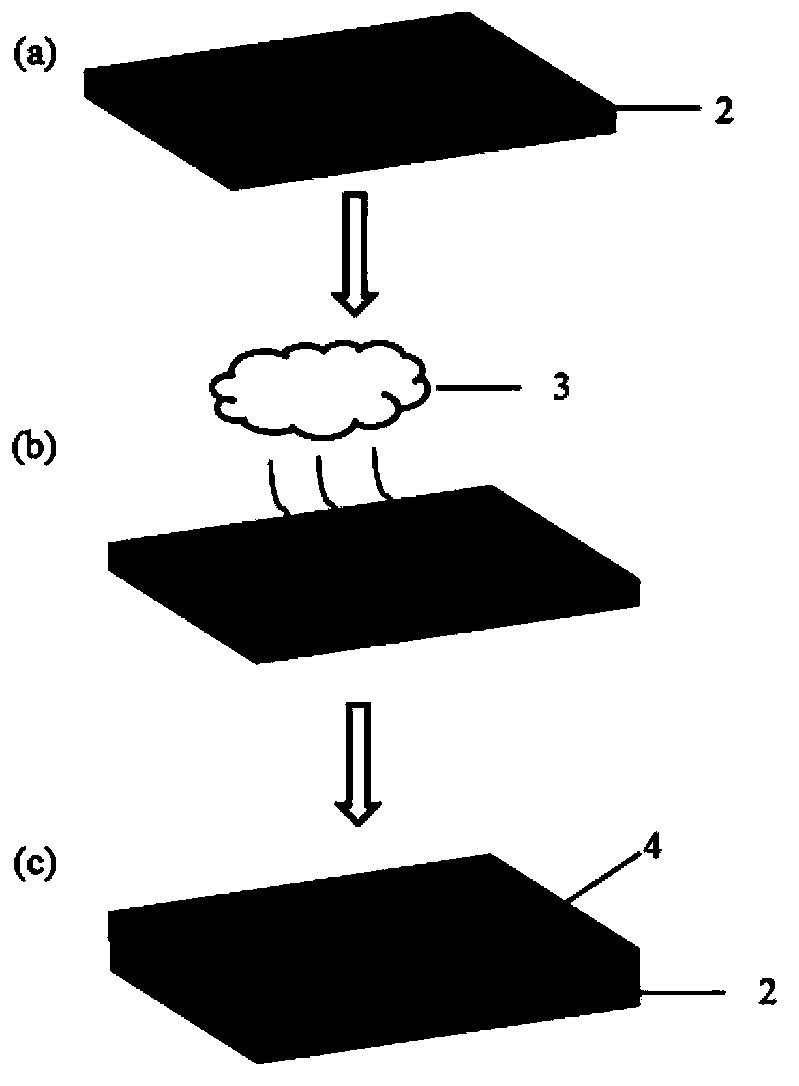

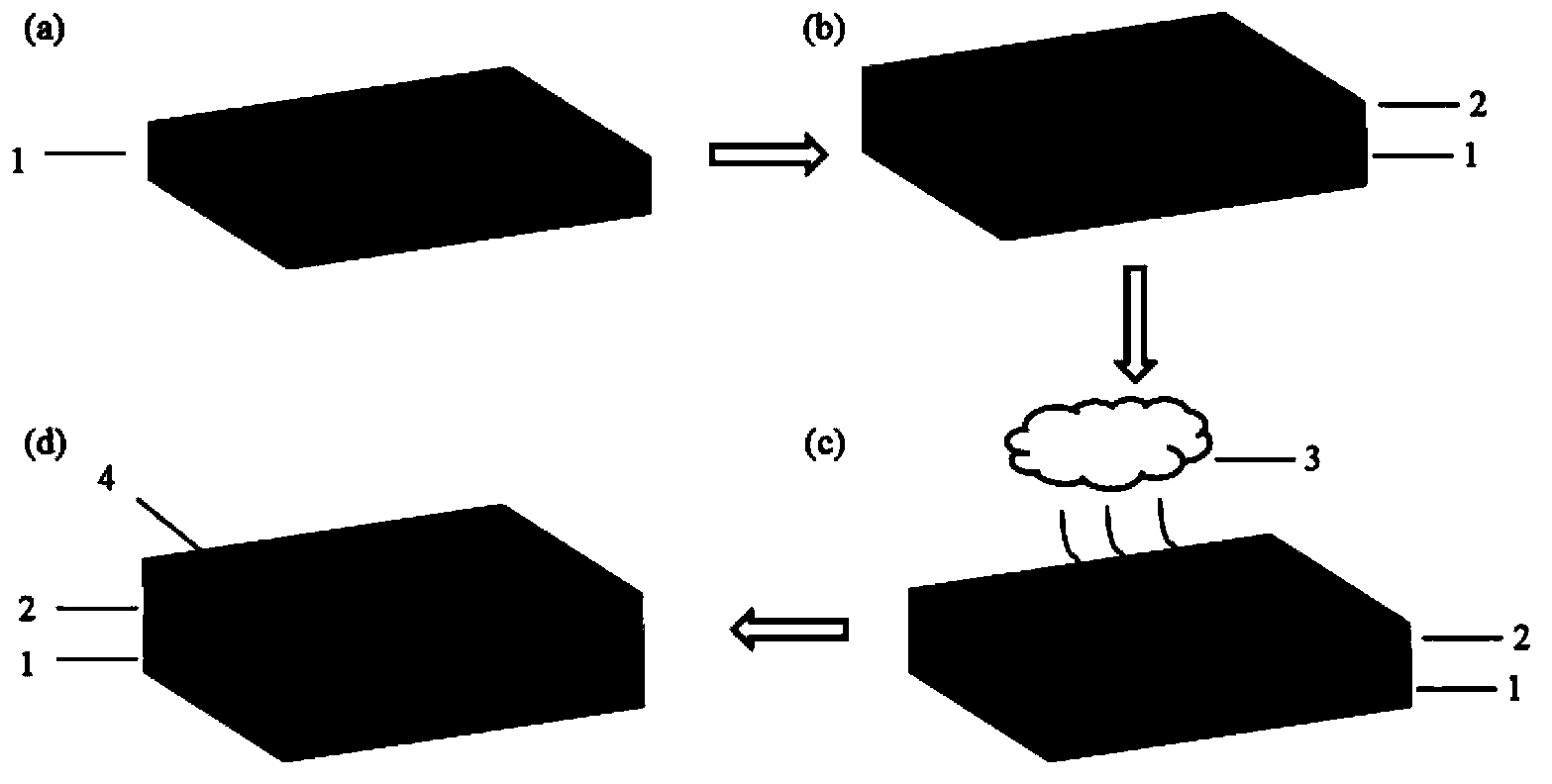

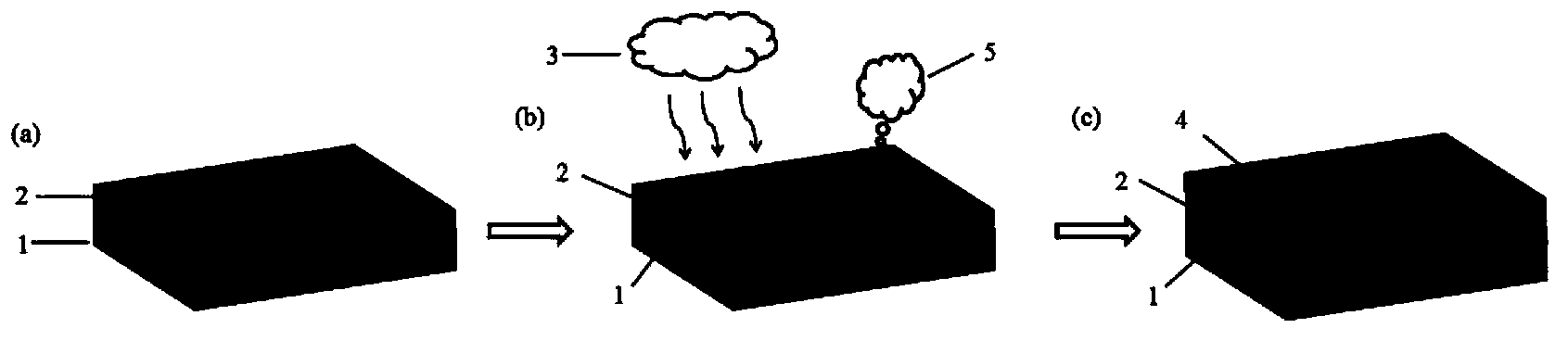

[0039] like figure 1 shown in 1×10 -9 Under the ultra-high vacuum of Pa, heat-treat the SiC catalytic layer with a thickness of 25mm at 1600°C for 10 minutes; then pass it into Ar:H 2 : SiHCl 3 (100sccm: 10sccm: 5sccm), the silicene film was prepared by ultra-high vacuum chemical vapor deposition for 5 minutes; finally, the temperature was lowered to 20°C at a cooling rate of 400°C / min, so that two layers were grown on SiC silicene thin films4.

[0040] In this example, SiC is both the substrate 1 and the catalytic layer 2, SiHCl 3 As the gaseous silicon source 3, a 2-layer silicene film 4 was synthesized.

Embodiment 2

[0042] like figure 1 As shown, for Al with a thickness of 10mm 2 o 3 Plasma treatment was carried out for 5 minutes, and SiH was injected at 240°C by plasma-enhanced CVD 4 (20sccm) and water vapor (10sccm) for 20 minutes to prepare a silicene film, and then lower the temperature to 20°C at a cooling rate of 0.2°C / min to obtain a silicene film 4 with 10 layers.

[0043] In this example, Al with a thickness of 10mm 2 o 3 Both substrate 1 and catalyst layer 2, SiH 4 is the silicon source 3.

Embodiment 3

[0045] like figure 1 As shown, MgO with a thickness of 2 mm was heat-treated at 600 °C for 20 minutes; then, silicene films were prepared at 300 °C by microwave plasma-enhanced CVD: for liquid Si 3 h 8 The silicon source 3 is heated to generate steam, and the generated steam (20 sccm) and Ar (100 sccm) are passed into the silicene film synthesis chamber, the temperature of the catalytic layer is 300 ° C, and the Si is stopped after 20 minutes of growth. 3 h 8 Steam and Ar; modified N 2 And the temperature is lowered to 20° C. at a cooling rate of 80° C. / min, thereby obtaining a silicene thin film 4 with an uneven number of layers (40-50 layers).

[0046] In this example, MgO is both substrate 1 and catalyst layer 2, liquid Si 3 h 6 The steam generated is the silicon source 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com