Device for continuously preparing two-dimensional nano tin films

A two-dimensional nano-film technology, which is applied in the field of equipment for continuous preparation of two-dimensional nano-films, can solve the problems of poor electron transport performance, structural defects, and poor graphene film performance, and achieve large-scale production and application promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

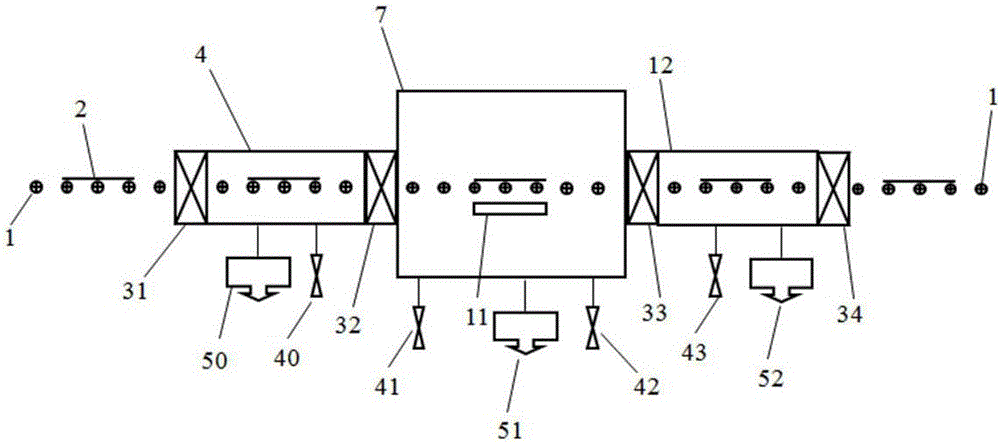

Embodiment 1

[0050] see figure 1 , the equipment for continuously preparing two-dimensional nano-films of the present invention comprises: a feed chamber 4, a sample preparation chamber 7, and a discharge chamber 12; The chambers 12 are all equipped with rollers 1 for transferring samples; the feeding chamber 4 is provided with a valve 31 connected to the atmosphere, and a valve 32 is arranged between the feeding chamber 4 and the sample preparation chamber 7, and the sample preparation chamber 7 is connected to the outlet chamber. A valve 33 is provided between the material chambers 12, and a valve 34 connected to the atmosphere is provided in the discharge chamber 12; the feed chamber 4, the sample preparation chamber 7 and the discharge chamber 12 are connected into a single chamber through rollers and valves. overall.

[0051] A second heating device 11 is provided in the sample preparation chamber 7 .

[0052] The feeding chamber 4 is provided with a vacuum device 50 , the sample p...

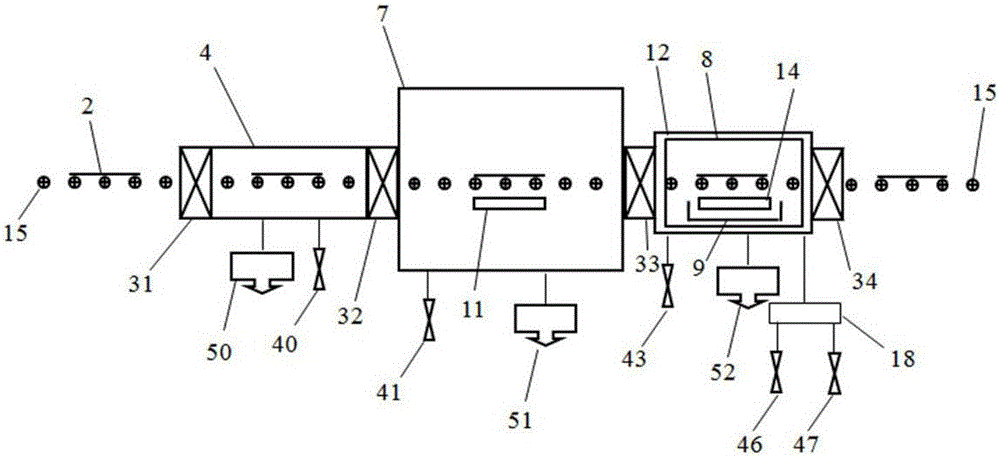

Embodiment 2

[0057] see figure 2 , the equipment for continuously preparing two-dimensional nano-films of the present invention comprises: a feed chamber 4, a sample preparation chamber 7, and a discharge chamber 12; The chambers 12 are all provided with belt pulleys 15 for transferring samples; the feeding chamber 4 is provided with a valve 31 communicating with the atmosphere, a valve 32 is provided between the feeding chamber 4 and the sample preparation chamber 7, and the sample preparation chamber 7 is connected to the outlet chamber. A valve 33 is provided between the material chambers 12, and a valve 34 communicating with the atmosphere is provided in the discharge chamber 12; the feed chamber 4, the sample preparation chamber 7 and the discharge chamber 12 are connected into one by a belt pulley and a valve. overall.

[0058] The sample preparation chamber 7 is provided with a second heating device 11 , and the discharge chamber 12 is provided with a third heating device 14 .

...

Embodiment 3

[0065] see image 3 , the equipment for continuously preparing two-dimensional nano-films of the present invention comprises: a feed chamber 4, a sample preparation chamber 7, and a discharge chamber 12; The chambers 12 are all equipped with rollers 1 for transferring samples; the feeding chamber 4 is provided with a valve 31 connected to the atmosphere, and a valve 32 is arranged between the feeding chamber 4 and the sample preparation chamber 7, and the sample preparation chamber 7 is connected to the outlet chamber. A valve 33 is provided between the material chambers 12, and a valve 34 connected to the atmosphere is provided in the discharge chamber 12; the feed chamber 4, the sample preparation chamber 7 and the discharge chamber 12 are connected into one by rollers and valves. overall.

[0066] The feeding chamber 4 is provided with a first surface processor 5 , the sample preparation chamber 7 is provided with a second heating device 11 , and the discharging chamber 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com