High-thermal-stability battery diaphragm as well as preparation method and application thereof

A technology of high thermal stability and battery diaphragm, which is applied in the direction of batteries, fuel cells, lithium batteries, etc., can solve the problems of poor thermal stability and heat dissipation of battery diaphragms, achieve simple and easy preparation methods, increase transmission speed, and reduce porosity The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a second aspect, the present invention provides a method for preparing a high thermal stability battery separator, comprising the following steps:

[0035] The siloxene is formulated into a slurry with a mass concentration of 2-30%, and then coated on the diaphragm and dried.

[0036] If the mass concentration of siloxene is too high, it is easy to disperse unevenly and agglomerate, which affects the uniformity of its coating on the diaphragm, which not only reduces the stability of the combination of the siloxene coating layer and the diaphragm, but also reduces the thermal stability of the diaphragm , After the separator and other components are assembled into a battery, the cycle performance of the battery will be reduced. If the mass concentration of siloxene is too low, siloxene cannot form a continuous and complete coating layer on the surface of the diaphragm, which will make the siloxene coating layer fall off easily, and the stable physical and chemical inte...

Embodiment 1

[0057] A method for preparing a battery separator with high thermal stability:

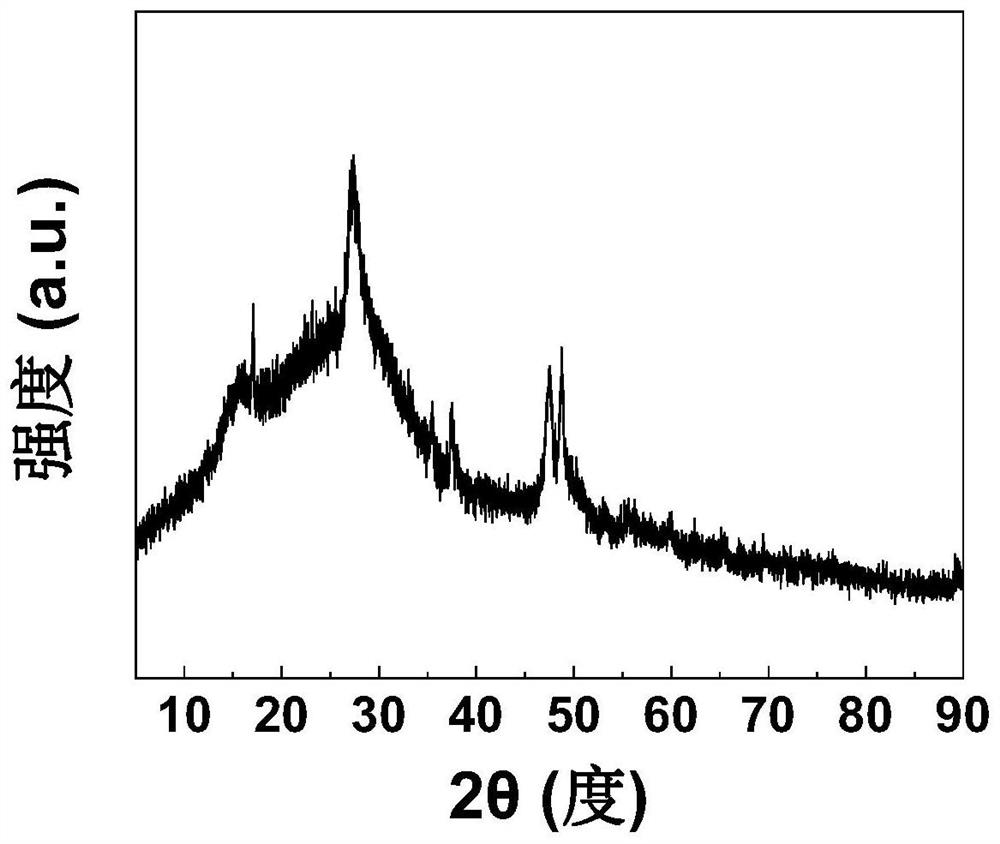

[0058] Take 1.0g of commercial calcium silicide, then in 50mL 5mol L -1 The hydrochloric acid solution was stirred at room temperature (30° C.) for 10 h, and then the obtained solution was washed with deionized water three times, and vacuum-dried at 80° C. for 20 h to obtain siloxene;

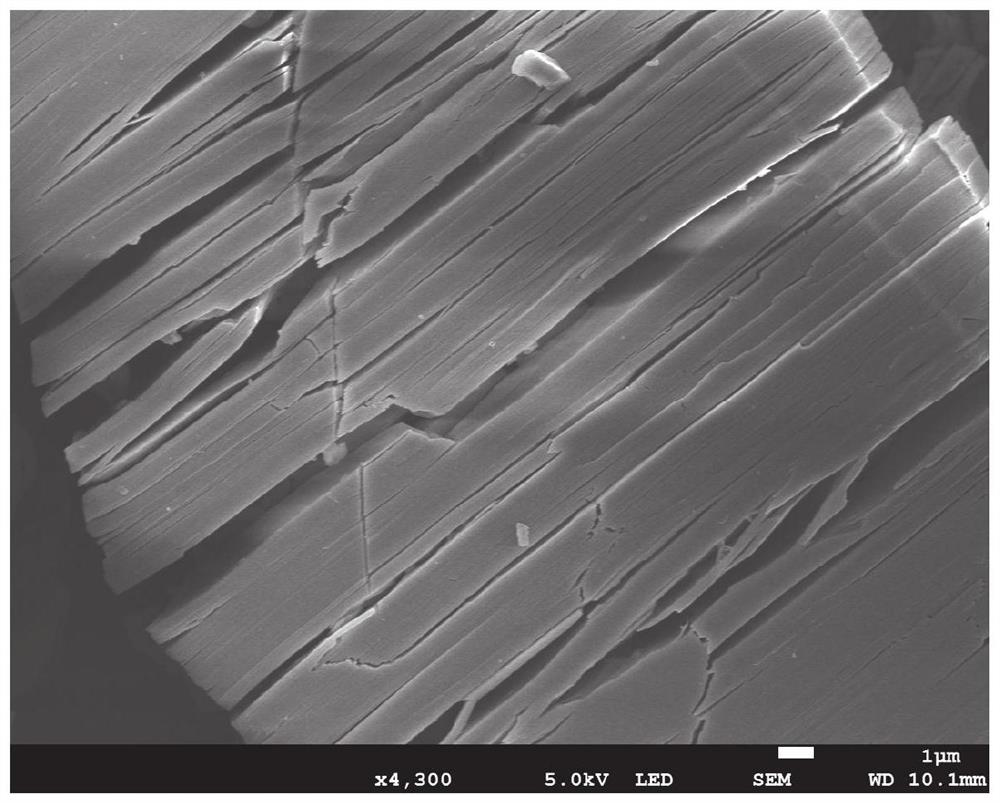

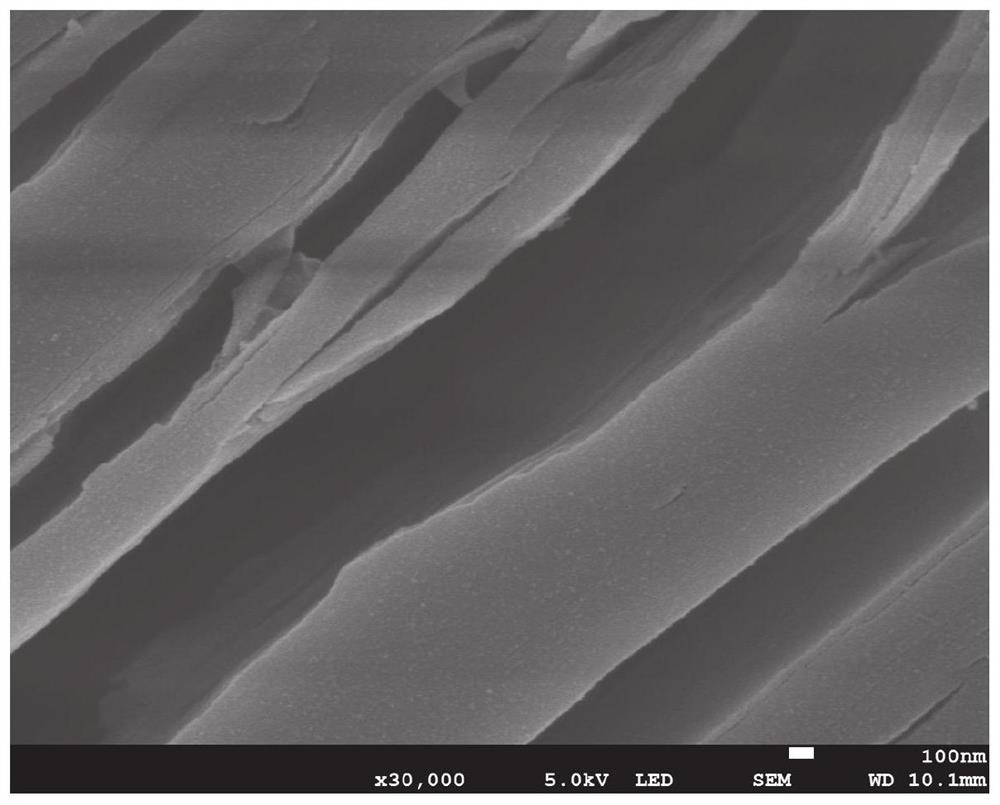

[0059] Take 0.5g of siloxane, add 0.04g of polyvinylidene fluoride in nitrogen methyl pyrrolidone solution, the mass fraction of polyvinylidene fluoride is 6%, stir evenly, and then spray it on the polyethylene diaphragm, after drying A two-dimensional siloxene separator (siloxene-polyethylene film) with a thickness of 30 μm can be obtained.

Embodiment 2

[0061] A method for preparing a battery separator with high thermal stability:

[0062] Take 1.0g of commercial calcium silicide, then use 2mol L -1 The hydrochloric acid solution was treated for 18 hours, and then the obtained solution was washed with deionized water for 3 times, and after vacuum drying at 80°C for 20 hours, siloxene was obtained;

[0063] Take 0.3g of siloxane, add 0.04g of polytetrafluoroethylene in N,N-dimethylformamide solution, the mass fraction of polyvinylidene fluoride is 7%, stir evenly, and then coat it on the diaphragm in a sliding manner. After drying, a two-dimensional siloxane membrane with a thickness of 25 μm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com