Silylene negative electrode plate capable of being directly used for preparing lithium ion battery and preparation and application of silylene negative electrode plate

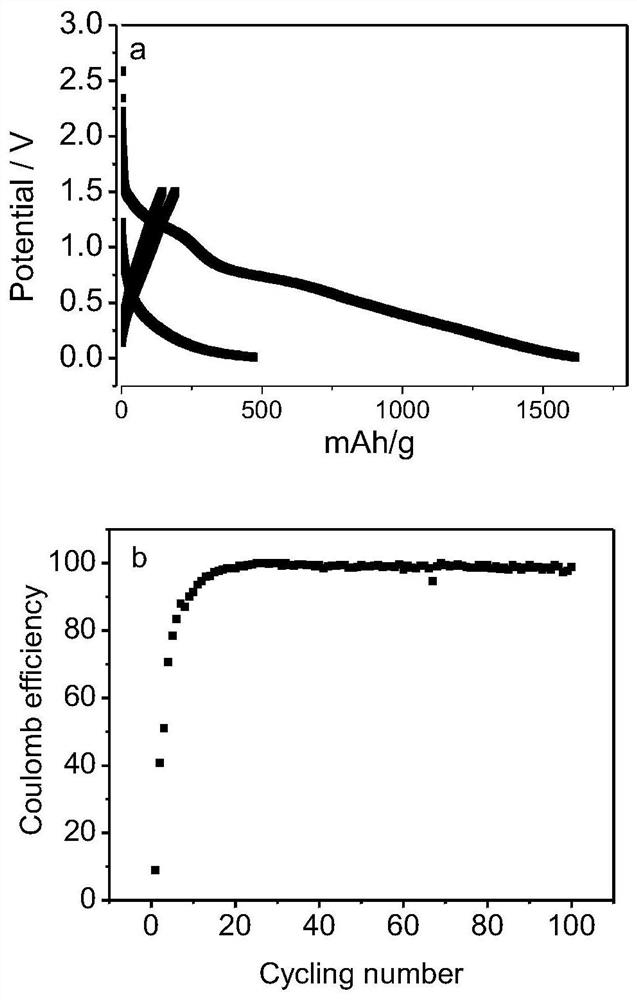

A technology for lithium-ion batteries and negative plates, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of long reaction time of silicene, low product quality, and low yield of silicene, and avoid high-temperature and high-vacuum reactions Conditions, high process safety, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

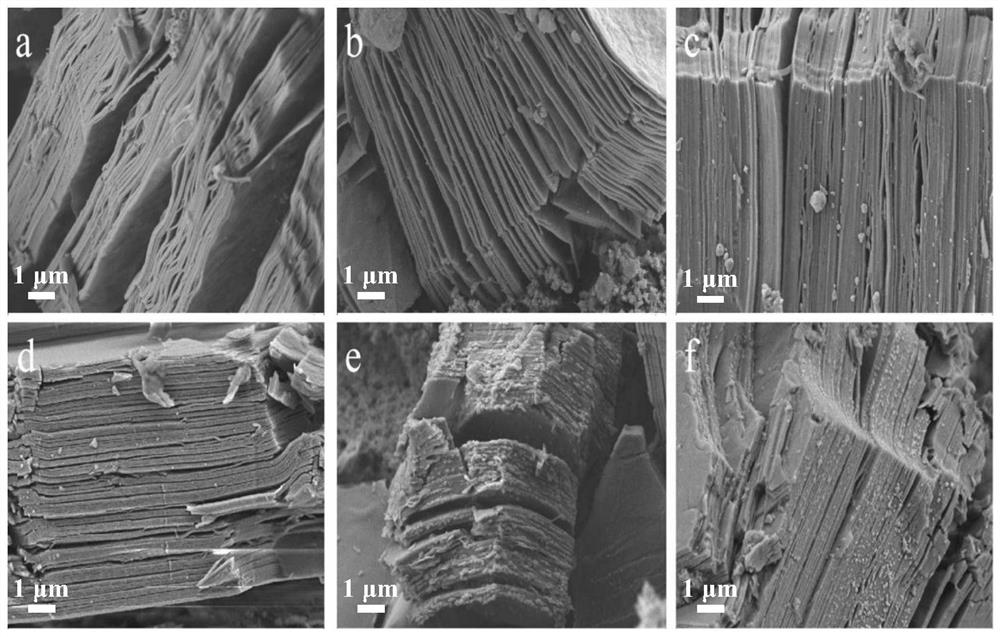

[0037] (1) Preparation of electrode foil: CaSi 2 , conductive carbon black, and polyvinylidene fluoride are mixed and dispersed in N-methylpyrrolidone at a mass ratio of 7:2:1, ultrasonicated at room temperature for 1 hour, stirred for 3 hours to form a uniform slurry, and the slurry is coated on copper foil On, vacuum drying to remove solvent to prepare electrode foil;

[0038] (2) Construction of the electrochemical reaction cell: use platinum wire as the cathode or anode, insert the platinum wire into the electrolyte of the reaction cell, use the electrode foil prepared in step (1) as the anode or cathode, and place the electrode foil on the reaction cell. Between the pool and the base, the electrolyte is a mixture of hydrochloric acid: ethanol = 1:10 (v / v) to construct an electrochemical reaction cell; the concentration of HCl in the hydrochloric acid is 37wt%;

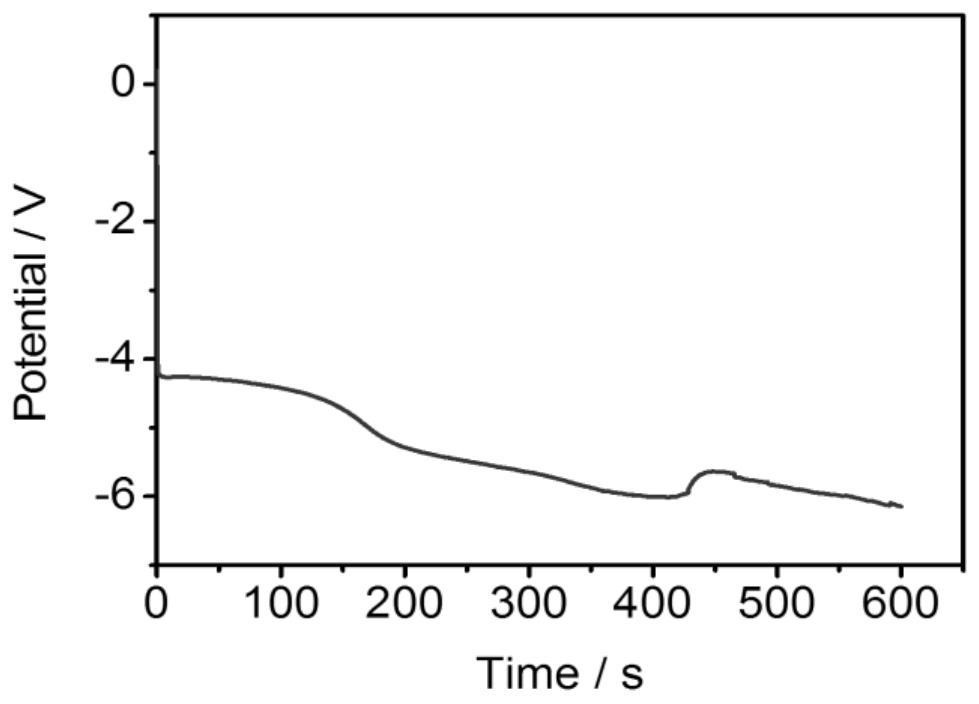

[0039] (3) Carrying out the electrochemical reaction: on the electrochemical workstation, set the current dens...

Embodiment 2

[0041] The difference with Example 1 is only that the reaction time of step (3) is 10min, all the other steps and conditions are the same, and the scanning electron micrograph of the prepared silicene is as follows figure 2 as shown in b.

Embodiment 3

[0043] The only difference from Example 1 is that the current collector in step (1) uses carbon-coated copper foil, and the current density in step (3) is 50mA / cm 2 , the rest of the steps and conditions are the same, the scanning electron micrograph of the prepared silicene is as follows figure 2 as shown in c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com