Preparation method of silicon carbene and method for preparing hydrogen by photodecomposition of water vapor

A silicene and photolysis technology, applied in the semiconductor field, can solve the problems of disordered charge, system collapse, low water splitting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

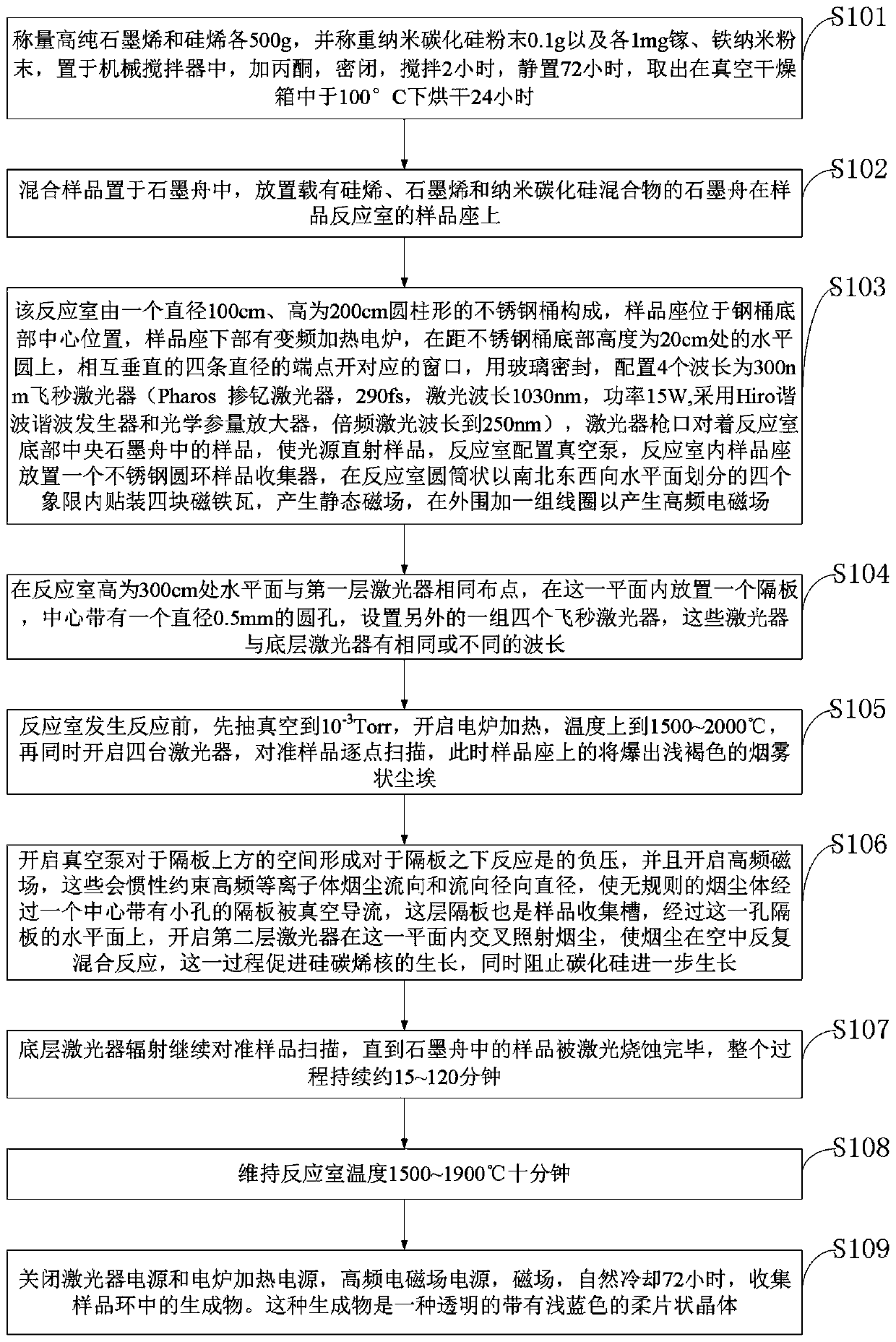

[0056] Such as figure 1 As shown, the preparation method of silicene provided in the embodiment of the present invention includes the following steps:

[0057] S101: Weigh 500g of high-purity graphene and silicene, and weigh 0.1g of nano-silicon carbide powder and 1mg of gallium and iron nano-powder, place in a mechanical stirrer, add acetone, airtight, stir for 2 hours, and let stand After 72 hours, take it out and dry it in a vacuum oven at 100° C. for 24 hours.

[0058] S102: The mixed sample is placed in a graphite boat, and the graphite boat loaded with a mixture of silicene, graphene and nano-silicon carbide is placed on the sample seat of the sample reaction chamber.

[0059] S103: The reaction chamber is composed of a cylindrical stainless steel barrel with a diameter of 100 cm and a height of 200 cm. The sample seat is located at the center of the bottom of the steel barrel. There is a frequency conversion heating furnace at the bottom of the sample seat, on a horizo...

Embodiment 1

[0088] Deposit a cobalt-iron alloy layer on the surface of silicon carbene particles by photodeposition to obtain cobalt-iron-silicon carbene nanoparticles with a mass fraction of 0.05-2.0% of the cobalt-iron alloy layer, and then soak the Co-Fe-silicon carbene nanoparticles in 0.05- 0.5mmol / L dye-methanol solution, put it in a dark place for 48-72 hours, filter it, rinse it with deionized water 5-10 times, place it in a vacuum drying oven, and dry it at 80-200°C for 12-24 hours. Dye-sensitized Co-Fe-siliconene nanoparticles were obtained. Dye-sensitized Co-Fe-silicon carbene nanoparticles (0.002-0.005 g) are added to a 150 ml volume concentration of 10-20% triethanolamine (TEOA) or methanol and triethanolamine aqueous solution reactor, The volume of the solution is 10-30ml, the sample solution is ultrasonically sonicated for 5-30 minutes, and the argon gas is passed for 10-60 minutes, so far a uniform Co-Fe-silicon carbene nanoparticle colloidal suspension without oxygen is o...

Embodiment 3

[0096] The doped preparation of silicene can be obtained by the following steps,

[0097] 1) Weigh 10g of self-made silicon carbene, divided into 2g, 2g, 2G, 2g and 2g;

[0098] 2) Implanting Cr, Fe, Ru, La and Yb into these 5 samples of the same weight by ion implantation method to obtain five kinds of doped silicene materials. The doping amount of these elements is maintained at 10 16 cm 3 . no more than 10 18 cm 3 .

[0099] 3) Experiments of photocatalytic water splitting to generate hydrogen were carried out with these five doped silicene materials.

[0100] 4) Weigh 2-5 mg of these 5 kinds of samples respectively, each kind has 30 samples, and carry out the test of photocatalytic water splitting to generate hydrogen. The data shows that La, Ru, Fe, and Yb show high hydrogen production rate, while Cr shows the effect of hydrogen production, but the hydrogen production rate is much lower than the first four.

[0101] Table 3 Effects of photocatalytic water splittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com