Graphene cladded silylene as well as preparation method and application method thereof

A technology of ene-coated silicene and graphene, which is applied in the field of silicene preparation, can solve problems such as high cost, enlarged unit cell, and reduced symmetry, and achieve the effect of loose preparation conditions and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

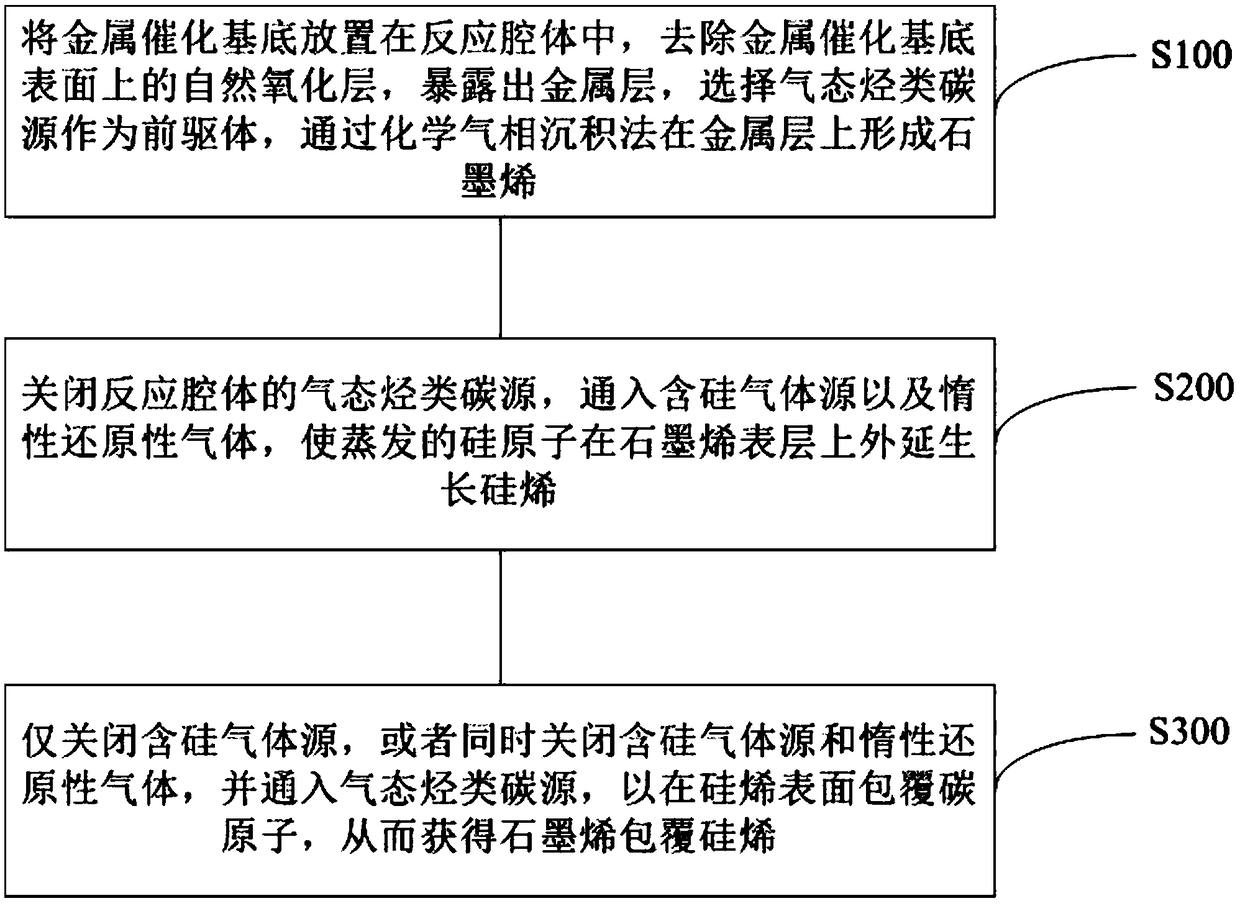

[0040] figure 1 A schematic flowchart of a method for preparing graphene-coated silicene according to an embodiment of the present invention is shown. Such as figure 1 Shown, this preparation method comprises the steps:

[0041] S100, placing the metal catalytic substrate in the reaction chamber, removing the natural oxide layer on the surface of the metal catalytic substrate, exposing the metal layer, selecting a gaseous hydrocarbon carbon source as a precursor, and forming graphite on the metal layer by chemical vapor deposition alkene;

[0042] S200, closing the gaseous hydrocarbon carbon source in the reaction chamber, introducing a silicon-containing gas source and a reducing gas, so that the evaporated silicon atoms epitaxially grow silicene on the graphene surface;

[0043] S300. Turn off only the silicon-containing gas source, or simultaneously turn off the silicon-containing gas source and the reducing gas, and feed a gaseous hydrocarbon carbon source to coat carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com