Lithium battery negative electrode material containing pre-lithiated silylene material, preparation method and lithium battery

A technology of pre-lithiated silicene and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low first-time cycle efficiency and volume expansion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

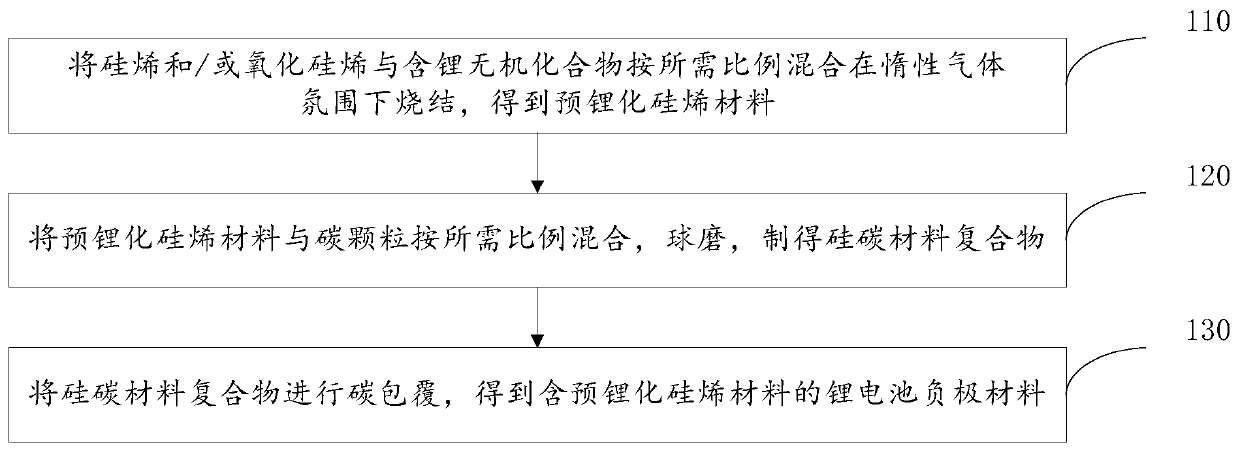

Method used

Image

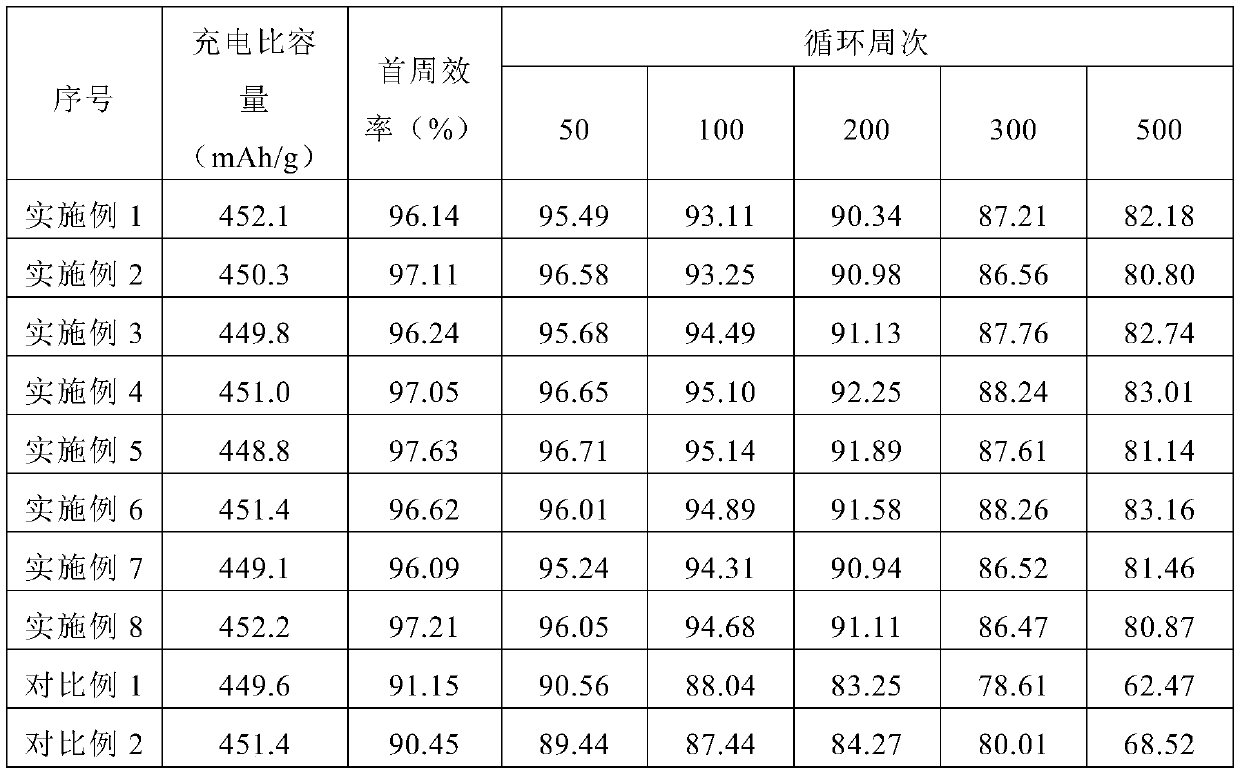

Examples

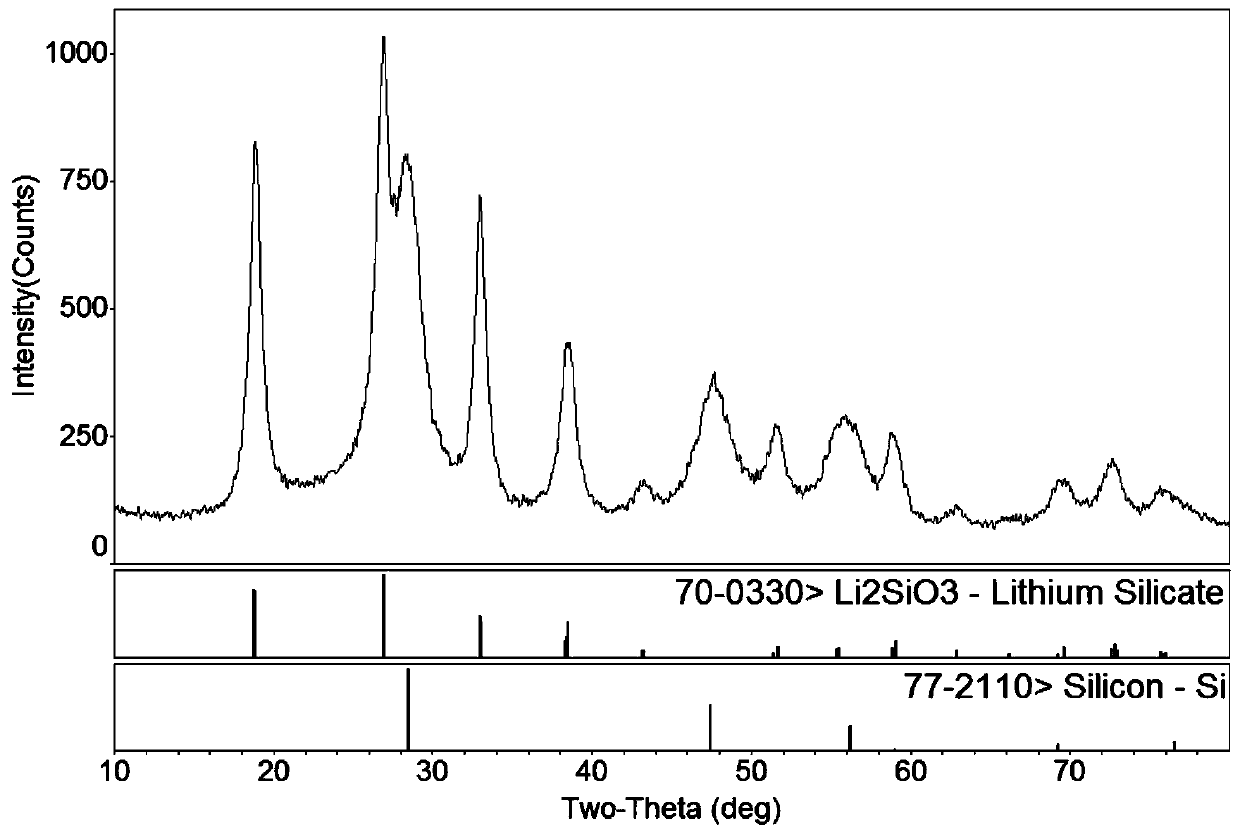

Embodiment 1

[0058] The silicon oxide sample and lithium carbonate powder were mixed according to the mass ratio of 6:1, and sintered in the argon protective atmosphere in the rotary furnace. The furnace tube speed was 10r / min, and the heating rate was 2°C / min. After 2 hours, the pre-lithiated siloxane material was obtained; the pre-lithiated siloxane material and natural graphite were added to a planetary ball mill in a mass ratio of 1:1, and ball milled and mixed at a speed of 250r / min for 1h. Obtain a silicon-carbon composite material; mix the above-mentioned silicon-carbon composite material with pitch at a mass ratio of 9:1, enter a rotary furnace under the protection of an argon atmosphere for pyrolysis coating of an organic carbon source, the furnace tube speed is 10r / min, and the heating rate is 2 °C / min, holding time at 900 °C for 2 hours, naturally cooling to room temperature, and sieving to obtain the negative electrode material containing pre-lithiated siloxane.

[0059] In the...

Embodiment 2

[0066] Mix the silicene sample and lithium carbonate powder at a mass ratio of 5:1, sinter in a rotary furnace under an argon protective atmosphere, the furnace tube speed is 10r / min, the heating rate is 2°C / min, the temperature is raised to 800°C, and the holding time is 30min , to obtain a pre-lithiated silicene material; the pre-lithiated silicene material and artificial graphite are added to a planetary ball mill in a mass ratio of 1:2 for ball milling and mixing at a speed of 150r / min for 2 hours to obtain a silicon-carbon composite Materials: the above-mentioned silicon-carbon composite material is heated to 800°C under the protection of argon atmosphere, and acetylene is passed through 800°C for carbon source gas gas phase coating, the furnace tube speed is 10r / min, the heating rate is 2°C / min, and the holding time is 800°C After 2 hours, it was naturally cooled to room temperature, and sieved to obtain a negative electrode material containing pre-lithiated silicene.

...

Embodiment 3

[0069] Mix silene oxide and lithium hydroxide powder at a mass ratio of 5.2:1, and sinter in a rotary furnace under an argon protective atmosphere. After 12 hours, the pre-lithiated siloxane material was obtained; the pre-lithiated siloxane material and the mesophase carbon microspheres were added to a planetary ball mill in a mass ratio of 1:1.2 for ball milling and mixing at a speed of 500r / min. The time is 30 minutes to obtain the silicon-carbon composite material; the above-mentioned silicon-carbon composite material is heated to 600°C under the protection of argon atmosphere, and acetylene is passed through acetylene at 600°C for carbon source gas vapor phase coating, the furnace tube speed is 10r / min, and the heating rate is 2°C / min, holding time at 600°C for 12 hours, naturally cooling to room temperature, and sieving to obtain the negative electrode material containing pre-lithiated siloxane.

[0070] The above-mentioned negative electrode material containing pre-lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com