Active anode active material, preparation method thereof and lithium ion battery

A technology of negative electrode active material and silicon material, which can be used in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., and can solve the problems of unsatisfactory cycle performance of silicon negative electrode active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention simultaneously provides a preparation method for the above-mentioned negative electrode active material, the steps comprising:

[0022] S1, mix the solution containing the tin source with the solution containing the phosphorus source to react to obtain a suspension solution; mixing the present invention is not limited, for example, the tin source can be first configured as a solution containing the tin source, and the solution containing the tin source can be tin The aqueous solution of the source and water configuration, the phosphorus source is configured as a solution containing the phosphorus source, the solution containing the phosphorus source can be an aqueous solution of the phosphorus source and water configuration, and then their aqueous solutions are directly mixed, or the aqueous solution of the tin source is added to the phosphorus In the aqueous solution of the source, it can be stirred to make it react evenly. In the present inventio...

Embodiment 1

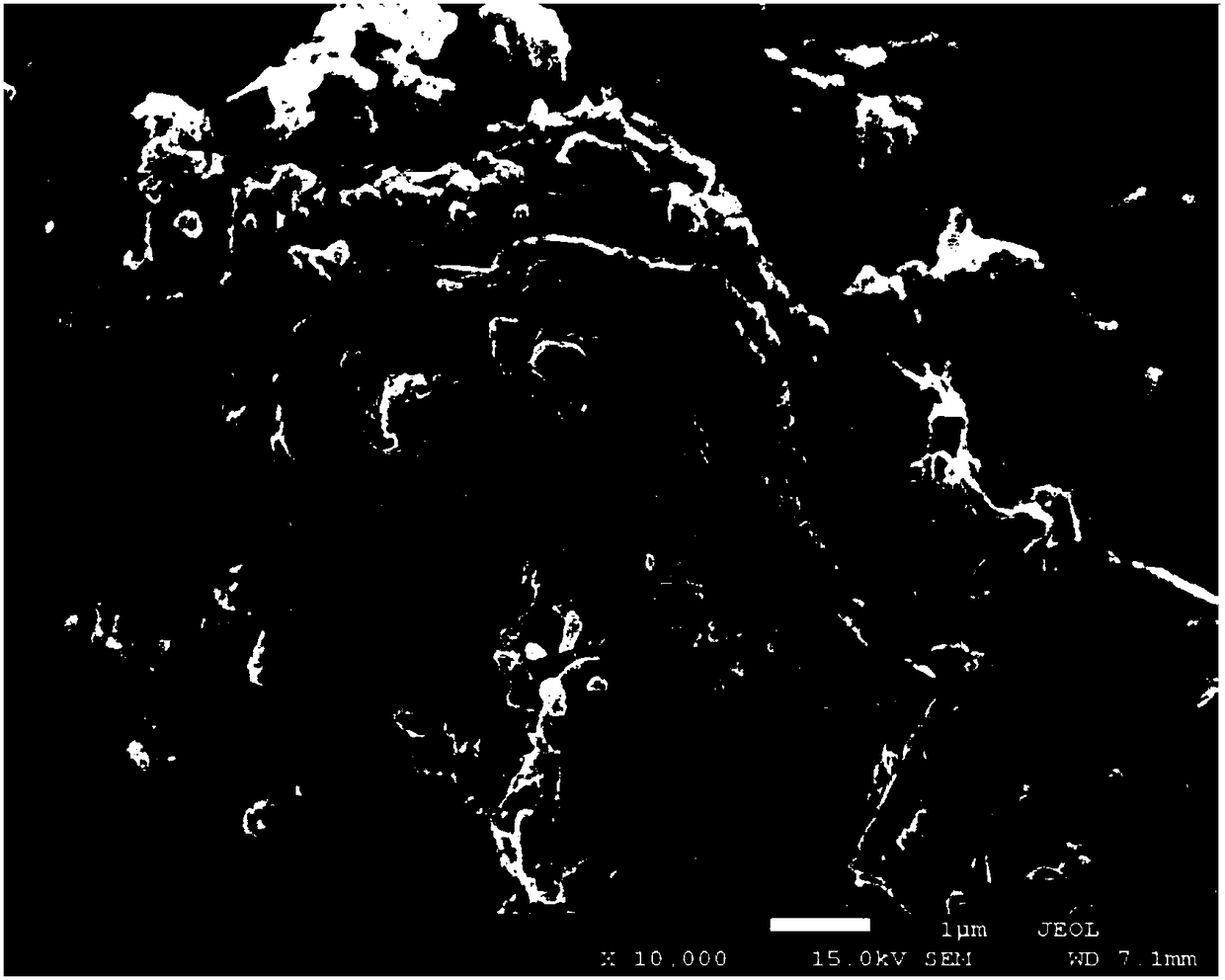

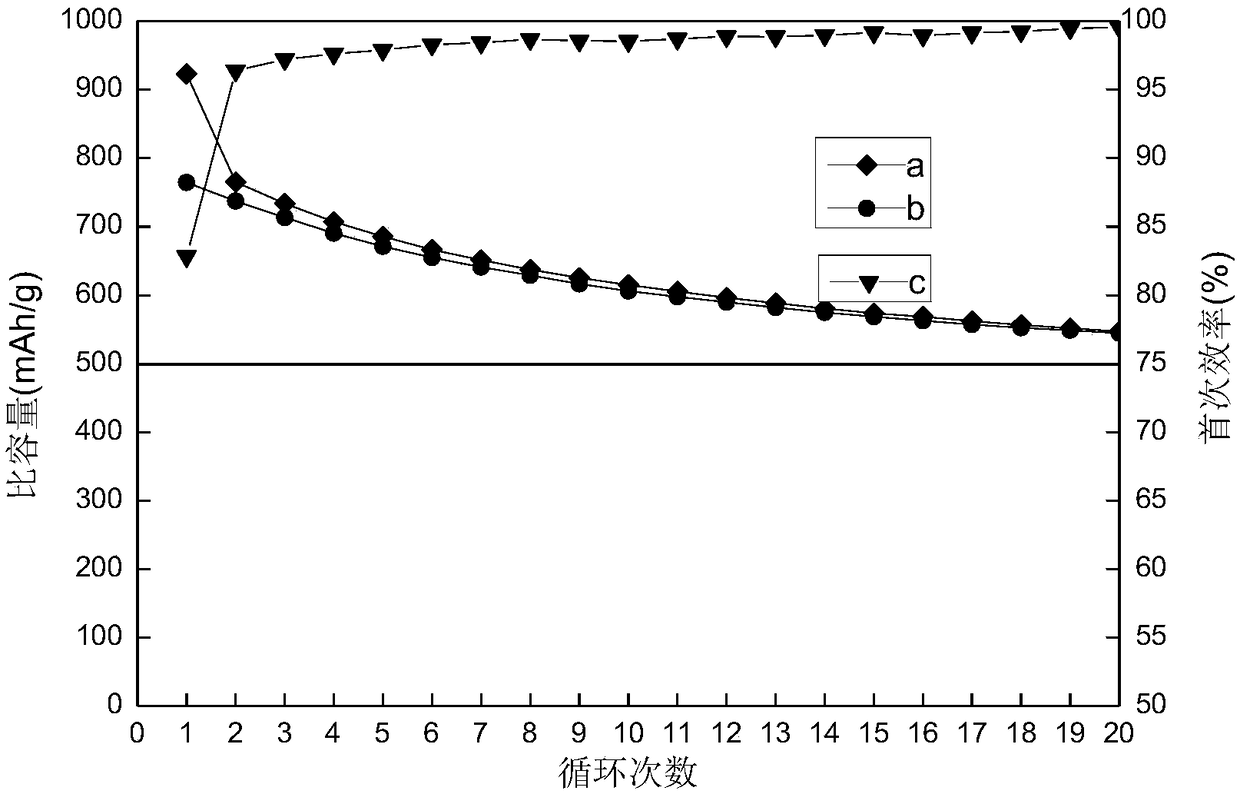

[0037] 4.51g of stannous chloride with 2 crystal waters is dissolved in 40ml of deionized water to form solution A, 1.85g of diammonium hydrogen phosphate is dissolved in 40ml of deionized water to form solution B, and 8g of glucose Dissolve in 40ml of deionized water to form solution C, and then add solution B dropwise to solution A under stirring conditions to form a white suspension solution. After the addition is completed, disperse 16.5g of nano-silicon in the white suspension solution and continue Stir, add solution C to the suspension solution that has been added with nano-silicon. The above reactions are all carried out in a water bath at 60°C. Finally, use ammonia water to adjust the pH value to 4.2; stir for 4 hours and stop stirring when the deionized water evaporates to half , put the product into an oven at 60° C. for drying treatment. After drying, transfer it to a tube furnace with argon gas, raise the temperature to 650°C for 4 hours at a rate of 5°C / min, and t...

Embodiment 2

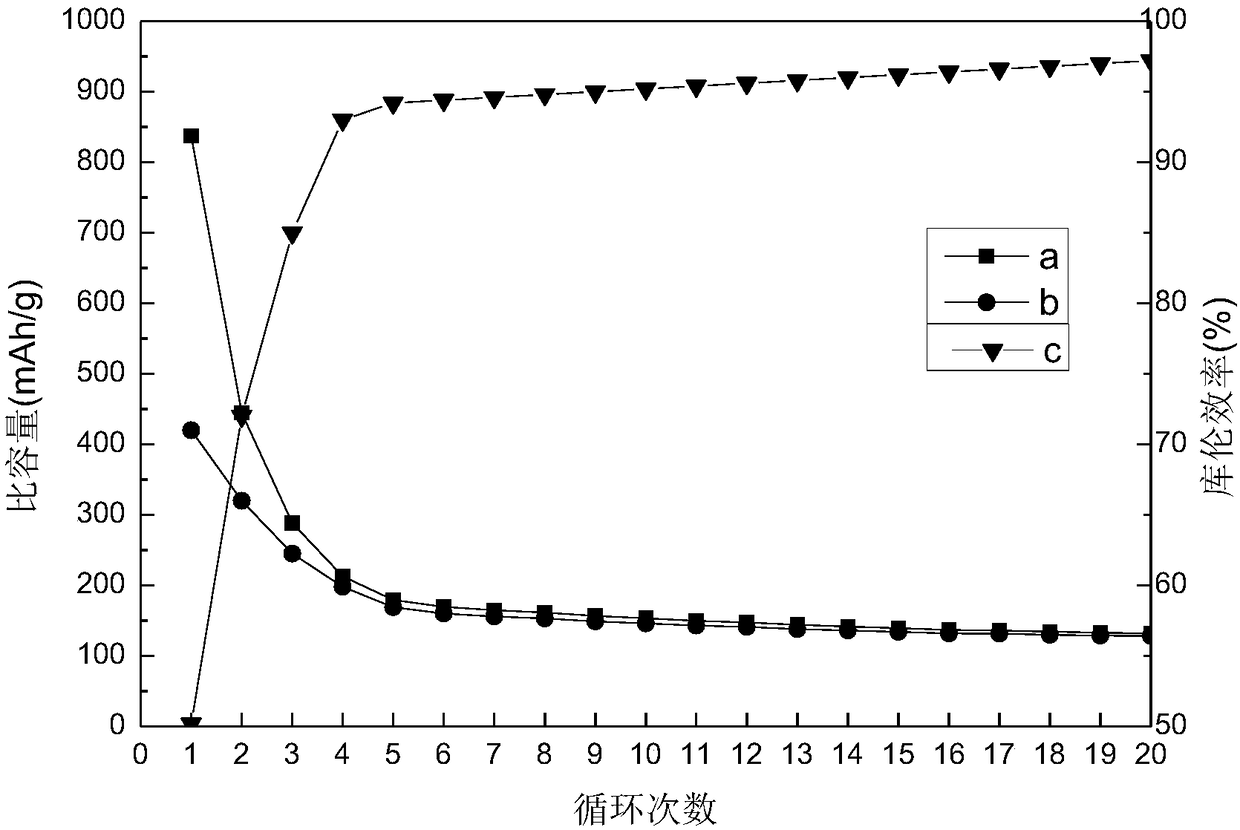

[0040]Dissolve 4.3g of stannous sulfate in 30ml of deionized water to form solution A, dissolve 2.3g of diammonium hydrogen phosphate in 60ml of deionized water to form solution B, and dissolve 6g of citric acid in 30ml of deionized water to form Solution C: Add solution B dropwise to solution A under stirring conditions to form a white suspension solution. After the addition is completed, disperse 16g of nano-silicon and 4g of silicon monoxide in the white suspension solution and continue stirring. Solution C Add to the above suspension solution, the above reaction is carried out in a water bath at 80°C, and then use ammonia water to adjust the pH value to 6.8; stir for 2 hours and stop stirring when the deionized water evaporates to half, and put the product in a 100°C vacuum drying Drying in box. After drying, transfer it to a tube furnace with nitrogen, raise the temperature to 600°C at a rate of 3°C / min and keep it warm for 5 hours, then cool down naturally to obtain a na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com