Method for manufacturing ultra-high temperature long-service life nickel-hydrogen batteries

A nickel-metal hydride battery, long-life technology, applied in the direction of nickel storage batteries, secondary batteries, battery electrodes, etc., can solve the problems of high cost, poor floating charge resistance, low high temperature efficiency, etc., to control the occurrence of side reactions and ensure durability The effect of using and discharging for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

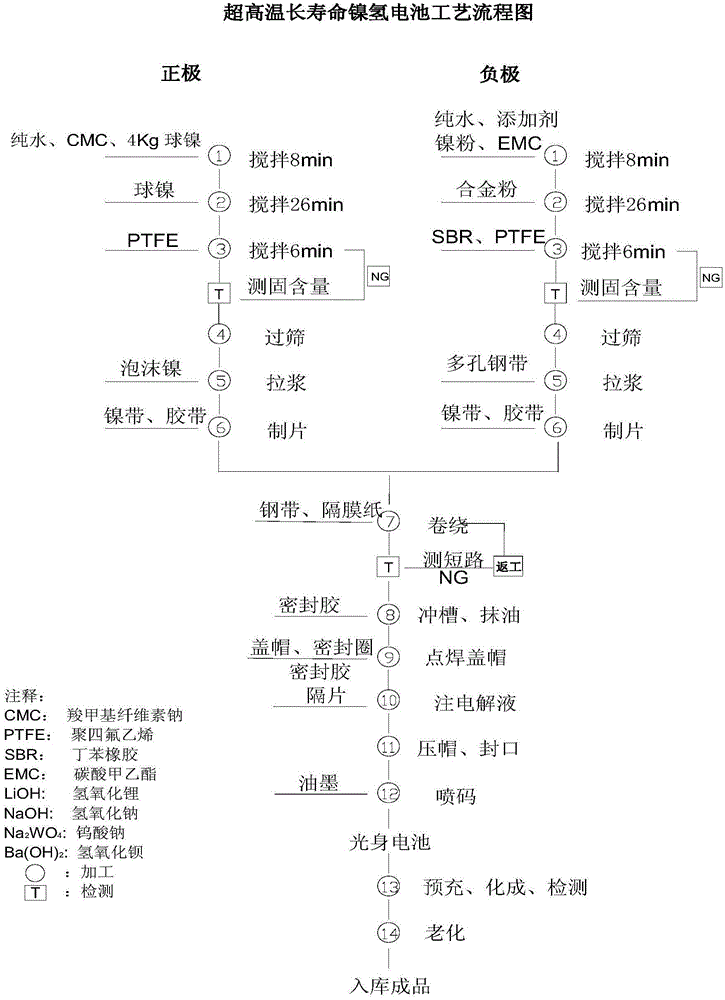

[0038] Such as figure 1 As shown, the invention discloses a method for manufacturing an ultra-high temperature long-life Ni-MH battery, comprising:

[0039] Making the positive electrode sheet includes the following steps:

[0040] ① Stir 7.14kg of pure water, 3.76kg of CMC and 4kg of spherical nickel for 7-9 minutes;

[0041] ②Add 33.60kg spherical nickel and stir for 24-28 minutes;

[0042] ③ Add 1.50kg PTFE and stir for 5-7 minutes to obtain qualified solid content slurry;

[0043] ④ sieving;

[0044] ⑤ Paddle pulling, the solid content slurry is pulled and baked through the nickel foam matrix;

[0045] ⑥ Sheet production, cutting the positive electrode substrate into the size of each process model, cleaning the powder, spot welding the tab (nickel sheet), and pasting the tape to complete the positive electrode sheet production process.

[0046] Making the negative electrode sheet includes the following steps:

[0047] ① Stir 1.17kg of pure water, 1.02kg of nickel pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com