Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

967results about "Alkaline accumulators manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

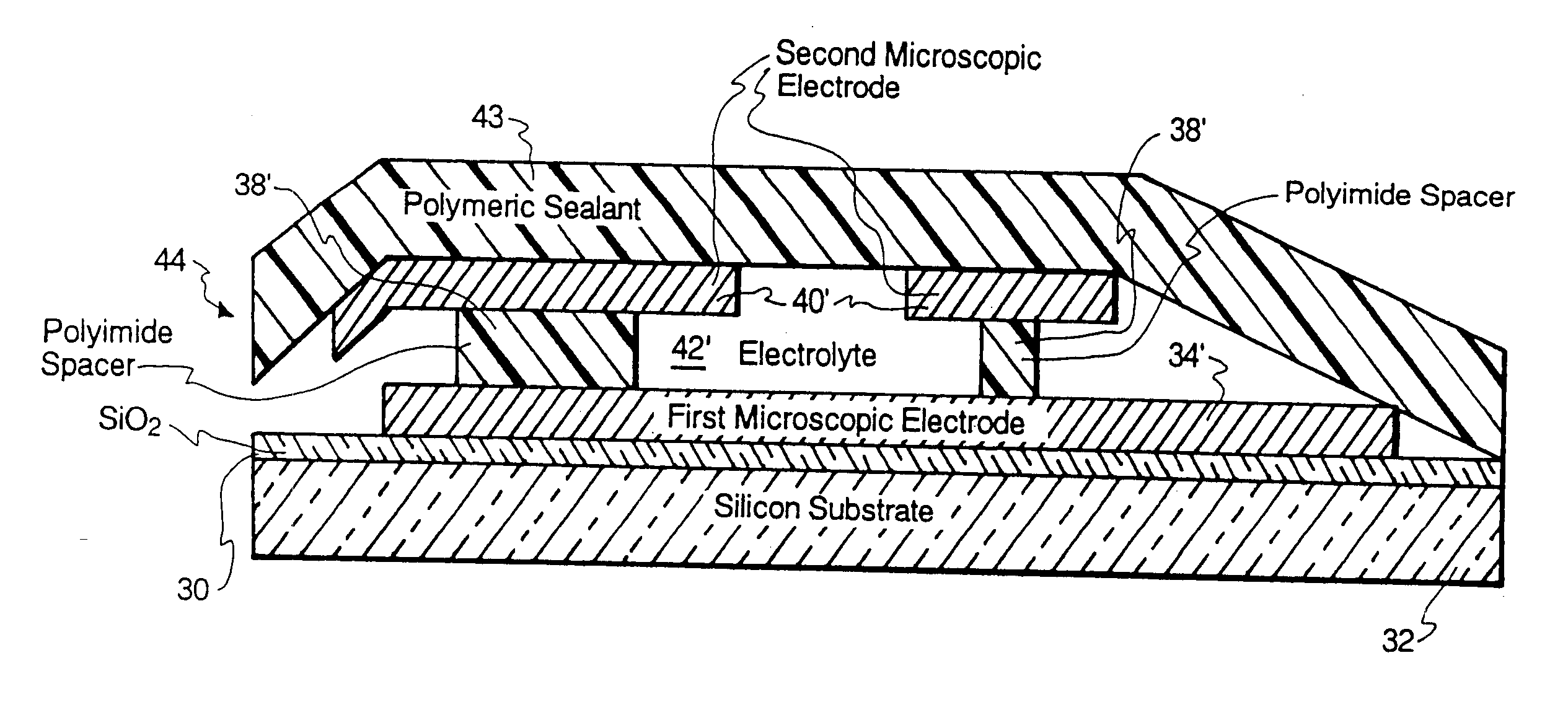

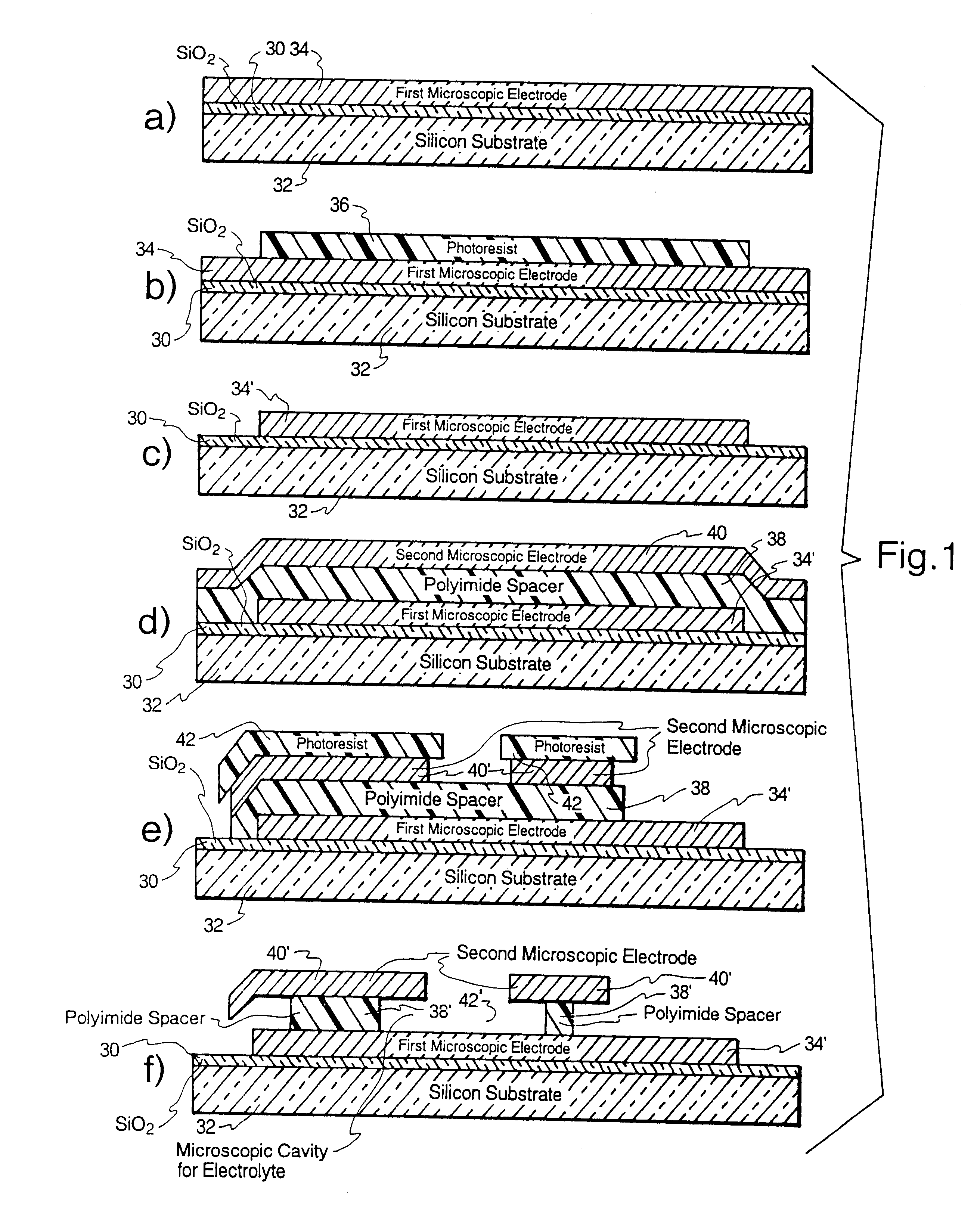

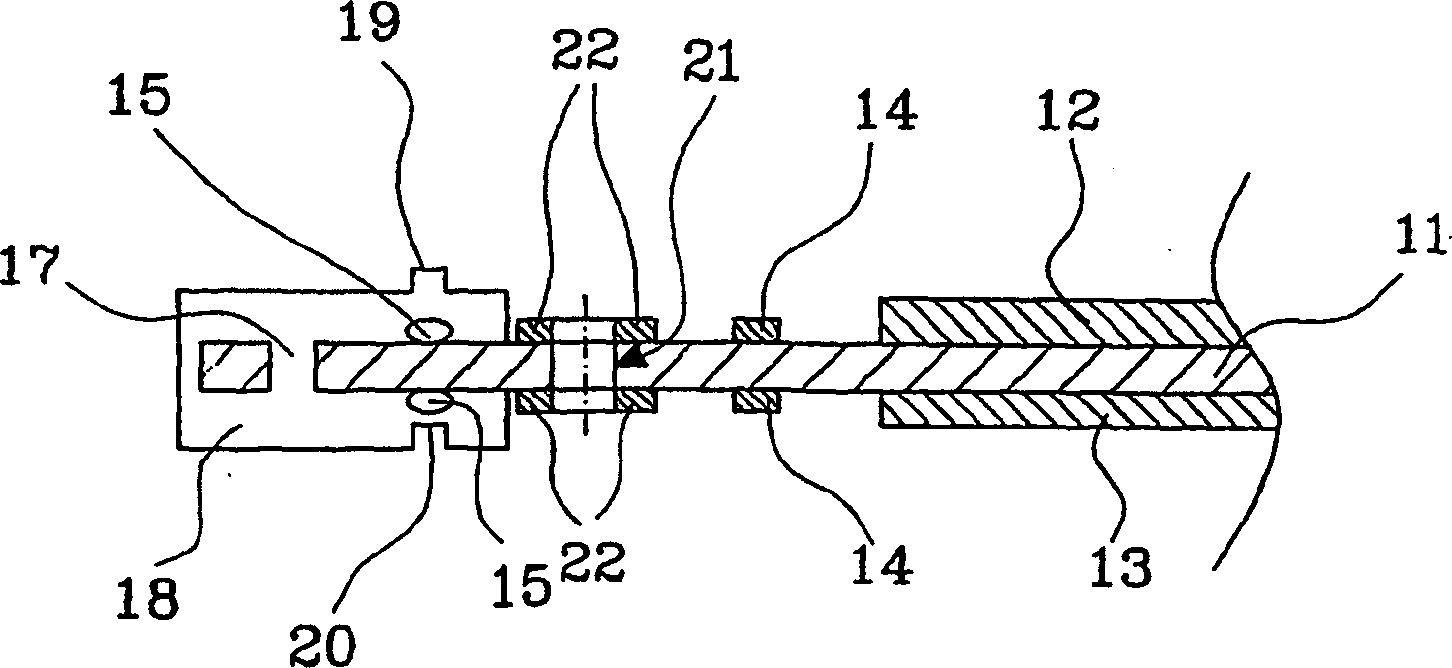

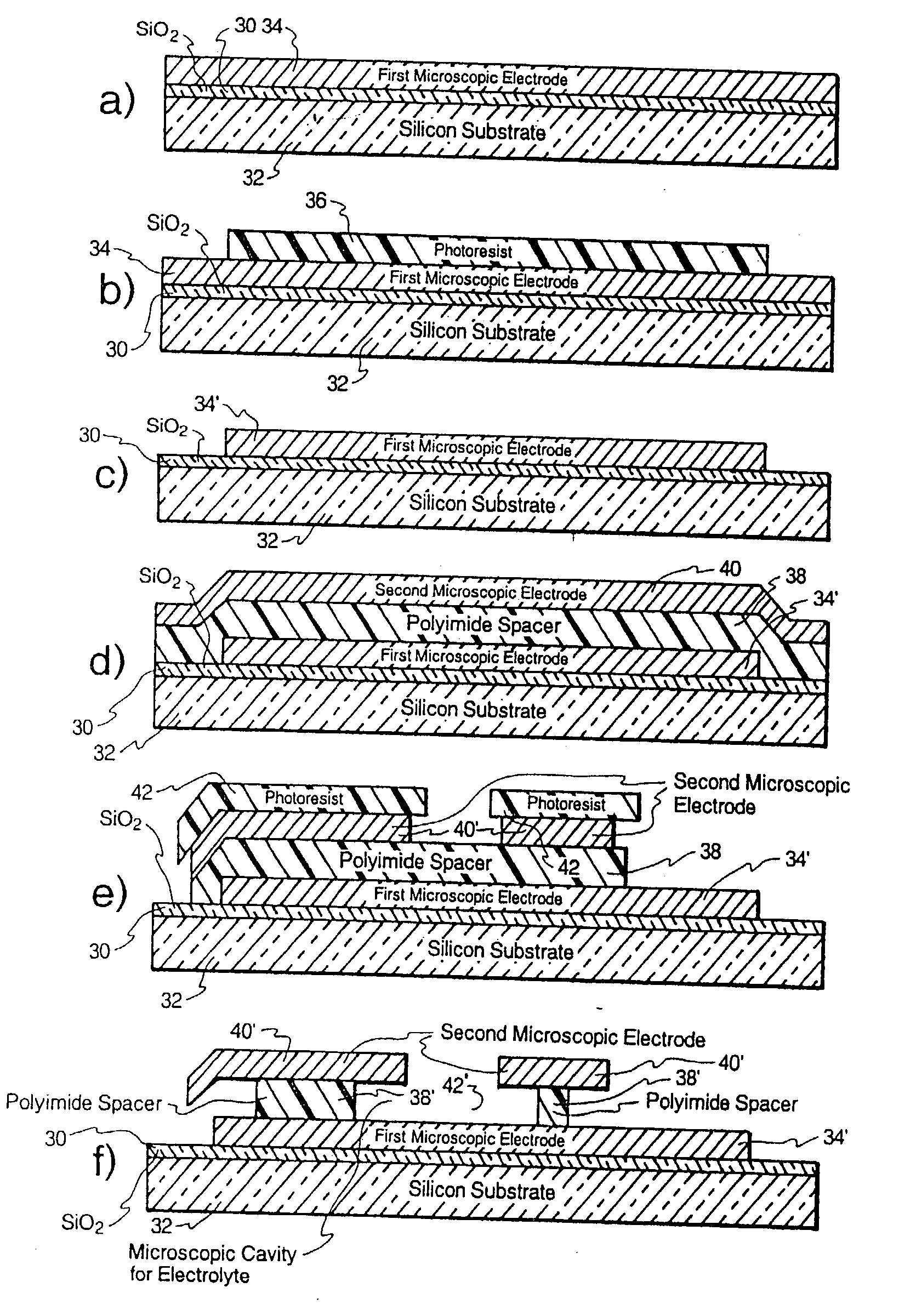

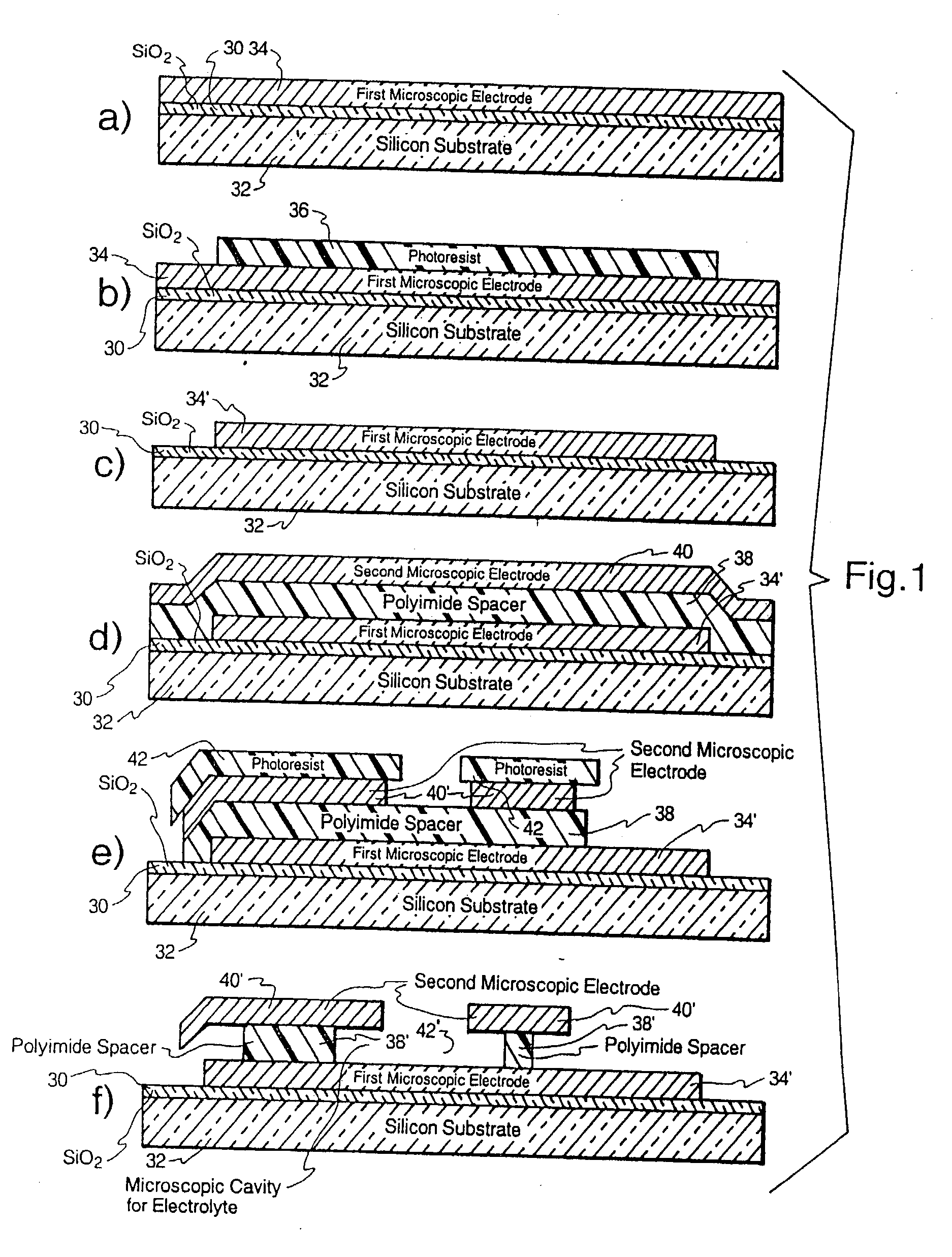

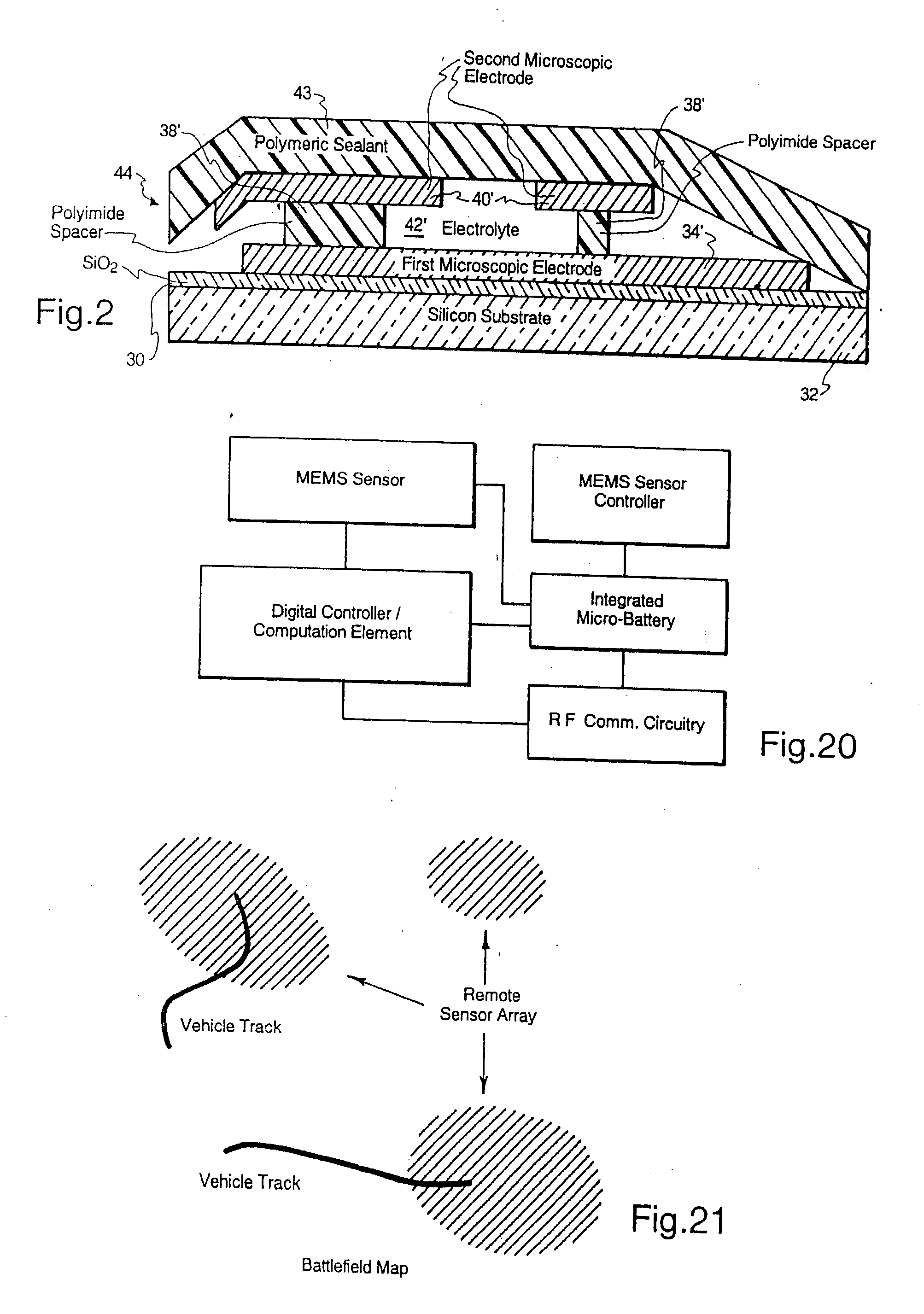

Microscopic batteries for MEMS systems

InactiveUS6610440B1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureElectricityMicrofabrication

Microscopic batteries, integratable or integrated with microelectromechanical systems or other microscopic circuits, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed, among which comprise closed system microscopic batteries for internal storage of electricity using interval reactants only, which comprise microscopic electrodes, electrolyte and reservoir for the electrolyte.

Owner:BIPOLAR TECH

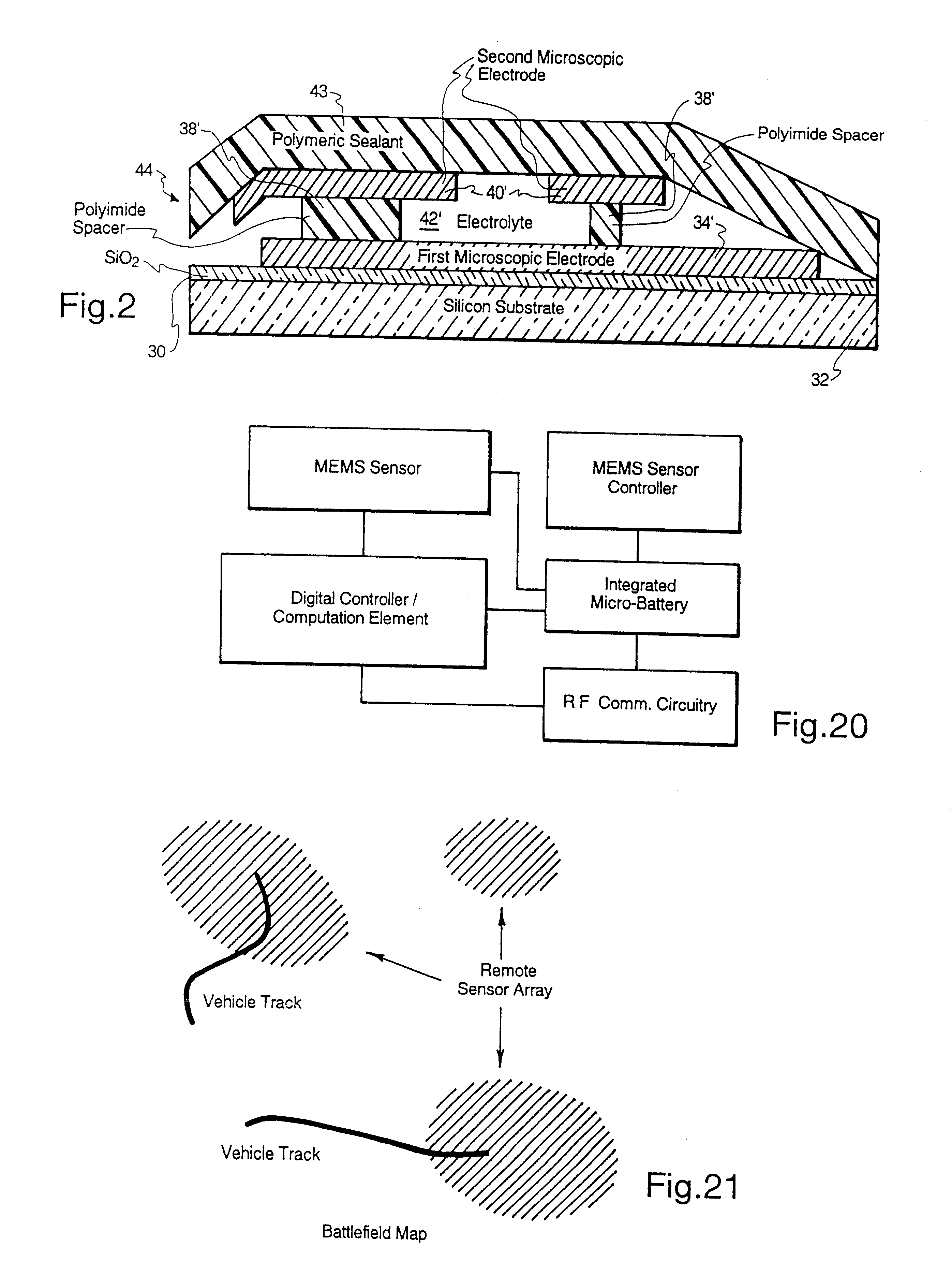

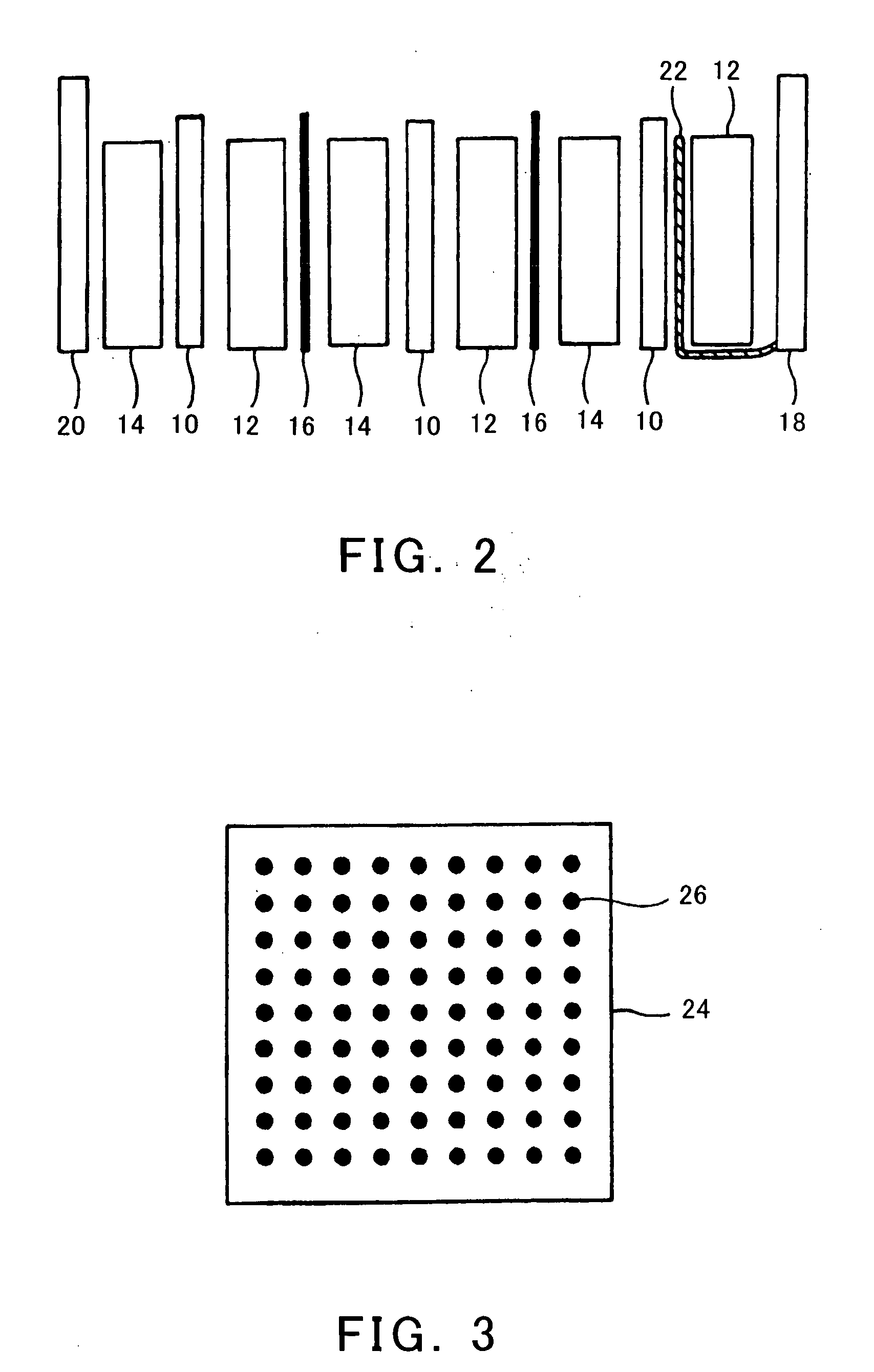

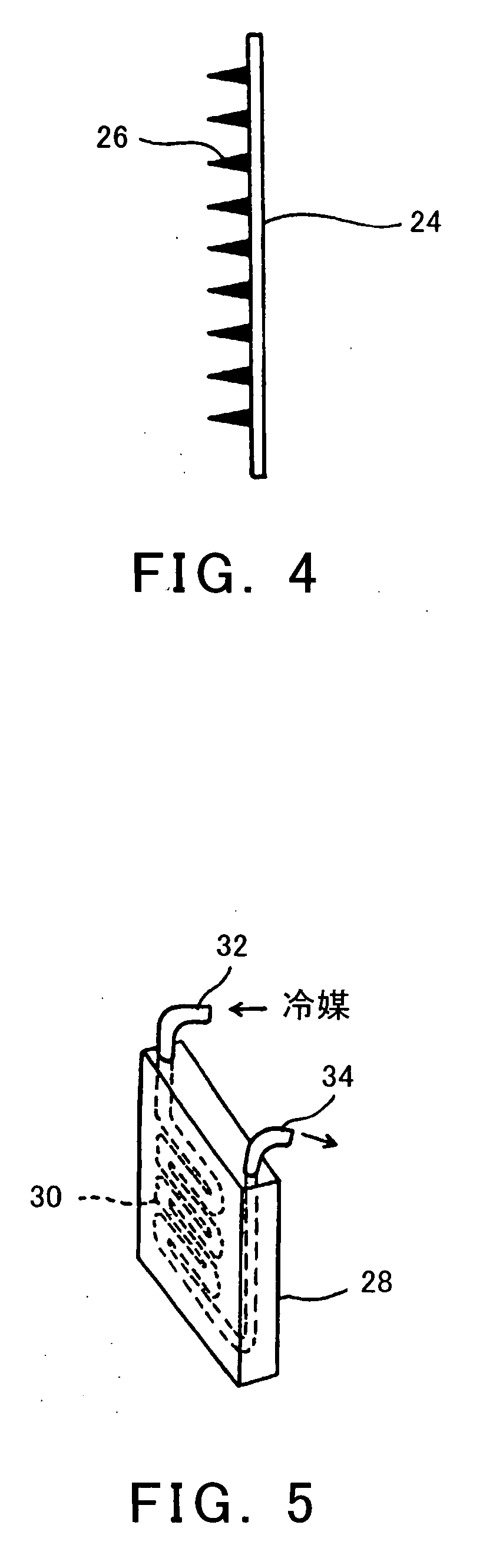

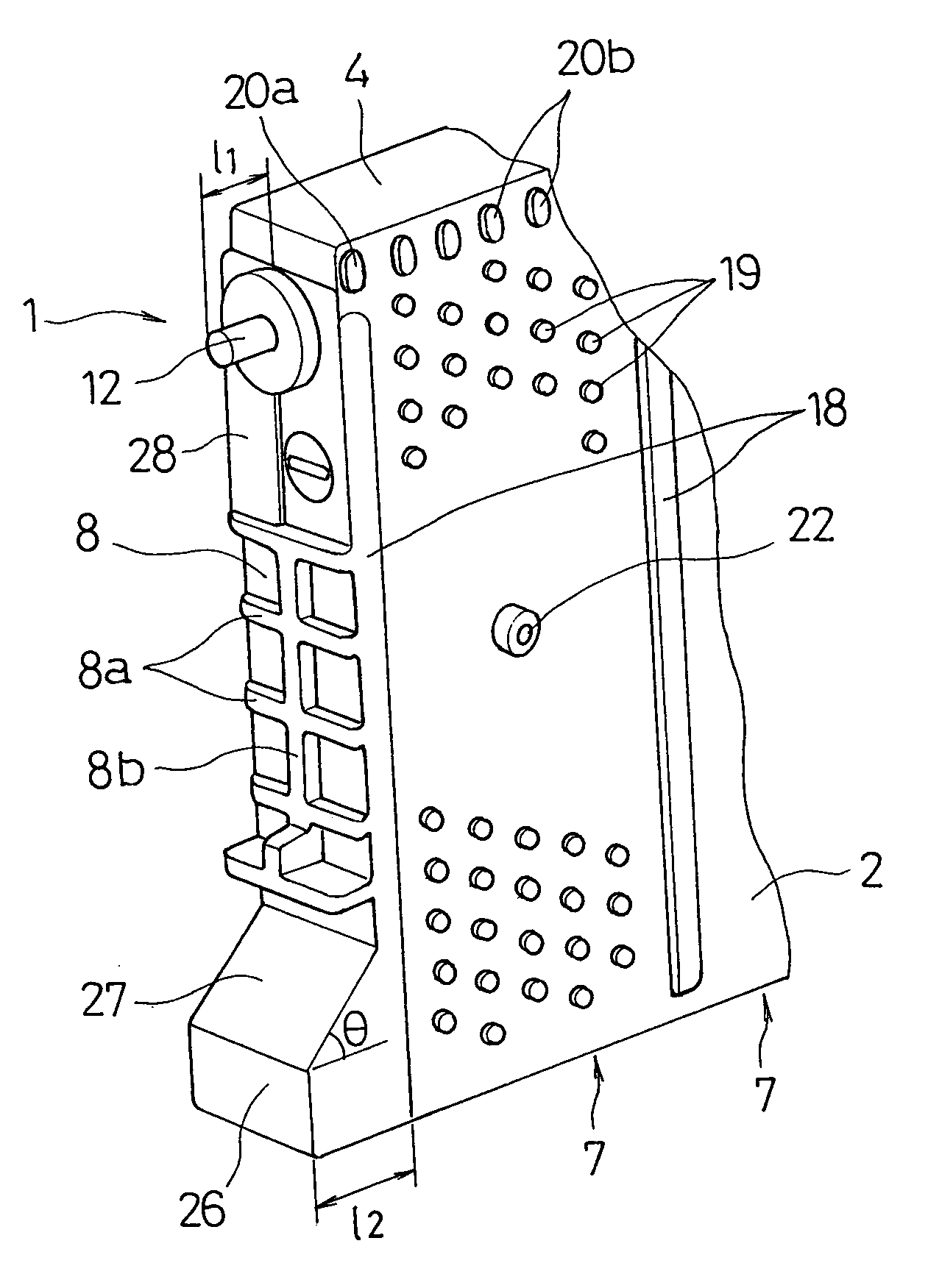

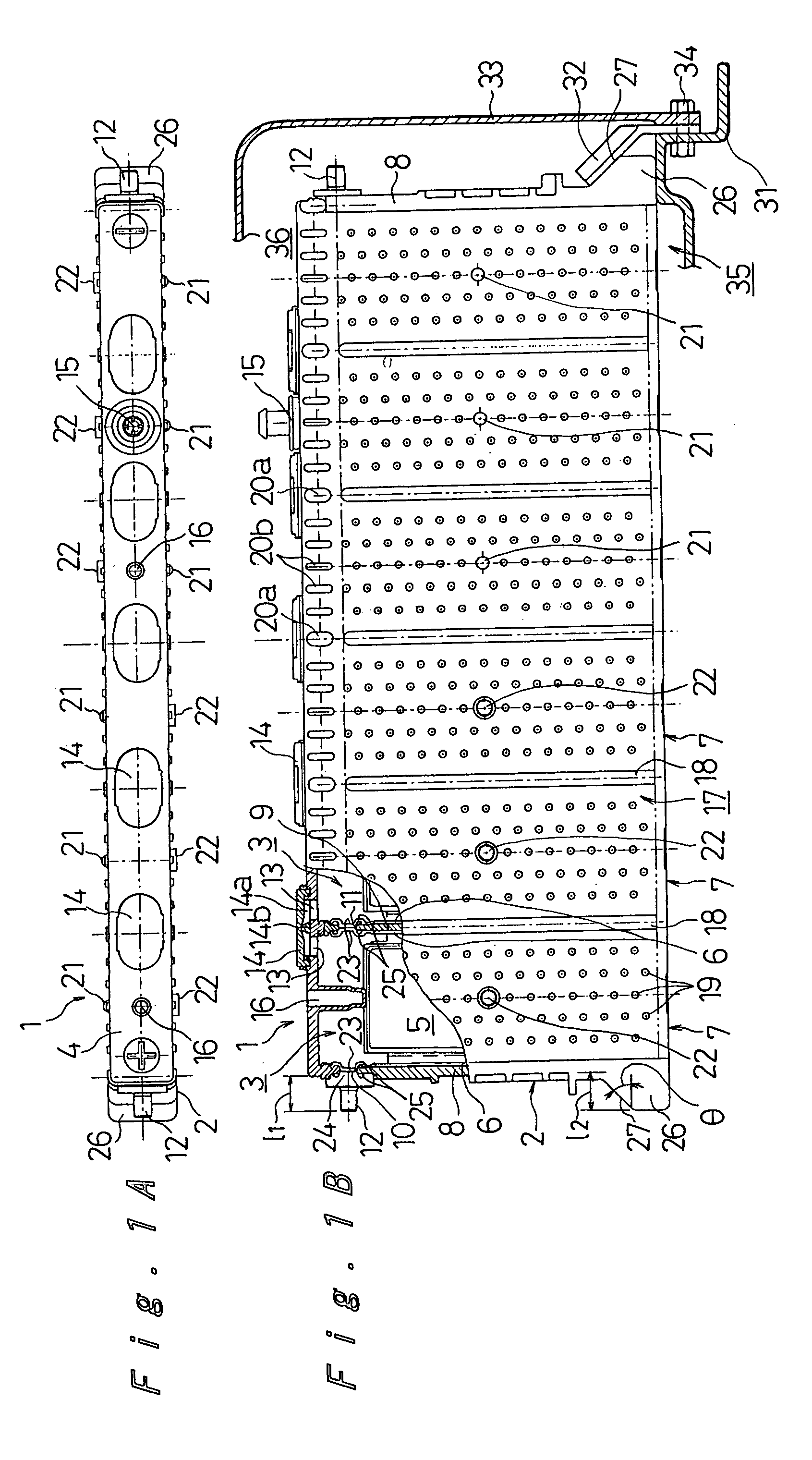

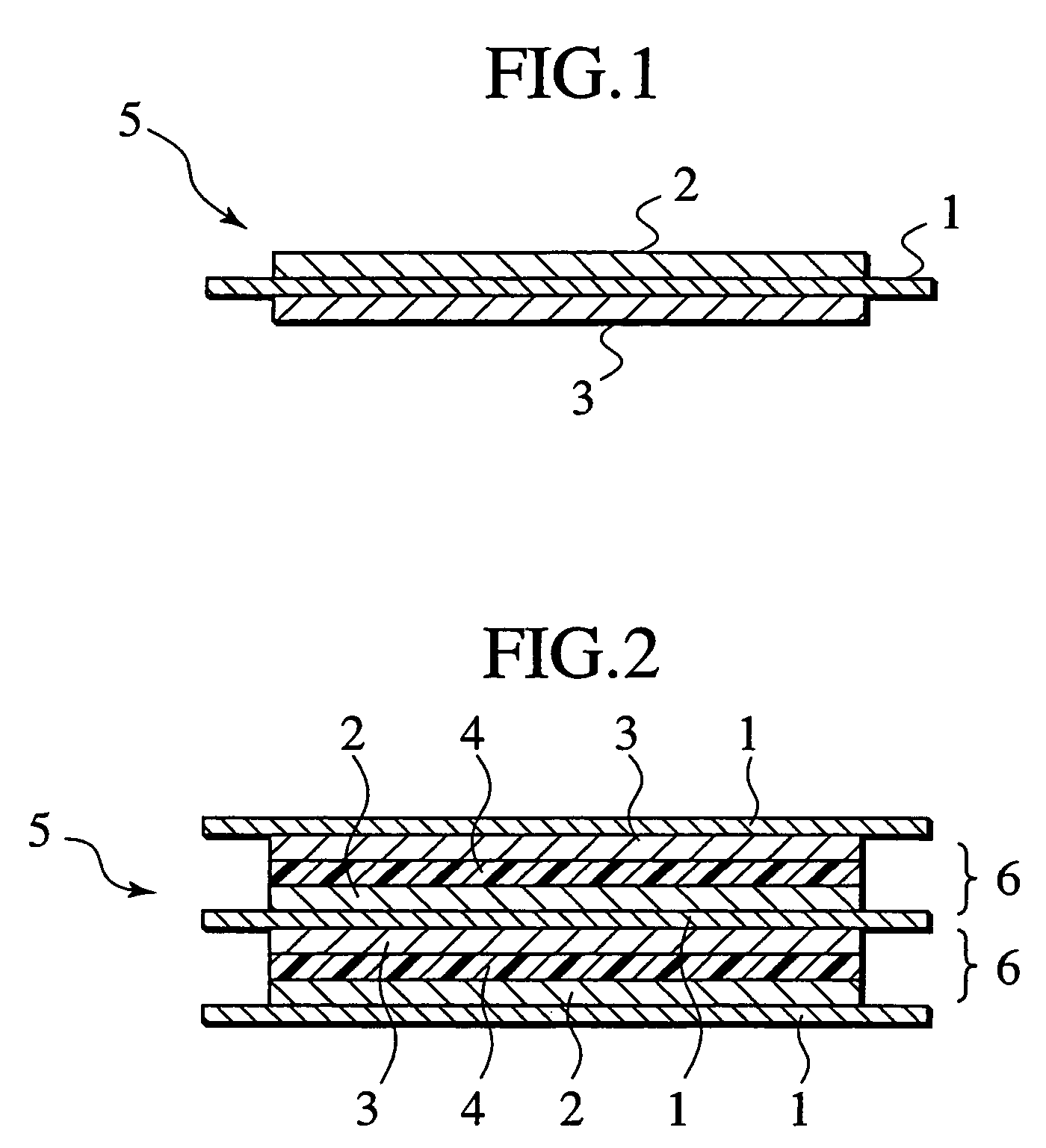

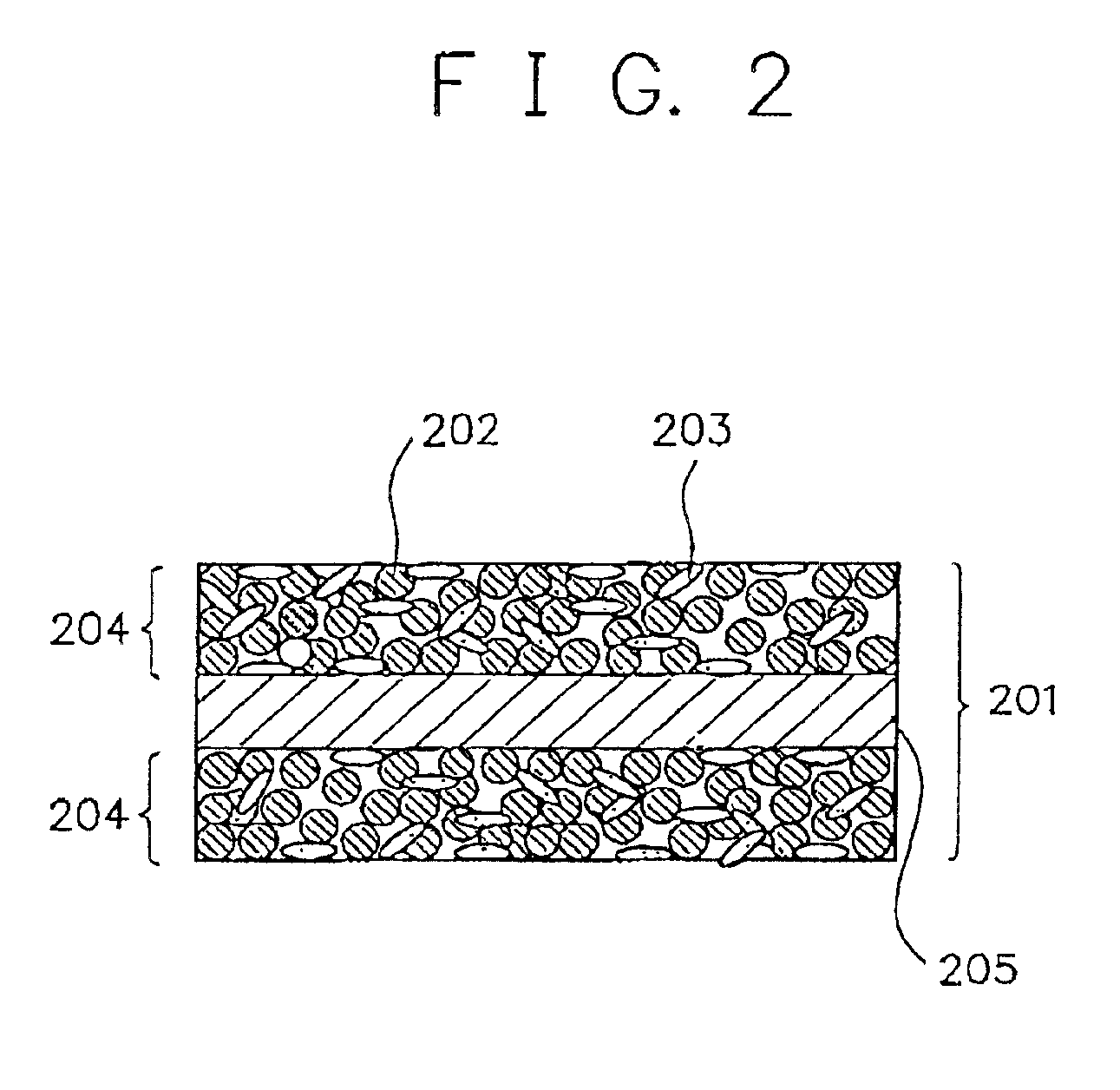

Three-dimensional cell and its electrode structure and method for manufacturing electrode material of three-dimensional cell

InactiveUS20040241540A1Easy to specifyEasy to getCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesEngineeringElectrode material

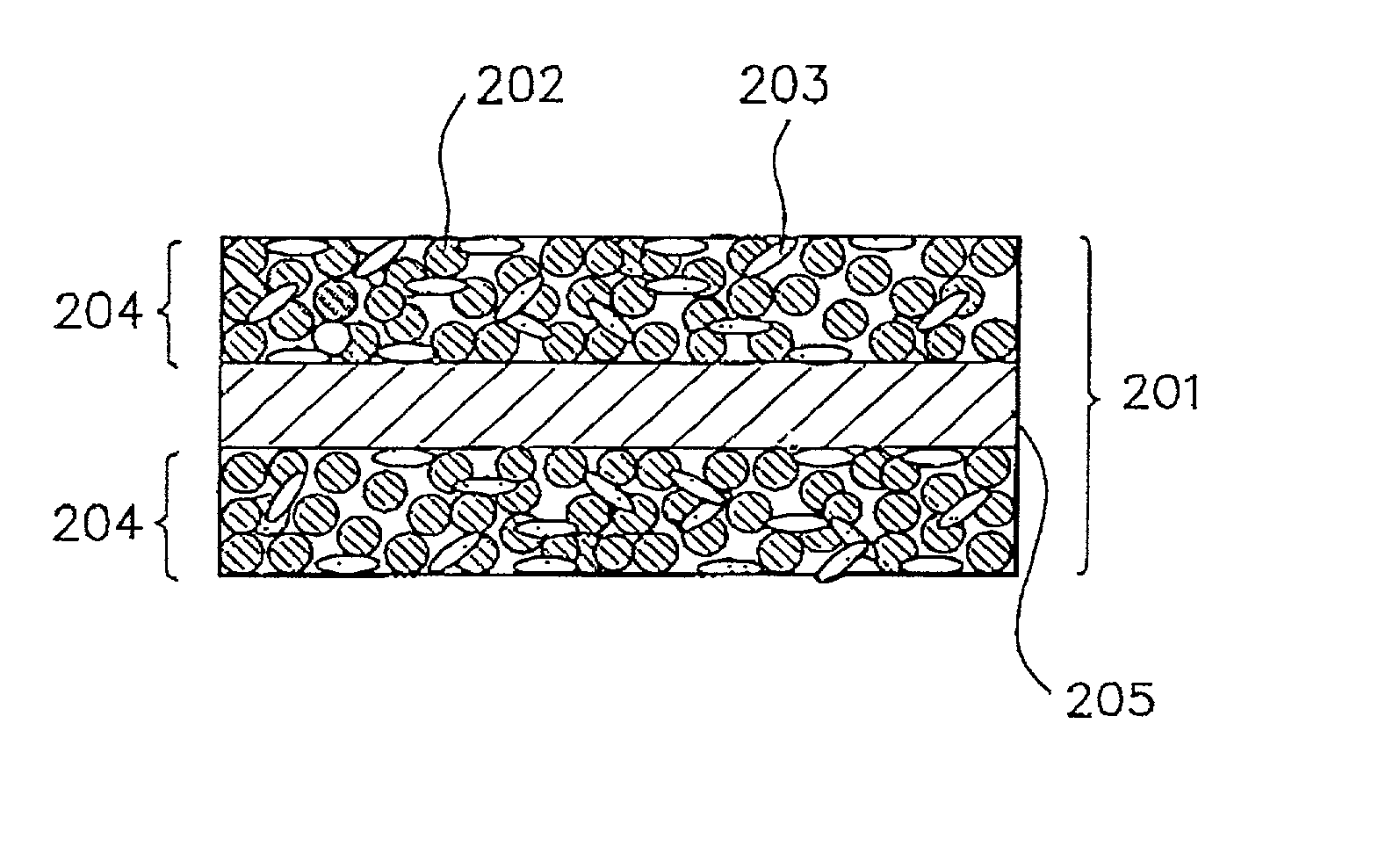

When producing an electrode for use in a three-dimensional battery, an active material is combined with at least one of a separator, a dividing wall, and a current collector for simultaneous formation. Both the dividing wall and the current collector are planar or are so formed as to have projected portions in needle, plate, wave, particle, or the like form. Both the dividing wall and the current collector may be provided with a cooling structure. As an additional current collector, an ion permeable current collector, which has voids therein, permits passage of ions, and exhibits electrical conductive properties, is provided.

Owner:KAWASAKI HEAVY IND LTD +1

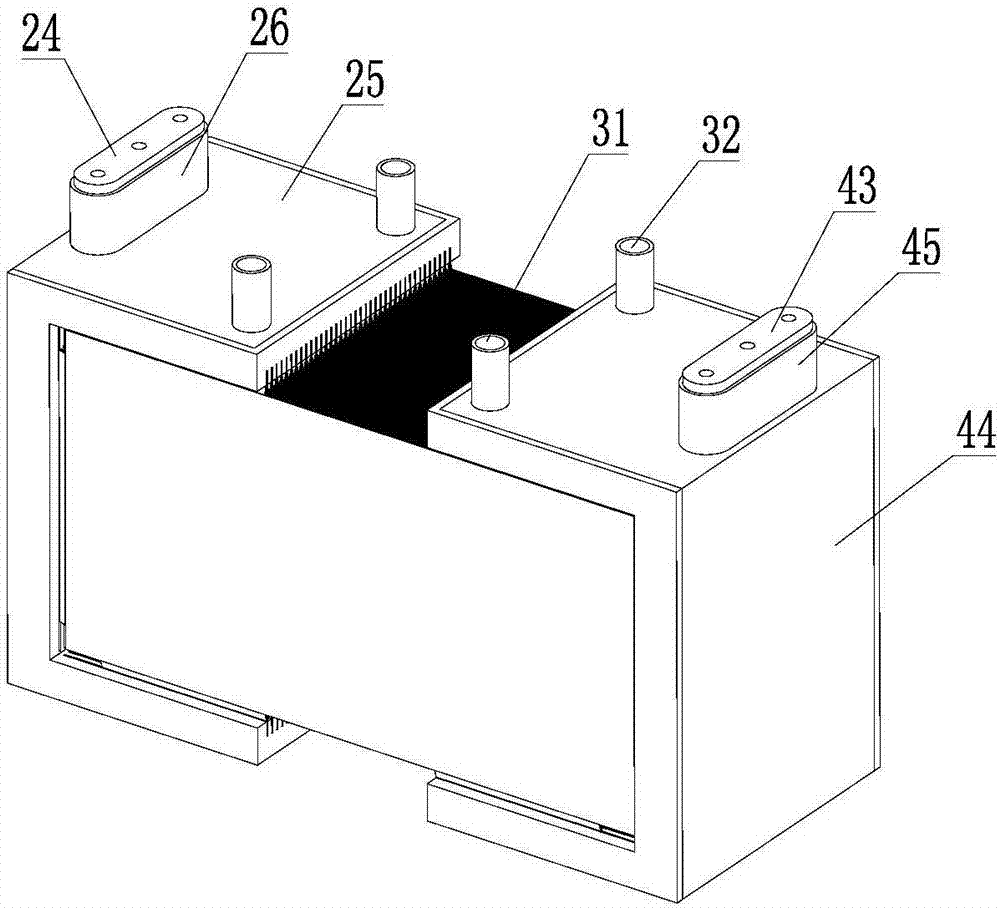

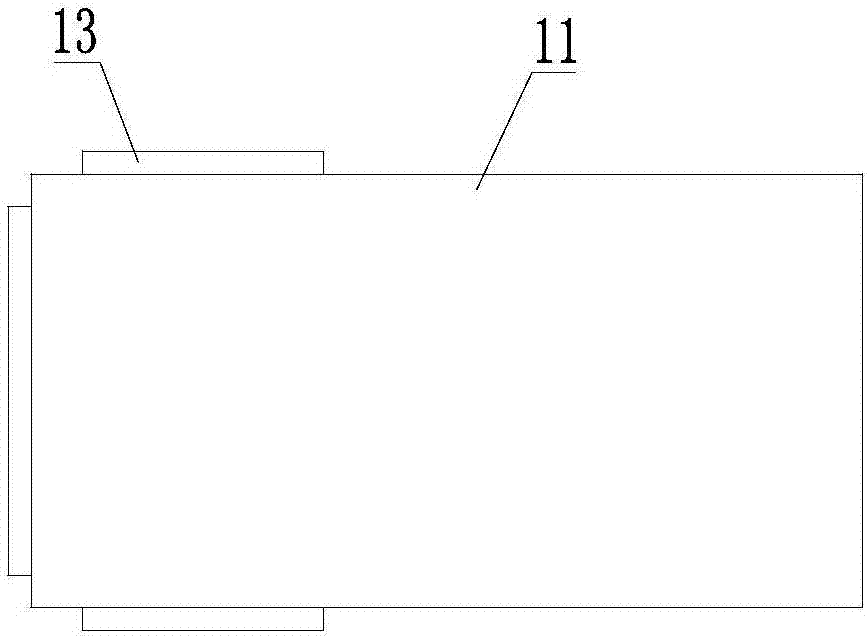

Large-capacity nickel-metal hydride battery

InactiveCN106876651ALow resistivityIncrease charge and discharge rateFinal product manufactureCell temperature controlElectrical conductorHigh rate

The invention discloses a large-capacity nickel-metal hydride battery, comprising a pole plate group, wherein a diaphragm is arranged between the adjacent positive plate and negative plate, three pole ears with C-like distribution are arranged on the pole plates, and the positive plate and the negative plate are oppositely arranged at intervals; one side of the pole plate group is coated with a positive current collector, the outer side of the positive current collector is coated with a positive flow deflector, the positive flow deflector is connected with the positive current collector through a low-melting-point welding layer, a positive pole rod is arranged on the positive flow deflector, the outer side of the positive flow deflector is coated with a positive guard plate, and a positive cooling system is arranged between the positive guard plate and the positive flow deflector; and the negative side structure is the same as the positive side structure. The pole plate adopts the pole ears with C-like distribution, the positive and negative current collectors are connected with the corresponding pole ears, the flow deflector and the current collector are welded together through a low-melting-point silver alloy, the resistivity of a conductor can be reduced, and thus the charge and discharge rate can be increased to a maximum extent; and the positive cooling system and the negative cooling system can cool the temperature rise generated by high-rate charging and discharging of the batteries.

Owner:山东三尺企业管理咨询有限公司

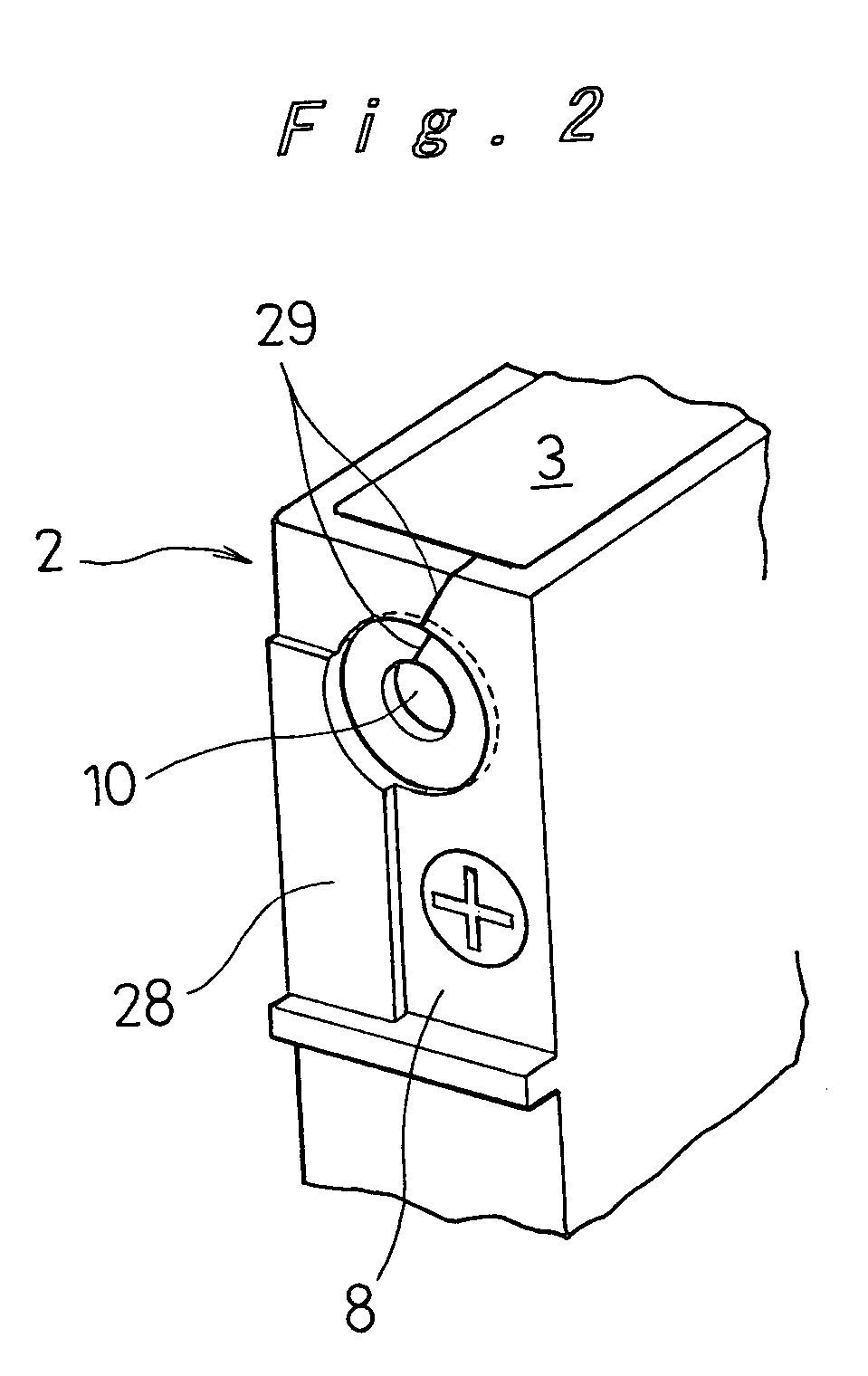

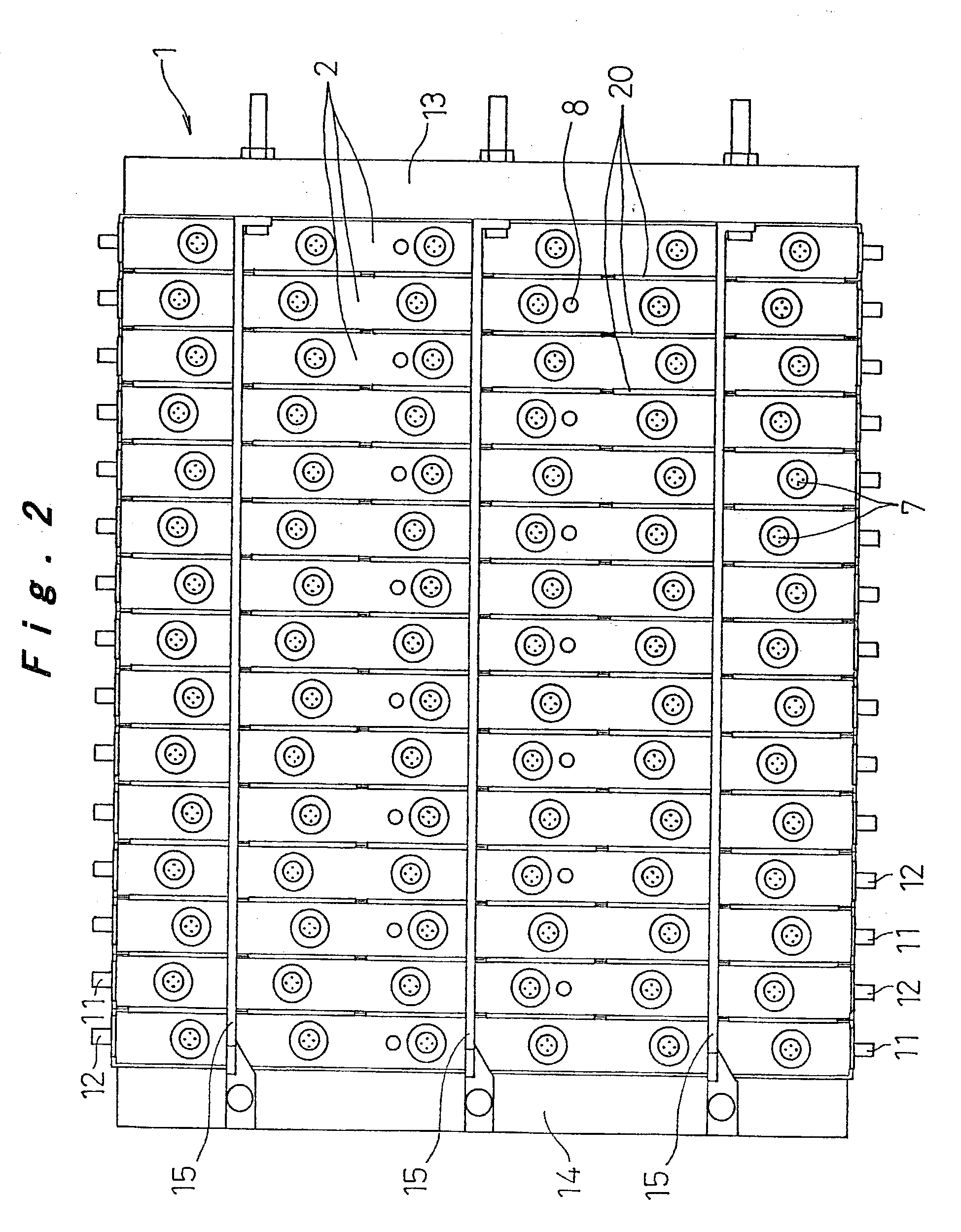

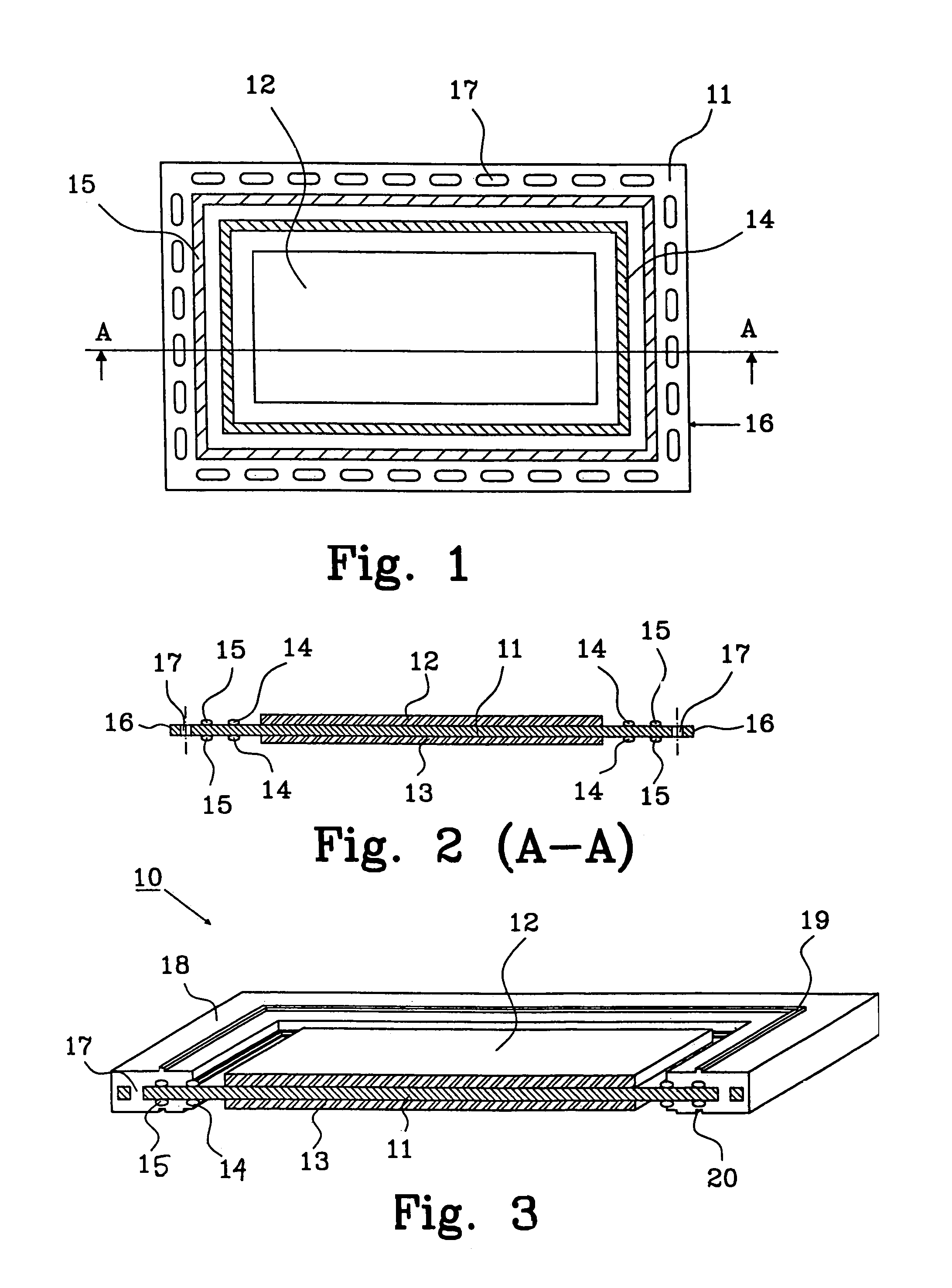

Structure for electrode terminals of battery module

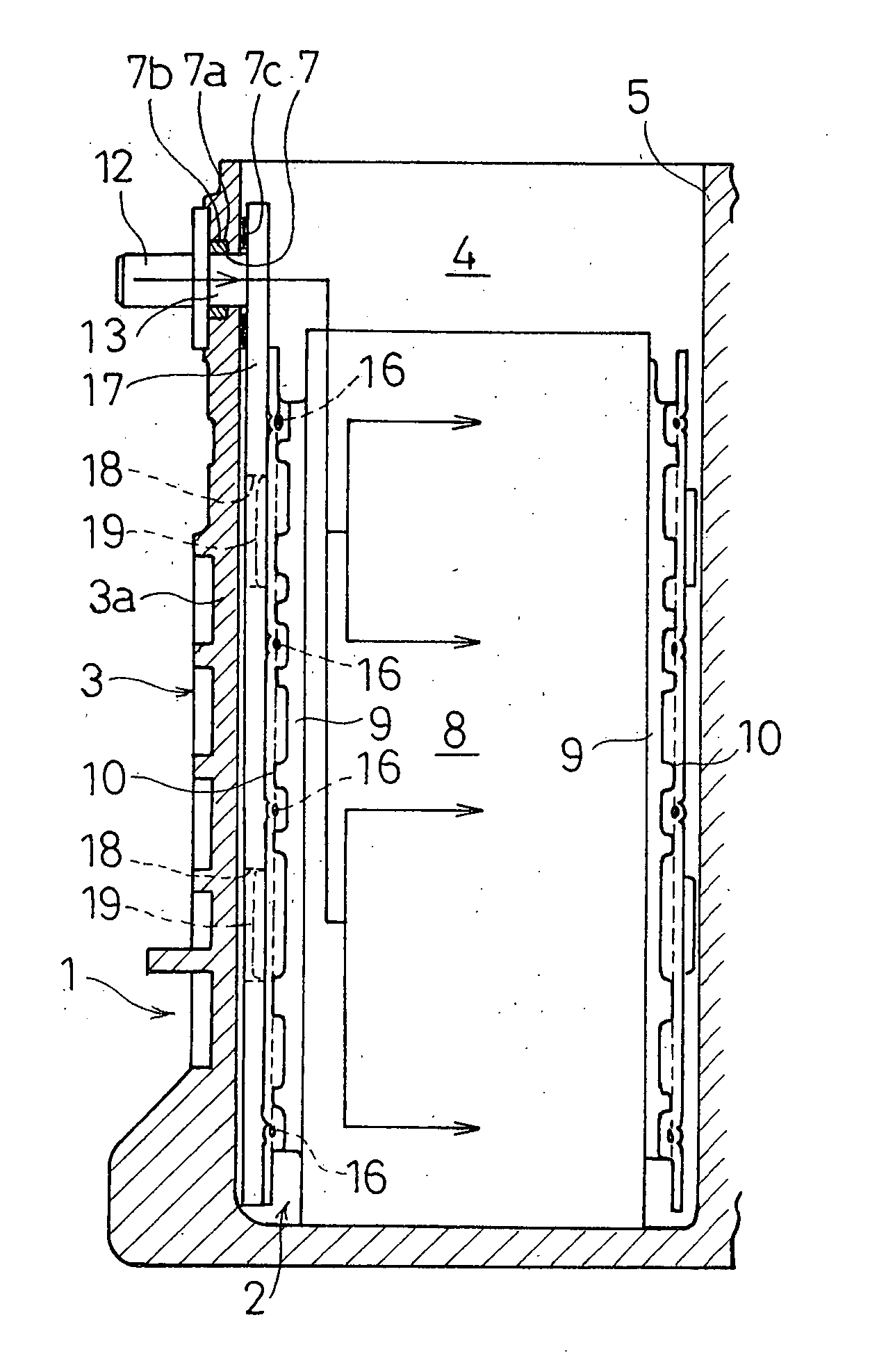

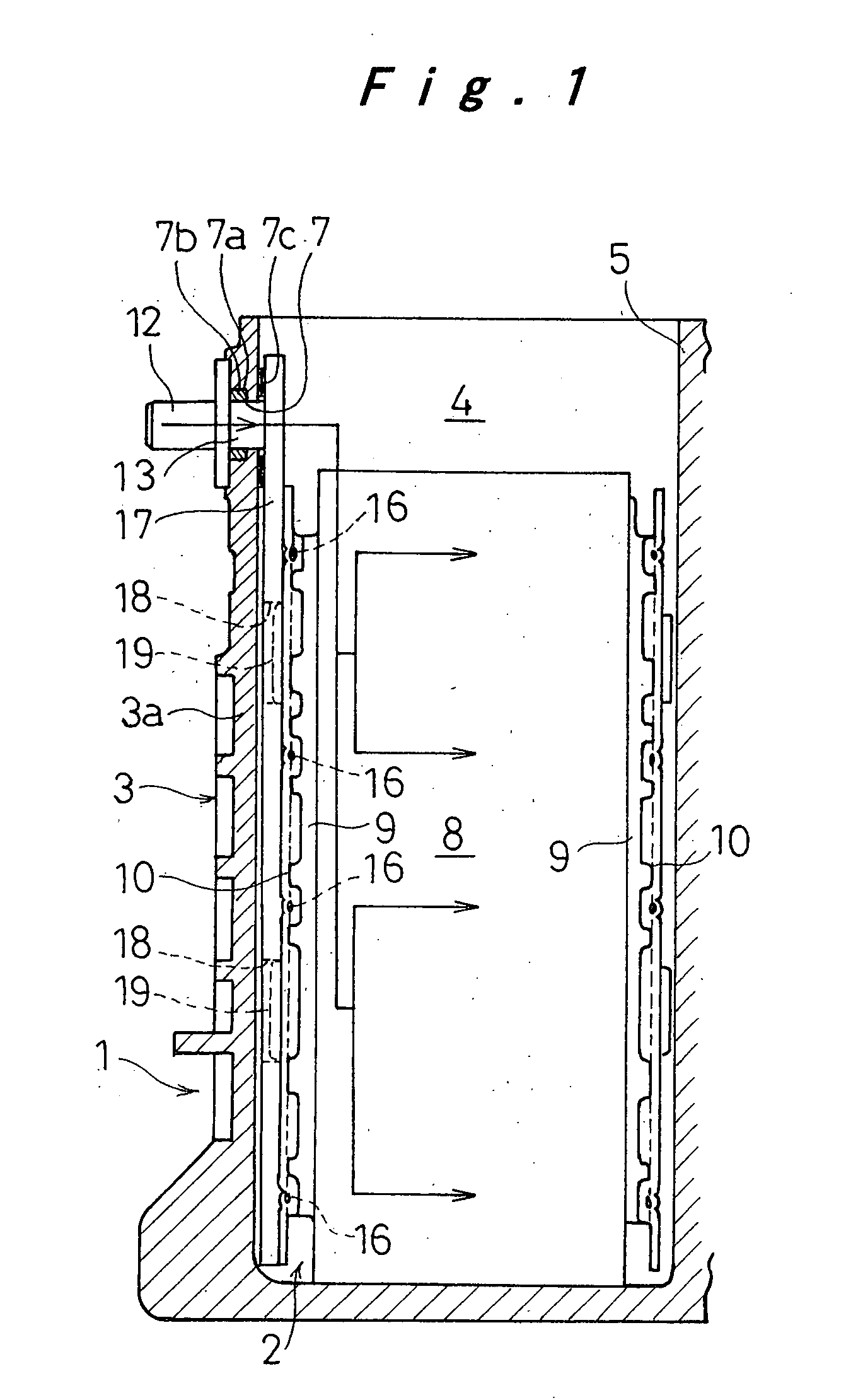

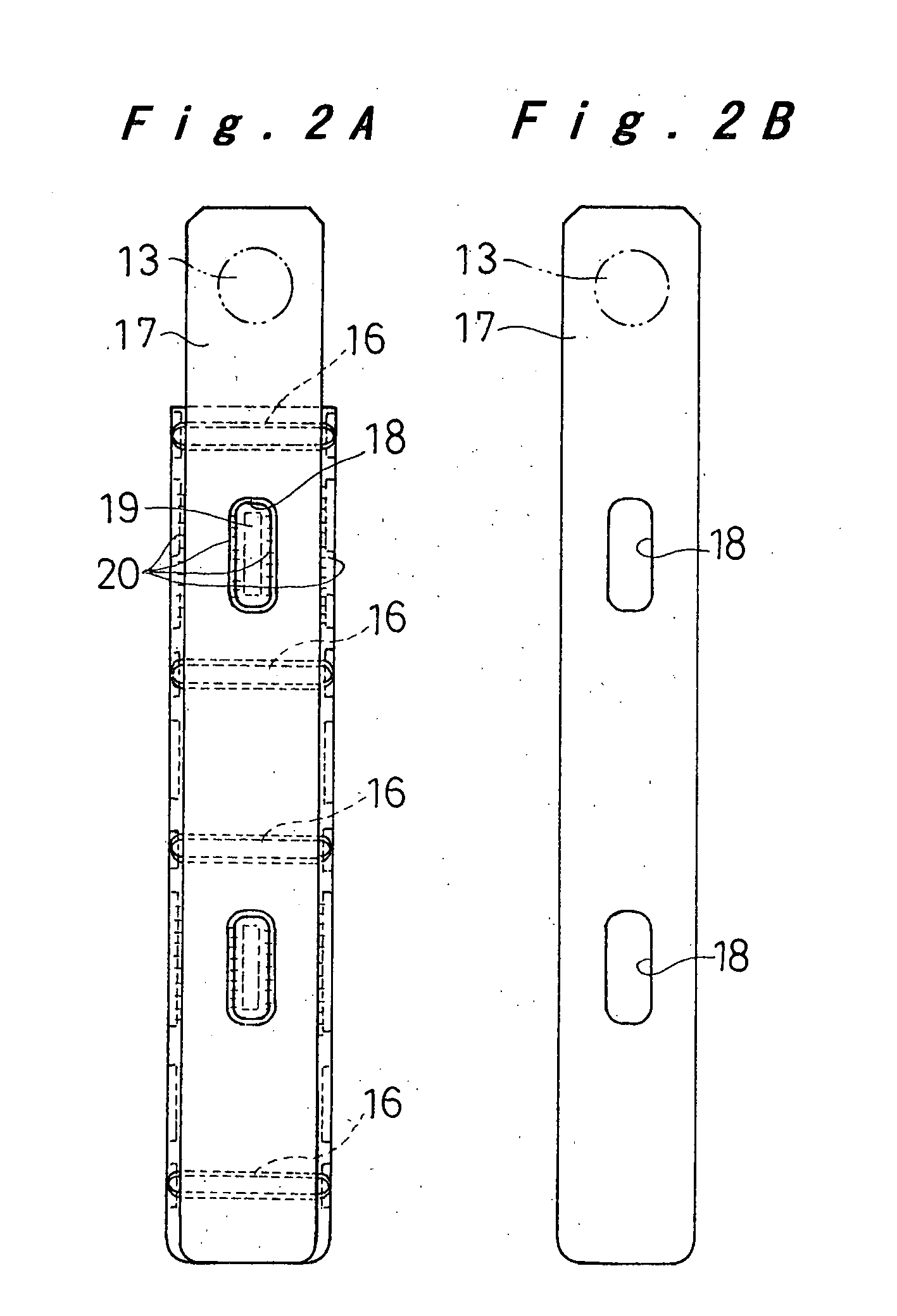

InactiveUS6982131B1Compact structurePrimary cell to battery groupingLarge-sized flat cells/batteriesElectrical and Electronics engineeringHorizontal ribs

On the opposite end walls of a flat, prismatic battery case of a battery module where electrode terminals are attached, protruding components are formed such as to protrude further than the electrode terminals. Terminal holes are formed in the end walls in which the electrode terminals are fitted, and the thickness of the end walls of the integral battery case in the vicinity of the terminal holes is not the same on both sides of each of the terminal holes. Also, one or a plurality of vertical and horizontal ribs are formed on the end walls between the electrode terminals and the protruding components. Further, a sealing structure is included for a battery.

Owner:PANASONIC CORP +1

Lithium Ion Batteries with Supplemental Lithium

Supplemental lithium can be used to stabilize lithium ion batteries with lithium rich metal oxides as the positive electrode active material. Dramatic improvements in the specific capacity at long cycling have been obtained. The supplemental lithium can be provided with the negative electrode, or alternatively as a sacrificial material that is subsequently driven into the negative electrode active material. The supplemental lithium can be provided to the negative electrode active material prior to assembly of the battery using electrochemical deposition. The positive electrode active materials can comprise a layered-layered structure comprising manganese as well as nickel and / or cobalt.

Owner:IONBLOX INC

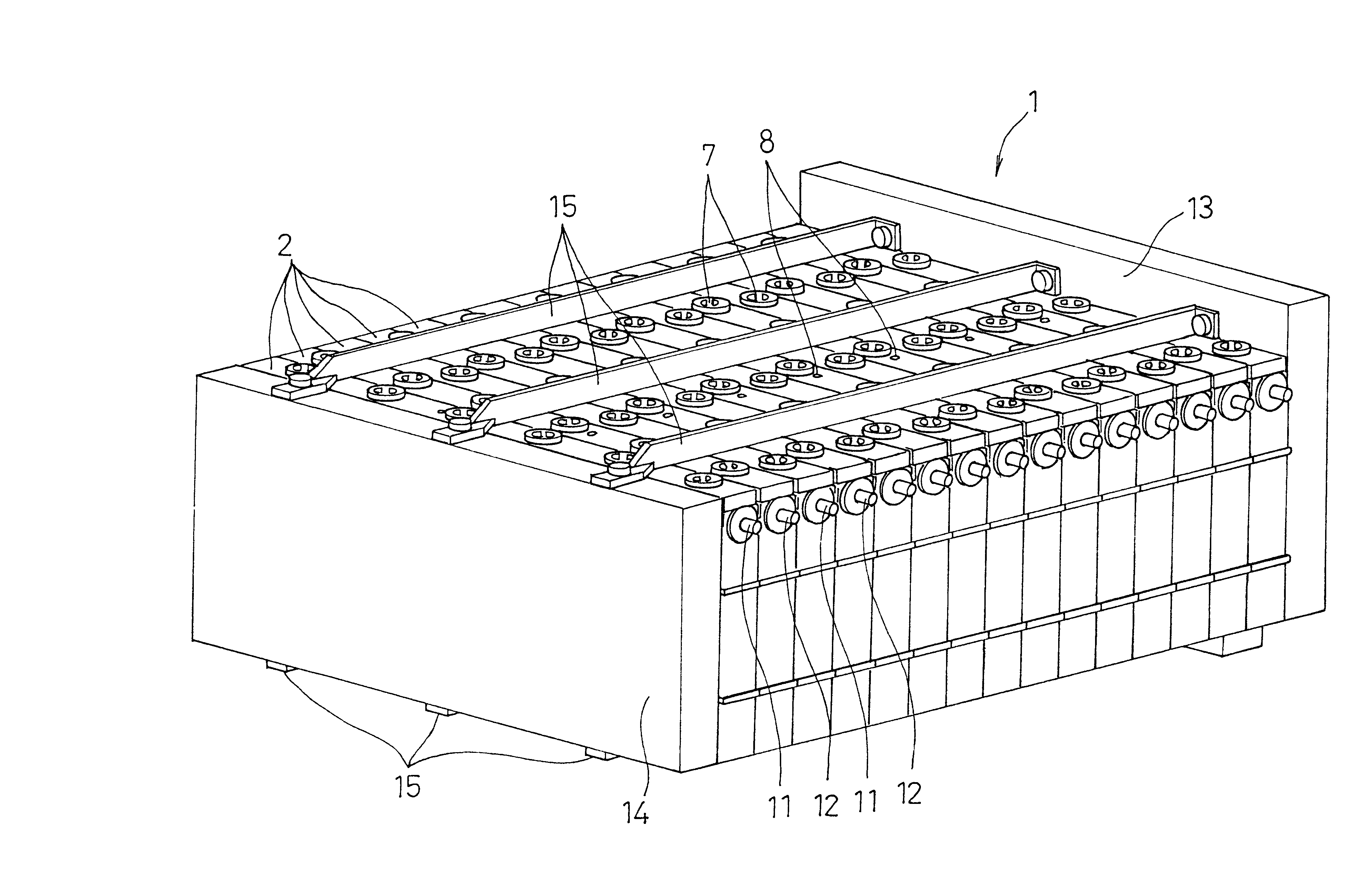

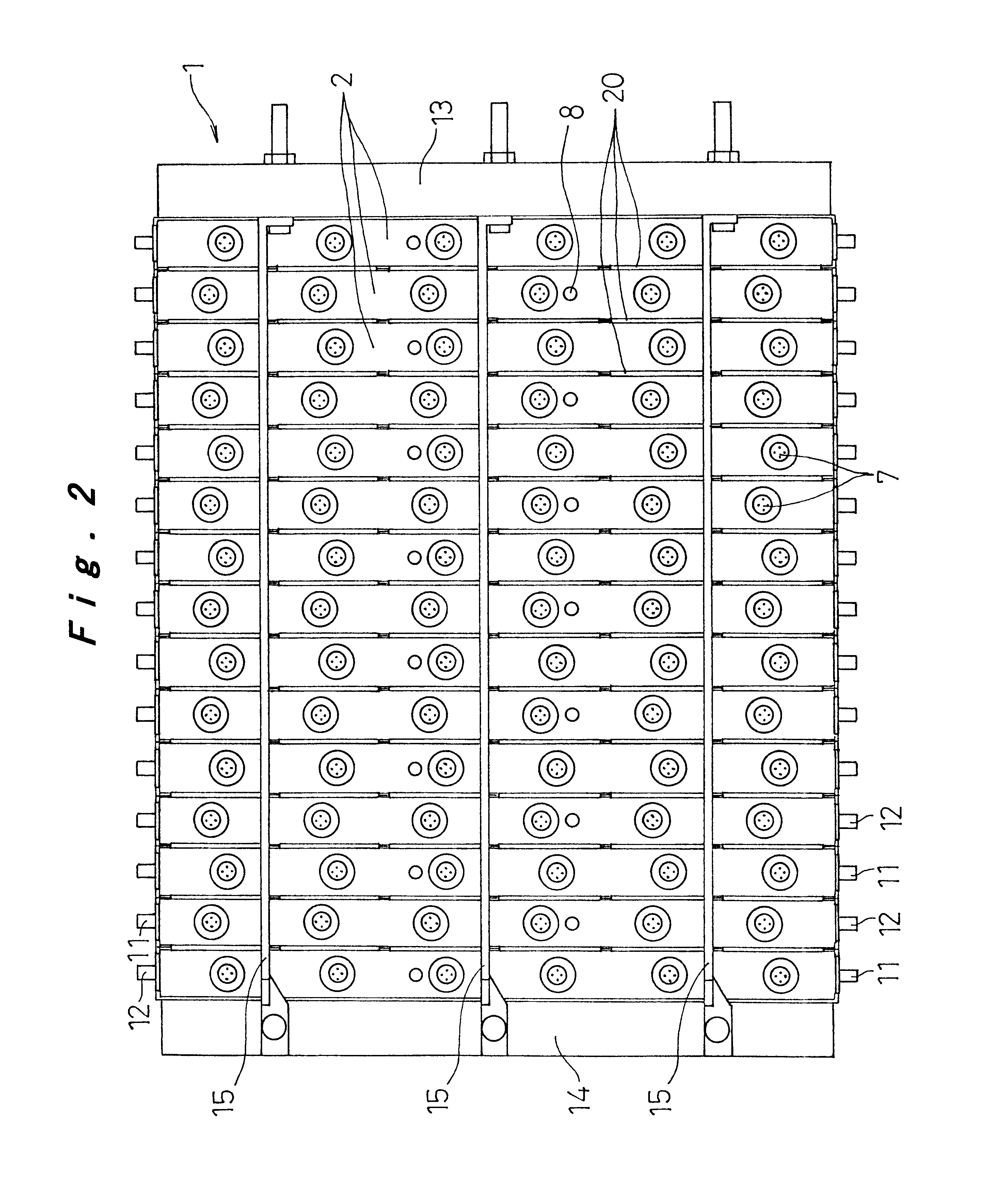

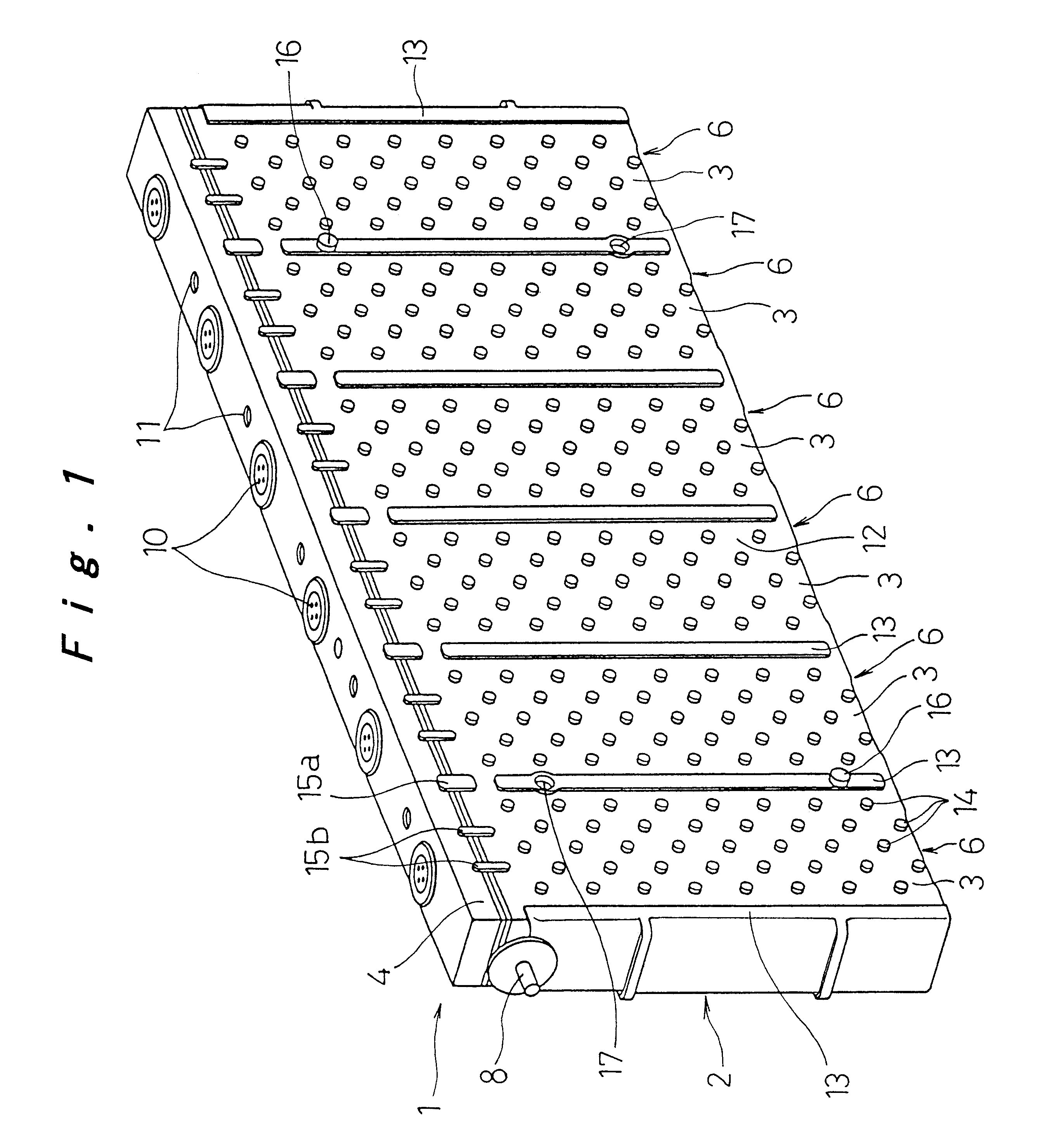

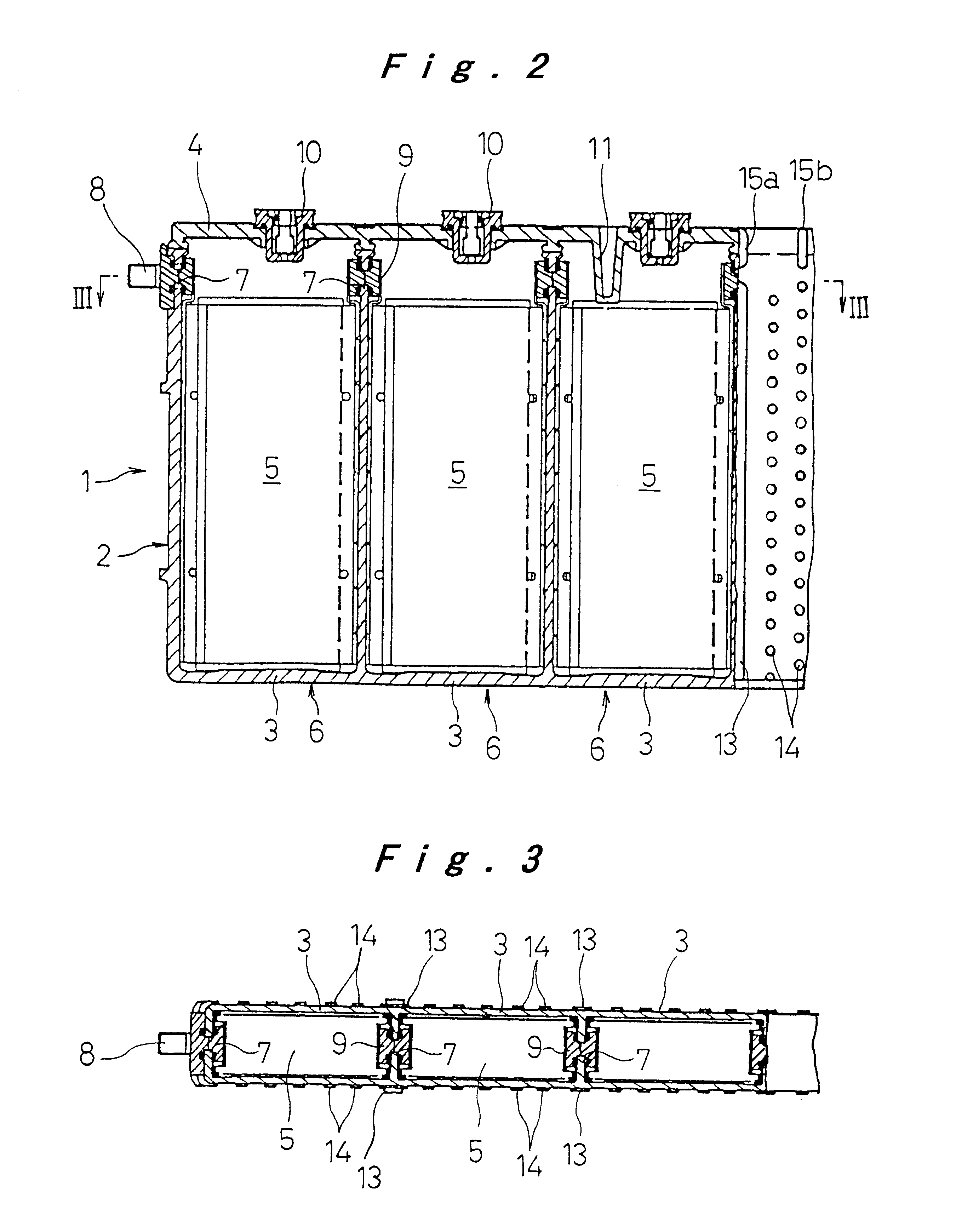

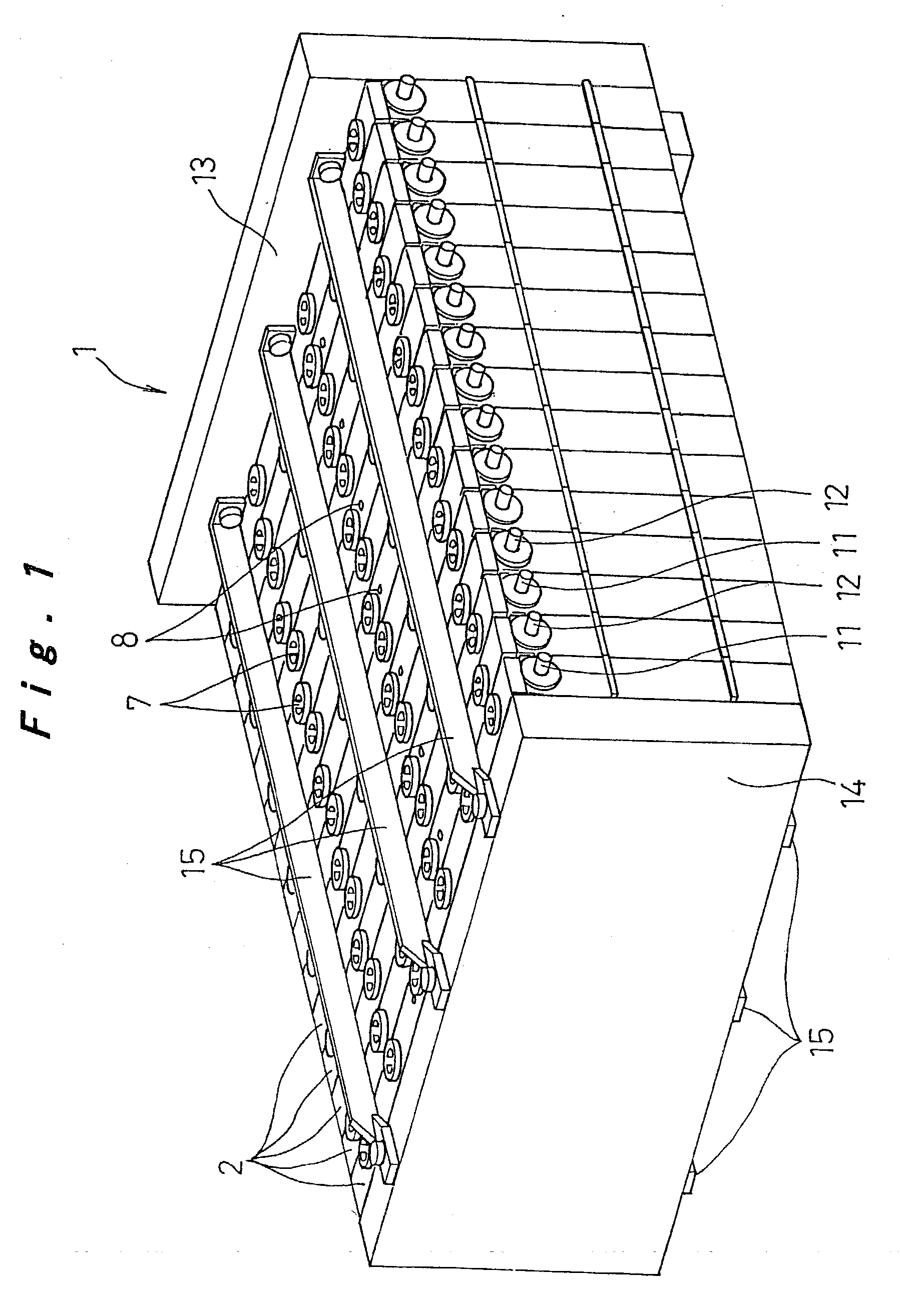

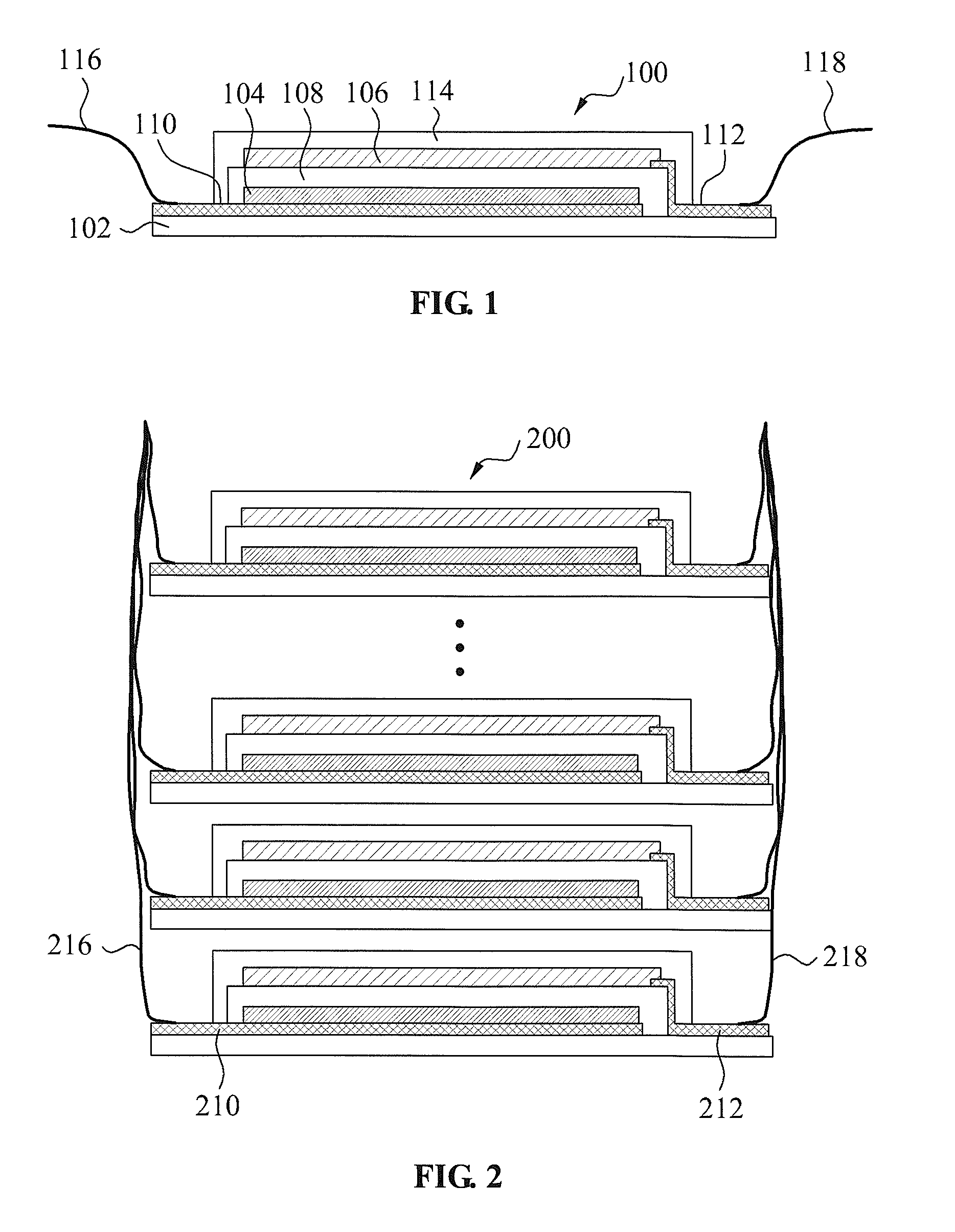

Battery pack

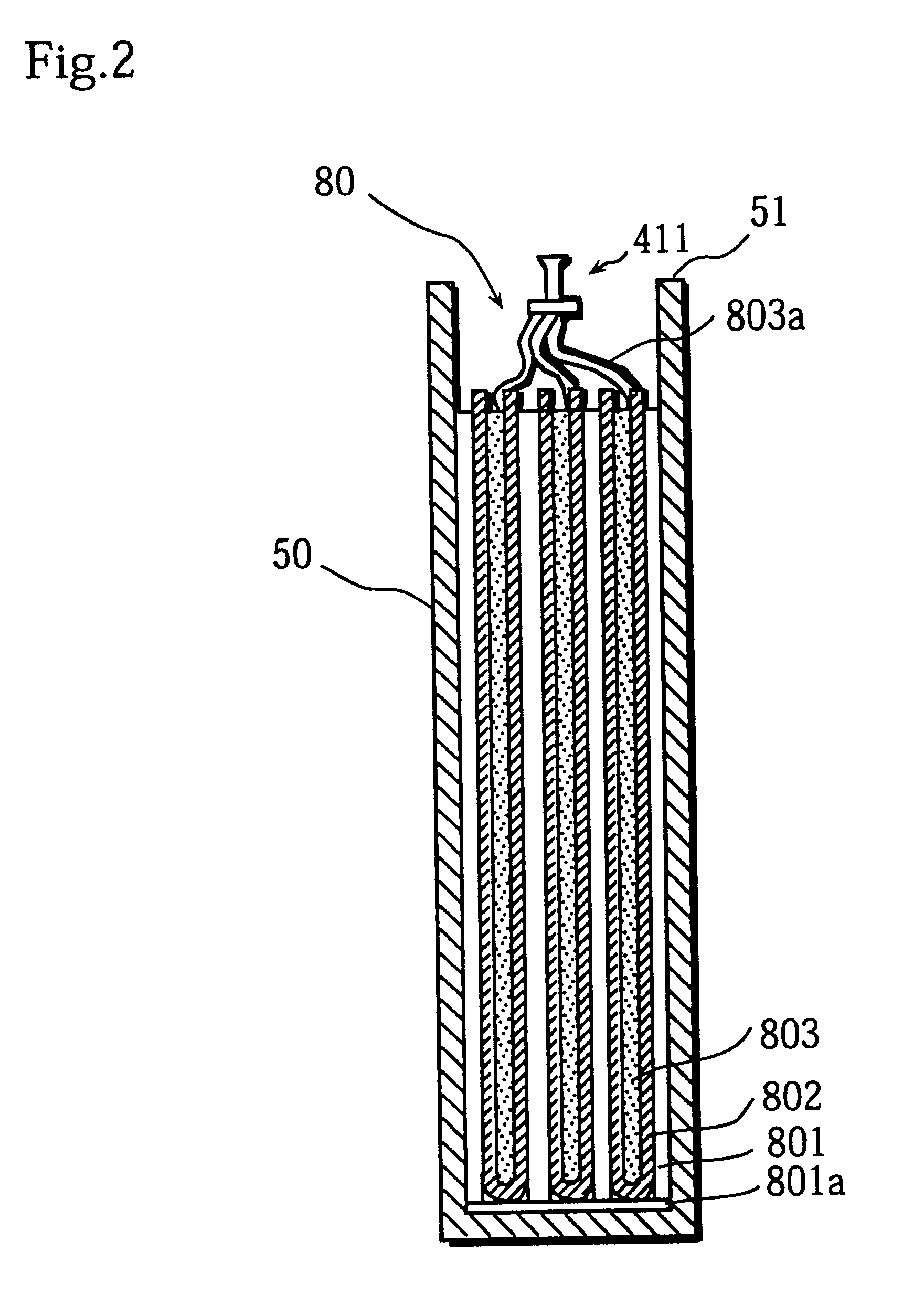

InactiveUS6569561B1Large-sized flat cells/batteriesFinal product manufactureBattery packElectrical and Electronics engineering

A battery module is constructed of an integral battery case which is constituted by forming a plurality of prismatic cell cases into a unitized body, wherein positive electrode plates and negative electrode plates laminated alternately upon one another with intervening separators are respectively accommodated in each of the cell cases, thereby constituting a plurality of cells, these cells being electrically connected in series. A plurality of such battery modules are arranged in a direction in which the electrode plates within each cell are laminated in a condition with coolant passages formed between the battery modules, and bound tightly together with end plates arranged at both ends in the direction of adjacent arrangement of the battery modules.

Owner:PANASONIC CORP +1

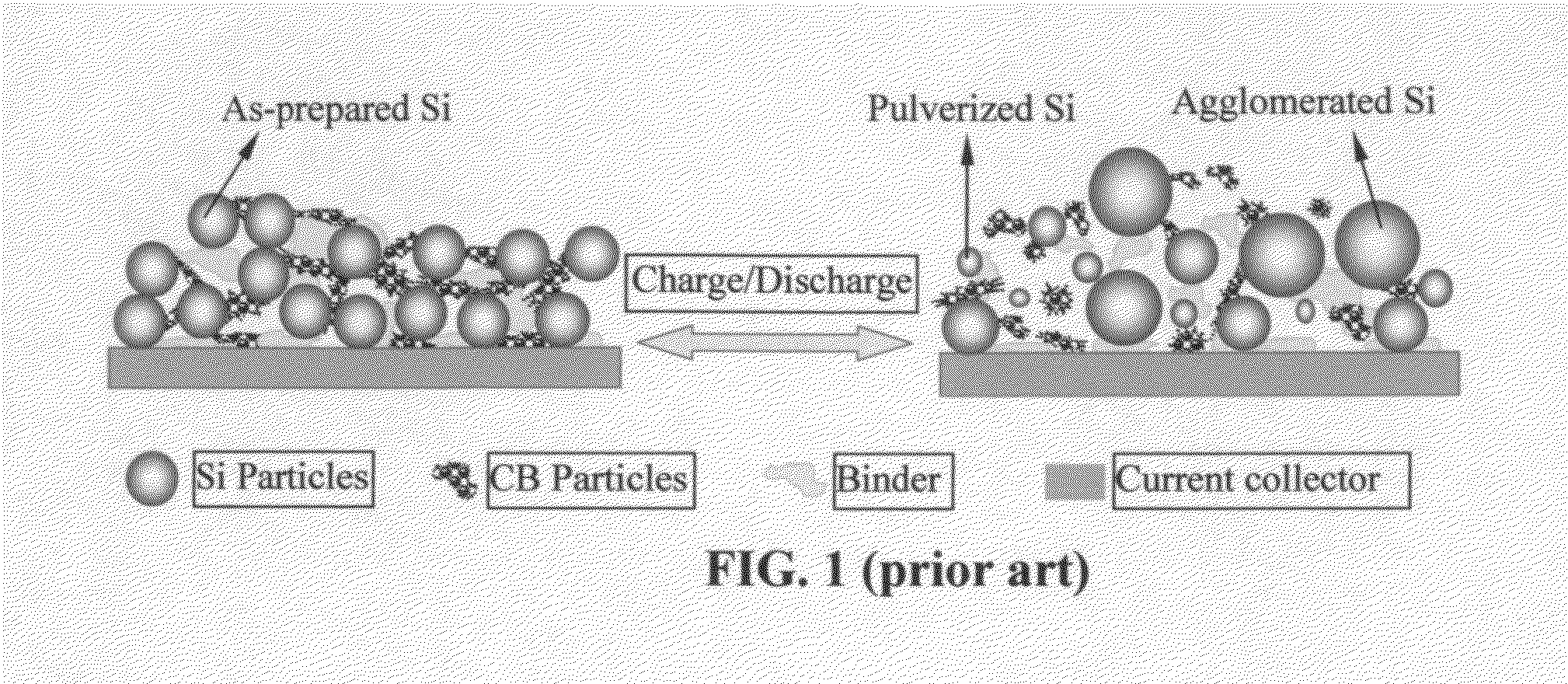

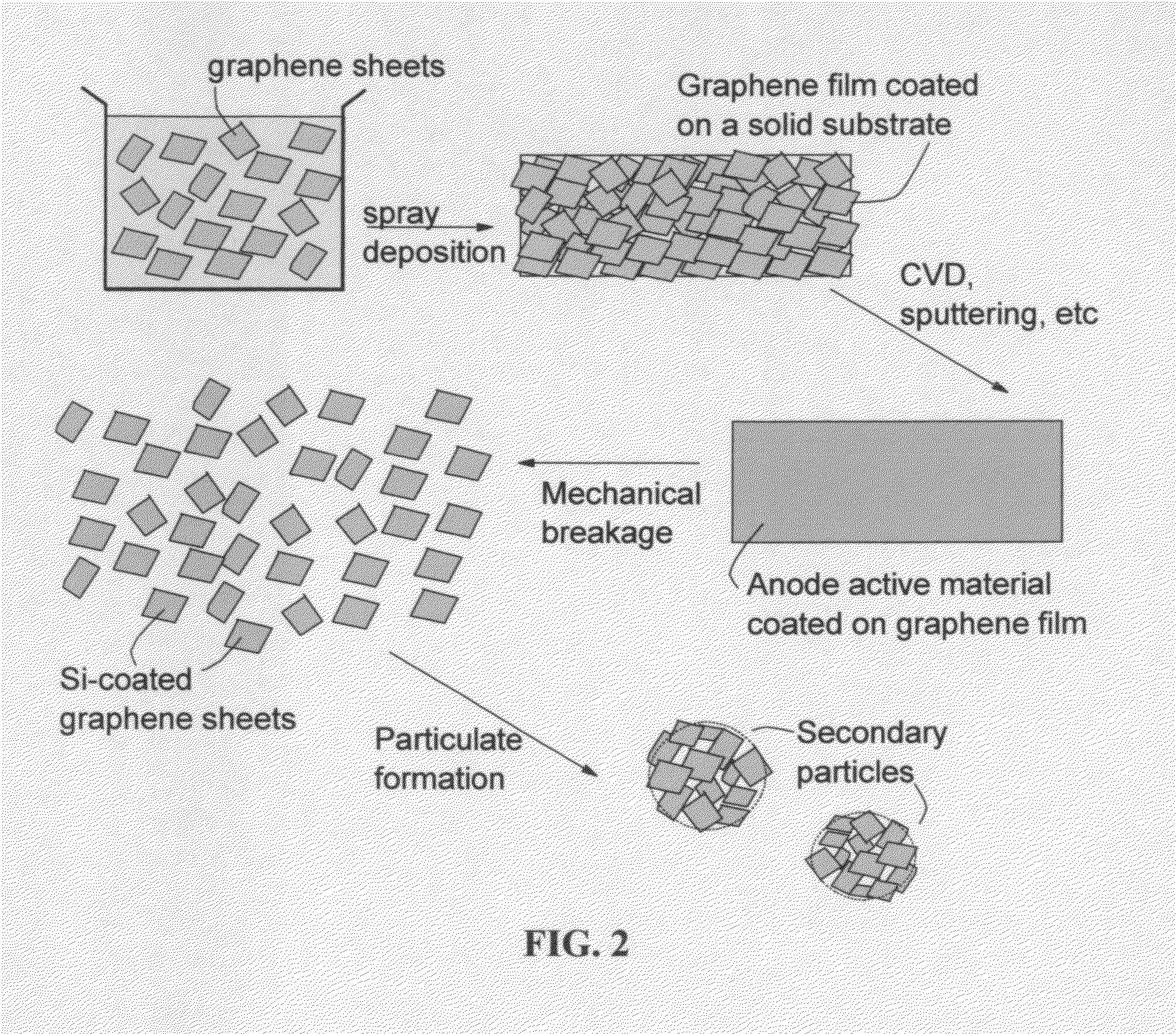

Anode active material-coated graphene sheets for lithium batteries and process for producing same

ActiveUS20150044565A1Enhanced Li-ion insertionIncrease capacityElectric discharge heatingFinal product manufactureMetallurgyLithium-ion battery

The present invention provides a process for producing a graphene-enhanced anode active material for use in a lithium battery. The process comprises (a) providing a continuous film of a graphene material into a deposition zone; (b) introducing vapor or atoms of a precursor anode active material into the deposition zone, allowing the vapor or atoms to deposit onto a surface of the graphene material film to form a sheet of an anode active material-coated graphene material; and (c) mechanically breaking this sheet into multiple pieces of anode active material-coated graphene; wherein the graphene material is in an amount of from 0.1% to 99.5% by weight and the anode active material is in an amount of at least 0.5% by weight, all based on the total weight of the graphene material and the anode active material combined.

Owner:GLOBAL GRAPHENE GRP INC

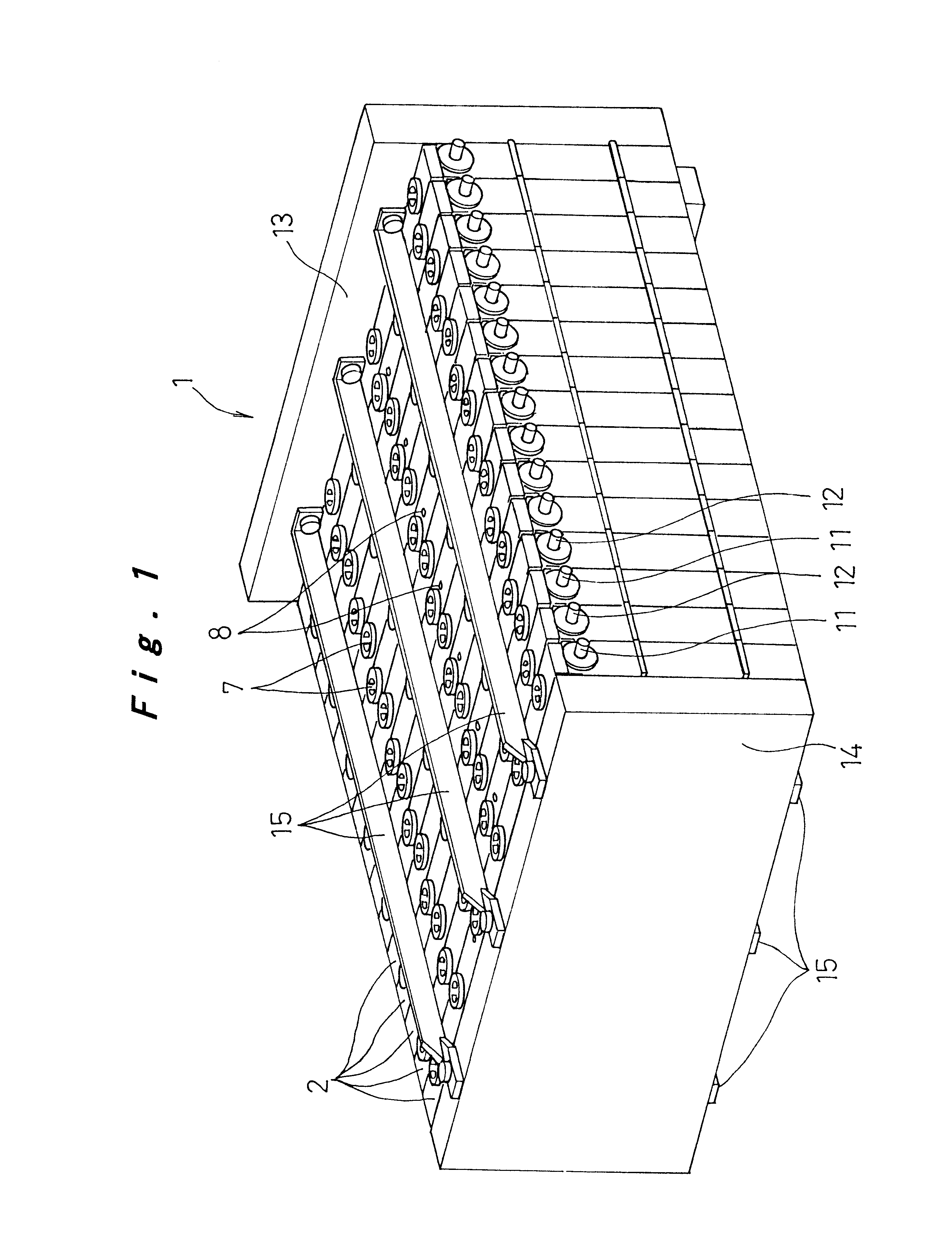

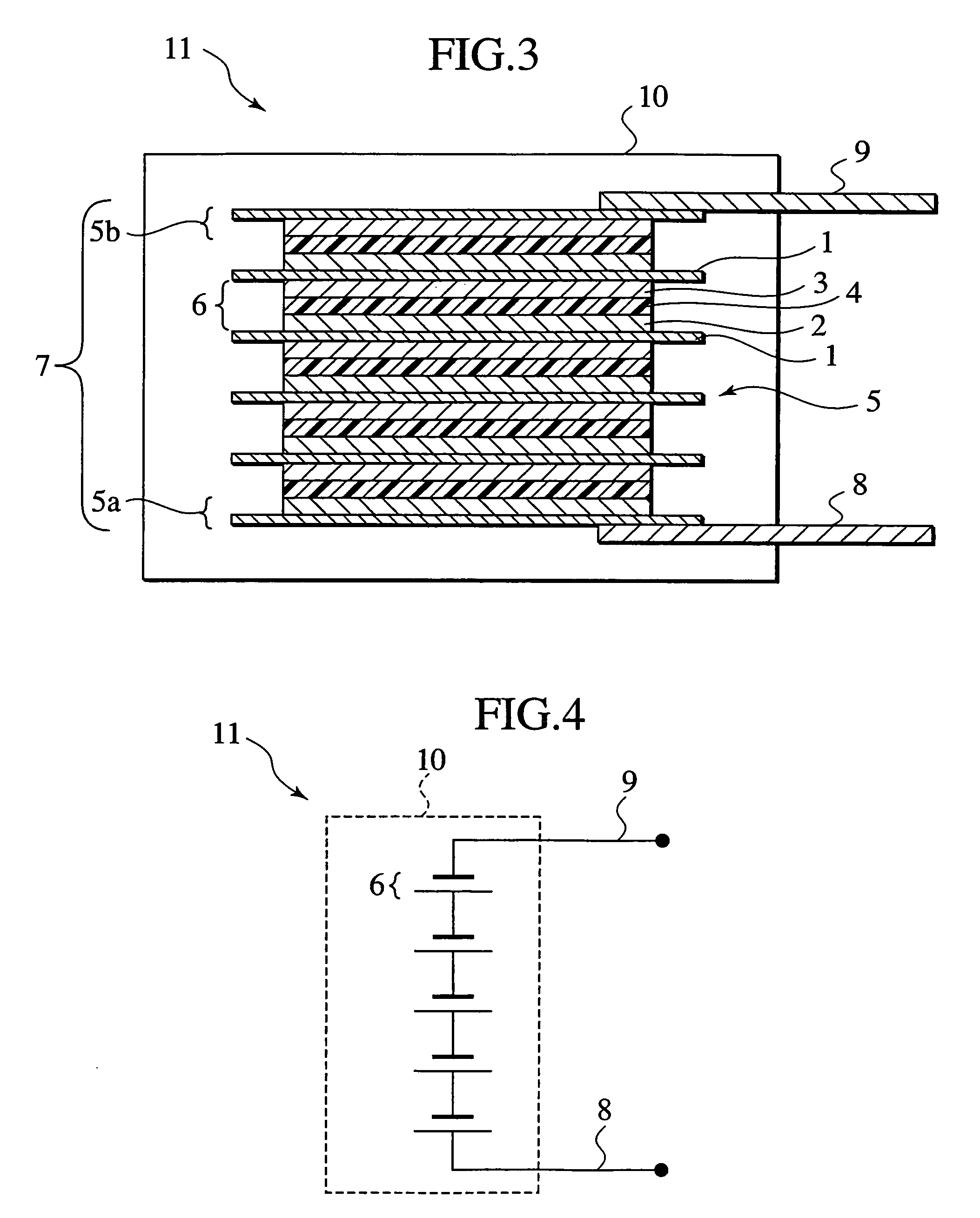

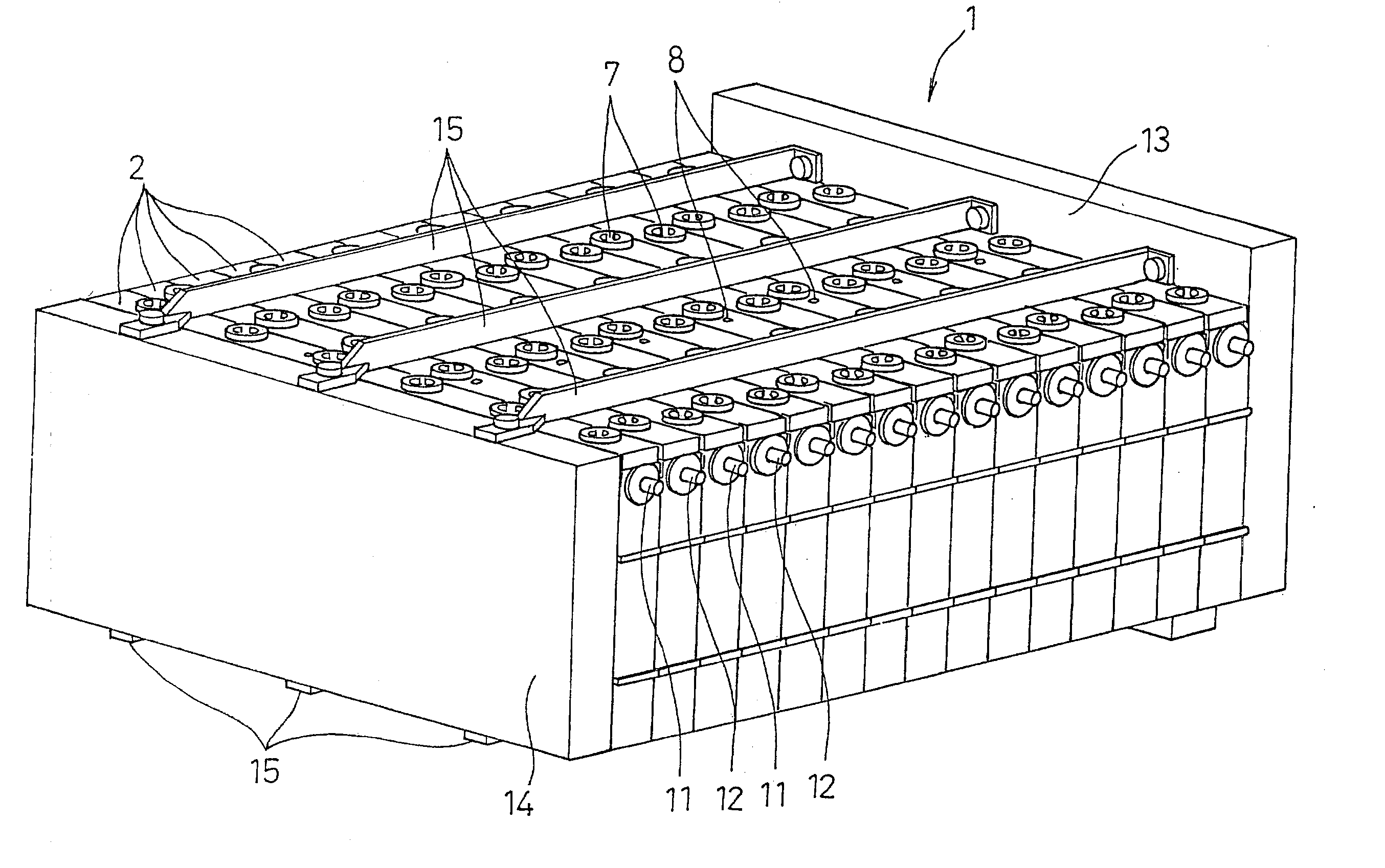

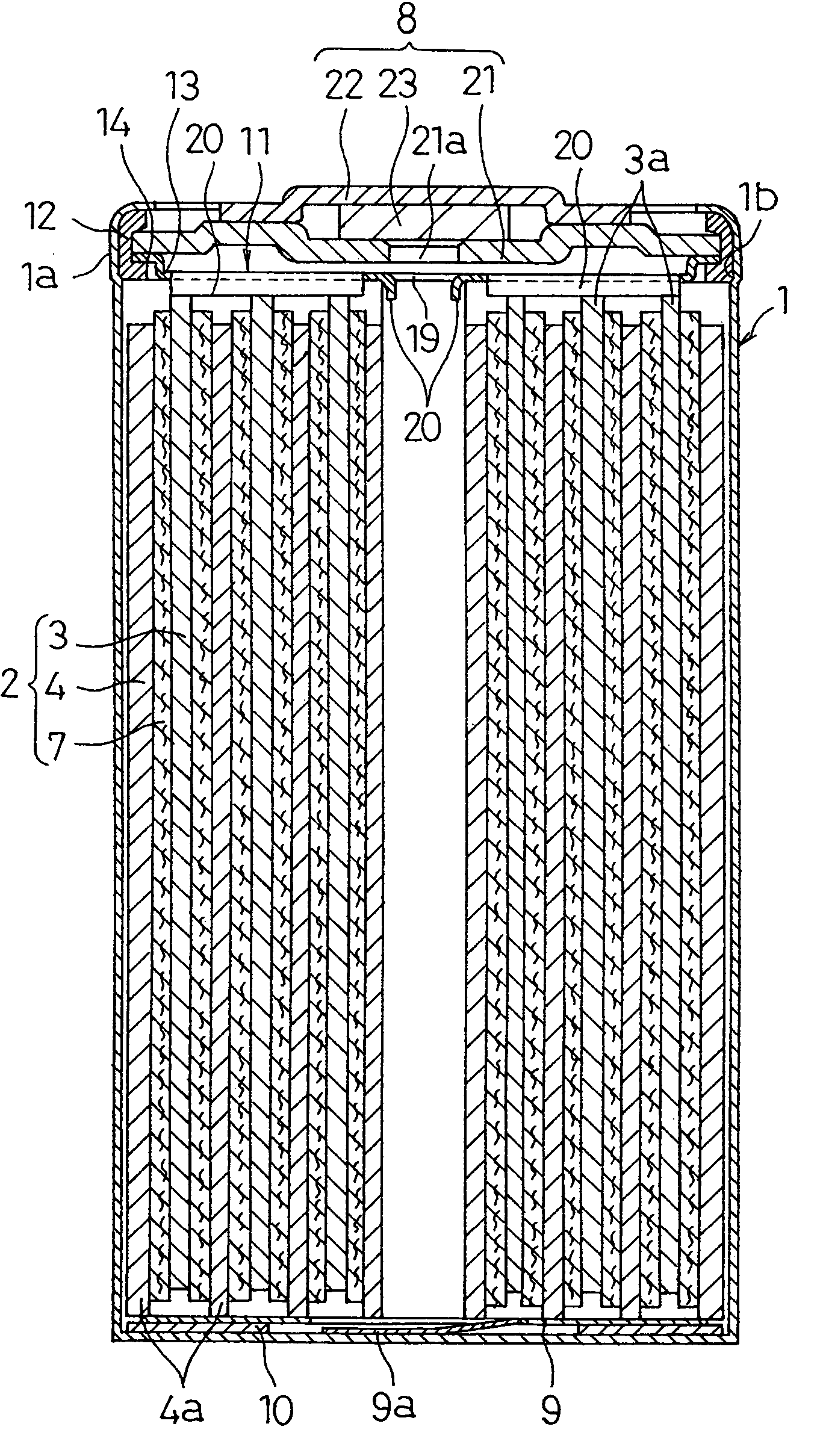

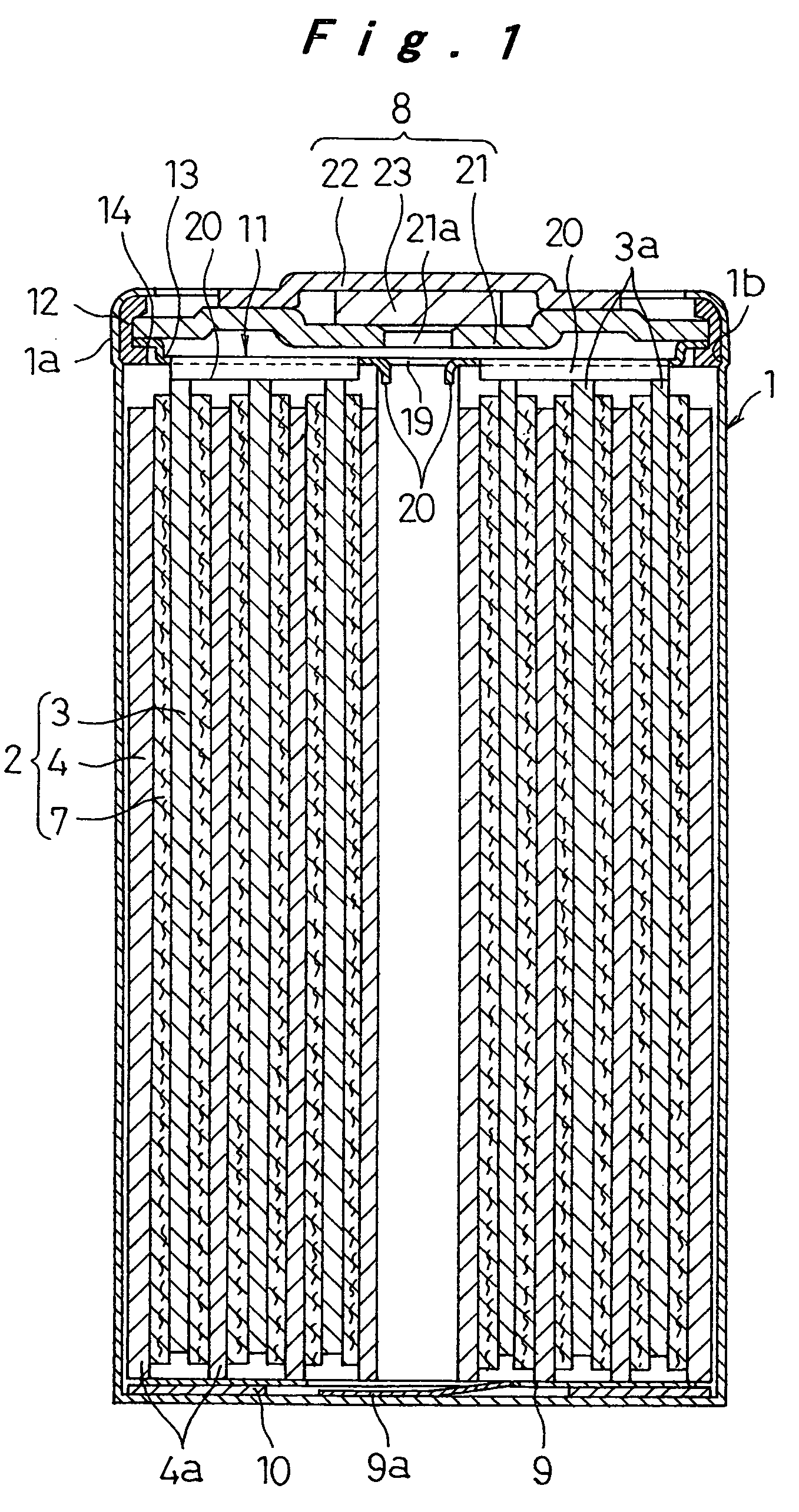

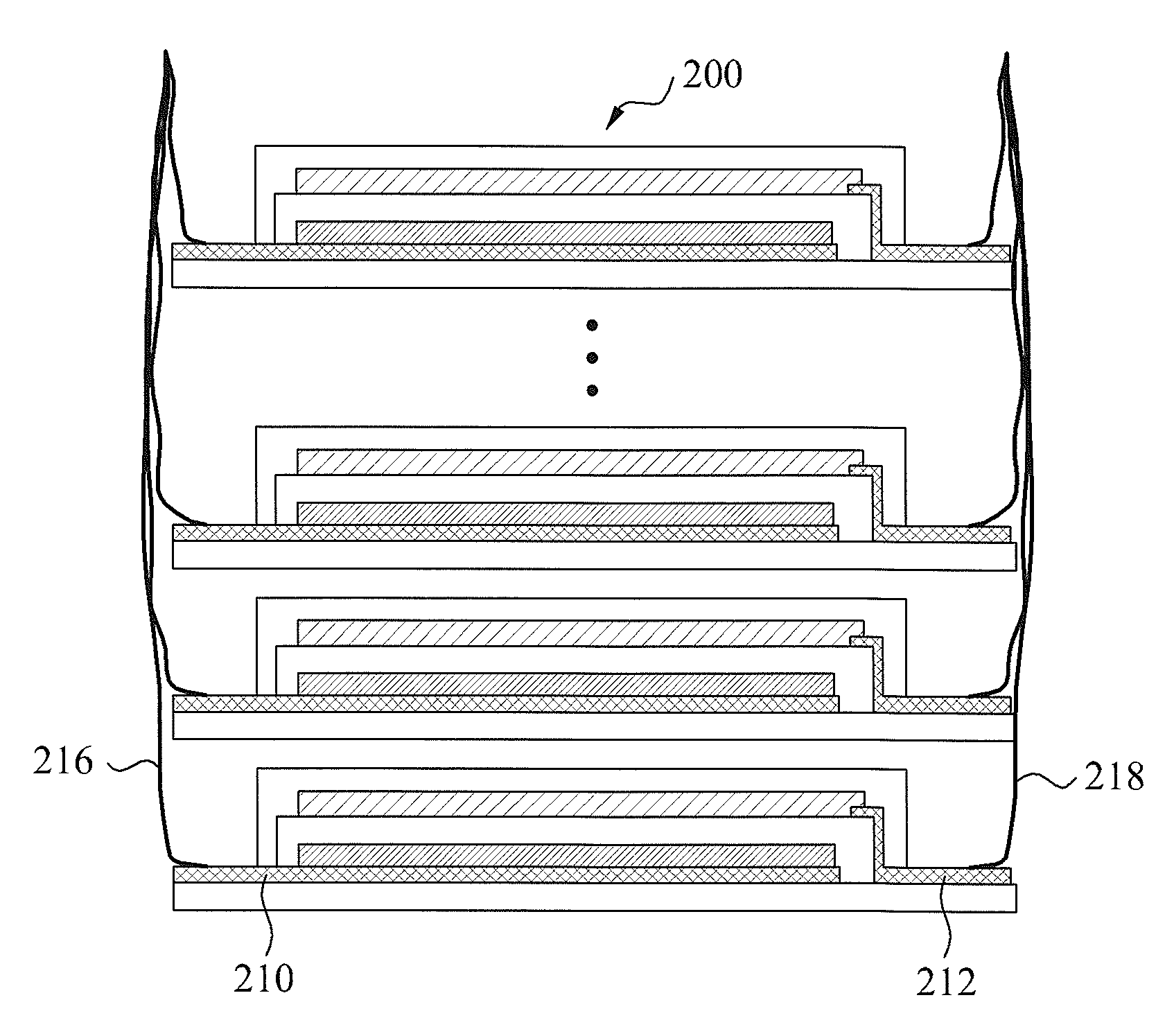

Battery module having a plurality of interconnected batteries

InactiveUS6555264B1Compact connectionImprove cooling effectPrimary cell to battery groupingFinal product manufactureEngineeringElectrical and Electronics engineering

A plurality of cells each encased in prismatic cell cases having short lateral walls and long lateral walls are arranged side by side, with adjacent short lateral walls being integral with each other, thereby constituting an integral battery case. The upper open ends of the plurality of prismatic cell cases are integrally closed by a single lid member. Each of the cells accommodates therein a group of electrodes stacked alternately upon one another parallel to the long lateral walls of the cell cases with intervening separators therebetween. Neighboring cells are connected in series at their abutting lateral opposite ends with each other.

Owner:PANASONIC CORP +1

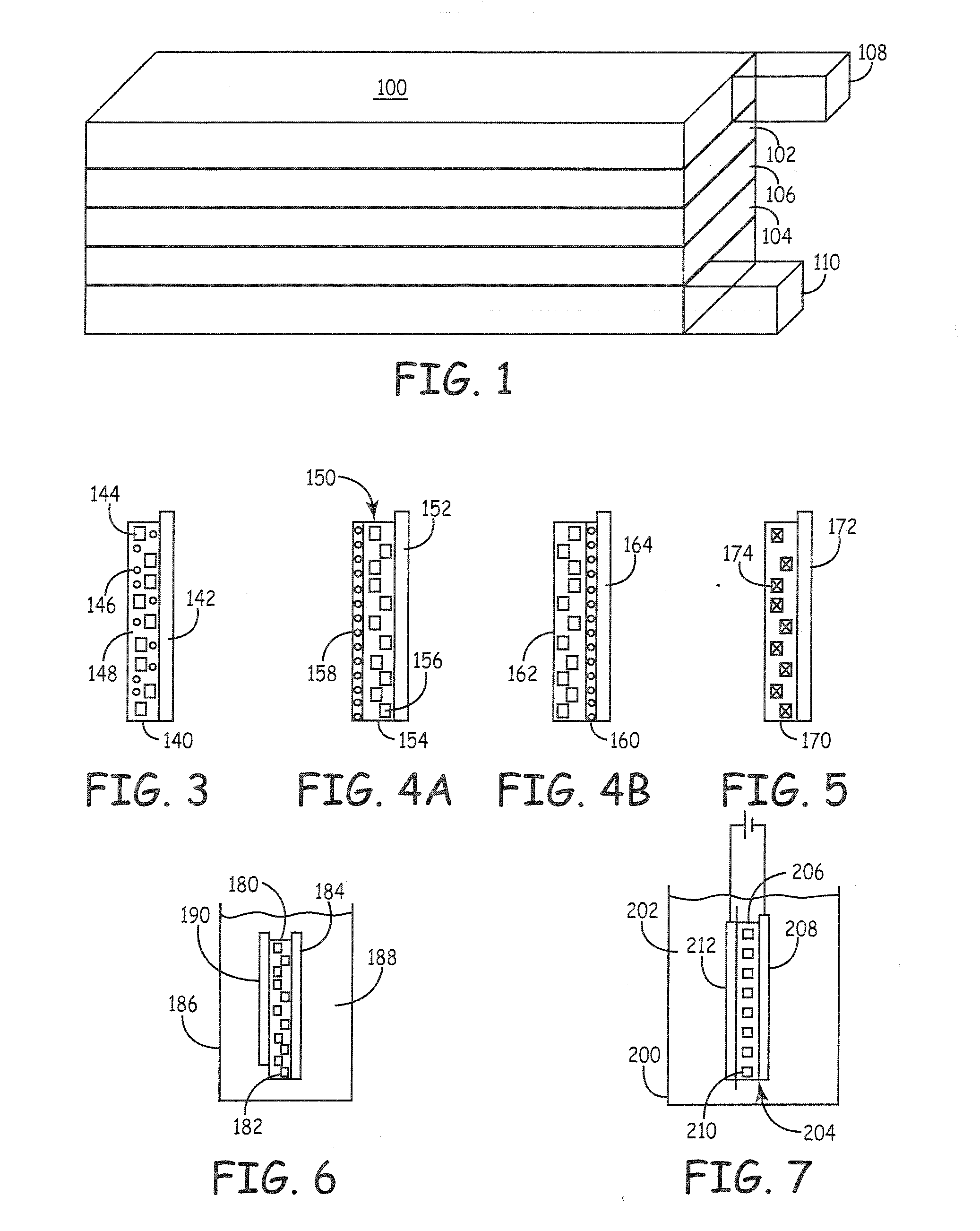

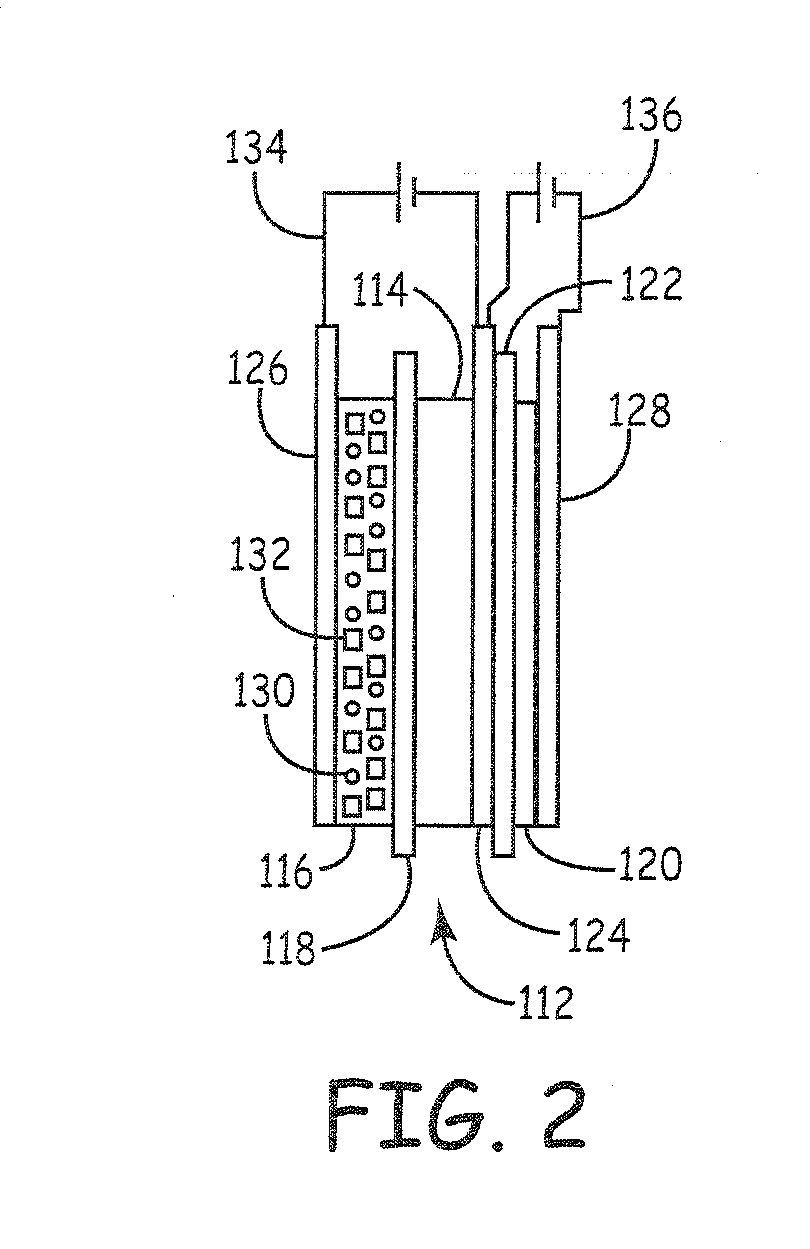

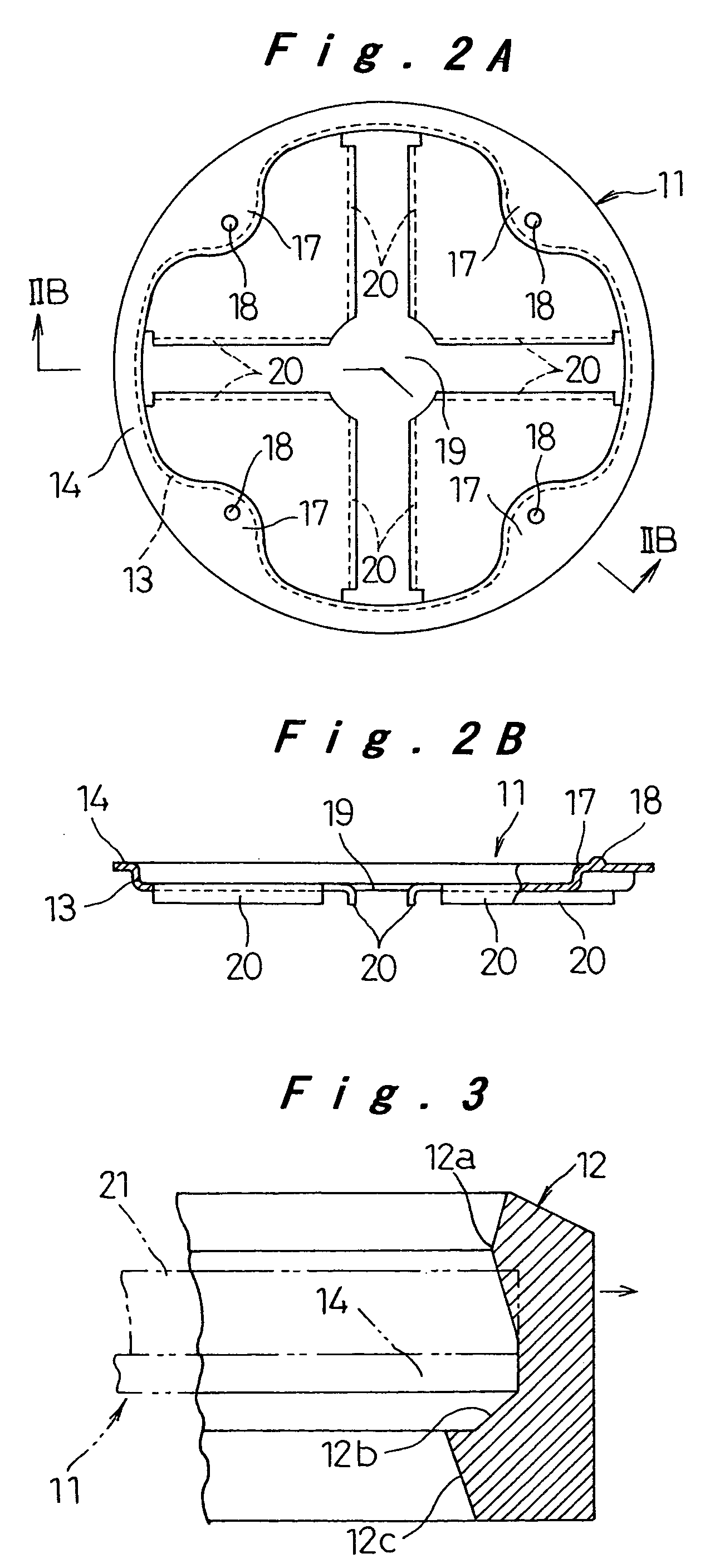

Bipolar battery and related method

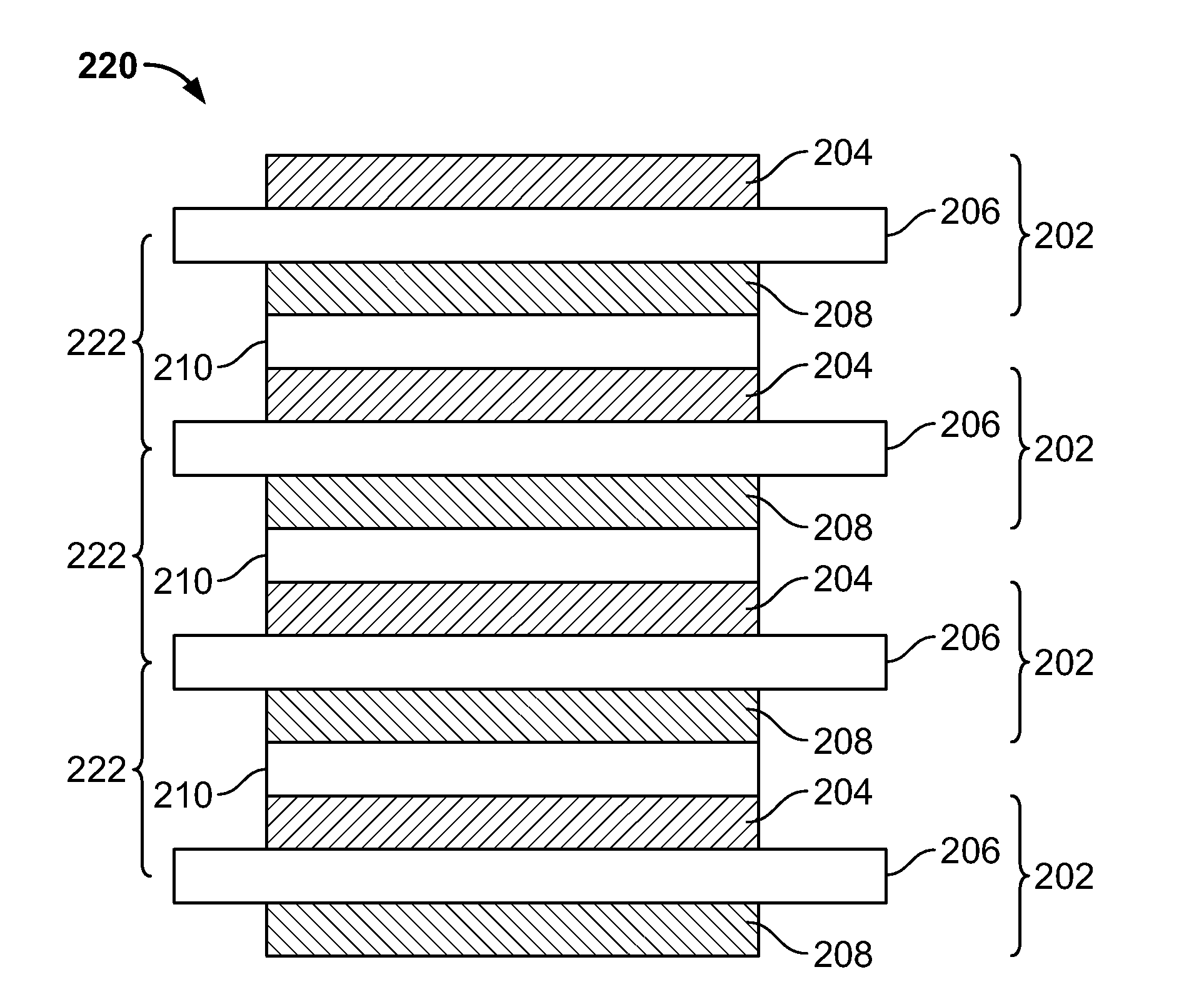

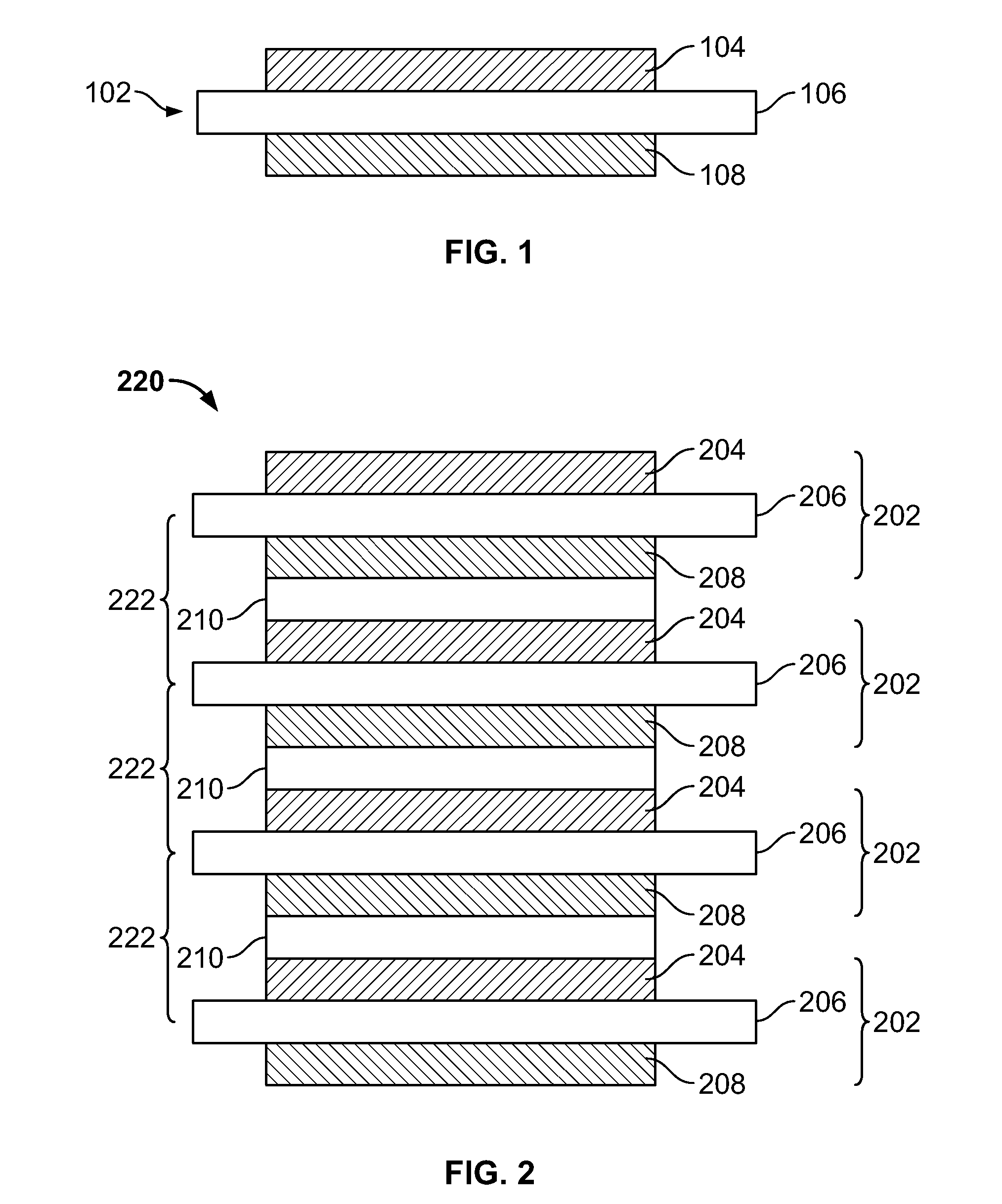

ActiveUS7279248B2Improve reliabilityKeep gapNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesEngineeringElectrolyte

A bipolar battery comprises: a plurality of bipolar electrodes; electrolyte layers formed between adjacent ones of the plurality of bipolar electrodes, respectively; sealing portions surrounding and sealing the electrolyte layers, respectively; and contributing members contributing to keeping gaps between the adjacent ones of the plurality of bipolar electrodes, respectively. The contributing members are disposed within areas of the sealing portions, respectively.

Owner:NISSAN MOTOR CO LTD

Biocompatible wire battery

ActiveUS20130034760A1Reliable and stable powerEasy to useFinal product manufactureSmall-sized cells cases/jacketsActive componentElectrochemistry

A rechargeable electrochemical battery in the form of a single or multi-stranded wire assembly may be utilized as a power source for any number of implantable or non-implantable medical devices. As the wire form battery may be scaled to micro size, it may be utilized to power medical devices that were traditionally non-active devices, but which may be enhanced with active components. The wire form battery may be cut to size for a particular application which provides the same open circuit voltage regardless of how the wire is ultimately configured and the length of the wire utilized. Although the battery is in wire form, various arrangements of the components within the battery are also possible.

Owner:JOHNSON & JOHNSON VISION CARE INC

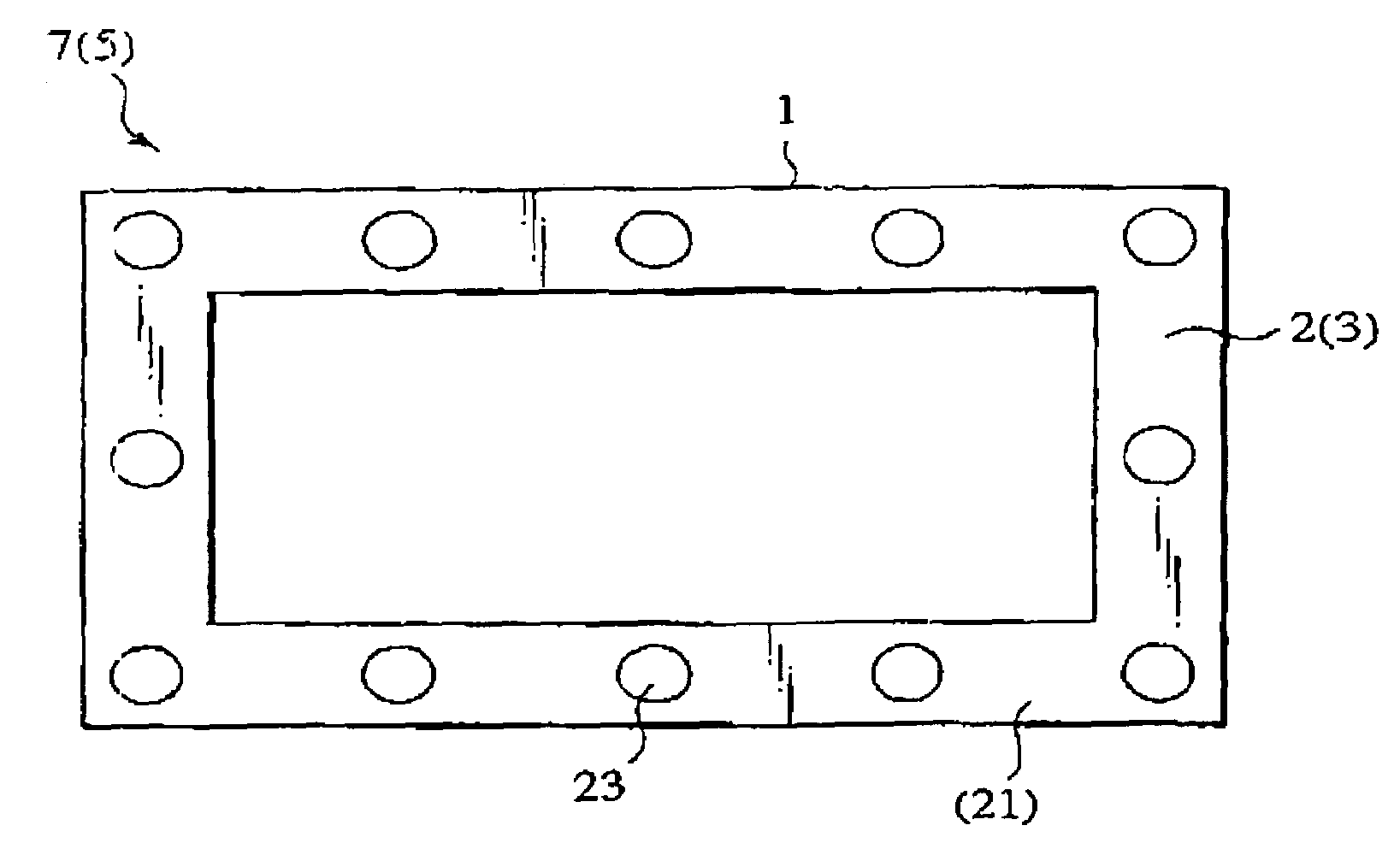

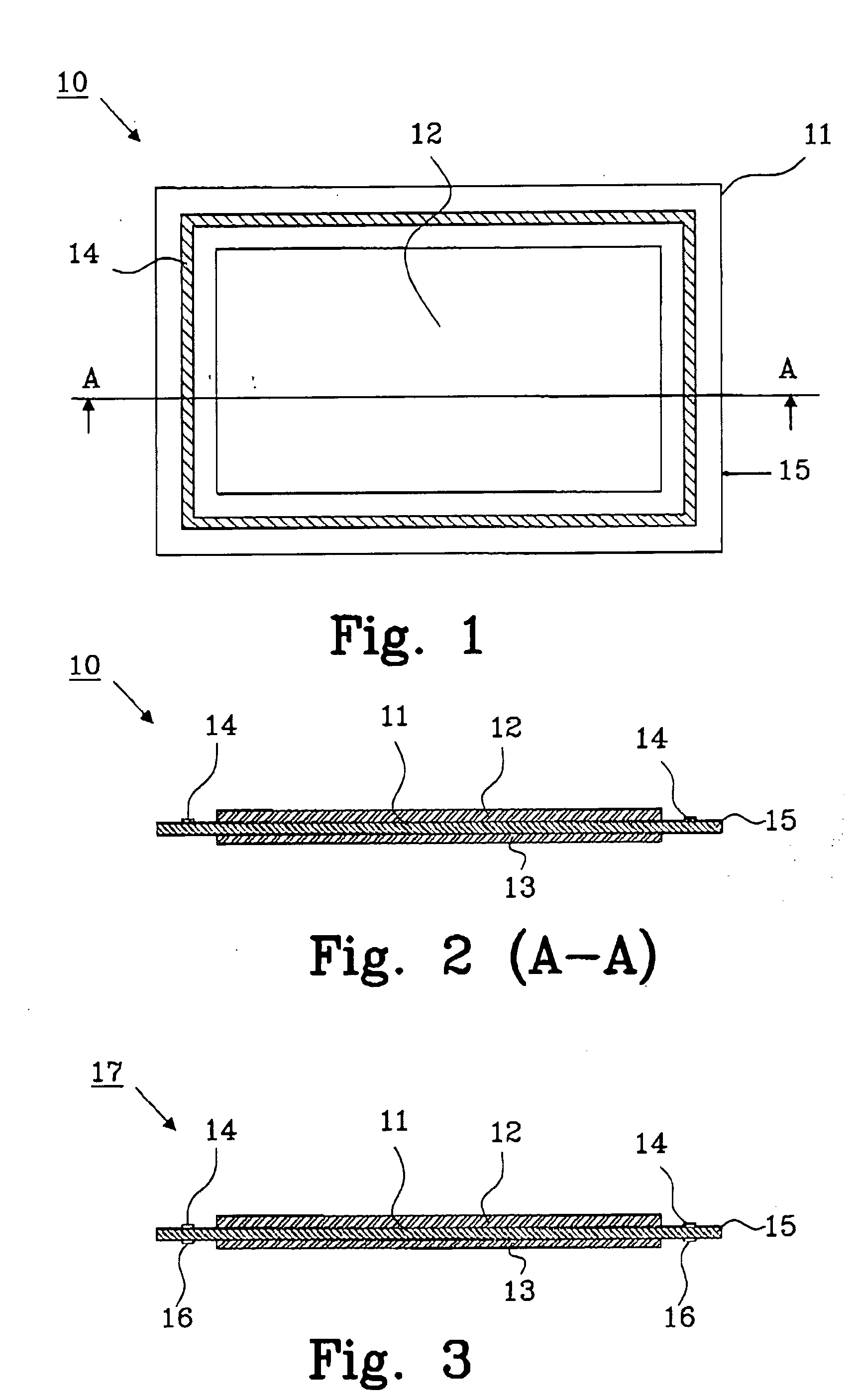

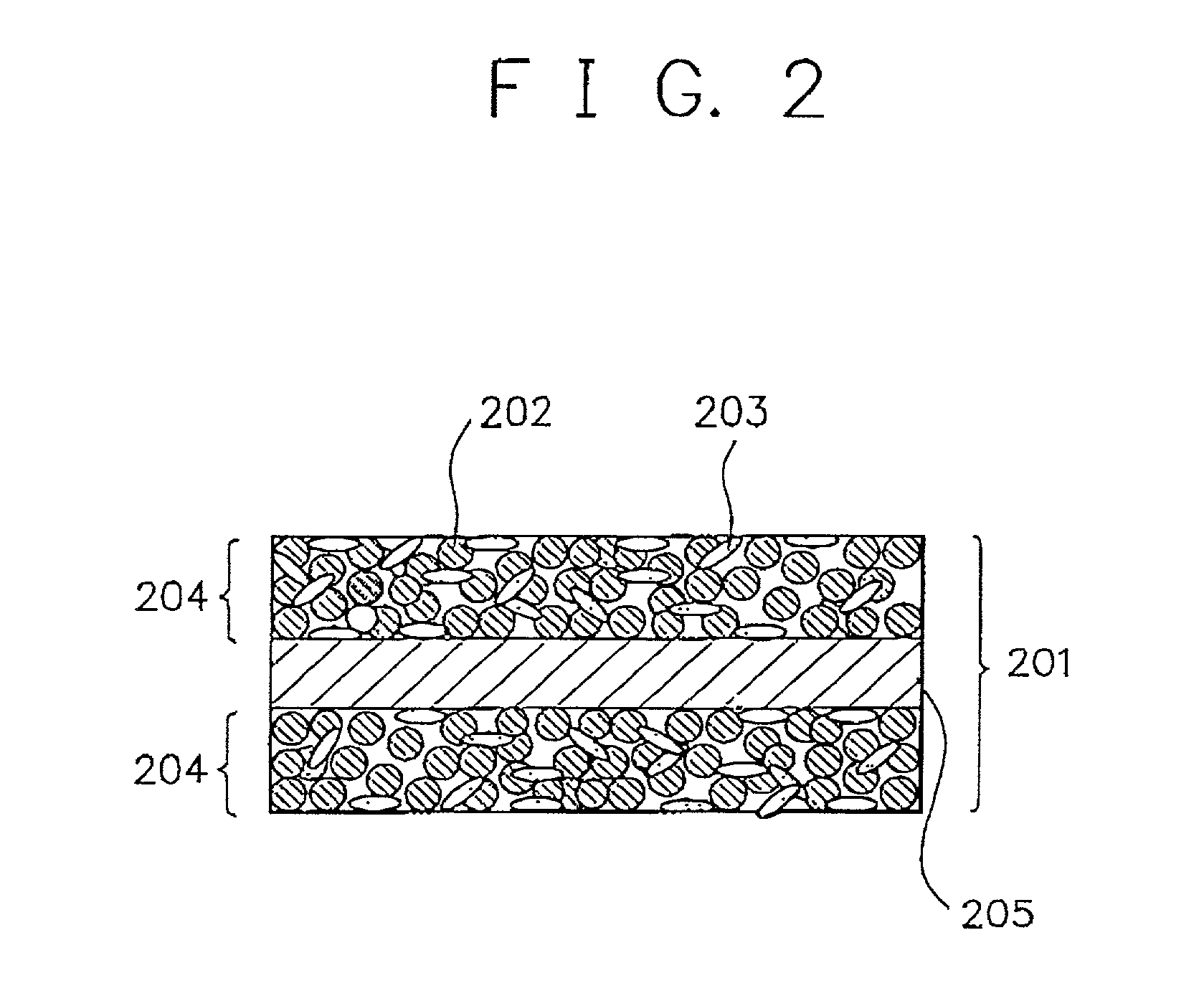

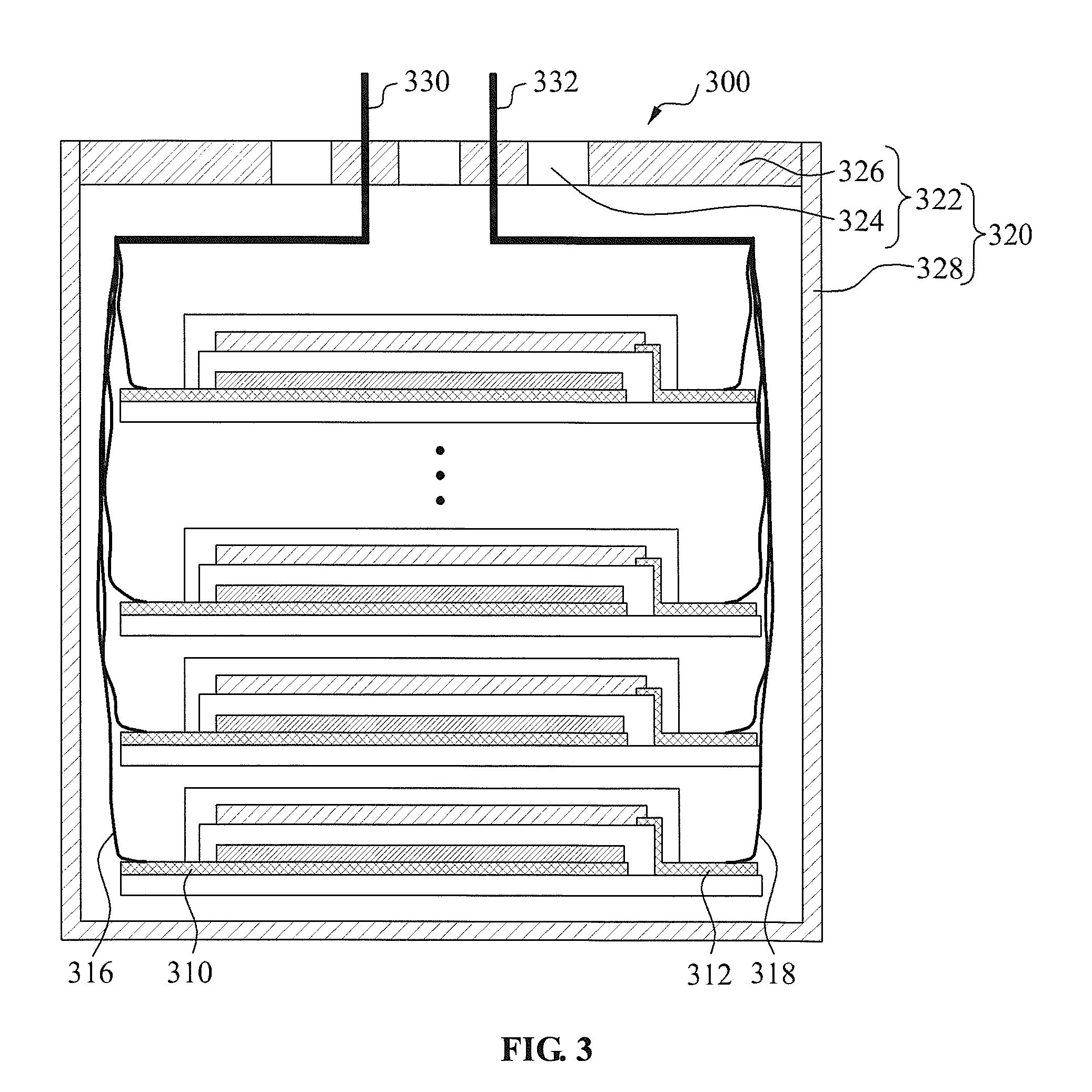

Bipolar battery and a method for manufacturing a bipolar battery

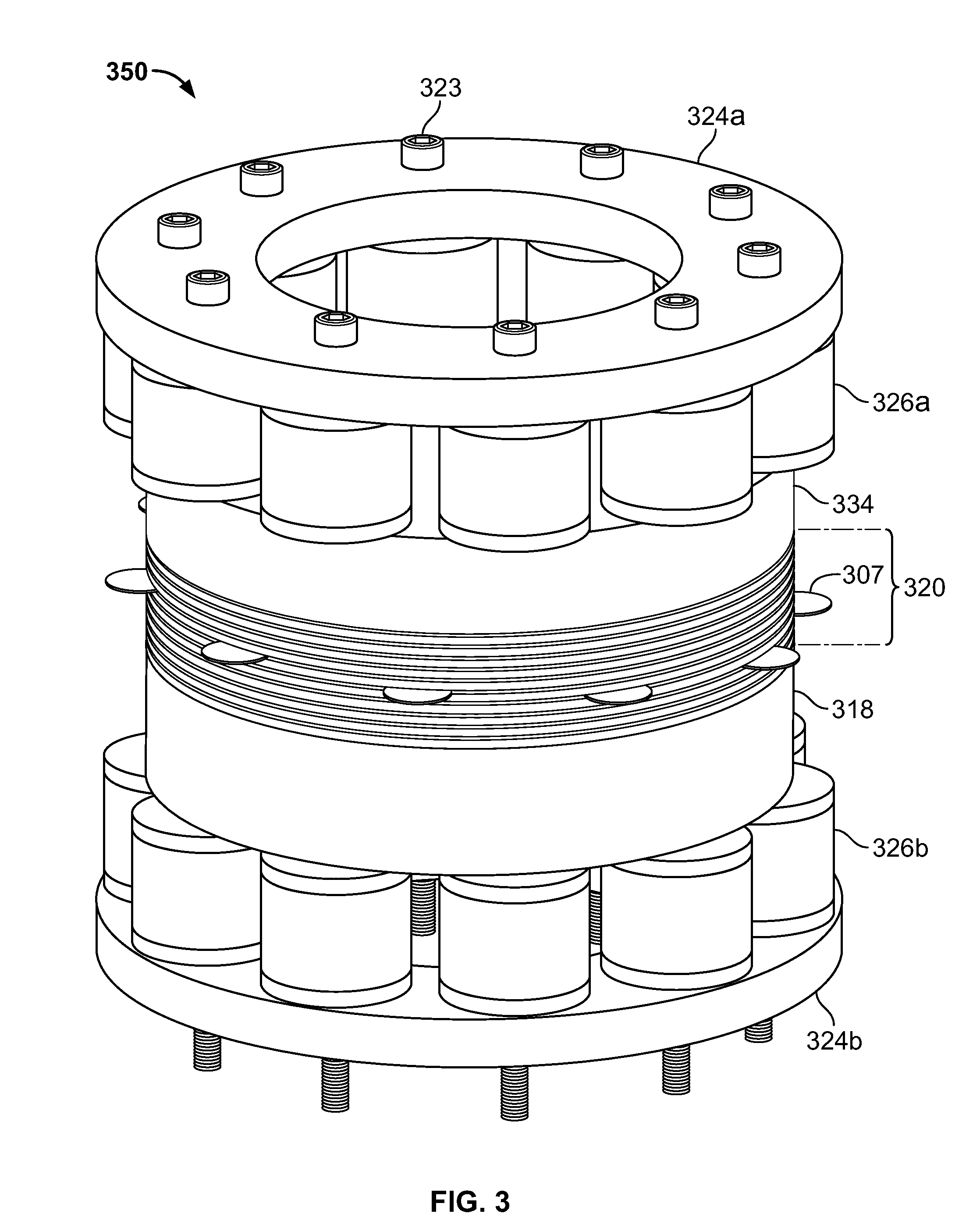

ActiveUS20050260493A1Easy to manufactureLow costLarge-sized flat cells/batteriesFinal product manufactureMechanical engineeringBattery cell

The present invention relates to a bipolar battery, especially a NiMH battery, having: a sealed housing, a negative end terminal, a positive end terminal, and at least one biplate assembly comprising a biplate, a positive and a negative electrode. A separator is arranged between each negative and positive electrode forming a battery cell, said separator includes an electrolyte. An inner barrier of a hydrophobic material is arranged around at least one electrode, whereby said inner barrier prevents an electrolyte path from one cell to another cell, and a frame is present to provide predetermined cell spacing between each biplate and / or biplate and end terminal. The frame is attached in such a way to each biplate to permit ambient gas to pass between adjacent cells, thereby creating a common gas space for all cells in the battery. The invention also relates to a method for manufacturing a bipolar battery.

Owner:NILAR INT AB

Battery pack

InactiveUS20030118898A1Primary cell to battery groupingLarge-sized flat cells/batteriesEngineeringBattery pack

Owner:PANASONIC CORP +1

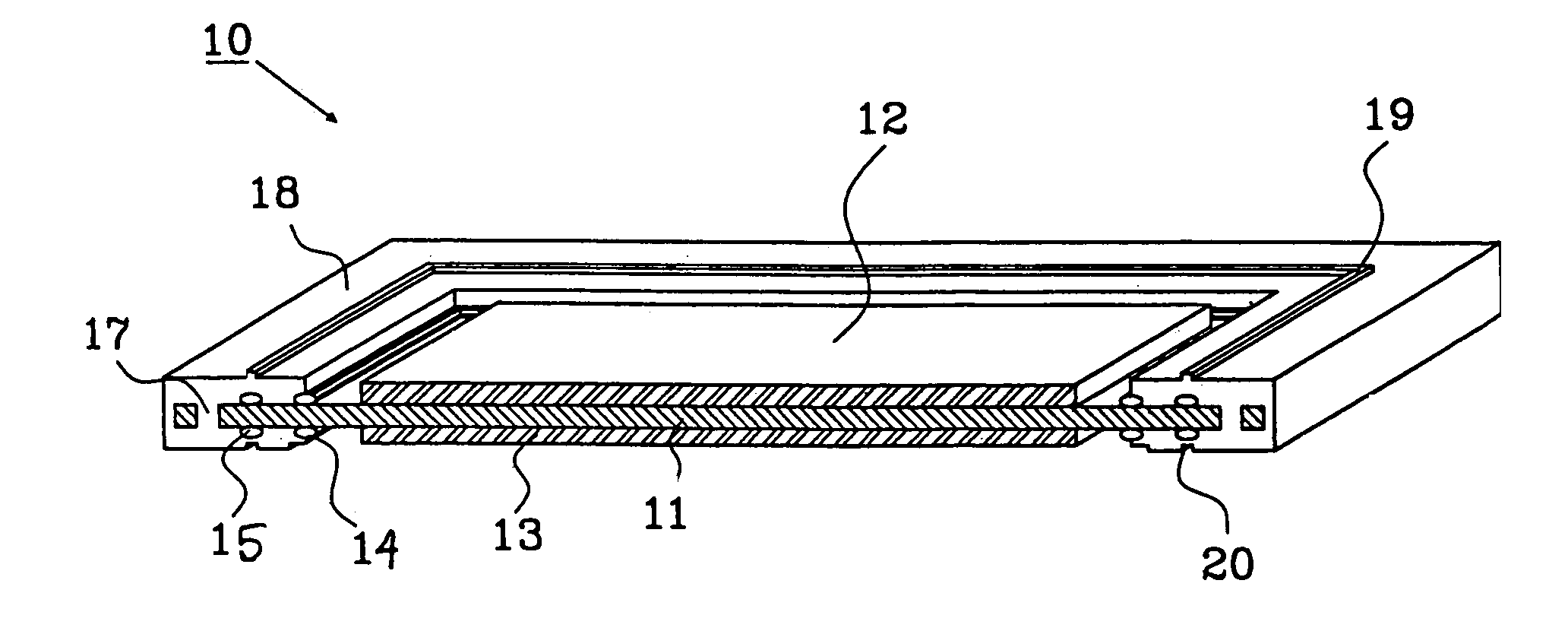

Bipolar battery and biplate assembly

ActiveUS7097937B2Improve sealingPrevent electrolyte leakage pathLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery cell

The present invention relates to a bipolar battery having at least two battery cells comprising: a sealed housing, a negative end terminal, a positive end terminal, at least one biplate assembly arranged in a sandwich structure between said negative and positive end terminals, and a separator, including an electrolyte, arranged between each negative and positive electrode forming a battery cell. The biplate assembly is provided with an inner barrier of a hydrophobic material around the negative and the positive electrode, respectively, and an outer seal around the edge of each biplate. Each end terminal is provided with a terminal seal. The edge of each biplate is positioned close to the sealed housing to provide means to conduct heat from each biplate assembly to the ambient environment. The invention also relates to a method for manufacturing a bipolar battery and a biplate assembly.

Owner:NILAR INT AB

Battery and manufacturing method thereof

InactiveUS20050048365A1Easily manufactured structureHigh power outputFinal product manufactureSmall-sized cells cases/jacketsFlangeElectrode

A battery which realizes high power output, cost reduction and increase in capacity. An enlarged port section is formed in an open end of a battery case. A ring-shaped support rack section is formed inside of the enlarged port section, and a ring-shaped insulating gasket is set on and supported by the support rack section. The battery has a collector of one pole, to which an end portion of an electrode plate of one pole protruding from an electrode plate group is connected. A ring and flange-shaped collar section, which is tiered with a step, is provided in the periphery of the collector, and the flange-shaped collar section is set on the bottom face of the insulating gasket. A port sealing member, in which a filter section and a cap-shaped terminal section are integrated with each other, is connected onto the collector. The enlarged port section is inwardly caulked, to fix the flange-shaped collar section of the collector and the periphery of the port sealing member, which are overlaid with each other, with the insulating gasket interposed therebetween.

Owner:PANASONIC CORP

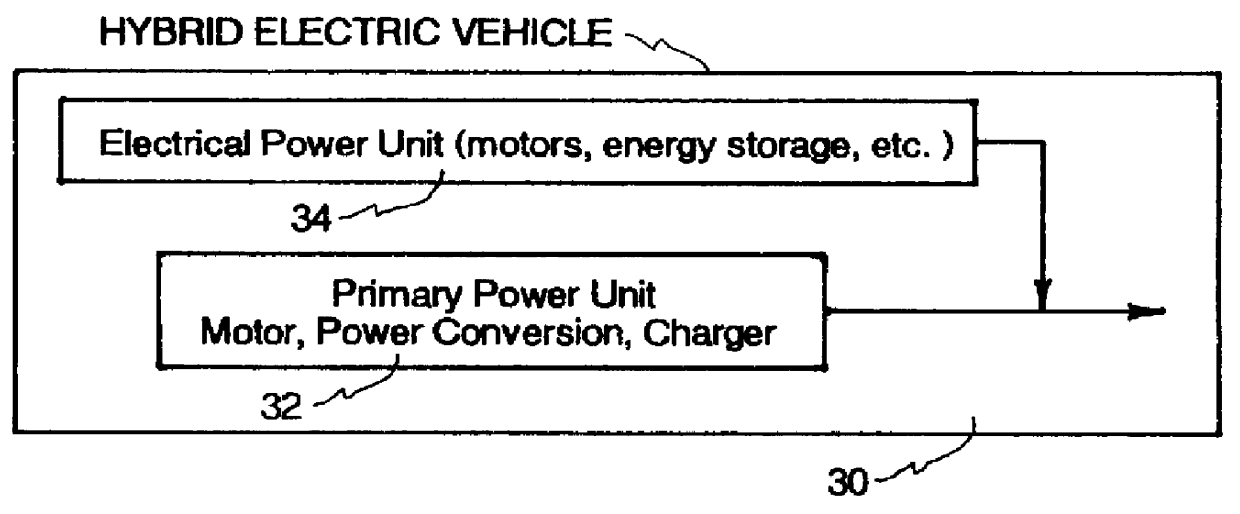

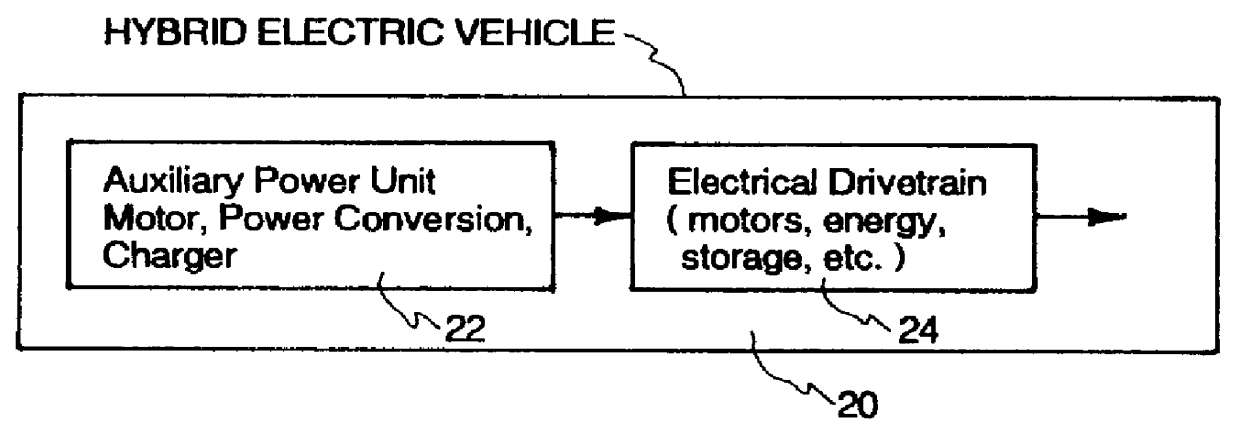

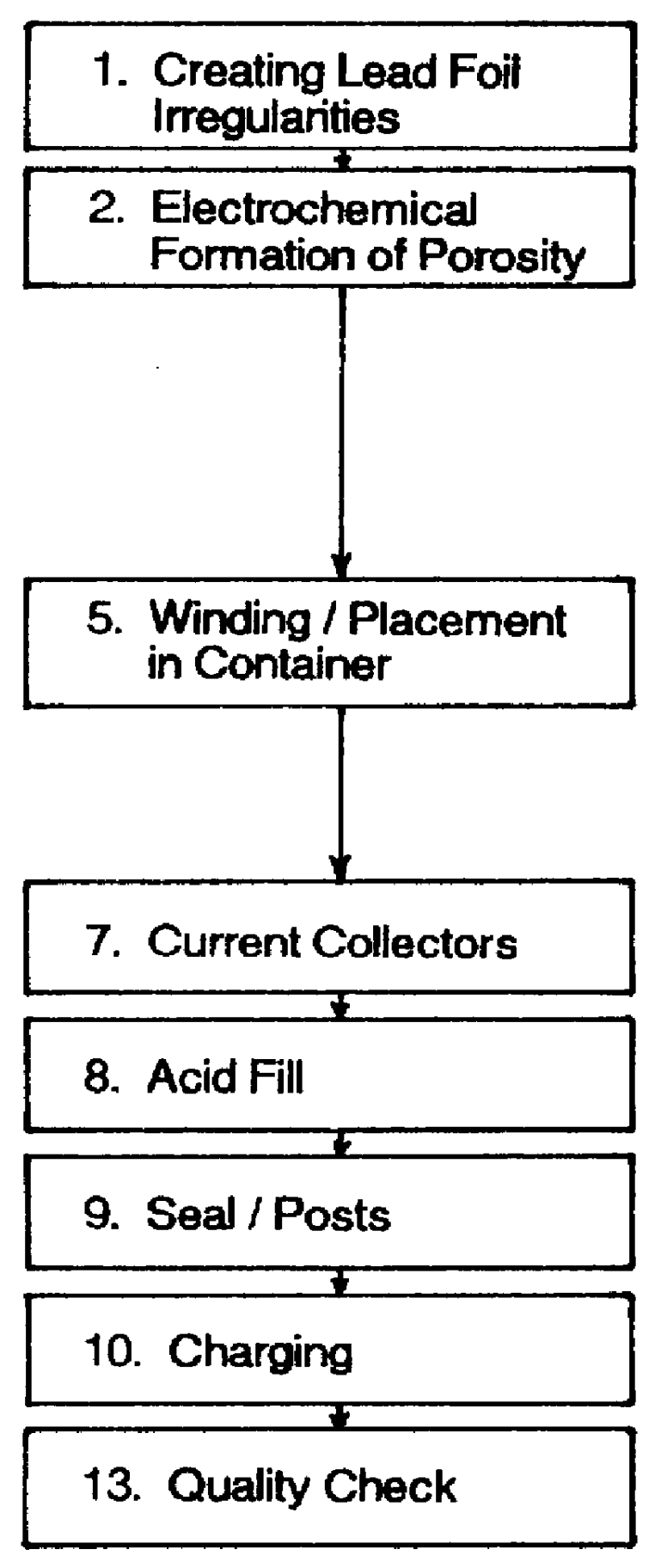

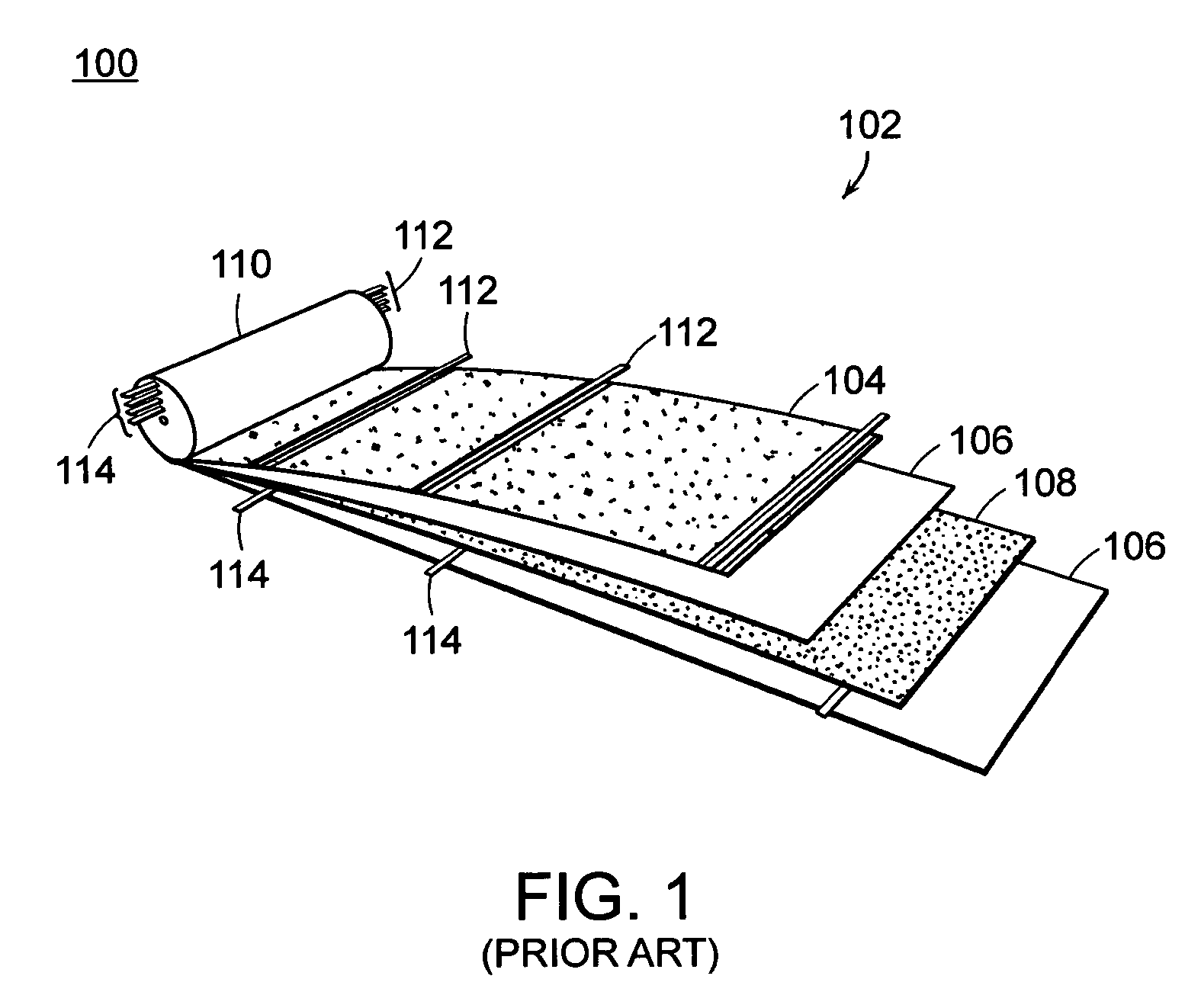

Source of electrical power for an electric vehicle and other purposes, and related methods

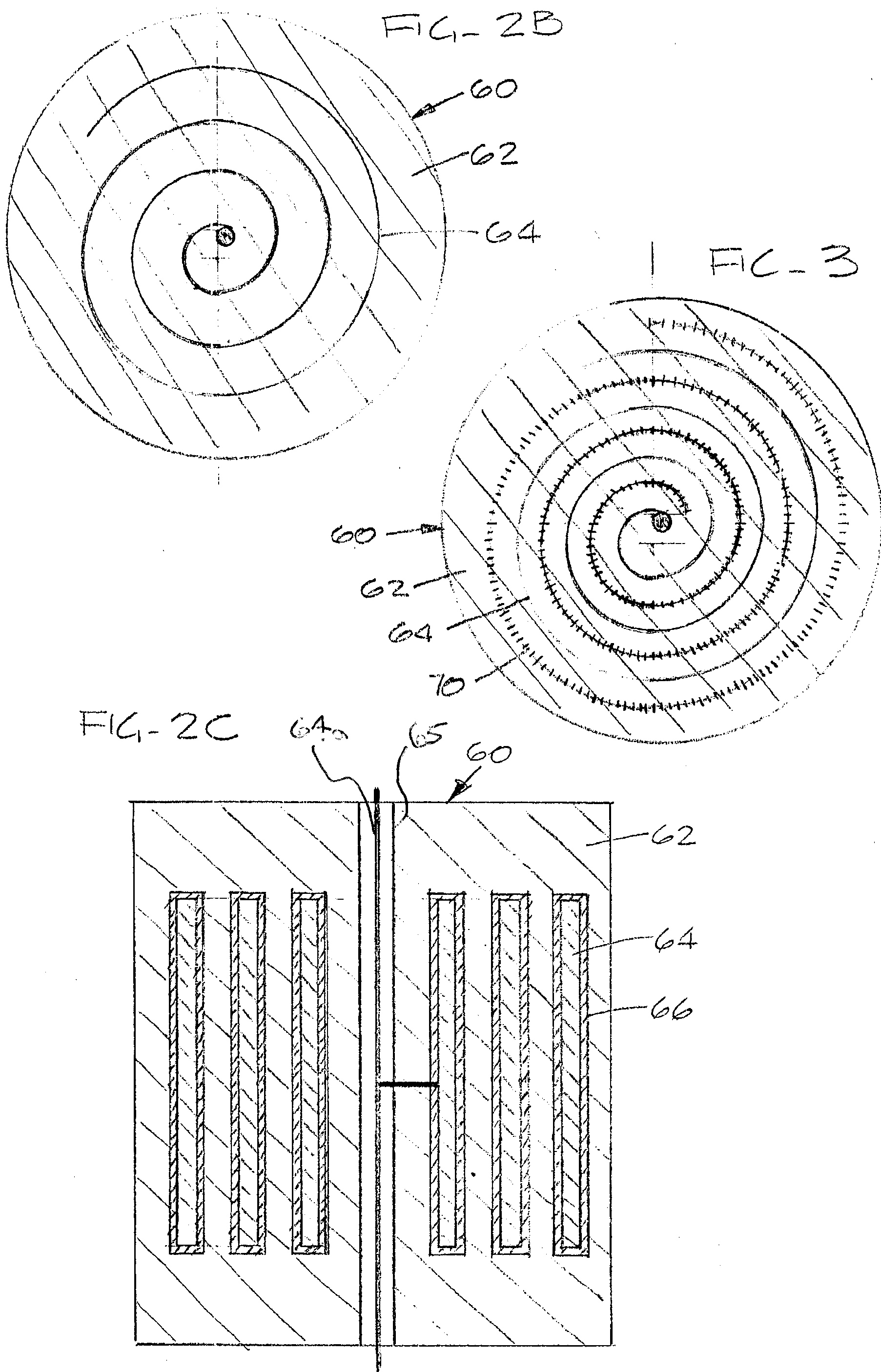

InactiveUS6063525AIncrease capacityIncrease powerSilver accumulatorsElectrode manufacturing processesCapacitancePorosity

Microthin sheet technology is disclosed by which superior batteries are constructed which, among other things, accommodate the requirements for high load rapid discharge and recharge, mandated by electric vehicle criteria. The microthin sheet technology has process and article overtones and can be used to form thin electrodes used in batteries of various kinds and types, such as spirally-wound batteries, bipolar batteries, lead acid batteries, silver / zinc batteries, and others. Superior high performance battery features include: (a) minimal ionic resistance; (b) minimal electronic resistance; (c) minimal polarization resistance to both charging and discharging; (d) improved current accessibility to active material of the electrodes; (e) a high surface area to volume ratio; (f) high electrode porosity (microporosity); (g) longer life cycle; (h) superior discharge / recharge characteristics; (j) higher capacities (Axhr); and k) high specific capacitance.

Owner:BIPOLAR TECH

Separator for alkaline battery, method for producing the same, and battery

InactiveUS20100310921A1Improve the blocking effectAvoid dendrite formationMaterial nanotechnologyCell seperators/membranes/diaphragms/spacersPolyvinyl alcoholElectrical battery

Provided is a separator for alkaline batteries which can not only prevent batteries from internal short circuit by inhibiting the dendrite formation at anode, but also enables to have a low electrical resistance. The separator for alkaline batteries comprises a composite sheet in which a base layer comprising a wet-type nonwoven material formed from alkaline resistant fibers is covered with a nanofiber layer comprising a modified polyvinyl alcohol fiber which has a fiber diameter of 10 to 1000 nm and a liquid absorption amount by fibers of 4.0 to 40.0 g / g after immersion in a 35% aqueous solution of KOH.

Owner:KURARAY CO LTD

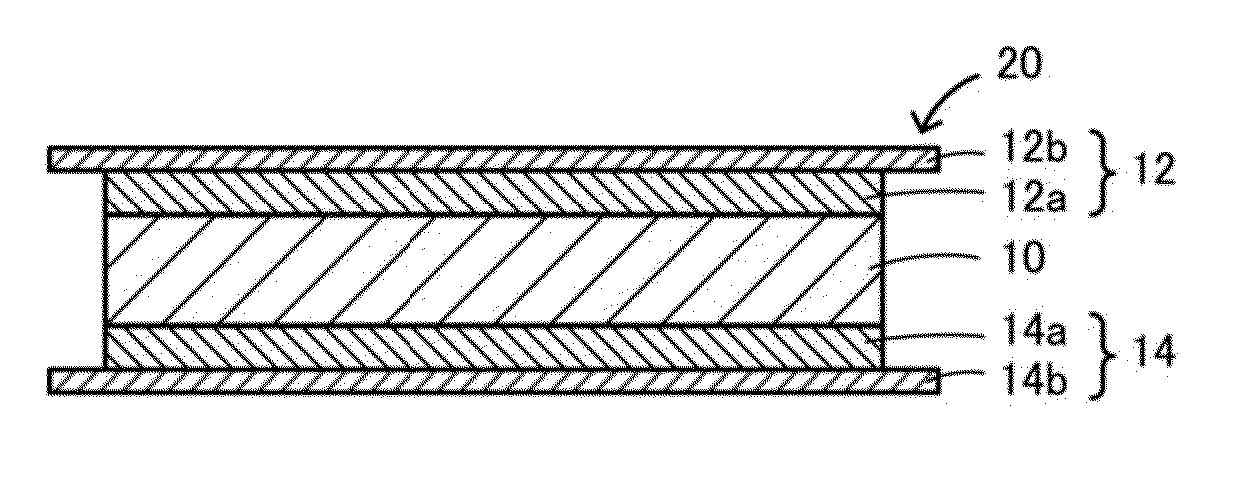

Garnet-type ion conducting oxide, complex, lithium secondary battery, manufacturing method of garnet-type ion conducting oxide and manufacturing method of complex

ActiveUS20150056519A1Reduce the temperatureAccelerates dissolution and diffusionElectrode thermal treatmentFinal product manufactureElectrolyteLithium borate

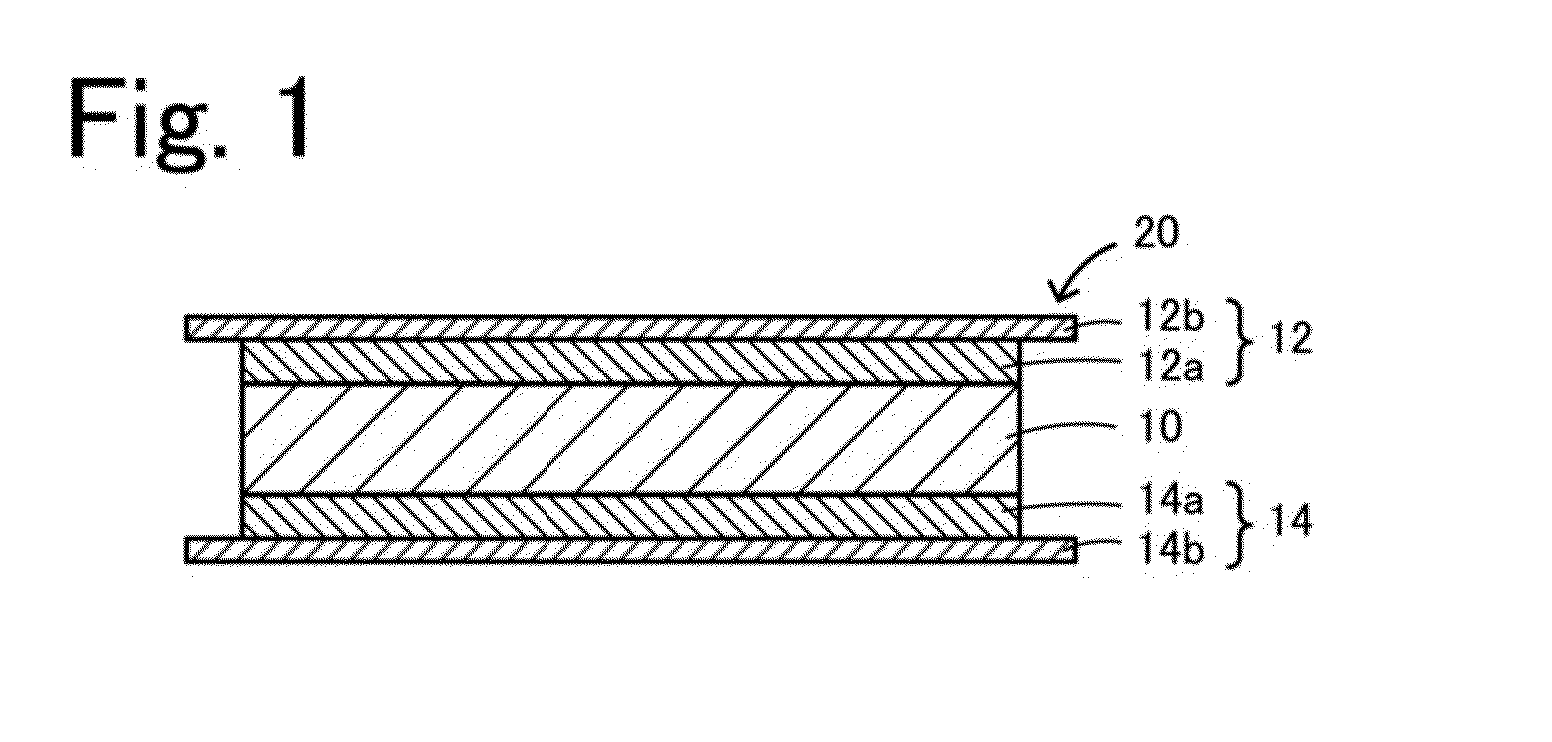

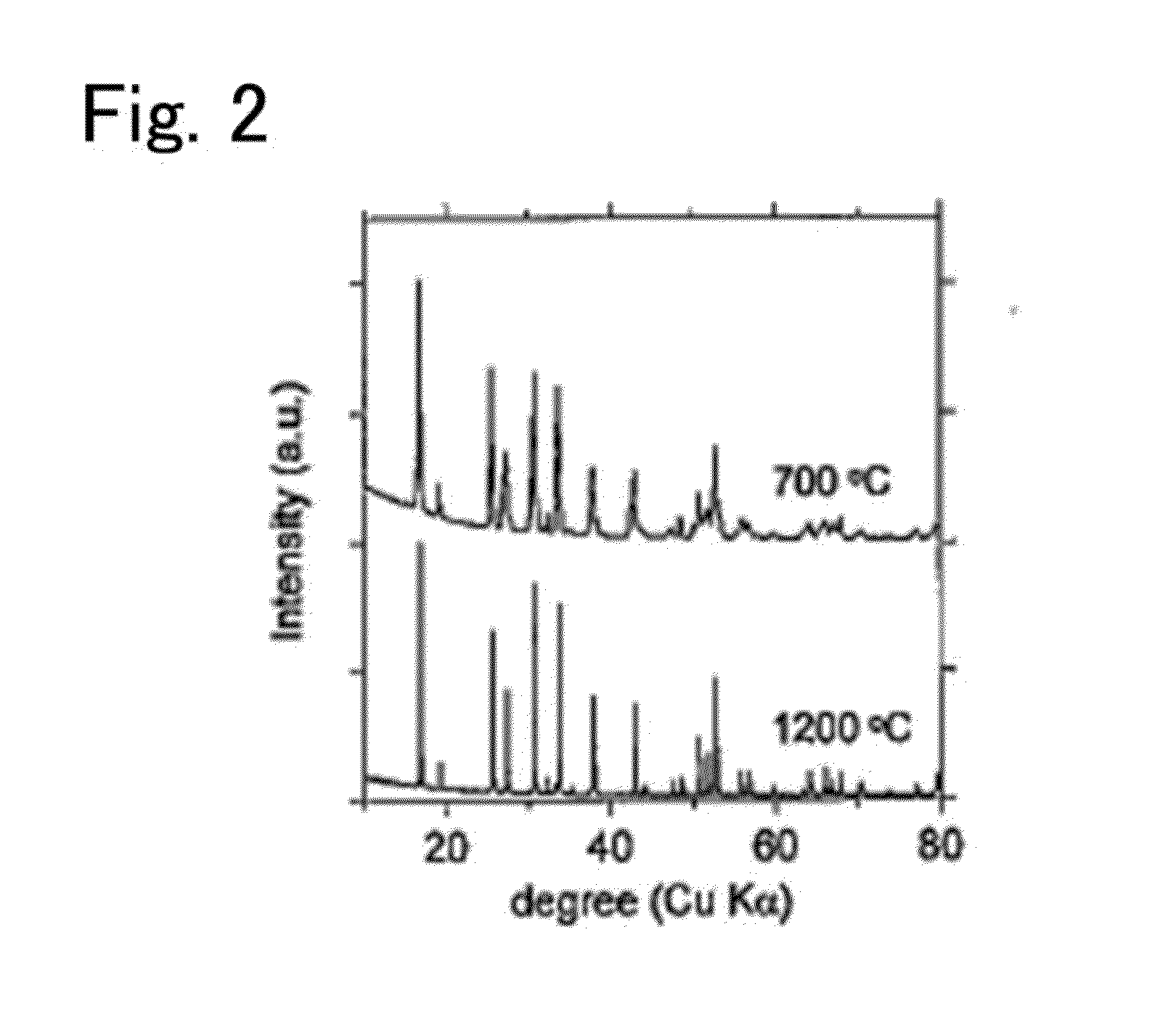

An all-solid lithium secondary battery 20 includes a solid electrolyte layer 10 composed of a garnet-type oxide, a positive electrode 12 formed on one surface of the solid electrolyte layer 10 and a negative electrode 14 formed on the other surface of the solid electrolyte layer 10. This all-solid lithium secondary battery 20 includes an integrally sintered complex of the solid electrolyte layer 10 and the positive electrode active material layer 12a. This complex is obtained by integrally sintering a stacked structure of an active material layer and a solid electrolyte layer. The solid electrolyte layer includes: abase material mainly including a fundamental composition of Li7+X−Y(La3−x,Ax) (Zr2−Y,TY)O12, wherein A is one or more of Sr and Ca, T is one or more of Nb and Ta, and 0≦X≦1.0 and 0≦Y<0.75 are satisfied, as a main component; and an additive component including lithium borate and aluminum oxide.

Owner:TOYOTA CENT RES & DEV LAB INC

Sealed rectangular battery and manufacturing method for the same

InactiveUS6579640B1Lower internal resistanceFinal product manufactureSmall-sized cells cases/jacketsInternal resistanceMiniaturization

A sealed rectangular battery has a conductive battery case including an external casing and a sealing cap. The external casing encloses a generator element and is sealed by attaching the sealing cap using heat. The battery includes an electrode terminal with an opposite polarity to the battery case, and a safety valve. The safety valve includes a cap that is charged with the same polarity as the battery case and a valving element that covers a vent hole. The electrode terminal and safety valve are provided separately at different positions on the battery case. This construction is simpler than conventional batteries where the safety valve is integrally formed with an electrode terminal, which means that the electrode terminal can be miniaturized. This battery also has improved internal resistance.

Owner:FDK CORP

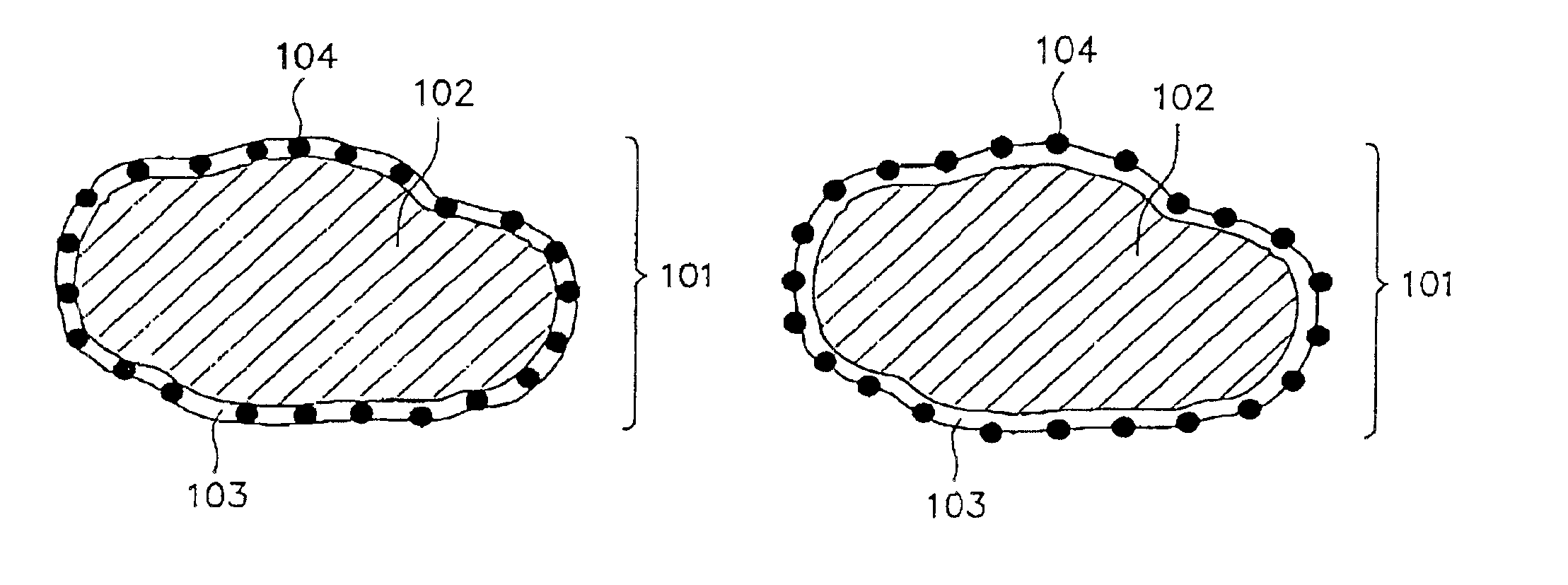

Alkaline rechargeable battery and process for the production thereof

InactiveUS20020197530A1High activityExtended service lifeFinal product manufactureElectrode carriers/collectorsHydrogenRechargeable cell

A rechargeable battery having an anode comprising a powdery composite material, said powdery composite material comprising a plurality of powdery composites having a structure comprising a core whose surface is covered by a coat layer, said core comprising an alloy particle of an alloy capable of reversibly storing and releasing hydrogen as a main component, said alloy containing at least one kind of a metal element selected from the group consisting of Zr, Ti and V as a main constituent element, and said coat layer comprising a hydrous oxide (including a hydroxide) of a metal element having an affinity with oxygen which is greater than that of any of said metal elements as the main constituent element of said alloy.

Owner:CANON KK

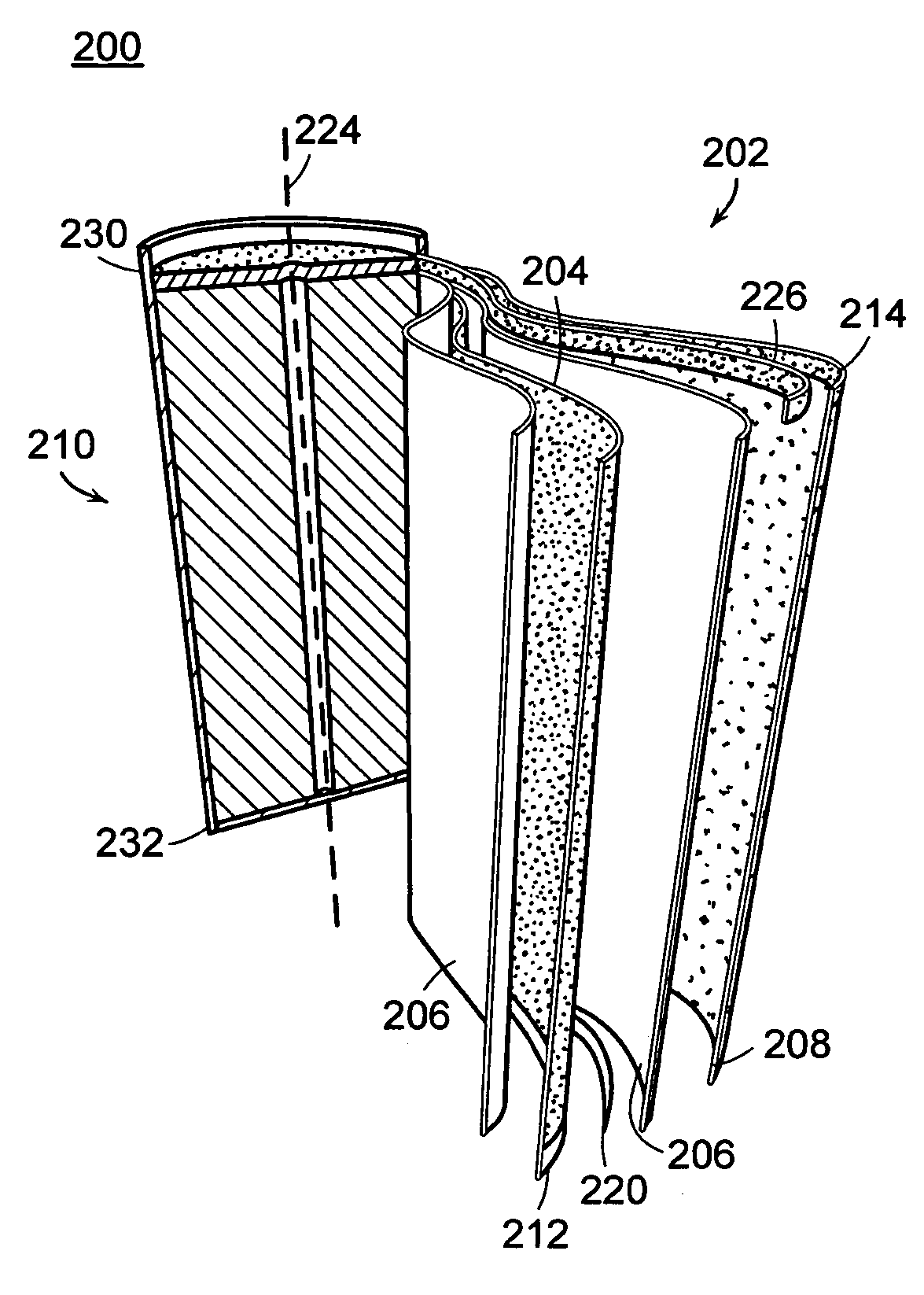

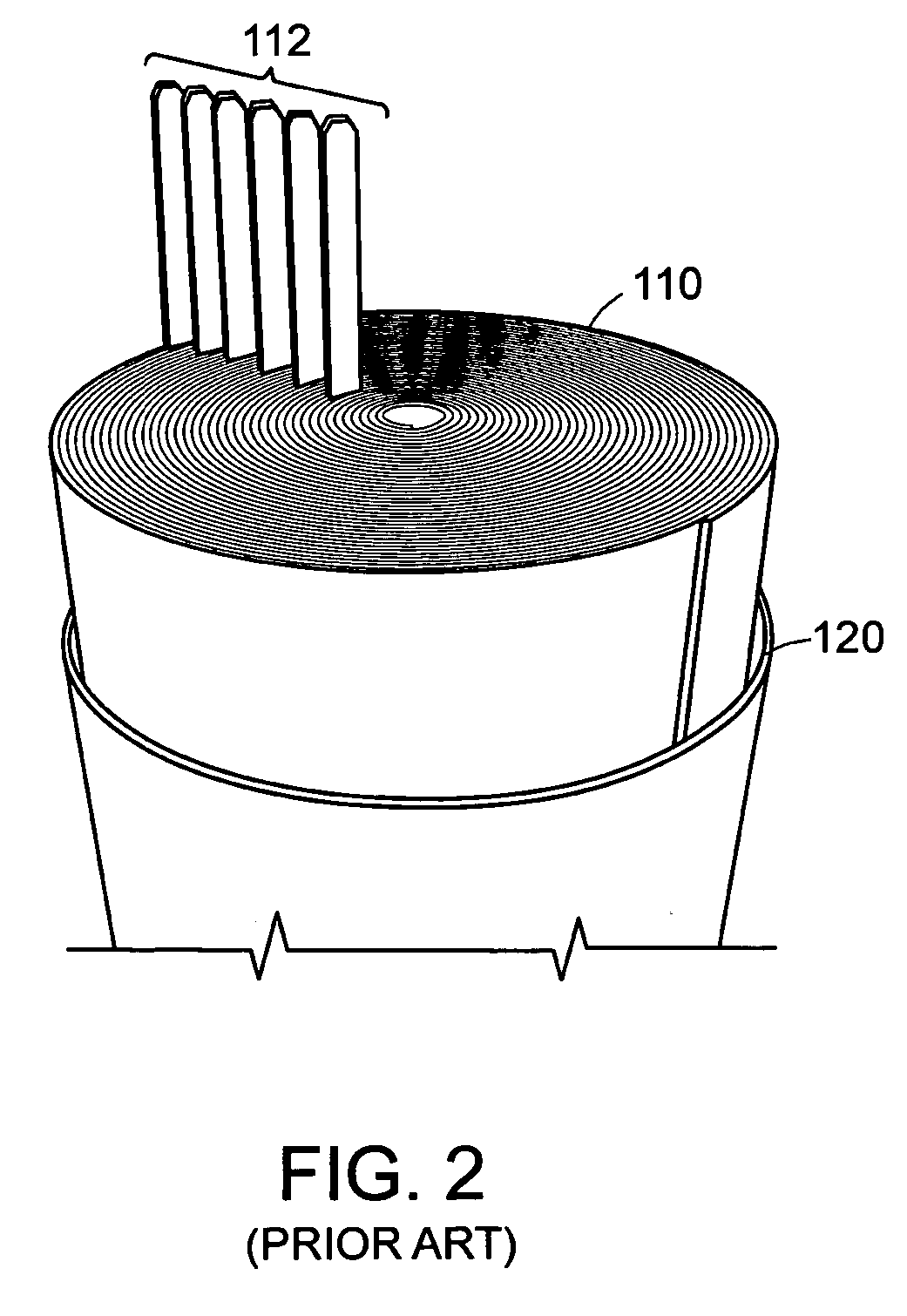

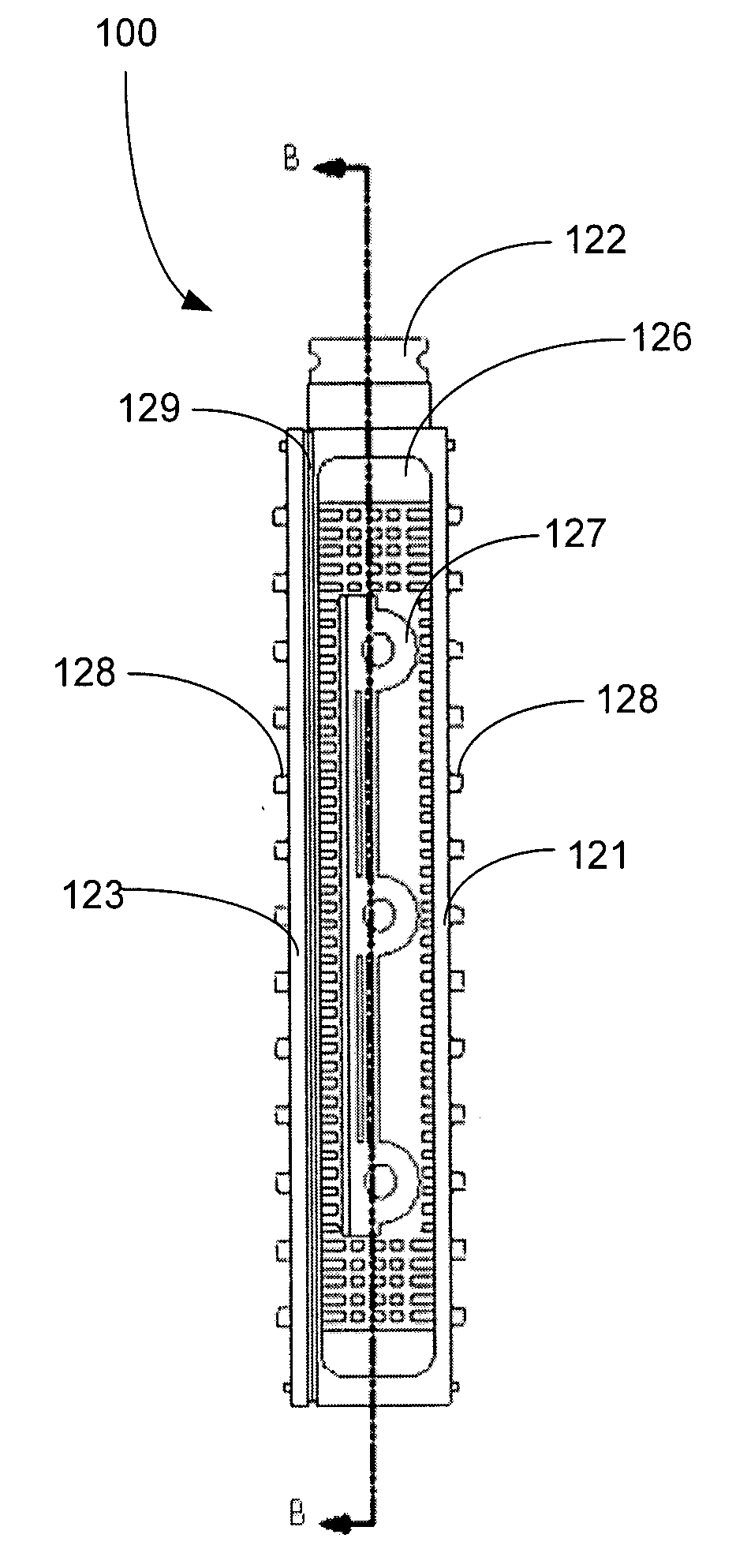

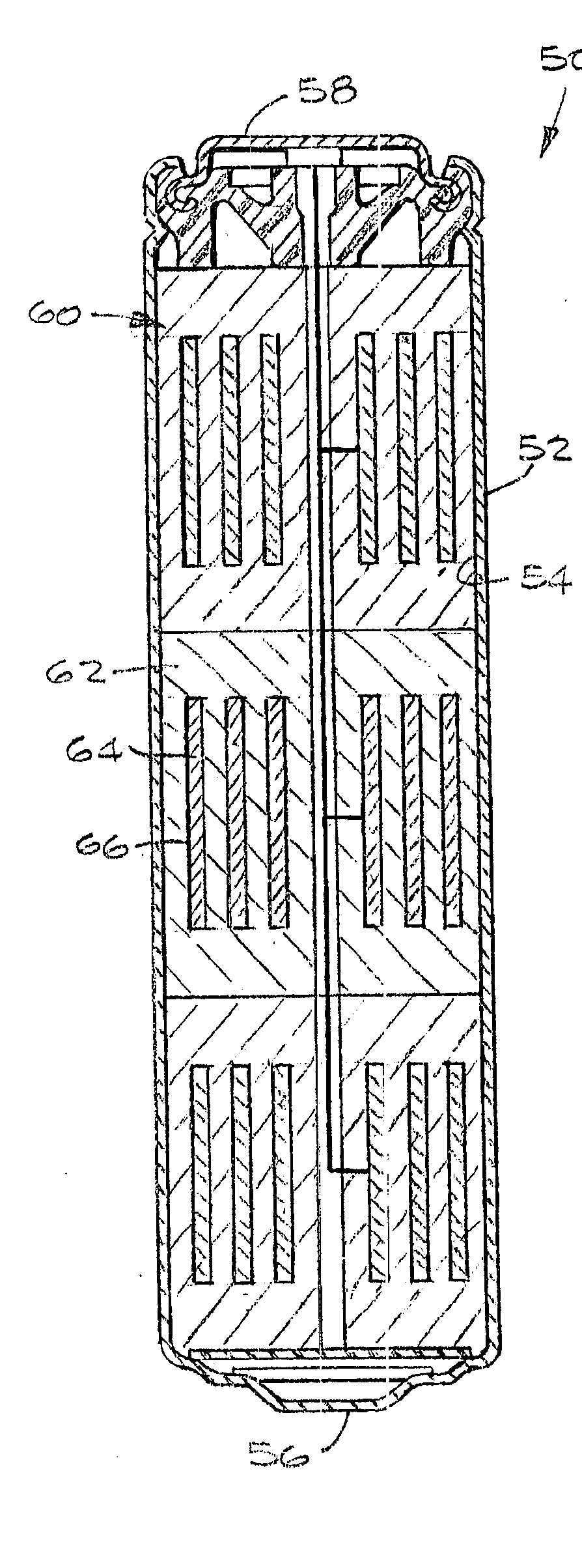

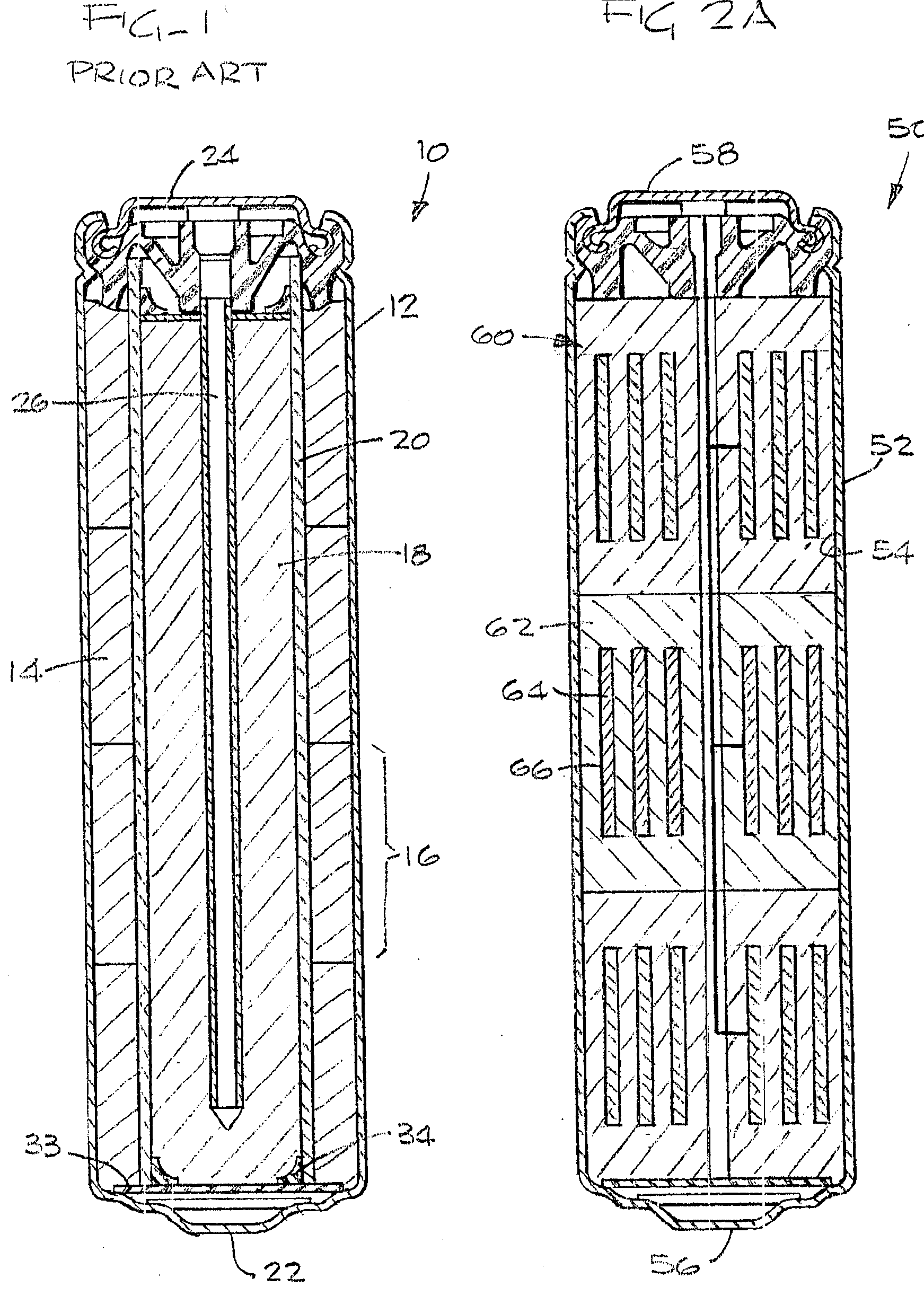

Low impedance layered battery apparatus and method for making the same

ActiveUS20050277019A1Primary cell to battery groupingAssembling battery machinesEngineeringExternal circuit

An electrochemical storage device is described, and a method for making the same. In some aspects, a guidewire is co-wound with sheet or ribbon-like electrode materials so that contact is made between the guidewire and collector extensions of the electrode materials thereby forming an endcap with low impedance and high thermal sinking capabilities. In one embodiment, the storage device includes a negative electrode sheet have an edge which is substantially free of electrode active material, a positive electrode sheet have an edge which is substantially free of electrode active material, a first conductive guidewire disposed adjacent to the edge of the negative electrode sheet which is substantially free of electrode active material, and a second conductive guidewire disposed adjacent to the edge of the positive electrode sheet which is substantially free of electrode active material. The first conductive guidewire and the edge of the negative electrode sheet which is substantially free of electrode active material define a first electrode endcap and the second conductive guidewire and the edge of the positive electrode sheet which is substantially free of electrode active material define a second electrode endcap. The electrode endcaps are coupled to terminals of the storage device, which are capable of being connected to the terminals of an external circuit.

Owner:LITHIUM WERKS TECH BV +1

Alkaline rechargeable battery and process for the production thereof

InactiveUS6902845B2High activityExtended service lifeFinal product manufactureElectrode carriers/collectorsAlloyMaterials science

A rechargeable battery having an anode comprising a powdery composite material said powdery composite material comprising a plurality of powdery composites having a structure comprising a core whose surface is covered by a coat layer, said core comprising an alloy particle of an alloy capable of reversibly storing and releasing hydrogen as a main component, said alloy containing at least one kind of a metal element selected from the group consisting of Zr, Ti and V as a main constituent element, and said coat layer comprising a hydrous oxide (including a hydroxide) of a metal element having an affinity with oxygen which is greater than that of any of said metal elements as the main constituent element of said alloy.

Owner:CANON KK

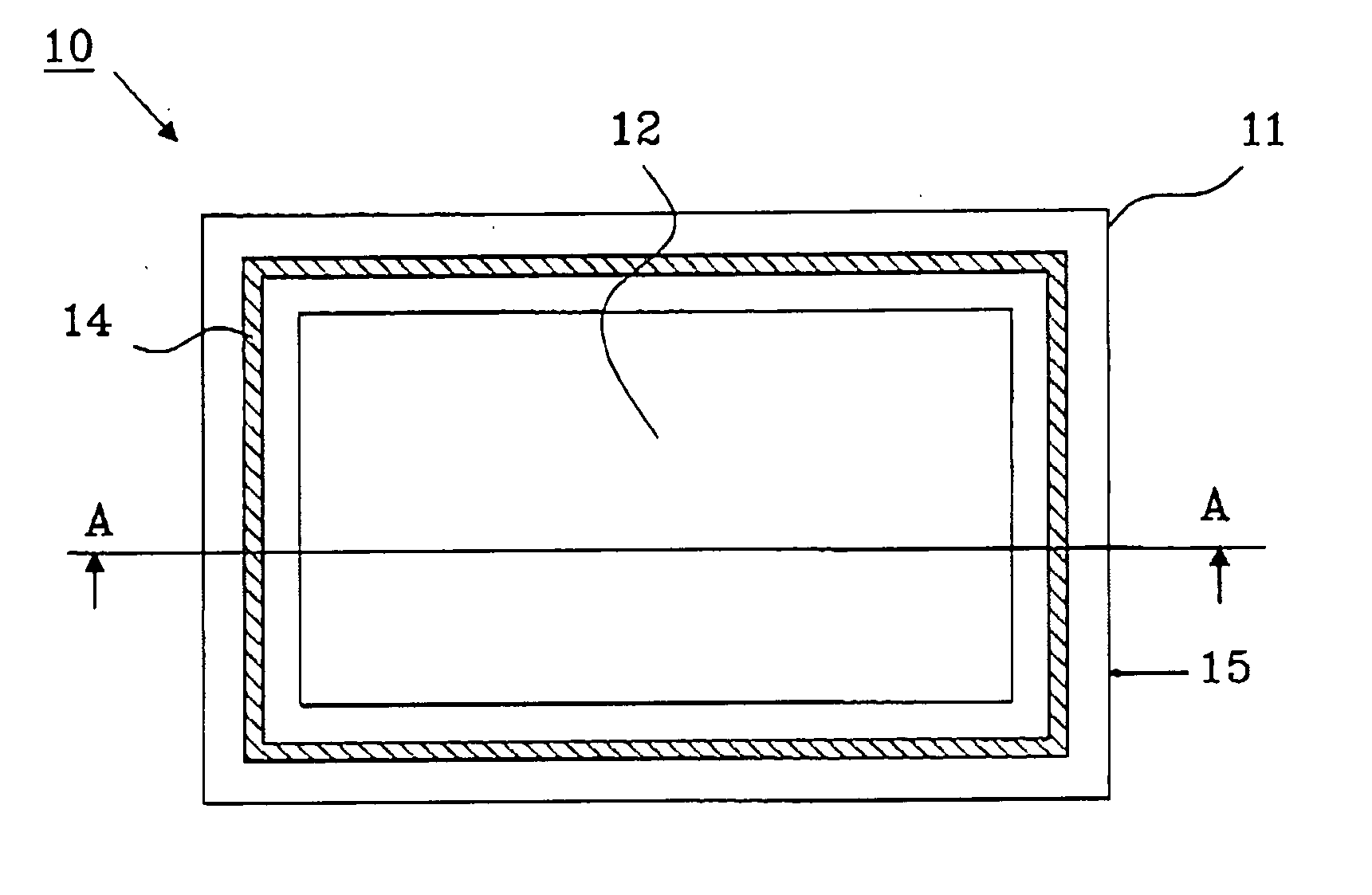

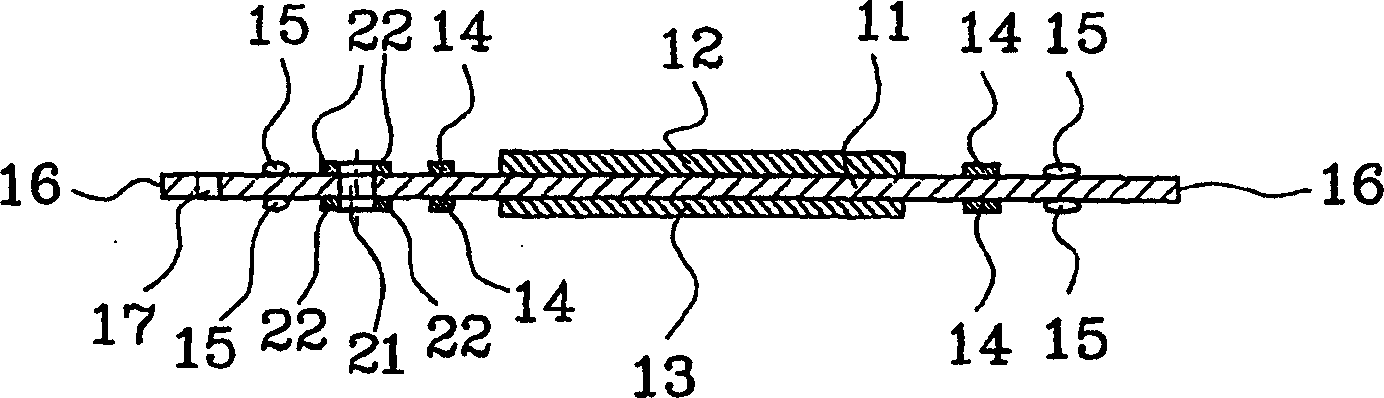

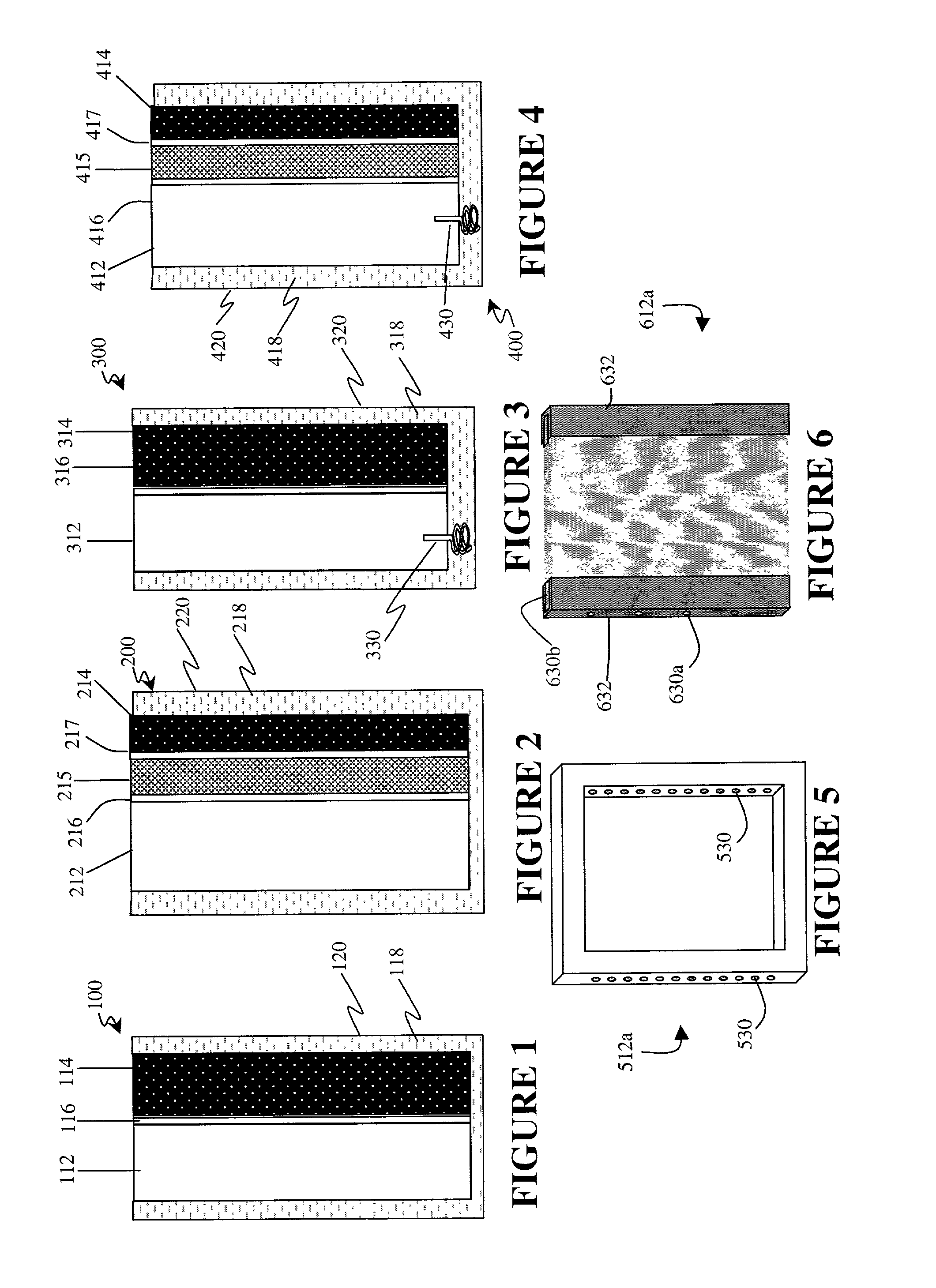

Thin film battery and method of connecting electrode terminal of thin film battery

InactiveUS20100330411A1Bonding forceReduce heat damagePrimary cell to battery groupingFinal product manufactureEngineeringAnode

Provided is a thin film battery, including: a base substrate; a cathode current collector pattern and an anode current collector pattern being formed on the base substrate and being electrically separate from each other; a cathode terminal and an anode terminal being directly bonded with the cathode current collector pattern and the anode current collector pattern; a cathode and an anode being disposed on the cathode current collector pattern and the anode current collector pattern; and an electrolyte layer being disposed between the cathode and the anode.

Owner:GSNANOTECH

Battery case having improved thermal conductivity

InactiveUS20070037053A1Improve cooling effectProviding mechanical stabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsFiberBoron carbide

The present invention discloses is a battery case, comprising a base case and an insert as two parts of the exterior case. The base case is formed of a first polymeric material and the insert is formed of a second polymeric material, wherein the second polymeric material has a higher thermal conductivity than the first polymeric material. The second polymeric material may comprise a base polymer and at least one thermally conductive filler, such as ceramic, glass or carbon fiber. The base polymer of the second polymeric material may be selected from the group consisting of polyphenylene ether, polystyrene, polypropylene, polyphenylene sulfide and the ceramic filler may be selected from the group consisting of alumina, fused silica, a glass ceramic sold under the trademark MACOR®, boron nitride, silicon nitride, boron carbide, aluminum nitride, silicon carbide, zirconia and combinations thereof. The first polymeric material may be selected from the group consisting of polyphenylene ether, polystyrene, polypropylene, polyphenylene sulfide. The base case and insert may be integrally molded by one of two-color molding and insert molding with the first polymeric material and the second polymeric material. The battery case of the present invention may comprise a monoblock alkaline storage battery case.

Owner:BATTERY PATENT TRUST

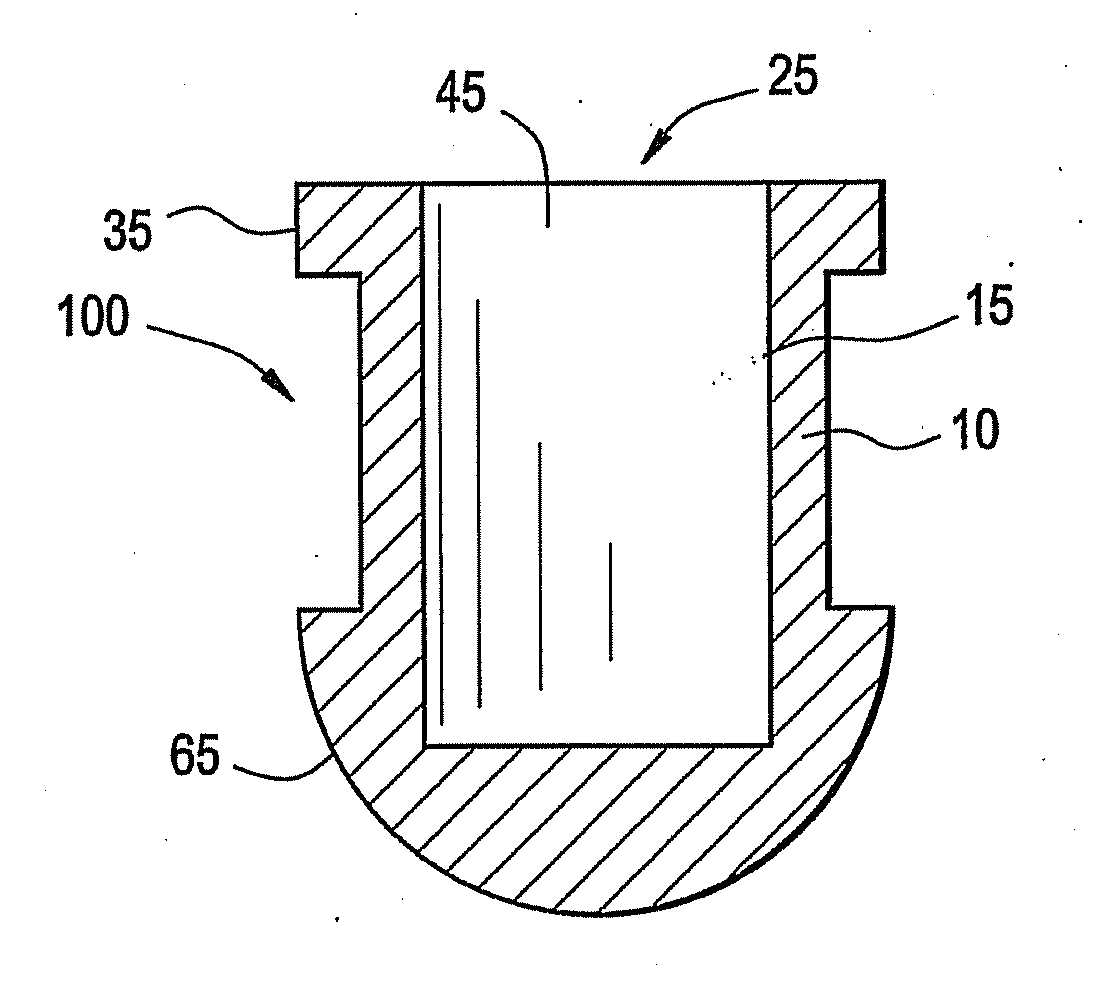

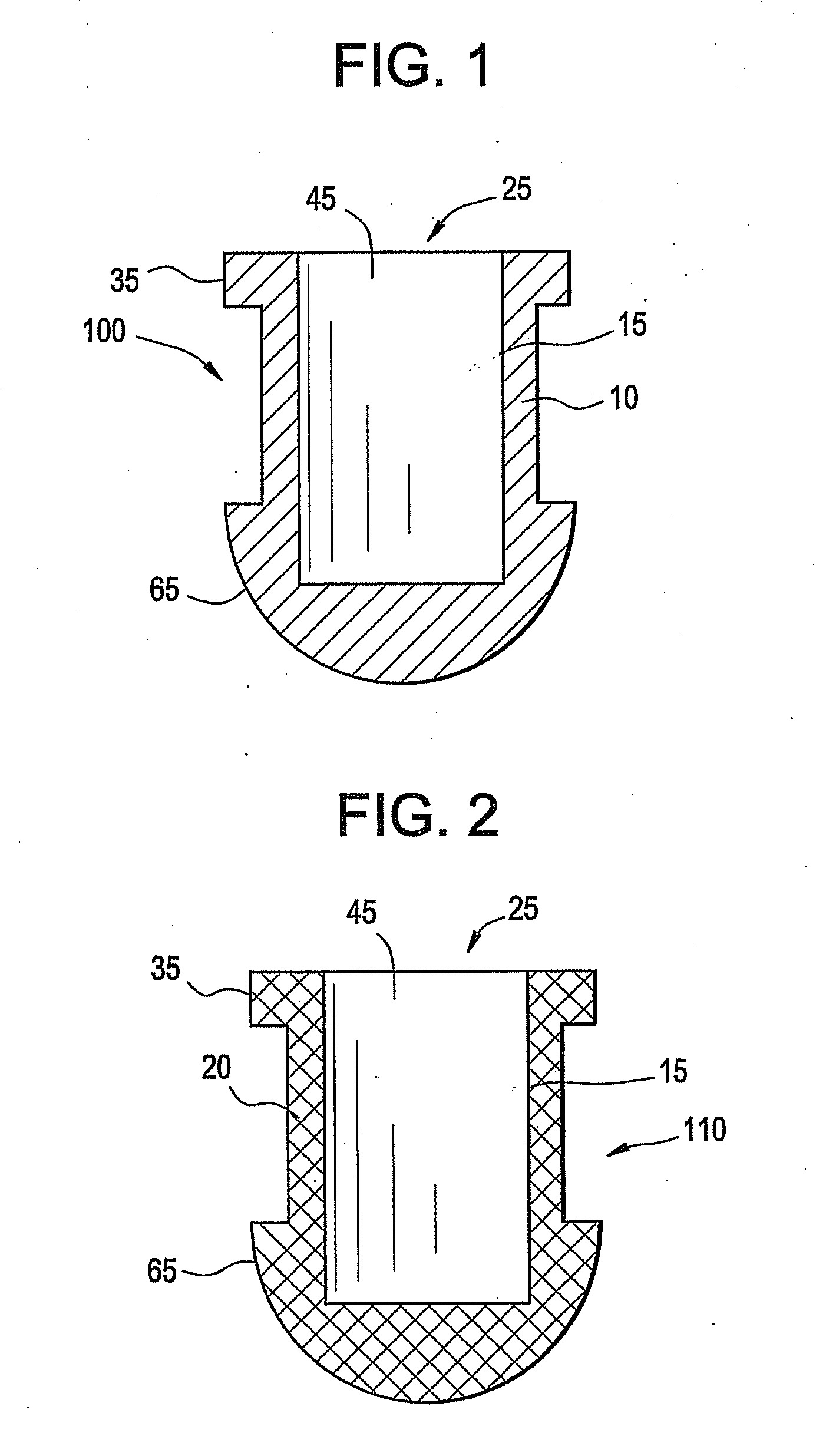

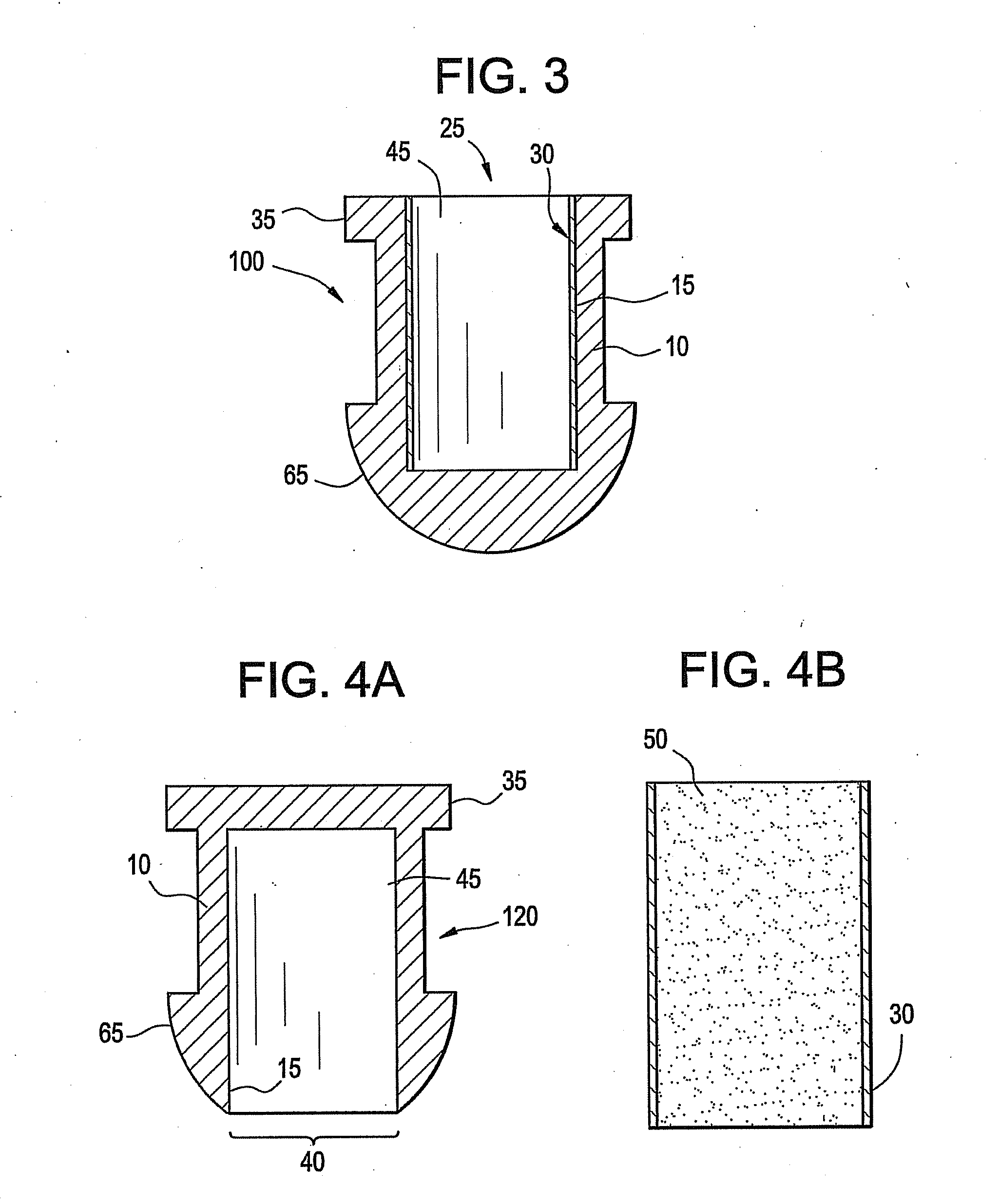

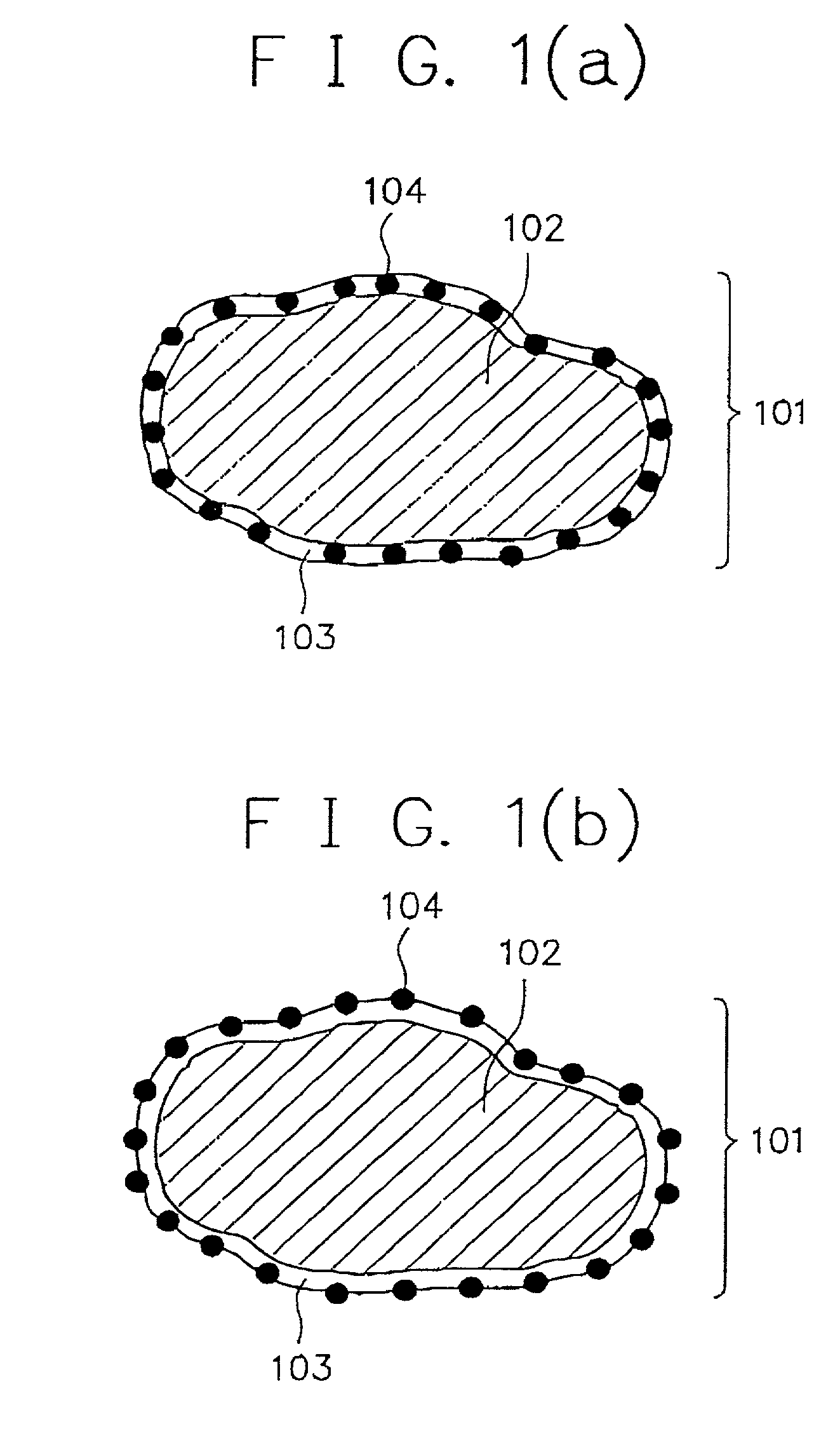

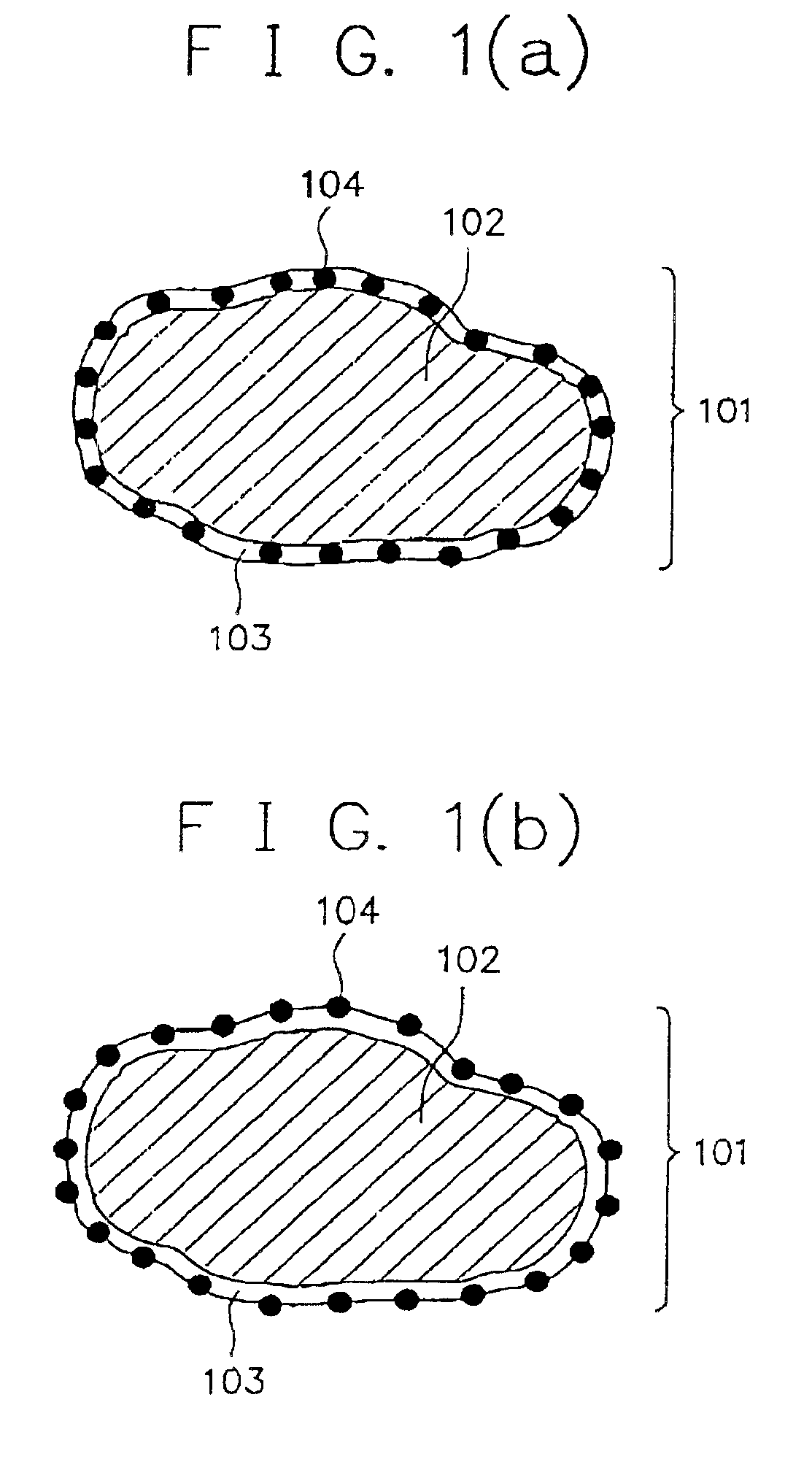

Battery employing an electrode pellet having an inner electrode embedded therein

InactiveUS20040258982A1Easy to integrateNot adversely affect performance characteristicElectrode carriers/collectorsActive material electrodesInterior spaceEngineering

An electrochemical battery cell comprising a cell housing defining an inner space, a first terminal and a second terminal; and at least one pre-formed pellet disposed within the inner space of the cell housing. The pellet includes an outer electrode portion formed from a material to geometrically define the pellet in a solid form. The outer electrode portion is in electrical communication with the first terminal of the cell housing. The pellet also includes an inner electrode encapsulated by a separator and embedded within the material of the outer electrode portion. The inner electrode is in electrical communication with the second terminal of the cell housing and electrically insulated from the outer electrode material. In a preferred embodiment, the inner electrode comprises an anode and the outer electrode portion comprises a cathode portion. The integrated anode / cathode pellet configuration facilitates lowers costs, a more robust design and ease of manufacturability while maintaining and allowing increased performance characteristics of the battery cell.

Owner:RECHARGEABLE BATTERY CORP

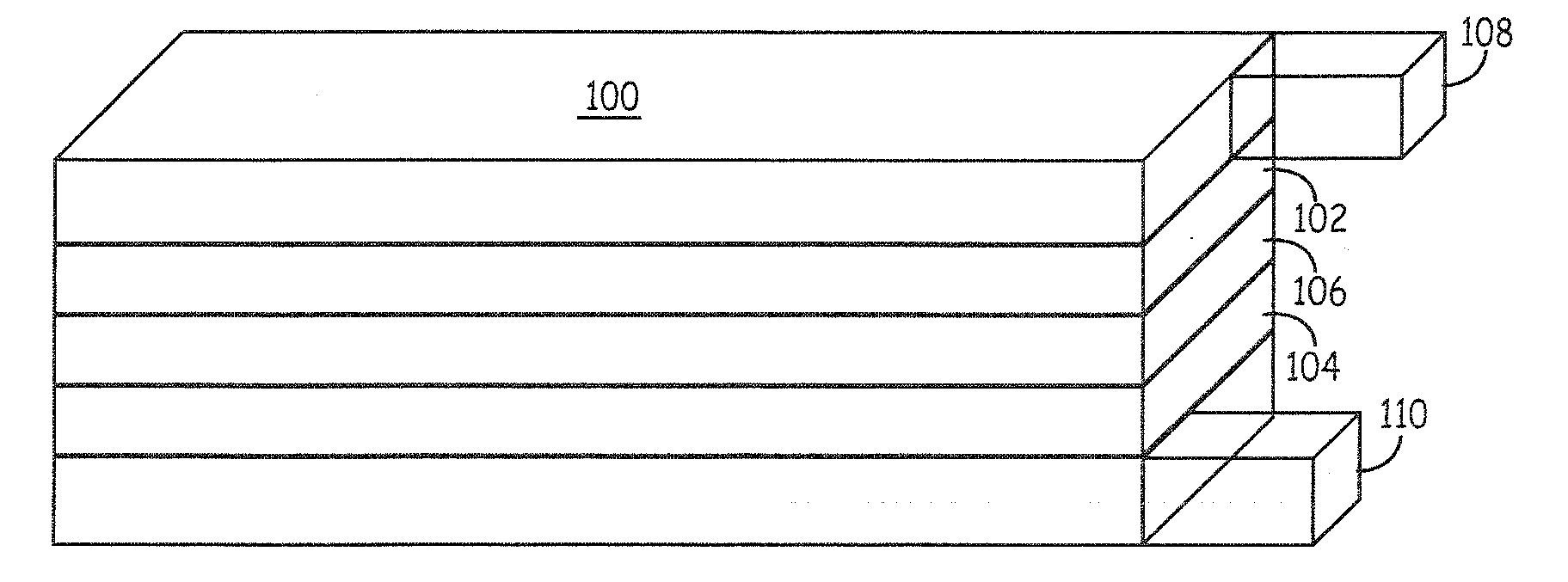

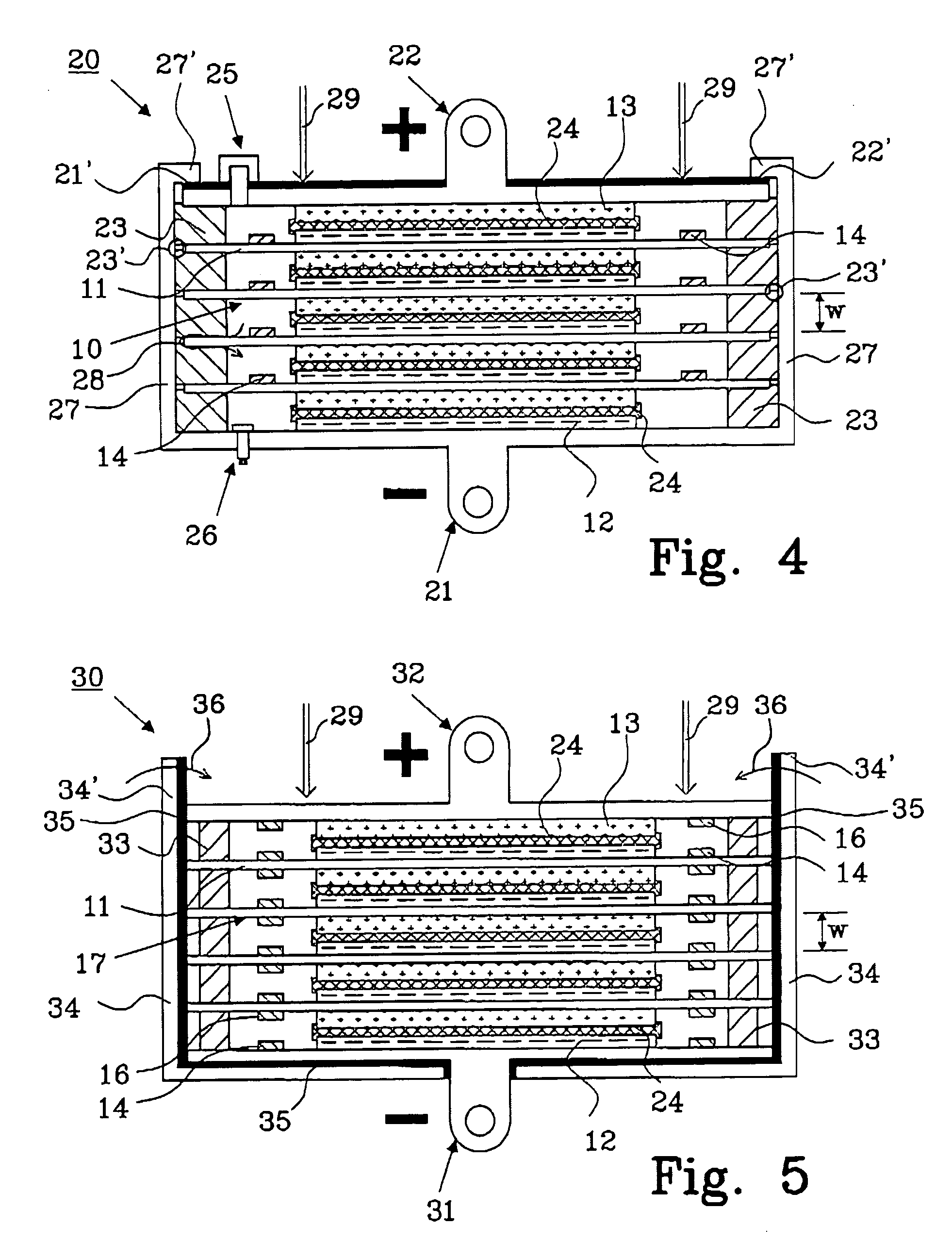

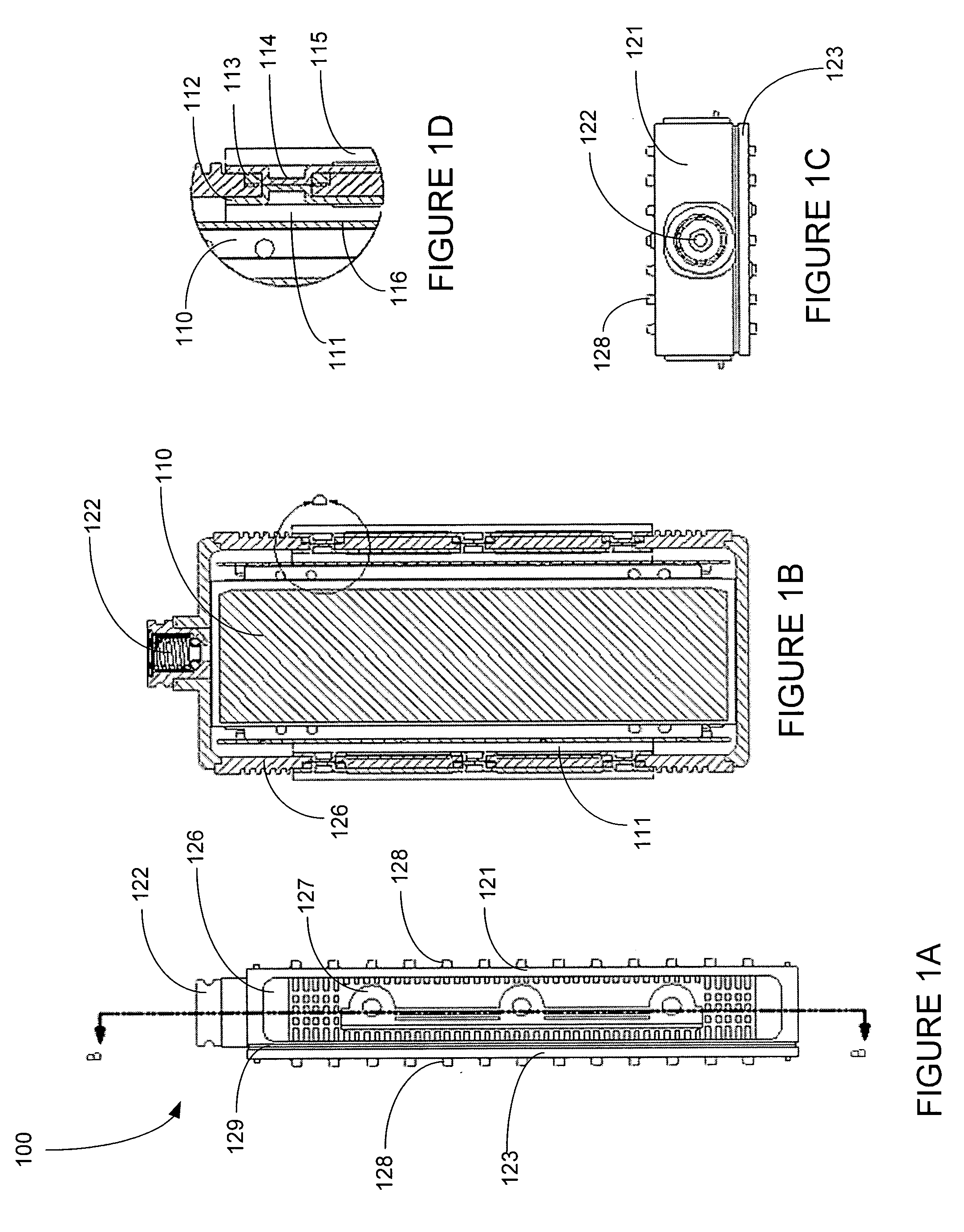

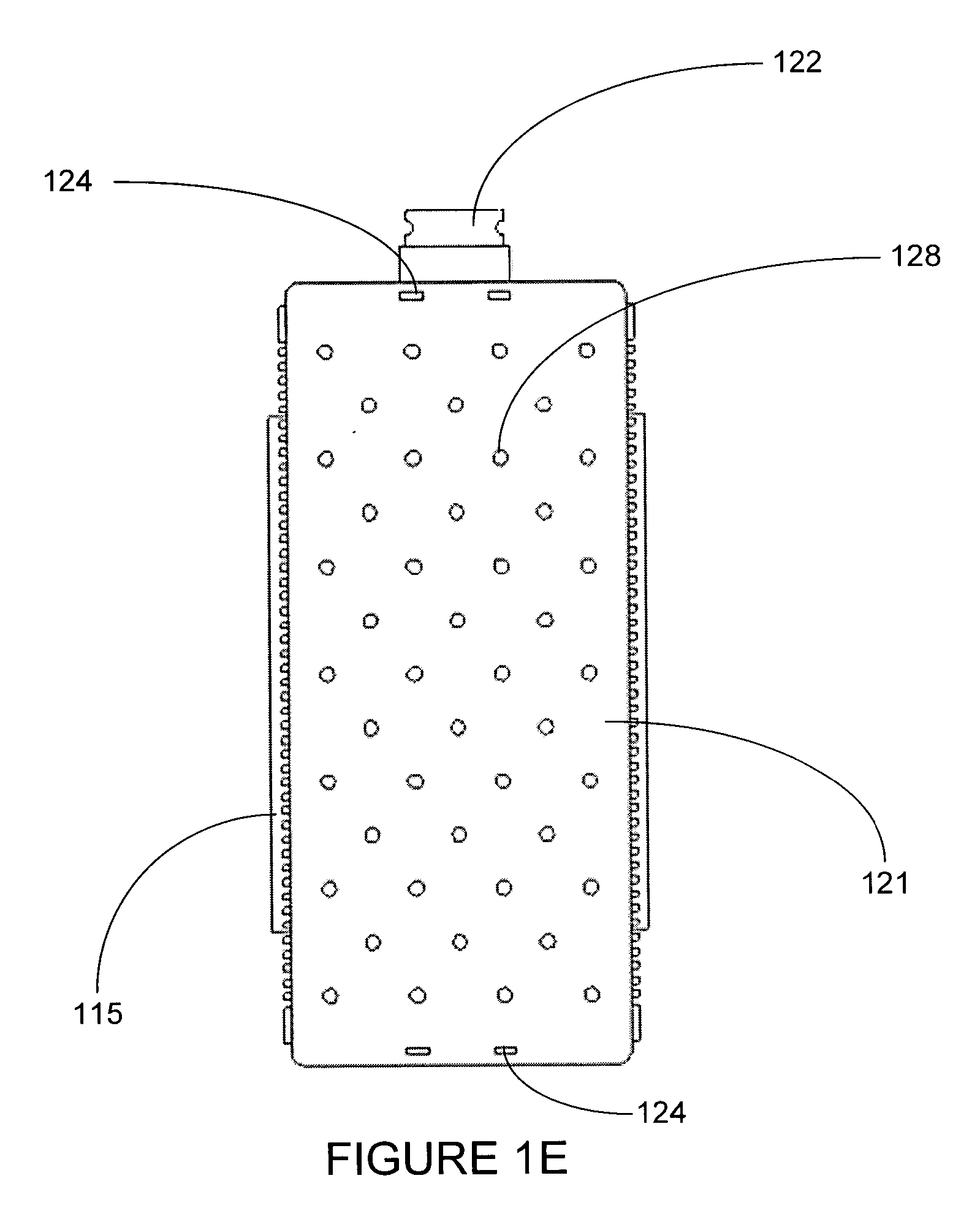

Variable volume containment for energy storage devices

A stacked energy storage device (ESD) has at least two cell segments arranged in a stack. Each cell segment may have a first electrode unit having a first active material electrode, a second electrode unit having a second active material electrode, and an electrolyte layer between the active material electrodes. Variable volume containment may be used to control the inter-electrode spacing within each cell segment. In some embodiments, one or more dynamic flexible gaskets may be included in each cell segment to seal the electrolyte within the cell segment and to deform in preferred directions. In some embodiments, hard stops may set the inter-electrode spacing of the ESD.

Owner:G4 SYNERGETICS INC

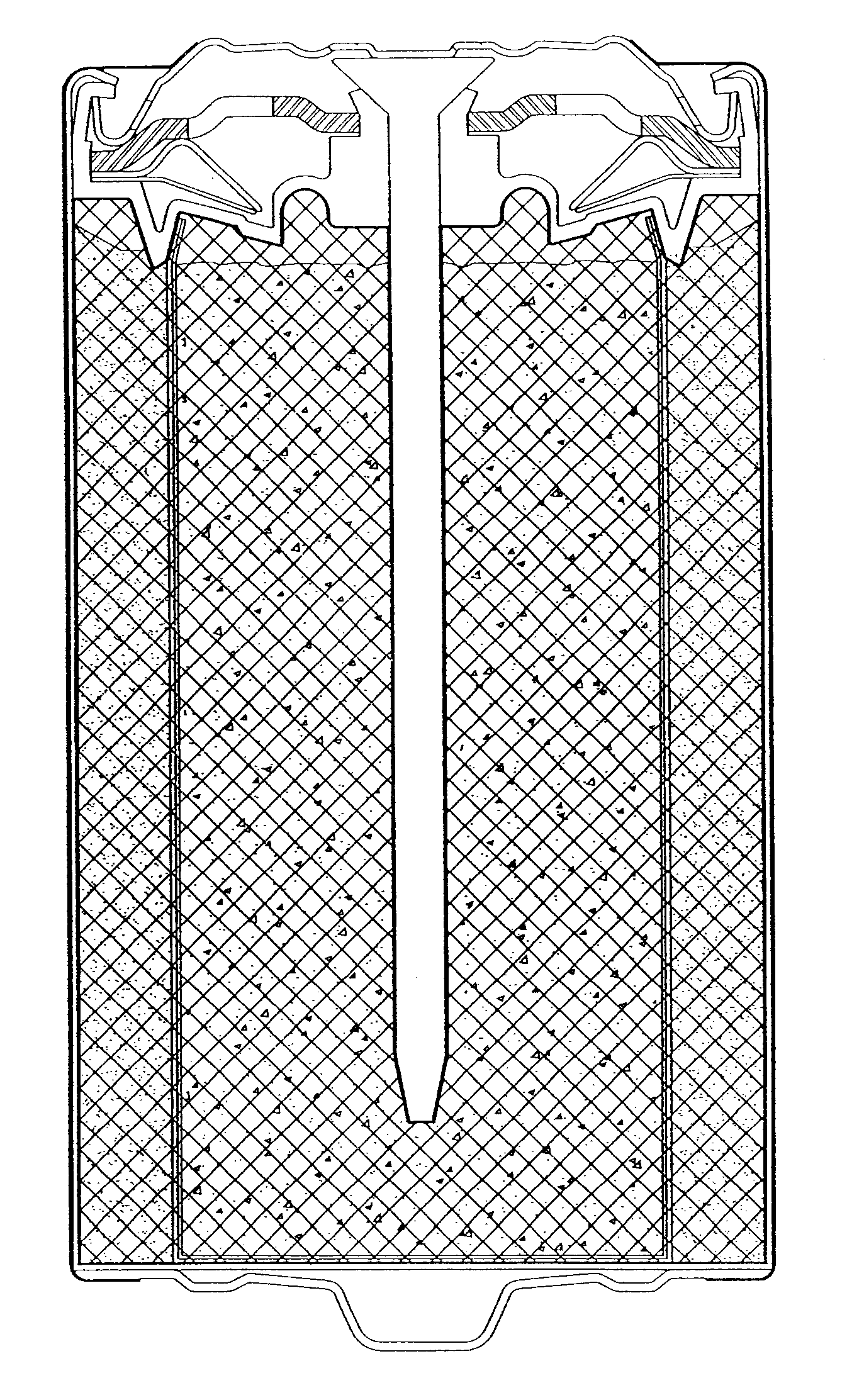

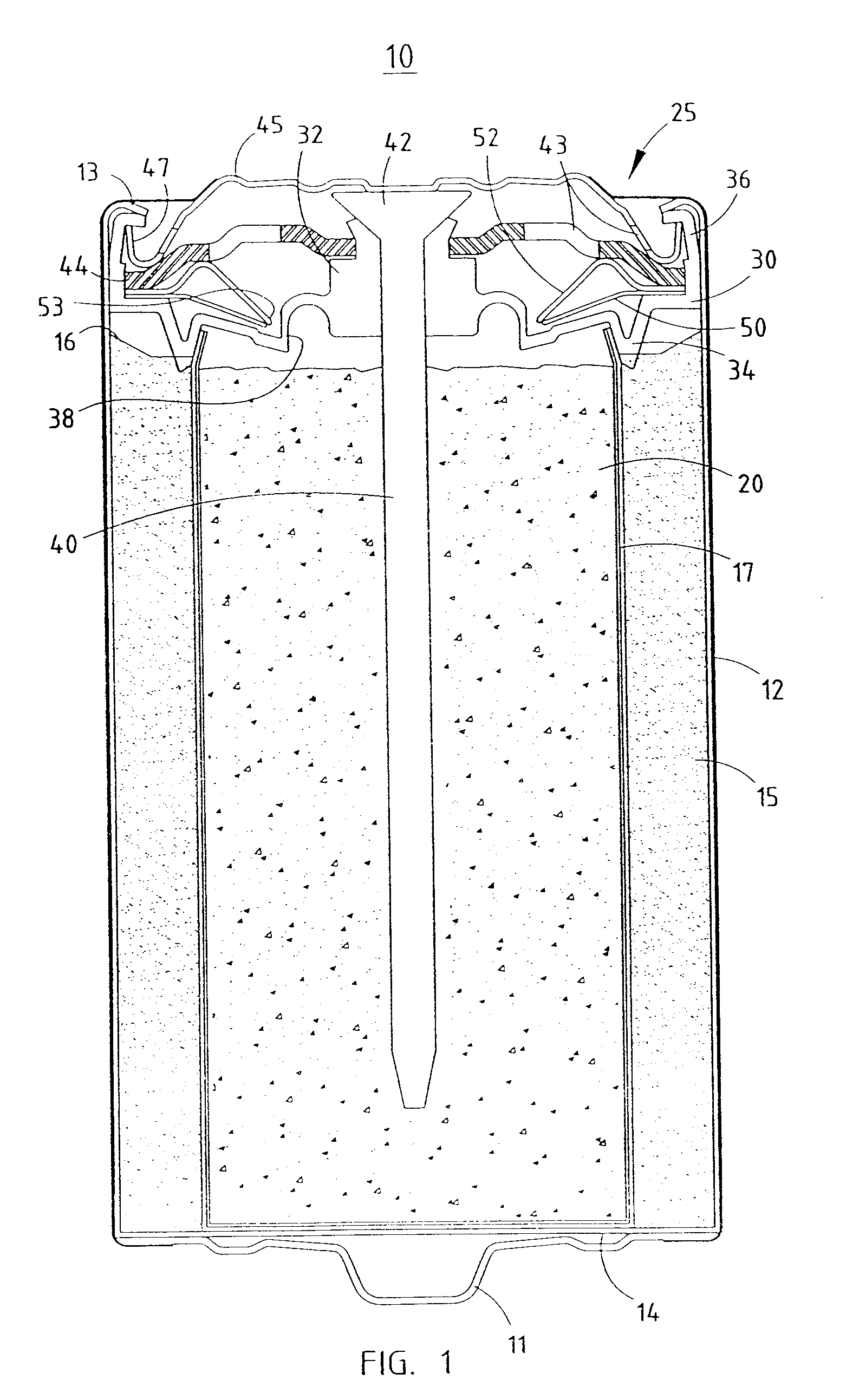

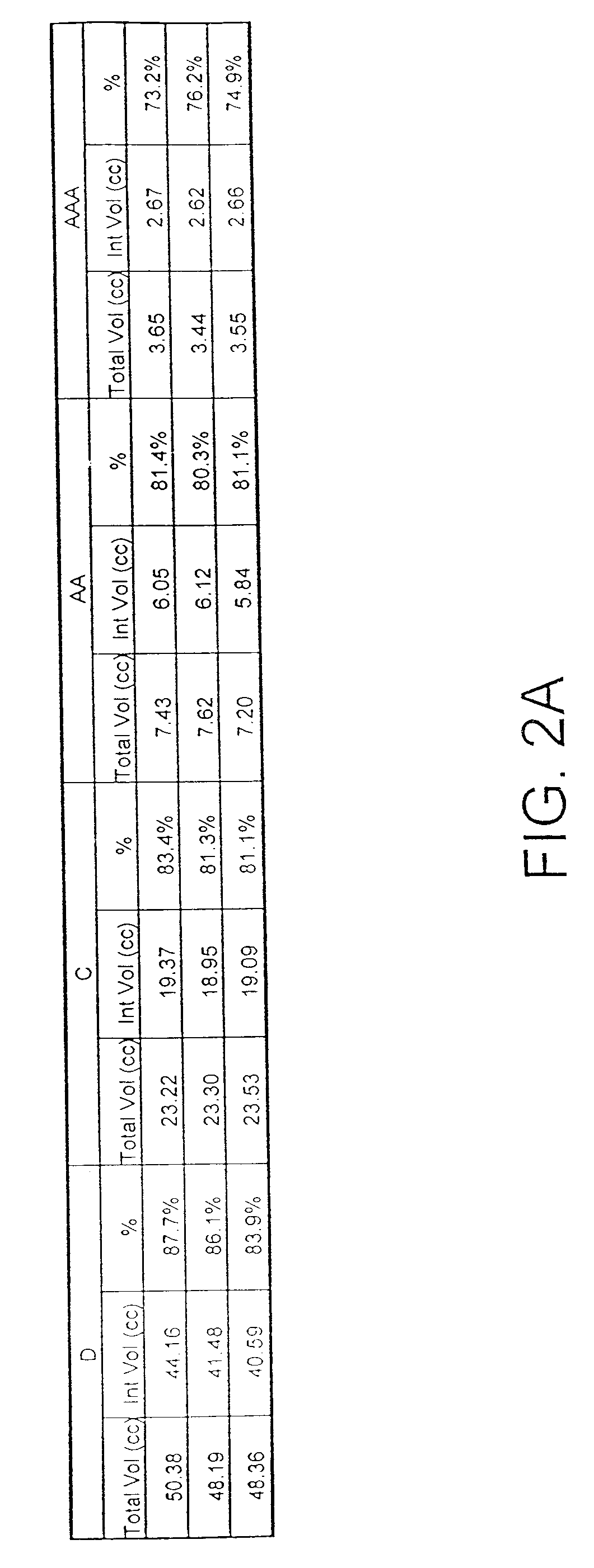

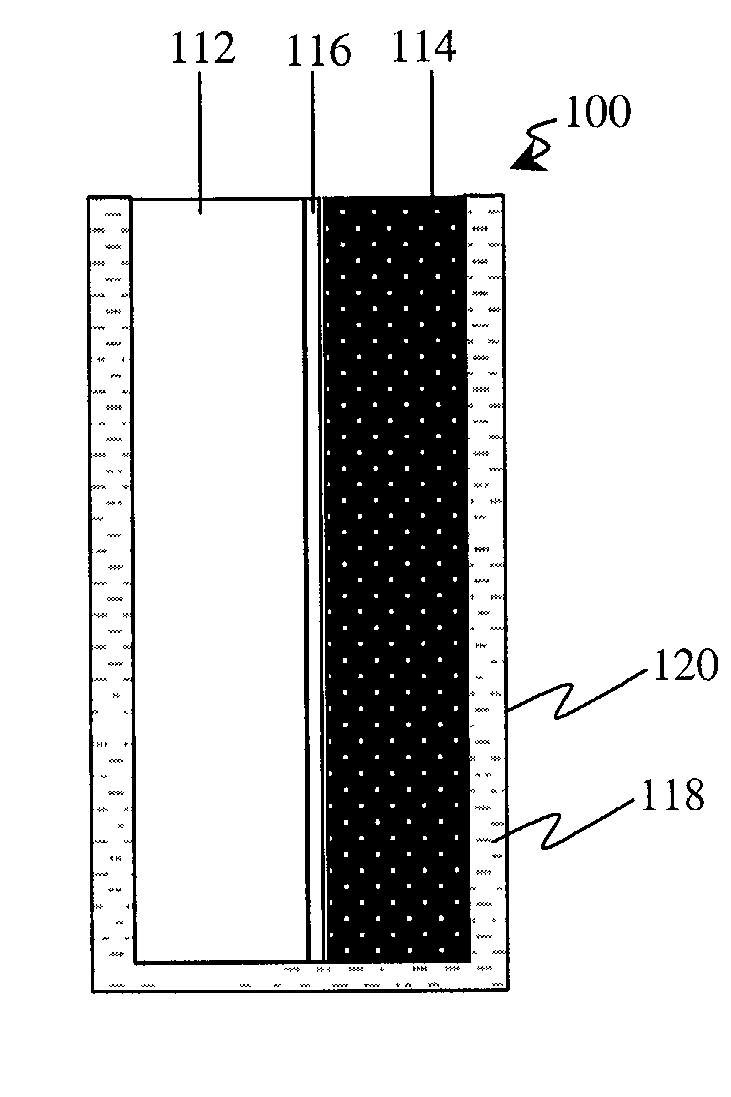

Battery constructions having increased internal volume for active components

InactiveUSRE38518E1Low profileLess spaceFinal product manufactureCell sealing materialsInternal pressureActive component

An electrochemical cell constructed in accordance with the present invention includes a can for containing electrochemical materials including positive and negative electrodes and an electrolyte, the can having an open end and a closed end; a pressure relief mechanism formed in the closed end of the can for releasing internal pressure from within the can when the internal pressure becomes excessive; a first outer cover positioned on the closed end of the can to be in electrical contact therewith and to extend over the pressure relief mechanism; a second outer cover positioned across the open end of the can; and an insulator disposed between the can and the second outer cover for electrically insulating the can from the second outer cover. According to another embodiment, the second cover is dielectrically isolated from a current collector. The battery comprises a collector assembly and can defining a sealed internal volume within the can and available for containing electrochemically active materials.

Owner:ENERGIZER BRANDS

A bipolar battery and a biplate assembly

The present invention relates to a bipolar battery having at least two battery cells comprising: a negative end terminal, a positive end terminal and at least one biplate assembly arranged in a sandwich structure between the negative and positive end terminals. The battery also comprises a separator, with electrolyte, arranged between each negative and positive electrode forming a cell. An inner barrier of a hydrophobic material is arranged at least around one electrode on a first side of the biplate. An outer sealing, e.g. a frame, is provided around the edge of each biplate assembly and each end terminal and a hole is arranged through each biplate interconnecting each cell with adjacent cell(s) to create a common gas space for all cells in the battery. The invention also relates to a biplate assembly.

Owner:NILAR INT AB

Microscopic batteries for MEMS systems

InactiveUS20040018421A1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureMicro fabricationMicrofabrication

Microscopic batteries, integratable or integrated with and integrated circuit, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed.

Owner:BIPOLAR TECH

Sealed prismatic battery

InactiveUS20070202402A1Lower internal resistanceIncrease powerLarge-sized flat cells/batteriesFinal product manufactureEngineeringFluid electrolytes

A sealed prismatic battery has a battery case made of a plurality of prismatic cell cases coupled together via partition walls. Electrode plate groups are accommodated together with liquid electrolyte in each of the cell cases. Each electrode plate group consists of alternately stacked-up positive and negative electrode plates with separators interposed therebetween, lead portions of positive and negative electrode plates being protruded on opposite sides. Collectors are bonded to these lead portions. Between the collectors and end walls (and / or partition walls) of the battery case are provided conductive plates that are connected to the collectors one or more than one location in their middle part so as to decrease the resistance between connection terminals and the electrode plate groups.

Owner:PANASONIC CORP +1

Electrolyte balance in electrochemical cells

InactiveUS20020098398A1Fuel and primary cellsElectrolyte moving arrangementsMetal–air electrochemical cellSolvent

A rechargeable metal air electrochemical cell is provided. The rechargeable metal air electrochemical cell generally includes an anode and a cathode in ionic communication via a separator and in fluid communication via one or more tubes or apertures, wherein the one or more tubes or apertures provide sufficient ionic resistance thereby preventing shorting between the electrodes while allowing liquid solvent to flow therebetween.

Owner:EVIONYX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com