Battery employing an electrode pellet having an inner electrode embedded therein

a technology of electrode pellets and battery cells, applied in the field of electrochemical pellet type battery cells, to achieve the effect of facilitating the integration of anodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

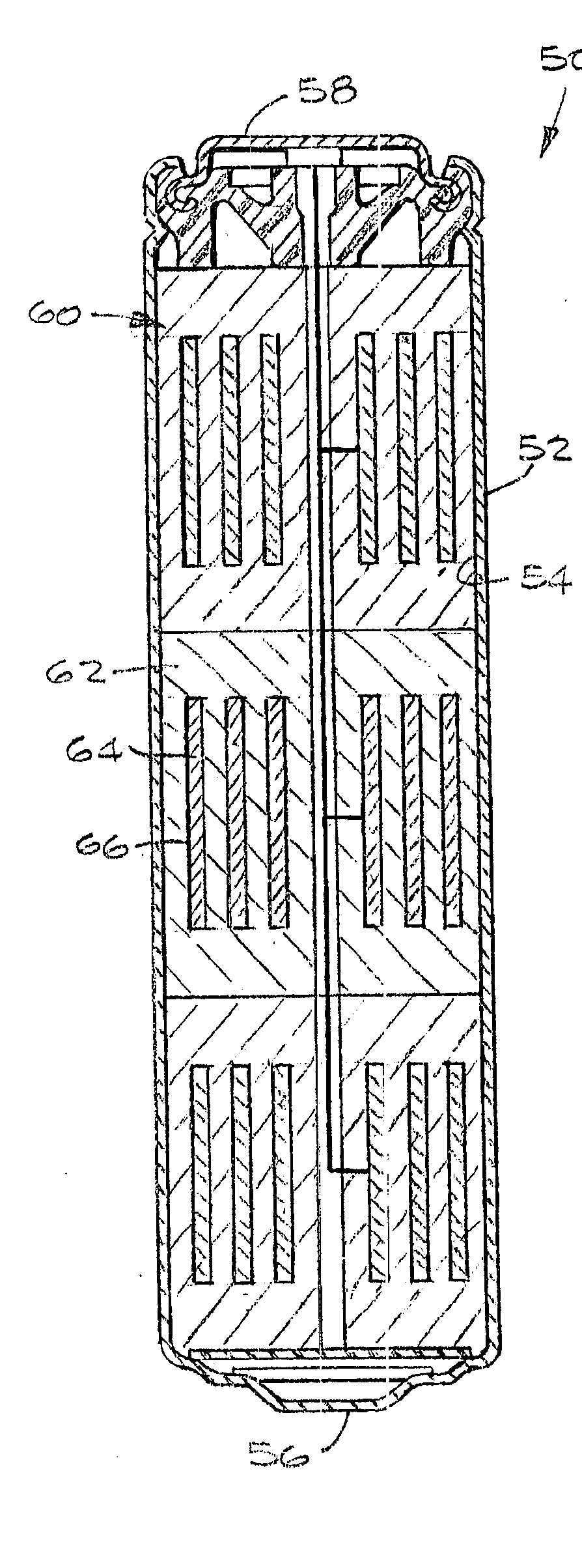

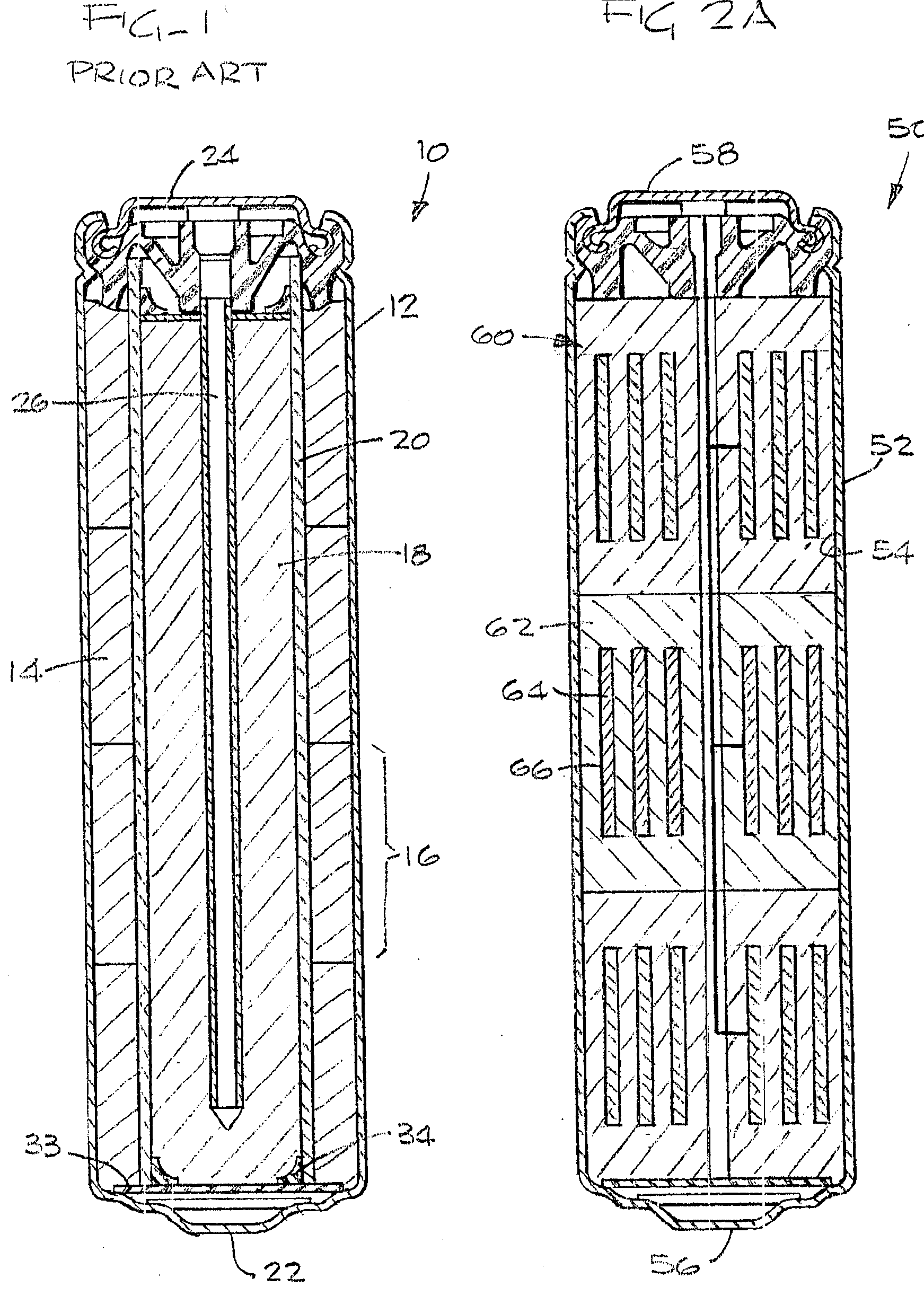

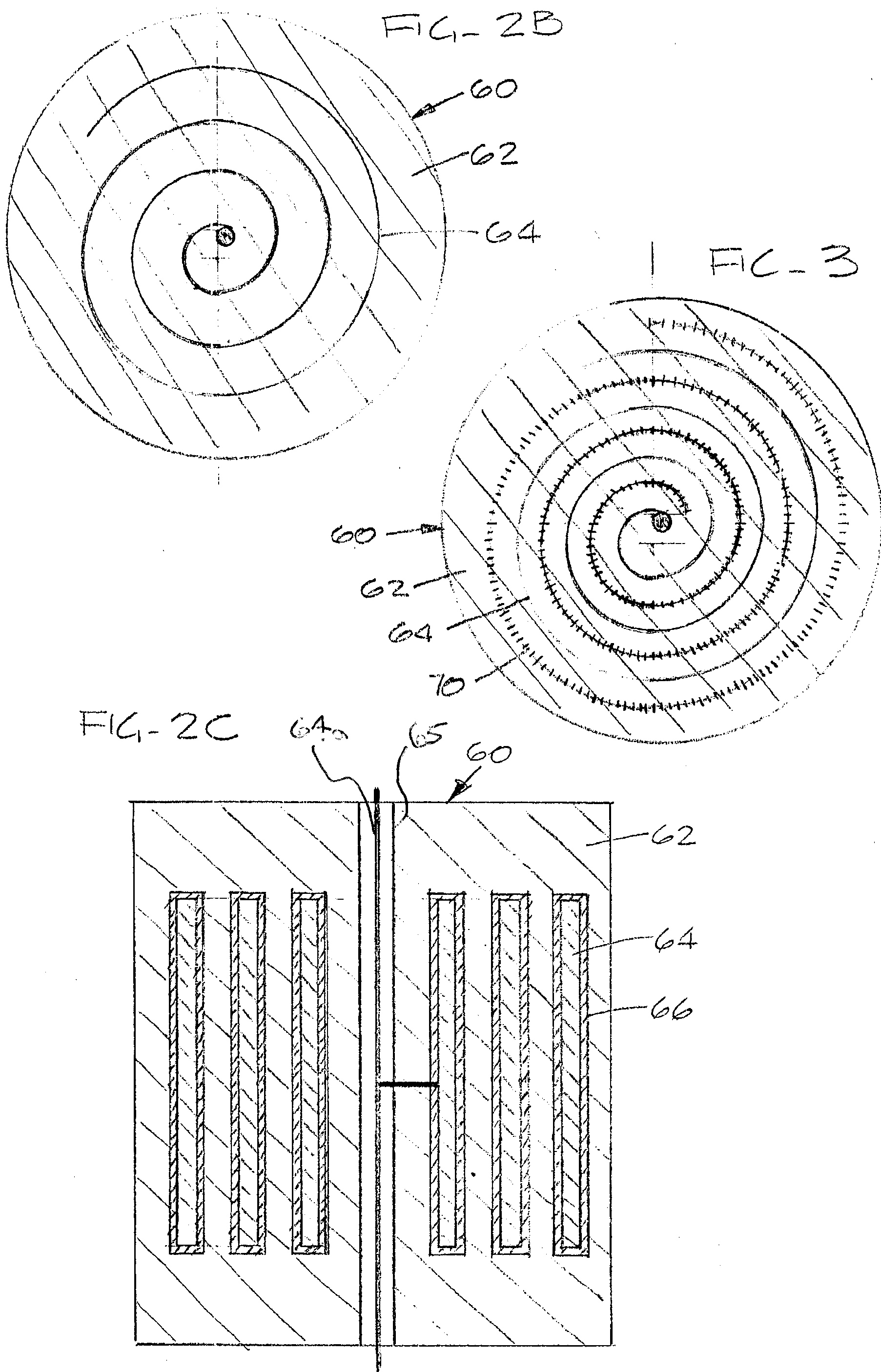

[0035] This example specifies some details concerning an embodiment of the present invention in the form of an alkaline manganese dioxide cell. In this particular example, each alkaline cell contains three cathode / anode pellets, such as the three pellets 60 shown in the cell 50 in FIG. 2A. The outer electrode material portion of each pellet, which in this example is a cathode material portion, is approximately 3.4 g. The cathode material formulation is a Type I formulation typical of primary alkaline cells and consists of 88 wt % EMD (MnO.sub.2), 7.5 wt % conductive powder, and the remainder being other additives such as binders, electrolyte, and recombination catalyst. The components of the cathode material formulation are blended and an inner electrode in the form of an anode is embedded therein. The material formulation is then pressed into a pellet geometry. Sufficient zinc weight (approx. 1 g) should be present in the anode to match the cathode capacity per pellet. The anode is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com