Silylene/carbon composite negative electrode material and preparation method thereof

A negative electrode material and carbon composite technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve technical problems that have not been completely solved, material specific surface area is too large, silicon simple substance low conductivity, etc., to achieve excellent cycle performance, The effect of high energy density and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

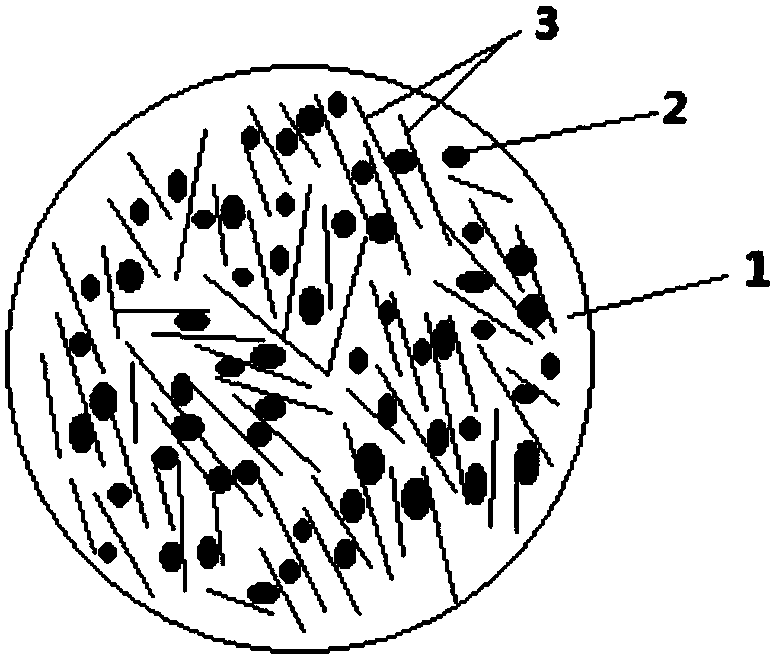

Image

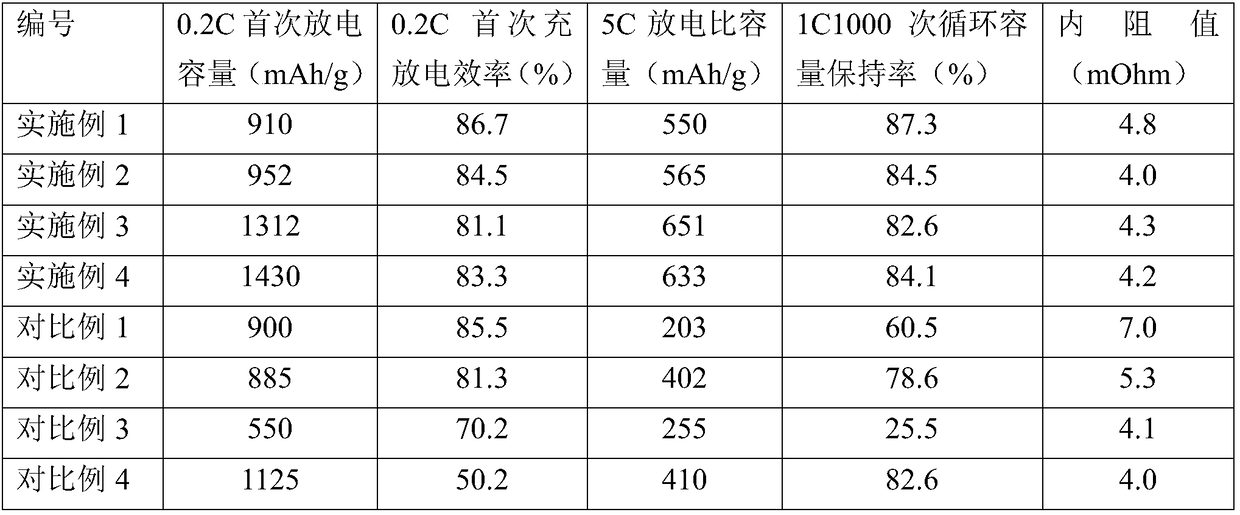

Examples

Embodiment 1

[0066] Prepare silicene (D50=1 μm, n=10), SP (D50=30nm), and asphalt powder in a mass ratio of 5:5:90 to prepare a mixed aqueous solution with a solid content of 2%, and carry out ball milling and mixing in a ball mill (ball feed The ratio is 10:1), the rotating speed is 2600r / min, and ball milling is performed for 3 hours to obtain a slurry; the slurry is spray-dried in an air atmosphere, the inlet air temperature is 250°C, and the outlet air temperature is 89°C to obtain silicene / Carbon spherical precursor; transfer the precursor to a tube furnace for carbonization treatment, the atmosphere is nitrogen, the heating rate is 2°C / min, heated to 900°C, kept for 3h, naturally cooled to room temperature, crushed and sieved to obtain silicene / carbon composite anode material.

[0067] After testing, the particle size D50 of the obtained silicene / carbon composite negative electrode material is 19.5 μm, and the specific surface area is 3.61 m 2 / g.

Embodiment 2

[0069] Prepare silicene (D50=0.5 μm, n=5), carbon nanotubes (D50=20nm), and phenolic resin powder in a mass ratio of 5:5:90 to prepare a mixed ethanol solution with a solid content of 5%, and carry out the process in a ball mill Mix by ball milling (the ratio of ball to material is 15:1) at a speed of 1000r / min, and ball mill for 3 hours to obtain a slurry; the slurry is spray-dried under a nitrogen protective atmosphere, the inlet air temperature is 175°C, and the outlet air temperature is 91°C °C to obtain a silicene / carbon spherical precursor; transfer the precursor to a tube furnace for carbonization treatment, the atmosphere is nitrogen, the heating rate is 5 °C / min, heated to 850 °C, kept for 3 hours, naturally cooled to room temperature, broken Sieve to obtain the silicene-carbon composite negative electrode material.

[0070] After testing, the particle size D50 of the obtained silicene / carbon composite negative electrode material is 20.1 μm, and the specific surface a...

Embodiment 3

[0072] Silene (D50=0.1 μm, n=15), acetylene black (D50=50nm), and glucose were prepared into a mixed aqueous solution with a solid content of 3% in a mass ratio of 10:5:85, and ball milled and mixed in a ball mill (ball The material ratio is 10:1), the rotating speed is 1500r / min, ball milling is 1h, and the slurry is obtained; the slurry is spray-dried in the air atmosphere, the inlet air temperature is 200°C, and the outlet air temperature is 95°C, to obtain silicene / Carbon spherical precursor; transfer the precursor to a tube furnace for carbonization treatment, the atmosphere is argon, the heating rate is 2°C / min, heated to 600°C, kept for 3h, naturally cooled to room temperature, crushed and sieved to obtain Sicene / carbon composite anode materials.

[0073] After testing, the particle size D50 of the obtained silicene-carbon composite negative electrode material is 17.3 μm, and the specific surface area is 4.22m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com