Silylene-copper-silylene composite material, preparation method and application thereof and lithium ion battery

A composite material and silicene technology, which is applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of complex preparation methods and uneven silicene sheets, and achieve low cost, low energy consumption, and large-scale preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

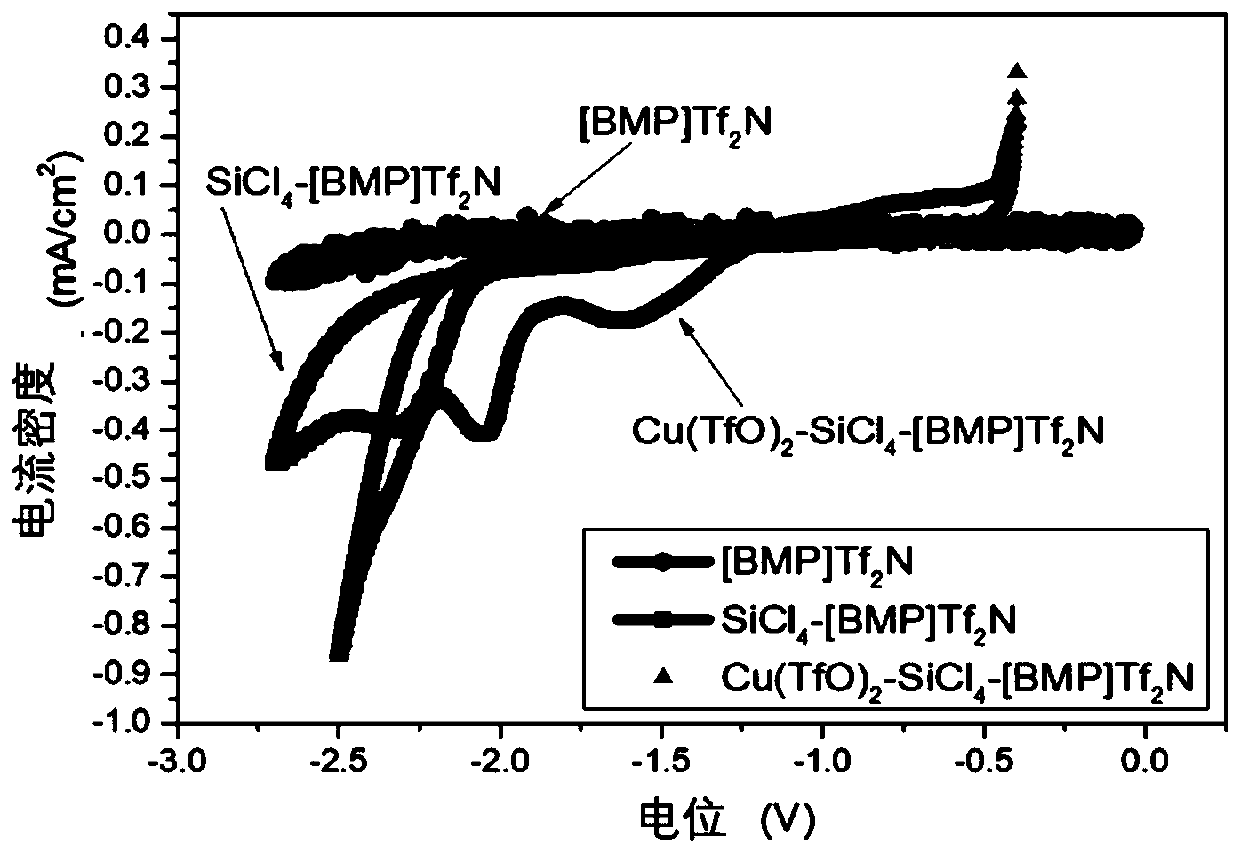

[0104] (1) Preparation of ionic liquid: preparation of 0.002mol / L Cu(TFO) 2 -1mol / L SiCl 4 [BMP]Tf 2 N solution, stir well until the solution is evenly dispersed.

[0105] (2) Electrode treatment: firstly, the electrode is ground and polished to a mirror image with metallographic sandpaper from coarse to fine, and then ultrasonically cleaned with deionized water. After that, the platinum electrode was pickled with 2mol / L nitric acid, the Cu electrode was pickled with 2mol / L sulfuric acid, rinsed with deionized water, and then dried in a vacuum oven. Finally, all electrodes were cleaned with acetone and allowed to air dry.

[0106] (3) Preparation of electrolyzer: The electrolyzer used in the experiment is a three-electrode system. Wherein, the three electrodes refer to a working electrode, a reference electrode and a counter electrode. The distance between the electrodes was kept constant in each experiment (the distance between the working electrode and the reference ele...

Embodiment 2

[0121] (1) Configuration of ionic liquid: configure 1mol / L SiCl 4 [BMP]Tf 2 N solution, add 0.002mol / L Cu(TFO) 2 Stir well to obtain a homogeneously dispersed yellow solution.

[0122] (2) Electrode treatment: First, the electrode is ground and polished to a mirror image with metallographic sandpaper from coarse to fine, and then ultrasonically cleaned with deionized water. After that, the platinum electrode was pickled with 2mol / L nitric acid, the Cu electrode was pickled with 2mol / L sulfuric acid, rinsed with deionized water and dried in a vacuum oven. Finally, all electrodes were cleaned with acetone and air-dried.

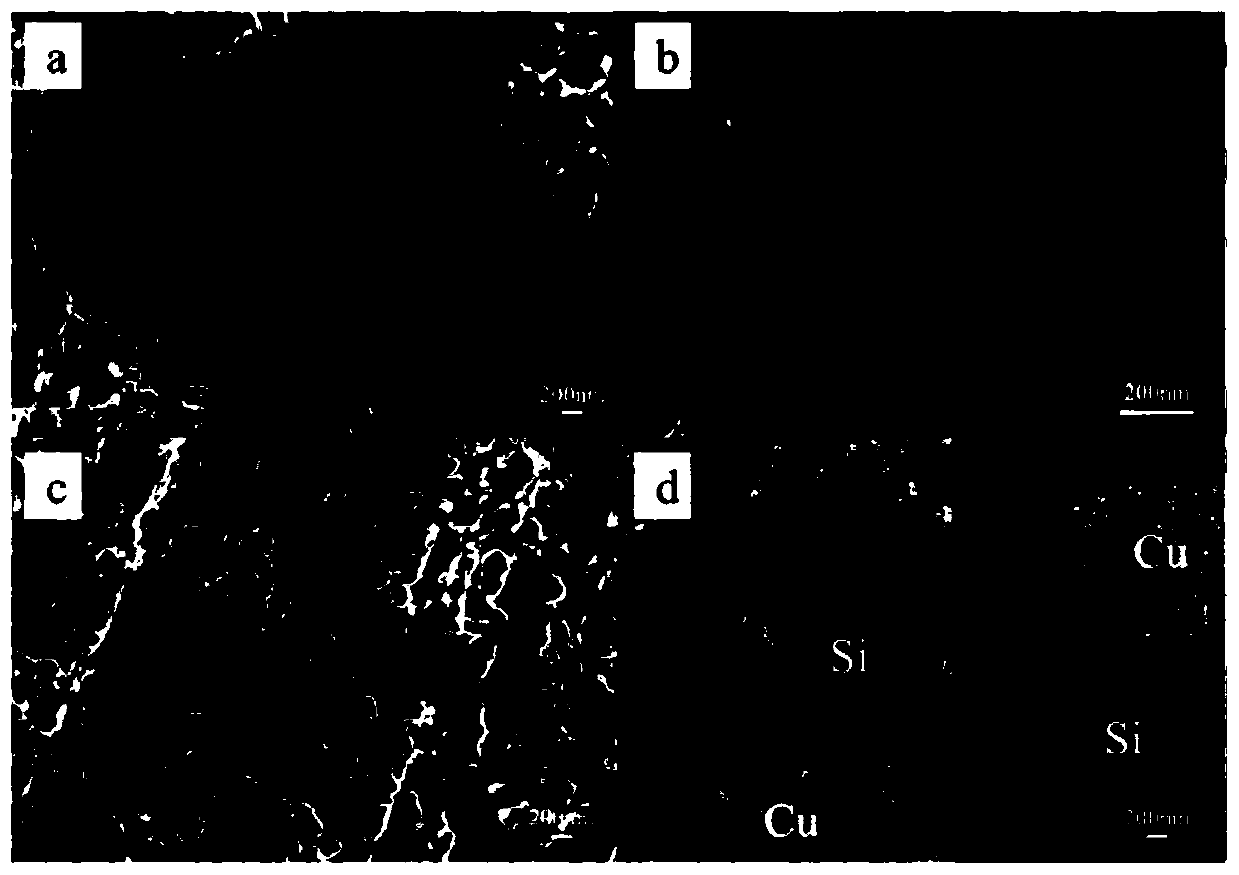

[0123] (3) Preparation of electrolyzer: The electrolyzer used in the experiment is a three-electrode system. Wherein, the three electrodes refer to a working electrode, a reference electrode and a counter electrode, and the intervals between the electrodes are controlled to be consistent in each experiment. The working electrode used is a copper sheet; the...

Embodiment 3

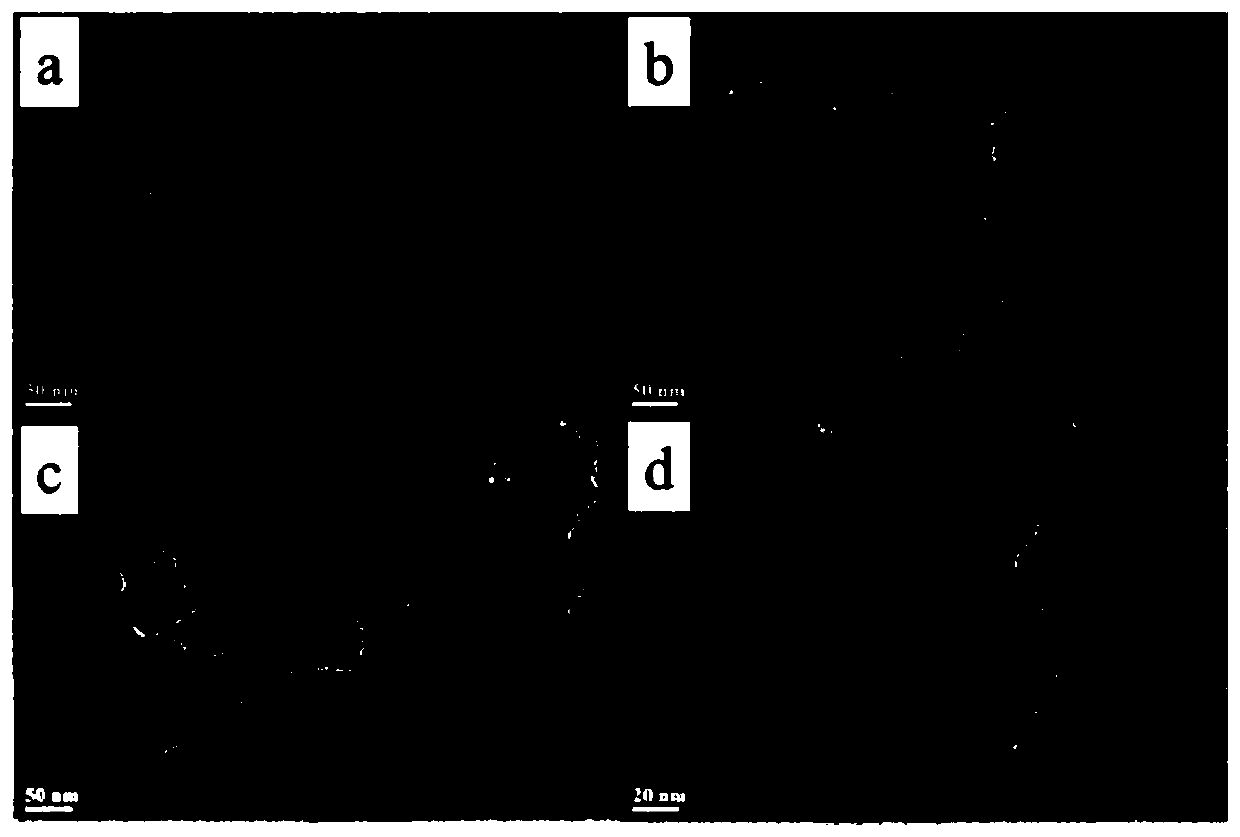

[0129] (1) Configuration of ionic liquid: configure 1mol / L SiCl 4 [BMP]Tf 2 N solution, add 0.002mol / L Cu(TFO) 2 Stir well to obtain a homogeneously dispersed yellow solution.

[0130] (2) Electrode treatment: First, the electrode is ground and polished to a mirror image with metallographic sandpaper from coarse to fine, and then ultrasonically cleaned with deionized water. After that, the platinum electrode was pickled with 2mol / L nitric acid, the Cu electrode was pickled with 2mol / L sulfuric acid, rinsed with deionized water and dried in a vacuum oven. Finally, all electrodes were cleaned with acetone and air-dried.

[0131] (3) Preparation of electrolyzer: The electrolyzer used in the experiment is a three-electrode system. Wherein, the three electrodes refer to a working electrode, a reference electrode and a counter electrode, and the intervals between the electrodes are controlled to be consistent in each experiment. The working electrode used is a copper sheet; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com