Manufacturing method of mullite-boron nitride composite ceramic side sealing plate for thin-strip continuous casting

A technology of composite ceramics and manufacturing methods, which is applied in the field of ceramic composite materials, can solve the problems of restricting the industrialization process of thin strip continuous casting, poor service life and wear resistance, and cannot meet the requirements of industrial production, and achieve resistance to thermal shock of molten steel , prolong service life, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

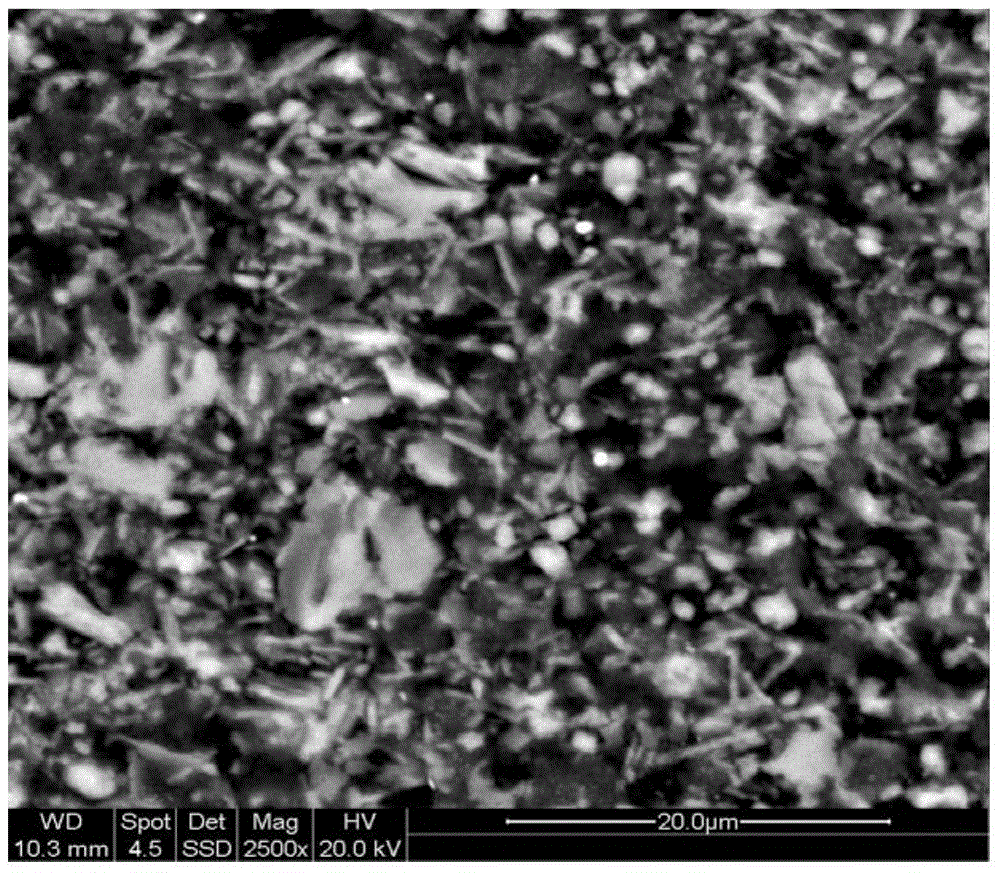

Image

Examples

Embodiment 1

[0026] A method for manufacturing a mullite-boron nitride composite ceramic side sealing plate for thin strip continuous casting, which comprises the following steps:

[0027] 1) Selection of raw materials: The selected raw materials include: hexagonal boron nitride (h-BN) with a particle size of 2 μm, which is chemically pure; silicon dioxide (SiO2) with a particle size of 3 μm 2 ), analytically pure; aluminum nitrate (Al(NO) with a particle size of 4 μm 3 ) 3 9H 2 O), is analytically pure; Ammonia (NH 3 ·H 2 O) is analytically pure; boron trioxide (B) with a particle size of 3 μm 2 o 3 ), is chemically pure; aluminum nitride (AlN) with a particle size of 1 μm is chemically pure; silicon nitride (SiN) with a particle size of 3 μm 3 N4 ), is chemically pure; titanium boride (TiB 2 ), is chemically pure;

[0028] 2) Preparation of the precursor slurry: the hexagonal boron nitride powder mass percentage is 50%, the sum of the mass percentages of silicon dioxide and alumi...

Embodiment 2

[0036] A method for manufacturing a mullite-boron nitride composite ceramic side sealing plate for thin strip continuous casting, which comprises the following steps:

[0037] 1) Raw material selection: The selected raw materials include: hexagonal boron nitride with a particle size of 3 μm, which is chemically pure; silicon dioxide with a particle size of 4 μm, which is analytically pure; aluminum nitrate with a particle size of 5 μm, which is analytically pure; ammonia water is analytically pure Diboron trioxide with a particle size of 2 μm is chemically pure; aluminum nitride with a particle size of 1 μm is chemically pure; silicon nitride with a particle size of 2 μm is chemically pure; titanium boride with a particle size of 4 μm is chemically pure;

[0038] 2) Preparation of precursor slurry: 60% by mass percentage of hexagonal boron nitride powder, 40% of the sum of mass percentages of silicon dioxide and aluminum nitrate is weighed, and control silicon dioxide: aluminum...

Embodiment 3

[0045] 1) Selection of raw materials: The selected raw materials include: hexagonal boron nitride with a particle size of 1 μm, which is chemically pure; silicon dioxide with a particle size of 2 μm, which is analytically pure; aluminum nitrate with a particle size of 2 μm, which is analytically pure; ammonia water is analytically pure Diboron trioxide with a particle size of 2 μm is chemically pure; aluminum nitride with a particle size of 0.5 μm is chemically pure; silicon nitride with a particle size of 1 μm is chemically pure; titanium boride with a particle size of 3 μm is chemically pure ;

[0046] 2) Preparation of precursor slurry: 70% by mass percentage of hexagonal boron nitride powder, 30% of the sum of mass percentages of silicon dioxide and aluminum nitrate is weighed, and control silicon dioxide: aluminum nitrate mol ratio is 1:3, add a certain amount of distilled water and ammonia water as a mixed solvent, so that the pH value of the slurry is 3.5, use an alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com