Manufacturing method of cadmium telluride film solar cell

A technology for thin-film solar cells and manufacturing methods, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of high production cost, difficult mass production, and complicated manufacturing methods, and achieves lower prices and simplified manufacturing. technology, the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

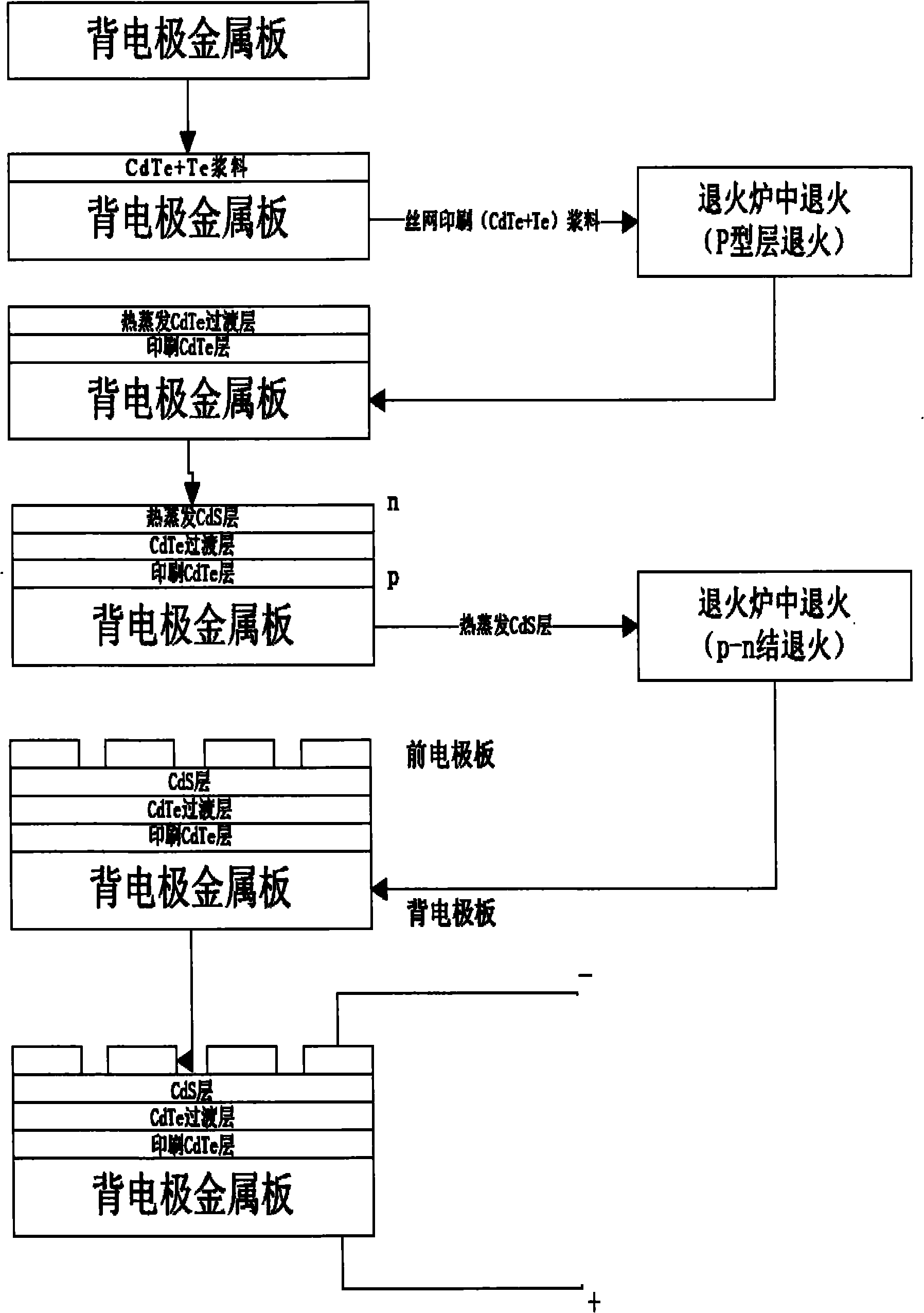

[0046] The preparation of embodiment 1 cadmium telluride thin film solar cell

[0047] 1) Fabrication of P-type cadmium telluride thin film laminates

[0048] (1) Clean the copper thin plate or stainless steel thin plate used to make the battery, rinse it with clean water, clean it with ultrasonic waves, and then bake it until it is completely dry.

[0049] (2) Preparation of cadmium telluride slurry: mix cadmium telluride powder and tellurium powder at a weight ratio of 100:1, and mix for 6-8 hours by ball milling.

[0050] (3) Using absolute ethanol / polar polymer solution-dimethylformamide to blend cadmium telluride and tellurium mixed powder into a slurry,

[0051] (4) Printing and coating the mixed paste of cadmium telluride and tellurium on the metal back electrode plate by means of screen printing.

[0052] (5) Put the metal plate coated with the slurry into an annealing furnace, anneal at 600° C. for about 40 minutes, and then raise the temperature to 850° C. for abou...

Embodiment 2

[0065] The preparation of embodiment 2 cadmium telluride thin-film solar cells

[0066] (1) Select a copper plate with a thickness of 0.05mm or more (both copper and brass are acceptable) as the support and back electrode of the battery, ultrasonically clean and dry.

[0067] (2) Mix cadmium telluride powder and tellurium powder in a weight ratio of 100:1, and mix for 6-8 hours by ball milling.

[0068] (3) Blend the cadmium telluride and tellurium mixed powders into a slurry by using absolute ethanol / polar polymer solution-dimethylformamide. The slurry is at medium viscosity and stirred for at least 1-2 hours.

[0069] (4) Using the screen printing method, the cadmium telluride and tellurium mixed paste was printed and coated on the metal back electrode plate, and then baked in an oven at 350° C. for one hour.

[0070] A nanoscale cadmium telluride nano layer is evaporated on the metal plate coated with the cadmium telluride film by vacuum evaporation method, as a transition...

Embodiment 3

[0079] The preparation of embodiment 3 cadmium telluride thin film solar cells

[0080] Fabrication of p-type CdTe thin film laminate and p-n junction

[0081] (1) Clean the metal plates, stainless steel sheets, and copper sheets used to make battery supports and back electrodes. Ultrasonic clean and bake until completely dry.

[0082] (2) Mix cadmium telluride powder and tellurium powder in a weight ratio of 100:1, grind and mix for 6-8 hours by ball milling.

[0083] (3) The mixed powder of cadmium telluride and tellurium is mixed into a slurry by using absolute ethanol solution / polar solution-dimethylformamide, and the viscosity of the slurry is moderate.

[0084] (4) Printing and coating the mixed paste of cadmium telluride and tellurium on the metal back electrode plate by means of screen printing.

[0085] (5) Put the metal plate coated with the slurry into an annealing furnace, anneal at 600°C for about 40 minutes, and then raise the temperature to 900°C for about 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com