Proppant and preparation method thereof

A proppant and curing agent technology, applied in the field of oil and gas fields, can solve the problems of reduced conductivity of rock formation fractures, corrosion and damage of resin film, corrosion of cladding layer, etc., and achieve high strength, firm bonding, and uniform surface stress distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

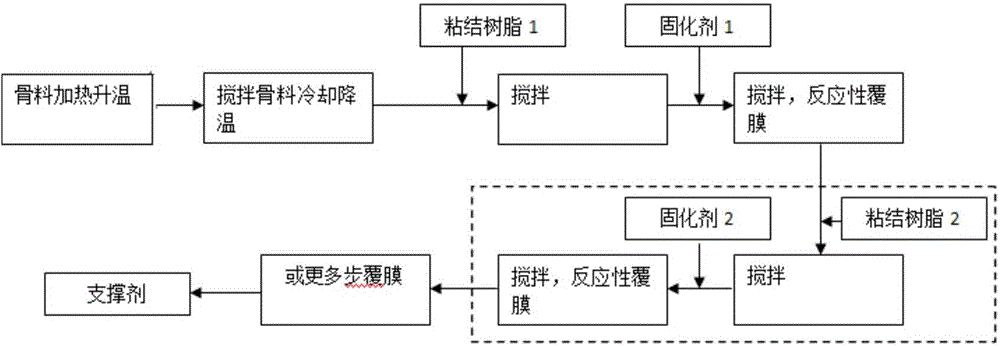

Method used

Image

Examples

Embodiment 1

[0038] The proppant of the present invention is composed of the following components in parts by weight:

[0039] Aggregate: 200 parts

[0040] Bonding resin: 6 parts

[0041] Curing agent: 1.6 parts

[0042] Preparation:

[0043] Heat 200kg of quartz sand (20-70 mesh) to 250°C, add 3kg of phenolic resin, stir evenly, add 0.6kg of corresponding curing agent UTO, stir and cure for a period of 80 seconds, then add 3kg of phenolic resin and stir evenly, add curing agent corresponding 1 kg of solidifying agent Utop, stirred until completely solidified (when the sand is agglomerated), cooled and sieved to obtain the proppant S1 of the present invention.

Embodiment 2

[0045] Aggregate: 200 parts

[0046] Bonding resin: 20 parts

[0047] Curing agent: 5.33 parts

[0048] Preparation:

[0049] Heat 200kg of quartz sand (30-50 mesh) to 180°C, add 10kg of phenolic resin, stir evenly, add 3.73kg of corresponding curing agent Uto, stir and cure for a period of 50 seconds, add 10kg of epoxy resin, stir for a period of time, add the corresponding ring Oxygen resin curing agent (amine curing agent) 1.6kg, stirred until completely solidified (when the sand is agglomerated), cooled and sieved to obtain the proppant S2 of the present invention.

Embodiment 3

[0051] Aggregate: 200 parts

[0052] Bonding resin: 9 parts

[0053] Curing agent: 3.37 parts

[0054] Calcium stearate: 0.075 parts

[0055] Preparation:

[0056] Heat 200kg of quartz sand (40-60 mesh) to 200°C, add 6kg of epoxy resin, stir evenly, add 0.67kg of epoxy resin curing agent (amine curing agent), stir and cure for a period of 60 seconds, add 3kg of phenolic resin, Stir evenly, add 2.7 kg of curing agent Uto, stir until completely solidified (when the sand is agglomerated), cool and sieve to obtain the proppant S3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com