Method and system for preparing cerium hydroxide

A cerium hydroxide, preparation system technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of inability to meet high-end quality requirements, difficult to filter cerium hydroxide, low purity of cerium hydroxide, etc. Easy to filter and dry, the solution is clear and transparent, and the price is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

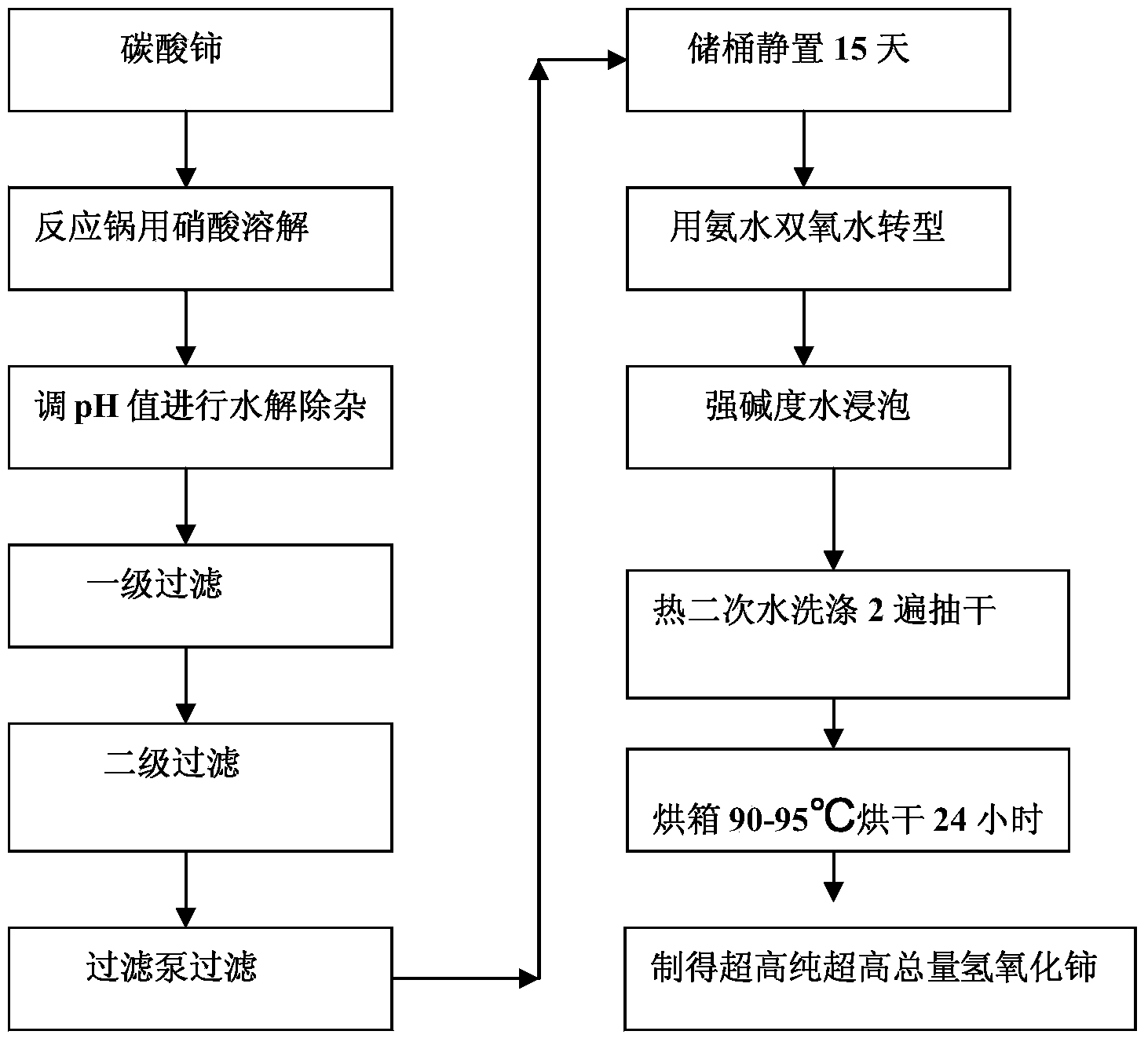

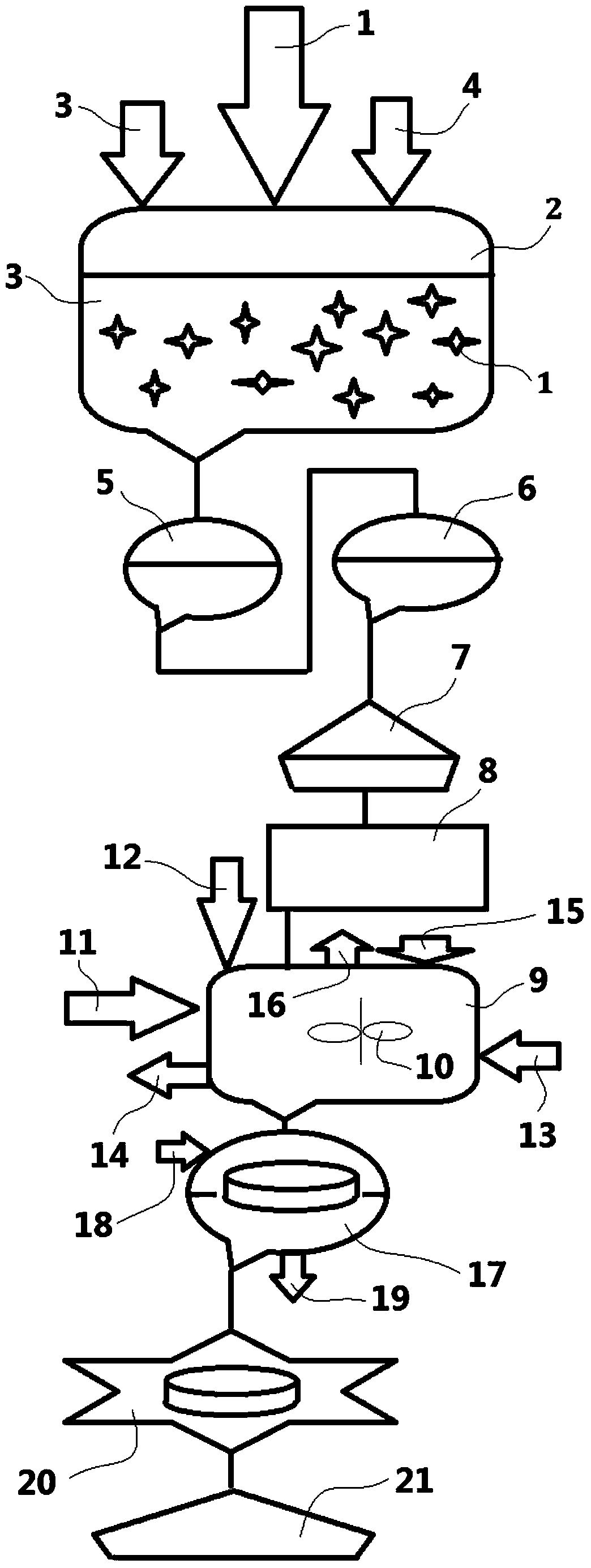

[0063] Such as Figure 1-2 Shown, in one embodiment, the preparation method according to cerium hydroxide of the present invention comprises the following steps:

[0064] 1. Quantitatively put high-purity cerium carbonate 1 (>99.99%) into the reaction kettle 2, add nitric acid 3 to dissolve, pay attention to oil removal during the dissolution process, after the dissolution is complete, adjust the pH value to 4.5- 5.5 (for example, about 5), heat up, and carry out hydrolysis to remove impurities. The input ratio of high-purity cerium carbonate and nitric acid is about 1:3 by molar ratio.

[0065] 2. The hydrolyzed feed liquid (inject secondary water through the water injection port 4) adjusts the feed liquid concentration to 1-1.5M (for example, about 1), and puts it into the primary airtight filter tank 5 to filter (preferably, double-layer filter cloth with filter paper in between).

[0066] 3. The filtrate after the primary filtration enters the secondary airtight filter ...

example 1

[0093] Cerium carbonate with a purity of 4N is mixed with secondary water, dissolved in nitric acid, hydrolyzed, and configured to contain CeO 2 The feed liquid of about 170g / l is filtered for the second time, transferred to the storage tank with a precision filter pump for storage, and left to stand for about 15 days. Transfer the static material liquid into the precipitation reaction kettle, adjust the concentration to 0.2-0.4M with secondary water, and convert it to hydrogen peroxide with ammonia water to completely oxidize it, keep it at 100°C for one hour, soak it in 3-5N hot ammonia water, and then Wash twice with hot secondary water, drain and transfer to an oven, and dry at a constant temperature of 90-95°C for several hours (for example, 24 hours).

[0094] The cerium hydroxide sample obtained by this step has an oxidation rate of 99.9%, is easily soluble in nitric acid, the total amount is 90.5%, bright yellow powder, excellent fluidity, and generally non-rare earth ...

example 2

[0096] Cerium carbonate with a purity of 4N is mixed with secondary water, dissolved in nitric acid, hydrolyzed, and configured to contain CeO 2 The feed liquid of about 170g / l is filtered for the second time, transferred to the storage tank with a precision filter pump for storage, and left to stand for about 15 days. Transfer the static material liquid into the precipitation reaction kettle, adjust the concentration to 0.2-0.4M with secondary water, and convert it to hydrogen peroxide with ammonia water for complete oxidation, keep it at 100°C for one hour, and wash it directly with hot secondary water for 2-3 Then, drain and transfer to an oven, and dry at a constant temperature of 90-95°C for several hours (for example, 24 hours).

[0097] The cerium hydroxide sample obtained by this step has an oxidation rate of 99.9%, is easily soluble in nitric acid, the total amount is 90.5%, bright yellow powder, excellent fluidity, and generally non-rare earth impurities - 4 2- <10p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com