Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Schreyerite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Schreyerite (V₂Ti₃O₉), is a vanadium, titanium oxide mineral found in the Lasamba Hill, Kwale district in Coast Province, Kenya. It is polymorphous with kyzylkumite. The mineral occurs as exsolution lamellae and particles in rutile, coexisting with kyanite, sillimanite, and tourmaline in a highly metamorphosed gneiss. It was named after German mineralogist and petrologist Werner Schreyer, for his research on mineralogy of rock-forming minerals and petrology of metamorphic rocks both in nature and by experiment.

Method for producing titanium and steel products by utilizing titanium and iron ores

InactiveCN101613825AIncrease profitHigh recovery rateProcess efficiency improvementElectric furnaceRutileContinuous rolling

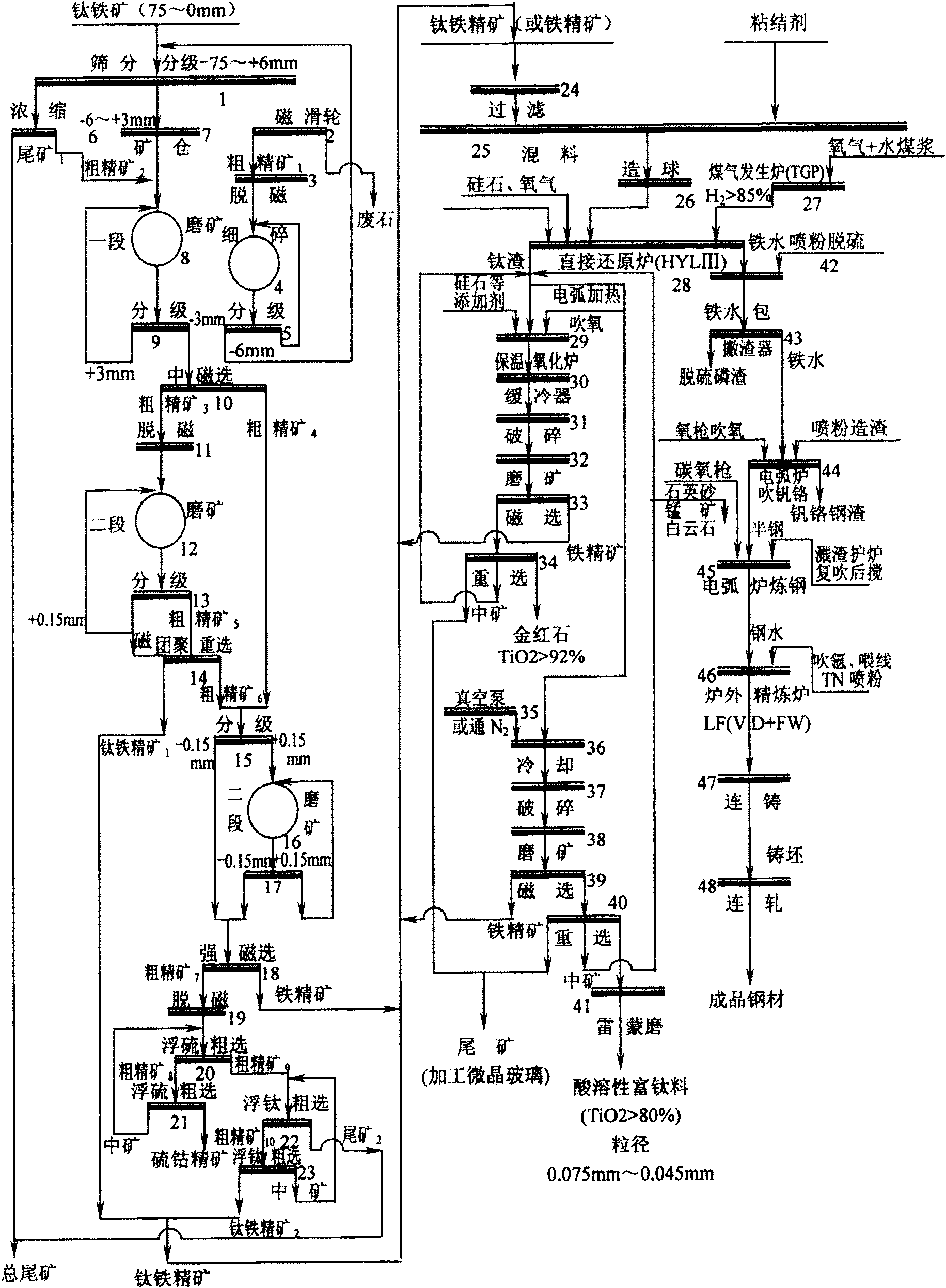

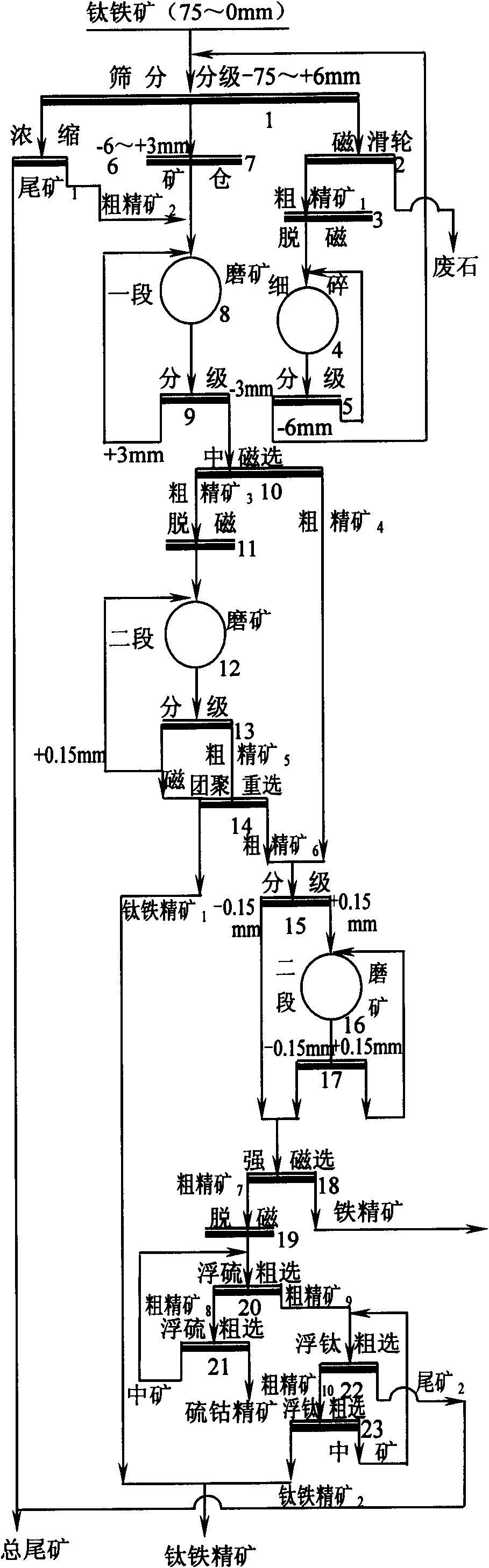

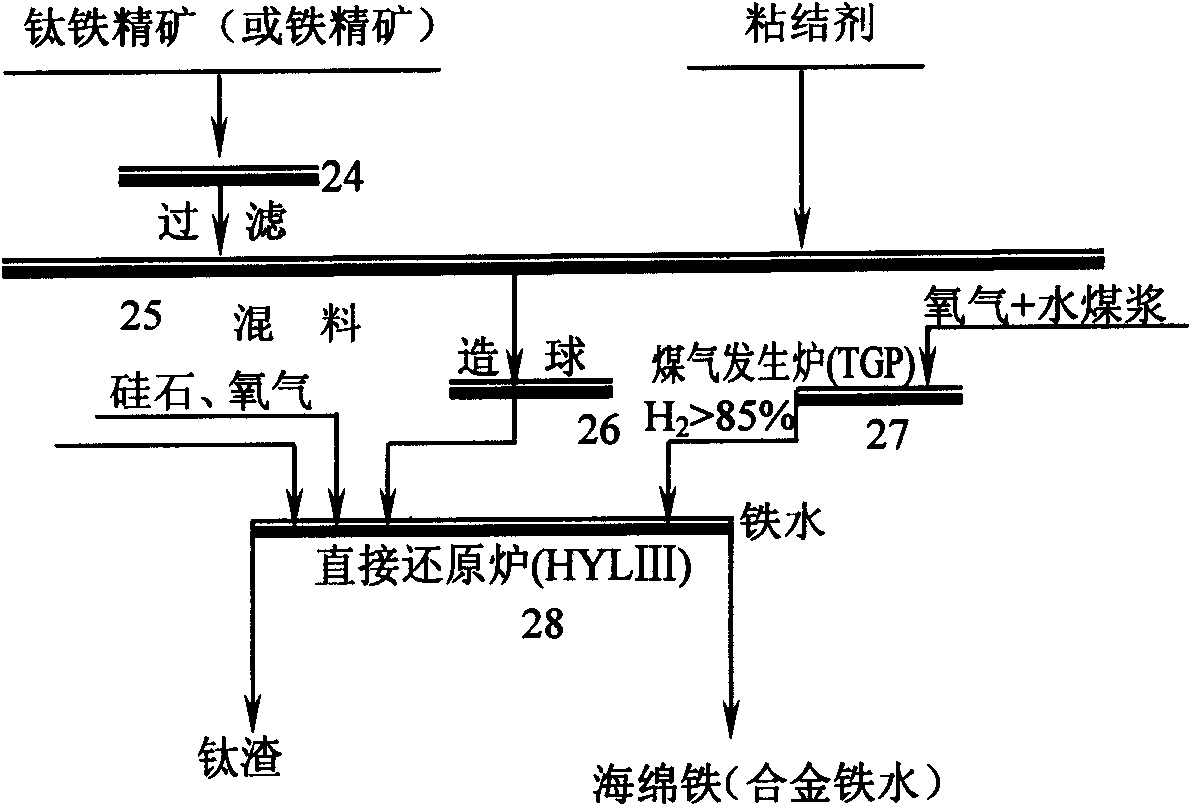

The invention discloses a method for producing titanium and steel products by utilizing titanium and iron ores, which belongs to the field of technical innovation of mining, dressing and smelting full process flow of the titanium and iron ores. Ordinary blast furnaces are not suitable for the smelting of high-titanium and medium-titanium schreyerite; and schreyerite mining, dressing and smelting enterprises in Panxi region extract rich parts and discard poor parts, and discard weathered ore of submarginal ore which accounts for over 95 percent of that of raw ore and is taken as mining mullock. The method comprises the following step: directly reducing titaniferous iron concentrate dressed from the mining mullock (TiO2 is over 5 percent, and TFe is over 13 percent) of the schreyerite, electric furnace melt producing titanium slag and molten water with electric furnace melt components, and producing a titanium-rich material and rutile with the titanium slag through mineral dressing by a fire method; producing alloy molten iron with the molten iron through electric smelting and vanadium-chrome steel slag blowing; and producing various alloy steel products the alloy molten iron in a continuous casting and continuous rolling mode through the electric smelting. The recovery rates of titanium, iron and vanadium are improved to 80 percent from 3.86 percent, improved to 70 percent from 34.5 percent and improved to 70 percent from 20.90 percent respectively.

Owner:PANZHIHUA JINTAI HI TECH

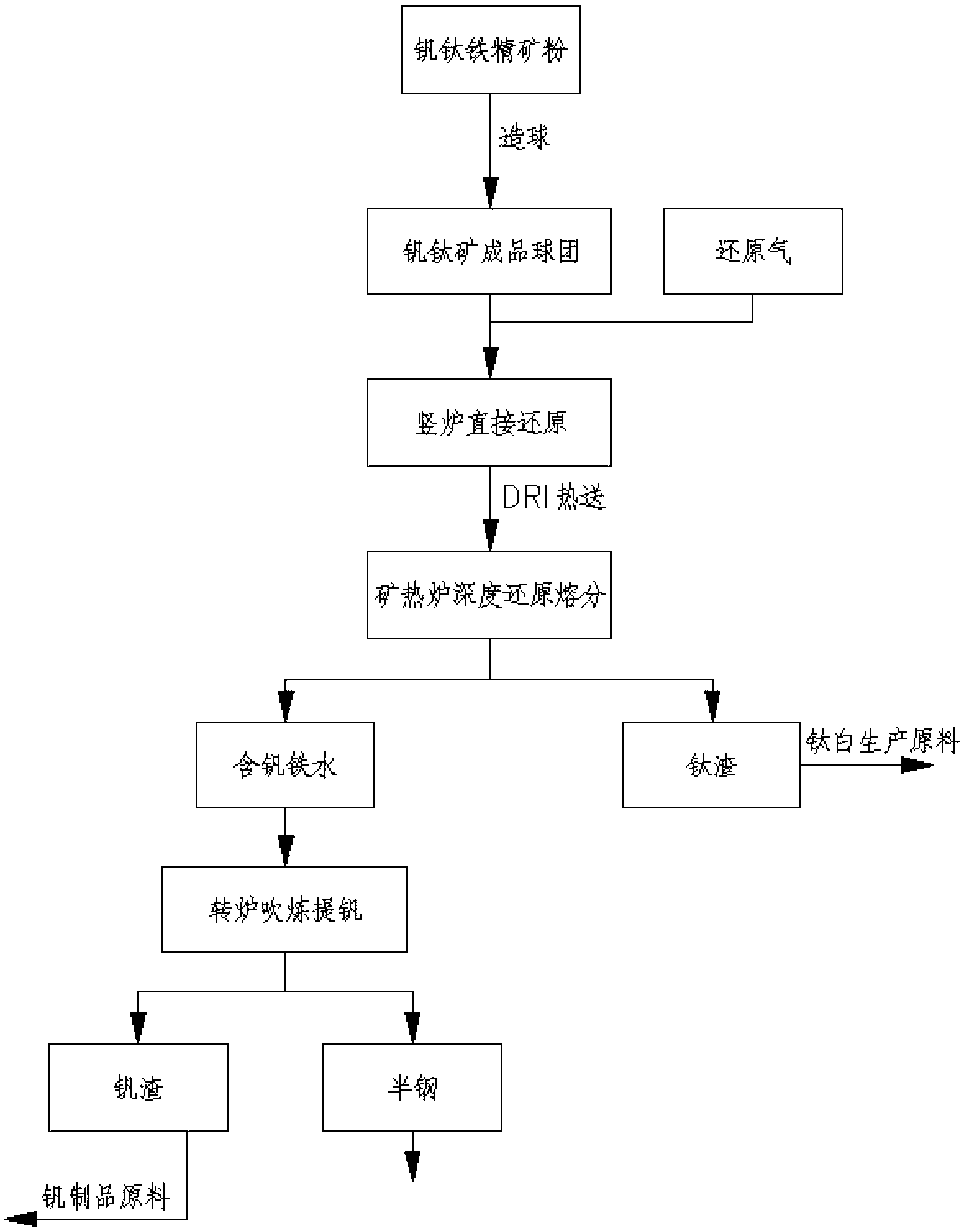

Method for recovering iron, vanadium and titanium from schreyerite through shaft furnace reduction and electric furnace smelting and separating deep reduction

ActiveCN103451419AHigh recovery rateReduce dependenceShaft furnaceGas emission reductionLand resourcesMagnetite

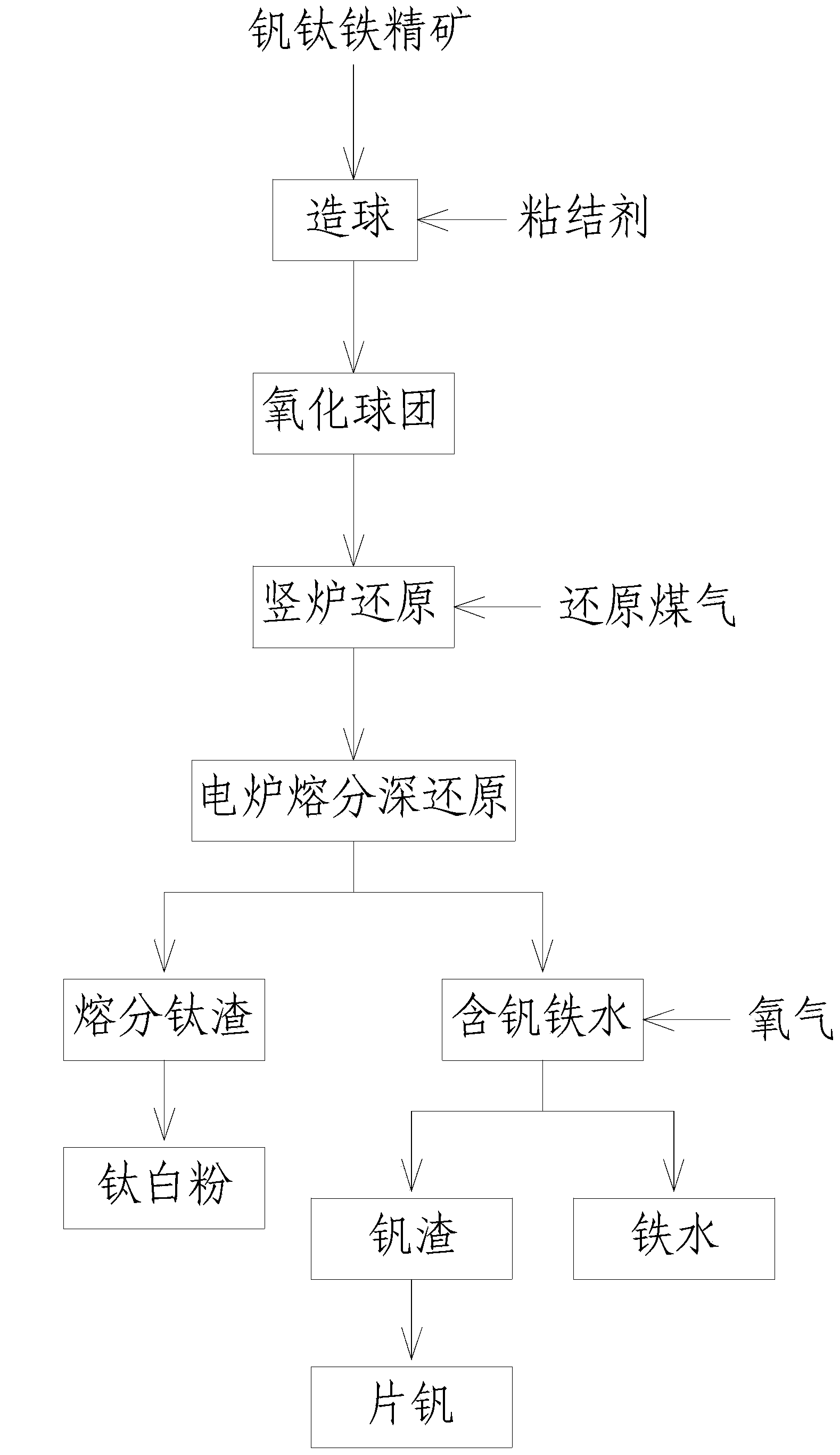

The invention discloses a method for recovering iron, vanadium and titanium from schreyerite through shaft furnace reduction and electric furnace smelting and separating deep reduction. The method comprises the following steps of: producing a vanadium-titanium oxidized pellet; directly reducing the vanadium-titanium oxidized pellet; smelting and separating a metalized pellet through an electric furnace; extracting vanadium from molten vanadium-containing iron; smelting and separating titanium slag to manufacture titanium dioxide; smelting and separating vanadium slag to manufacture V2O5. According to the method, coal gas, converted coke oven gas or natural gas is used as a reducing agent to reduce original vanadium titanium magnetite, so that the dependency of the traditional blast furnace process to coking coal can be greatly reduced, and diversification of metallurgical energy is realized; by adopting the process, the vanadium titanium magnetite can be smelted completely; mixed smelting of common iron ore and vanadium titanium magnetite is not needed, so that the smelting efficiency is higher; titanium dioxide in the smelted and separated titanium slag produced in smelting accounts for more than 50%, therefore, the slag can be directly used as the raw material for preparing titanium dioxide, and as a result, the recovery rate of vanadium, titanium and iron can be raised; simultaneously, the smelted and separated titanium slag and vanadium slag can be directly utilized, thus the environmental pollution and land resource occupation caused by piling and storing the slag can be avoided.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING +1

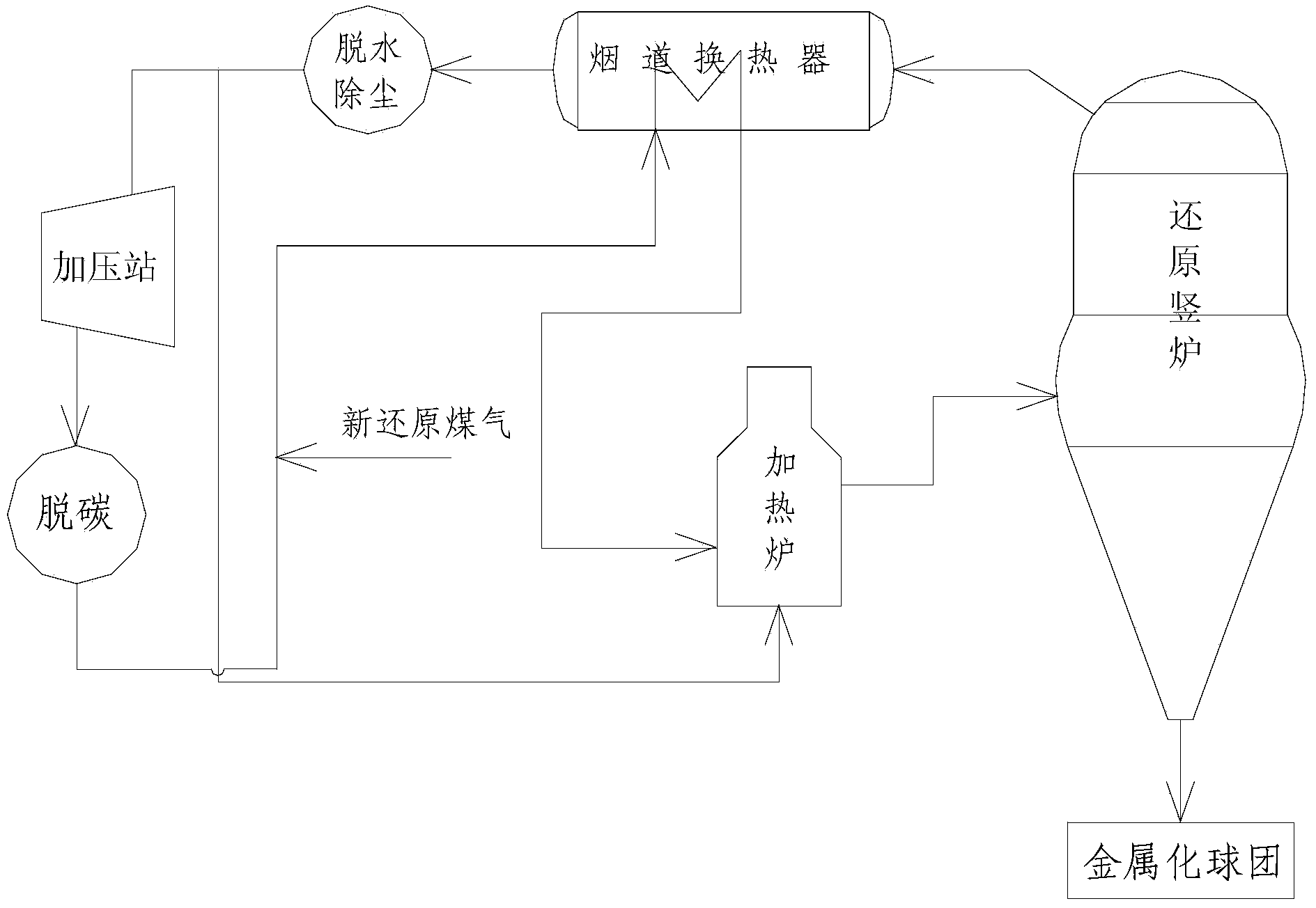

Gas-based shaft furnace direct reduction-electric furnace smelting separation process of vanadium titano-magnetite

InactiveCN103255255ARealize comprehensive utilizationEffective clean separationProcess efficiency improvementMagnetiteShaft furnace

The invention discloses a gas-based shaft furnace direct reduction-electric furnace smelting separation process of vanadium titano-magnetite. The process comprises the following steps of: a, forming finished product pellets; b, putting the finished product schreyerite pellets as raw materials into a direct-reduction shaft furnace and introducing a reducing gas to the shaft furnace to reduce the pellet ore, thus obtaining thermal-state direct reduced iron; c, feeding the thermal-state direct reduced iron to a smelting-separation electric furnace for reduction and smelting separation, thus separating out titanium slag and obtaining vanadium-containing iron liquid; and d, transferring the vanadium-containing iron liquid to a converter for blowing so as to separate out vanadium slag and semisteel. According to the gas-based shaft furnace direct reduction-electric furnace smelting separation process of vanadium titano-magnetite, the shortcomings of the existing process are improved, effective and clean separation of titanium, vanadium and iron is realized, the recovery and utilization rate of vanadium and titanium metal elements is improved and energy consumption and equipment one-time investment are reduced; and therefore, the process is suitable for large-scale production.

Owner:CISDI ENG CO LTD

Method for adjusting furnace charge structure before damping-down period of blast furnace for smelting high-titanium schreyerite

ActiveCN104694682AGuaranteed viscosityFast air supplyBlast furnace detailsAir volumeBlast furnace smelting

The invention belongs to the technical field of schreyerite blast furnace smelting, and particularly relates to a method for adjusting a furnace charge structure before a long damping-down period (the damping-down period is longer than five hours and shorter than five days) of a blast furnace for smelting high-titanium schreyerite. The method for adjusting the furnace charge structure before the damping-down period of the blast furnace for smelting the high-titanium schreyerite includes the step that in the smelting period before the damping-down period of the blast furnace, the furnace charge structure is adjusted to enable slag newly generated in the damping-down period of the blast furnace to meet the conditions that the content of TiO2 ranges from 1% to 20%, the binary alkalinity (CaO / SiO2) of the slag ranges from 1.00 to 1.03, the content of CaF2 ranges from 0.50% to 2.0%, and the content of MnO2 ranges from 1.0% to 4%. By means of the method, after damping-down overhauling is completed, the air volume can be rapidly (a period with the length 1 time to 1.5 times that of the damping-down period is needed) recovered to the air volume required by normal production.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Method for protecting blast furnace by injecting coal and spraying schreyerite powder

The invention discloses a method for protecting a blast furnace by injecting coal and spraying schreyerite powder. The method comprises the following steps of: continuously and uniformly adding a powdery schreyerite material into raw coal by using the conventional coal spraying facility in an iron mill; making powder by using the coal spraying facility and spraying the powder by using a spraying system; conveying the powder through a coal powder conveying pipeline and distributing the coal powder through a coal powder distributor; and spraying the powdery schreyerite material into a cylinder of the blast furnace from a coal spraying gun inserted from a belly pipe at the tuyere of the blast furnace. By adopting the method, the furnace cylinder and the furnace bottom can be safely and effectively repaired and maintained without influencing the normal production of the blast furnace.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Method for smelting medium titanium slag by blast furnace

InactiveCN101476001AIncrease production levelsImprove breathabilityBlast furnace detailsSteelmakingAlkalinity

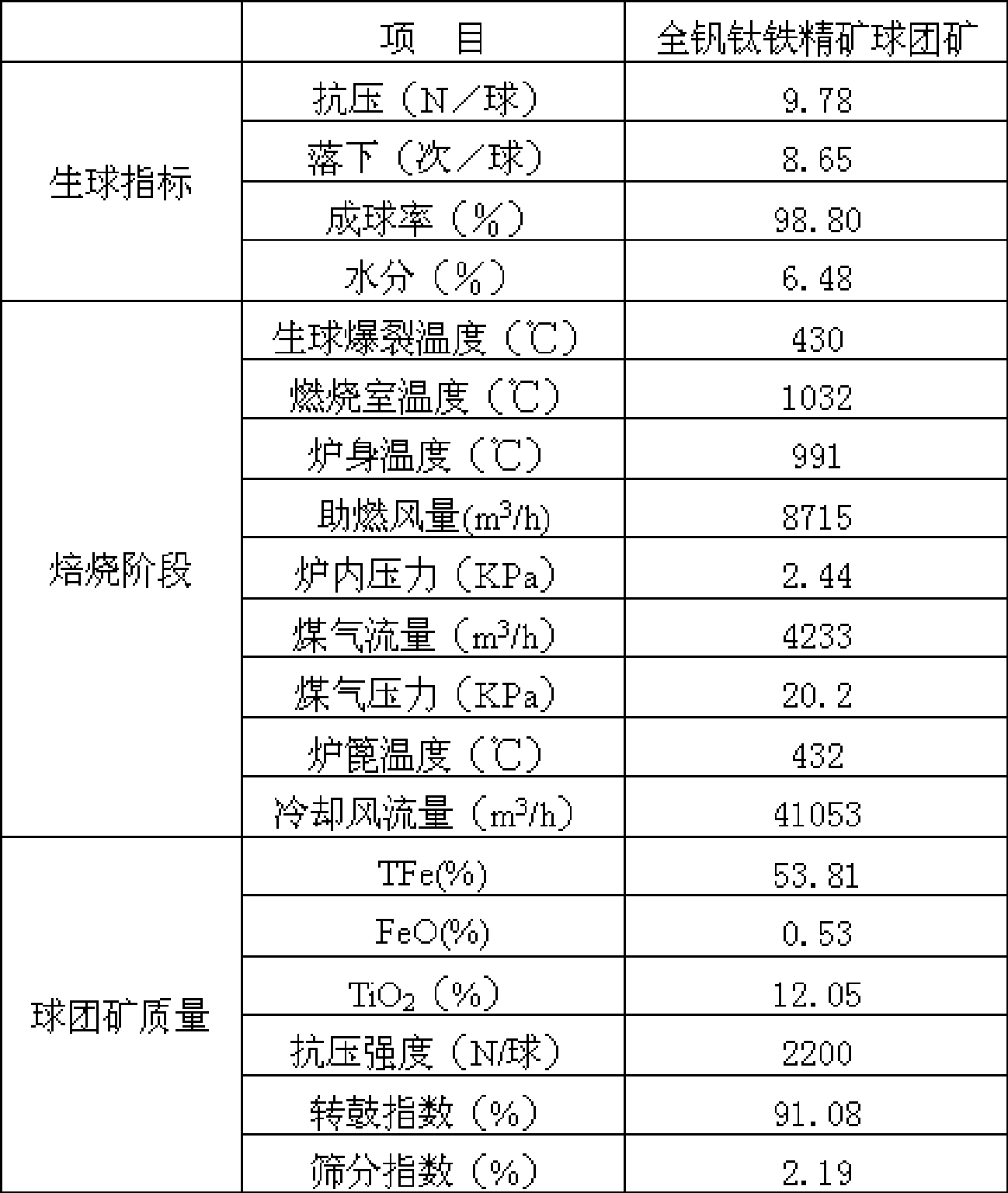

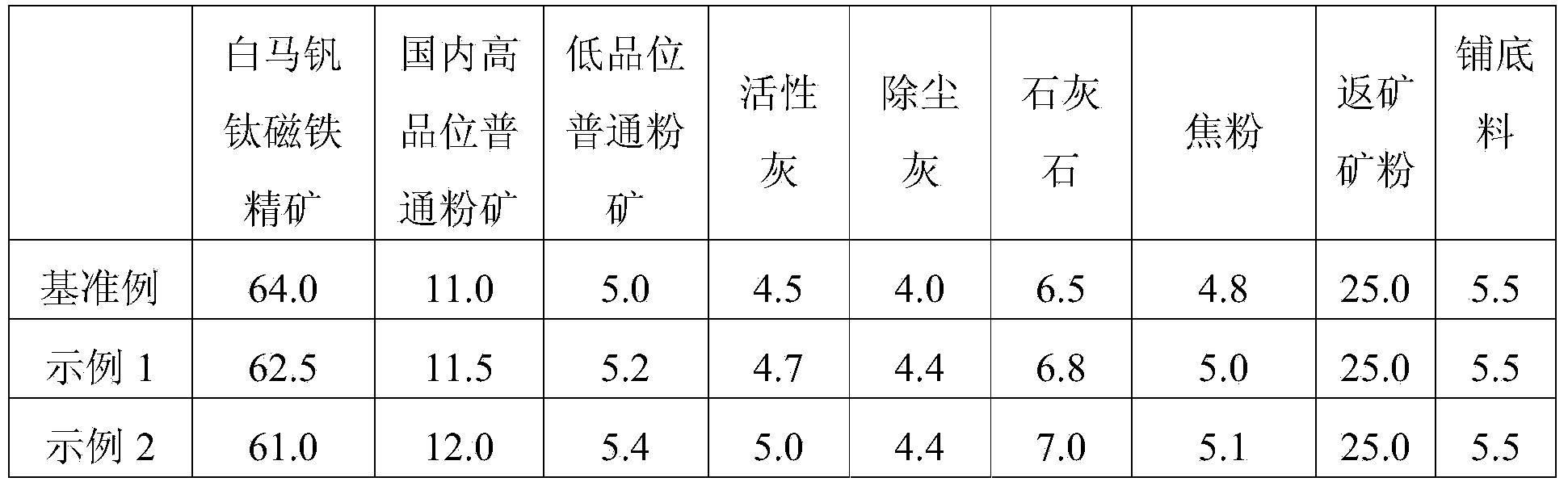

The invention belongs to the field of middle titanium slag melting technology, specifically to a middle titanium slag blast furnace smelting method. The technical problems the invention object to resolve is to provide a middle titanium slag melting method in a medium-sized blast furnace, the method can have a better use of schreyerite resources to perform middle titanium slag melting, specifically adopting 25 - 30 parts of all-vanadium-titanium pellet ore, 65 - 70 parts of low-vanadium-titanium magnetite ore and 5 - 10 parts of lump ore as raw materials for smelting in blast furnace. Obtained cast iron satisfies the quality requirements for further steelmaking, the furnace cinder dyadic alkalinity is 1.15 - 1.30, and can be used raw material of the composite powder. The method of the invention uses an appropriate charging stock structure in the blast furnace to reduce the sintering powder and to improve the air permeability, and makes full use of high cost-effective of schreyerite to effectively reduce production costs.

Owner:攀钢集团成都钢铁有限责任公司

Sintering method of high-chromium and high-vanadium schreyerite

InactiveCN102443694AHigh strengthImprove reducibilityBlast furnace detailsProcess efficiency improvementTerra firmaMagnetite

The invention relates to a sintering method of high-chromium and high-vanadium schreyerite and relates to a sintering method of schreyerite. The invention aims to solve the problems of the prior art that the yield of the liquid phase is low and the mineralization is poor in the sintering process of high-chromium vanadium-titanium magnetite. The sintering method comprises the following steps: 1) weighting schreyerite, an iron raw material, additives, auxiliary materials and fuel, and placing the materials in a mixer to perform mixing twice; and 2) distributing the mixture by a distributor at adistribution thickness of 550-580mm and then sintering at a sintering final temperature of 300-350 DEG C, a sintering final pressure of 10-11.5kPa and a sintering machine speed of 1.5-4 m / min to complete the sintering of high-chromium and high-vanadium schreyerite. By adopting the sintering method, the vanadium content of the vanadium-titanium sintered ore is up to more than 0.2% and a solid foundation is laid for the blast furnace smelting of schreyerite. The sintering method is used in the field of schreyerite sintering.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

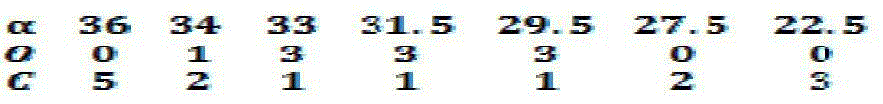

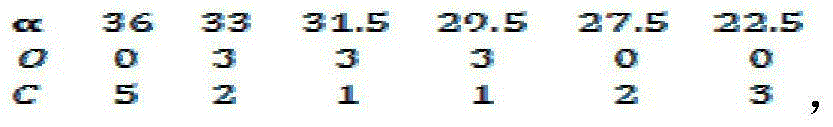

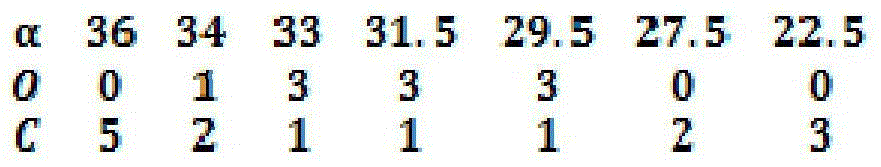

New charging method of schreyerite smelting blast furnace

ActiveCN103981308AStable furnace temperatureIncreased CO2 contentBlast furnace detailsTruckSchreyerite

The invention provides a new charging method of a schreyerite smelting blast furnace. The double ring burden distribution of ores and coke in a 430m<3> blast furnace is characterized in that ores of each batch are added at two angles, then coke is added at two angles, and finally center coke is added, wherein the ore and coke burden distribution alpha angles are 27DEG and 33DEG, and an angle difference alphadelta is fixedly controlled at 6DEG; and after the double ring charging of the ores and coke is carried out five times, the center coke is added, the addition amount of the center coke accounts for 1 / 5 of the total amount of coke added in the five-time charging, and the center coke is added with the alpha angle of 16DEG and a beta angle rotating for 2-3 rings. The ores, coke and the center coke of the blast furnace are weighed and screened, are added to a truck, are sent to a furnace roof distributing device, and finally are added to the blast furnace.

Owner:XINJIANG BAYI IRON & STEEL

Blast furnace smelting method for quickly acquiring stable indexes through ordinary ore and schreyerite interchange

ActiveCN111100961AReflect the changing trendReflect different requirementsSteel manufacturing process aspectsBlast furnace detailsMining engineeringSmelting process

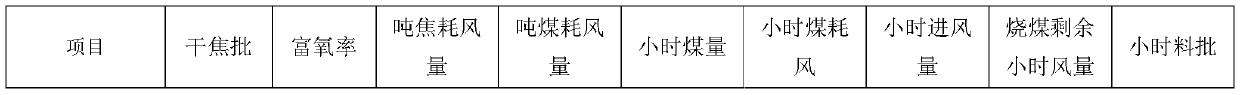

The invention discloses a blast furnace smelting method for quickly acquiring stable indexes through interchange ordinary ore and schreyerite. According to the blast furnace smelting method, in the material interchange process during one smelting cycle, the quantity of burned coke is calculated according to the well-timed in-furnace air quantity of a blast furnace, and the location where a new rawmaterial column accurately arrives is determined according to hour material batches under the conditions of specific smelting parameters; through combination with the specific blast furnace smeltingparameters, the influence of Si content and fuel ratio and change characteristics of smelting parameters of different mineral varieties are controlled, and the indexes such as proper smelting parameters, slag and iron compositions and the fuel ratio of an interchanged new mineral variety are realized accurately and stably. The problem that associated data such as smelting parameters, coke ratio, alkalinity balance, final slag compositions, pig iron composition control and the smelting cycle interact with each other during interchanging of ordinary ore and schreyerite in the smelting process issolved. The blast furnace smelting method guarantees that the stable smelting indexes are quickly acquired after interchanging of mineral varieties under the stable and smooth furnace conditions. Theblast furnace smelting method has the characteristics of being simple and quick and accurate in control.

Owner:WUKUN STEEL +1

Method for increasing yield of titanium-type agglomerate schreyerite

The invention discloses a method for increasing yield of titanium-type agglomerate schreyerite. Weight percentage is taken as basis, and the method comprises the following steps: mixing high-titanium-type vanadium titanium magnet ore concentrate and a binding agent according to the ratio of 97-98% to 2-3%; forming balls with the diameter of 12-16 mm; calcining the balls at the temperature of 400-600 DEG C to obtain acid oxidized calcined balls; using all or part of the acid oxidized calcined balls as end product high-titanium-type agglomerate schreyerite which is used as a backing material; performing material distributing, ignition, and sintering. The method provided by the invention can effectively increase the yield of the titanium-type agglomerate schreyerite, reduce the processing cost, and facilitate yield increase and efficiency increase.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Smelting method of schreyerite metalized pellets

ActiveCN104087703AThe composition is uniform and stableAppropriate degree of reductionElectric furnaceProcess efficiency improvementMelting tankSchreyerite

The invention provides a smelting method of schreyerite metalized pellets. The method comprises the following steps: laying a first carbonaceous reducing agent and first schreyerite metalized pellets accounting for 20-50% of total schreyerite metalized pellets on the bottom of a melt electric furnaces; starting arc to supply powder, thereby forming a melting bath; adding second schreyerite metalized pellets and a second carbonaceous reducing agent into the melting bath by many times, wherein the second carbonaceous reducing agent is firstly added, and the second schreyerite metalized pellets accounting for 2.5-15% of the total schreyerite metalized pellets are added each time; and after 10-15 minutes after finishing adding all the schreyerite metalized pellets, measuring the temperature, sampling, and discharging slag and tapping when the molten iron temperature is greater than or equal to 1550 DEG C and the FeO content in the furnace slag is 2-5%. The method can improve the melt and reducing condition effects, and can obtain the titanium-containing furnace slag and vanadium-containing molten iron with uniform and stable components and proper reduction degree.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Magnetic separator for mines

InactiveCN105170319AIncrease contact timeHigh impurity removal rateMagnetic separationMagnetiteMagnetic separator

The invention discloses a magnetic separator for mines, and belongs to the field of mine machines. The magnetic separator for the mines comprises a separator body. A containing cavity is formed in the separator body. A magnetic drum capable of rotating relative to the containing cavity is arranged in the containing cavity. A magnetic system is arranged in the magnetic drum. A concentrate opening is formed in one side of the containing cavity, the side, provided with the concentrate opening, of the containing cavity is connected with a feeding box through an ore feeding pipe, and the ore feeding pipe penetrates through the concentrate opening to be connected to the feeding box. A tailing opening and an overflow opening are formed in the other side of the containing cavity. The concentrate opening is higher than an outlet of the ore feeding pipe, the tailing opening and the overflow opening. The rotating direction of the magnetic drum is opposite to the flowing direction of materials in the containing cavity. By means of the magnetic separator for the mines, the technical problems that the existing schreyerite extracting accuracy is not high, and sundries such as magnetite are many are mainly solved; due to opposite rotation of ore pulp and the magnetic drum, the rate for removing the magnetite in the ore pulp is increased, and therefore the schreyerite extracting accuracy is improved.

Owner:张荣斌

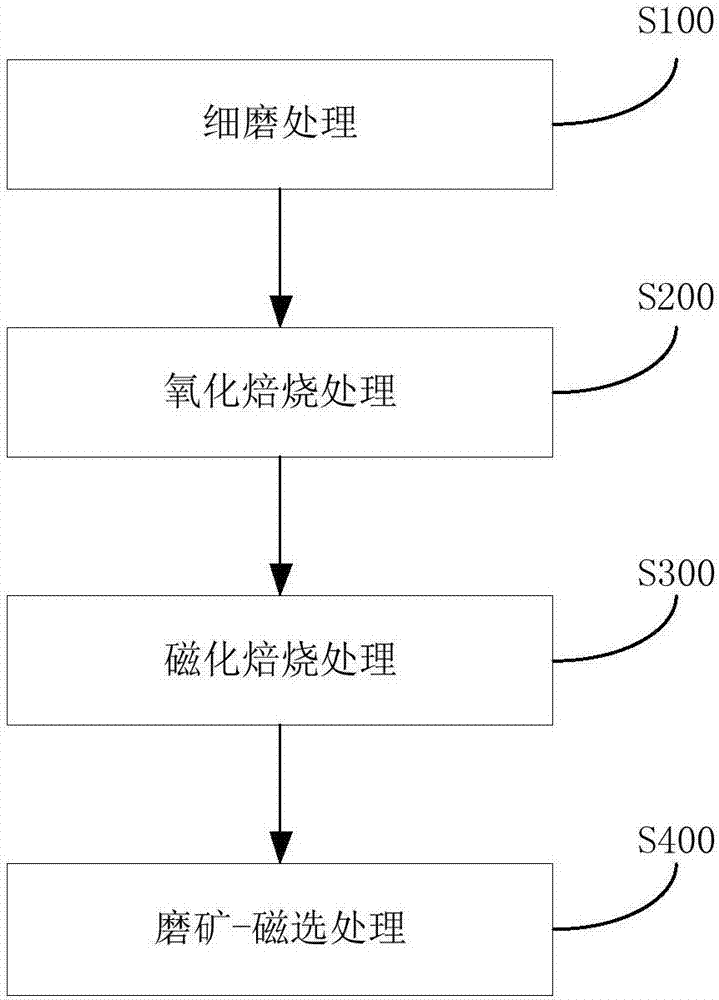

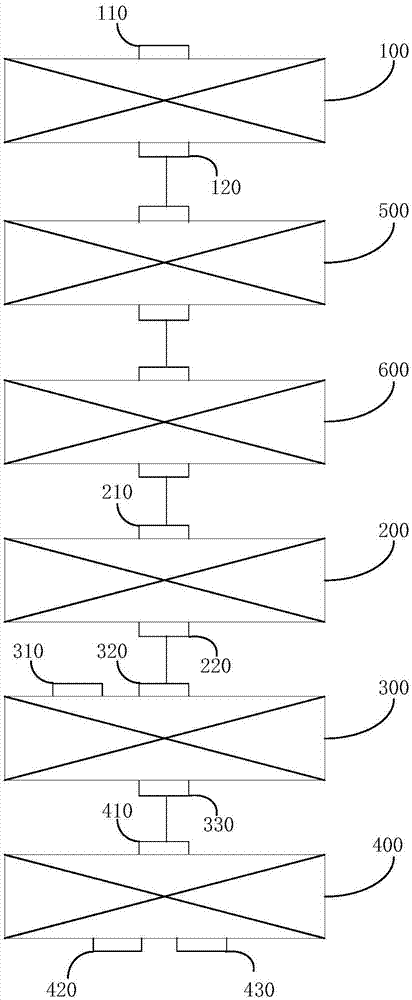

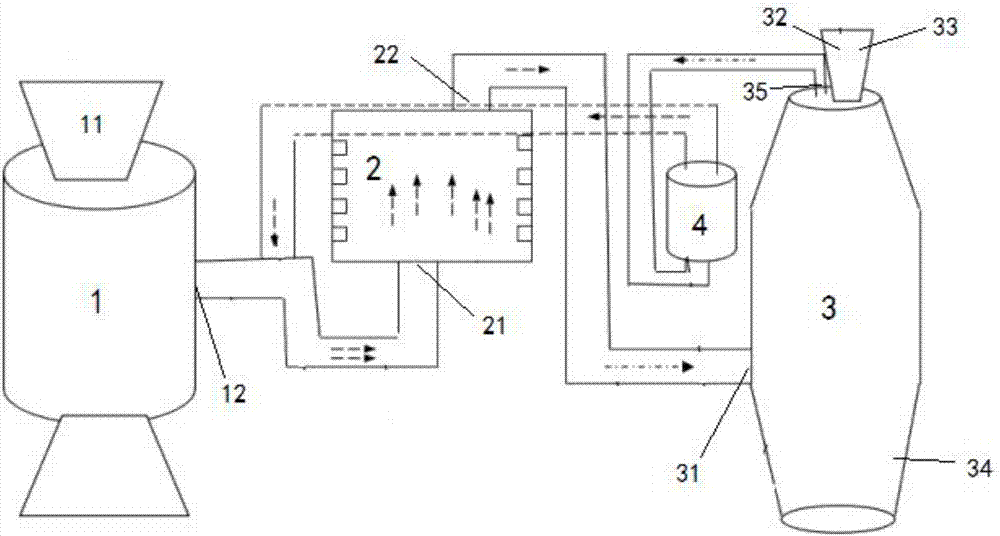

Method and system for treating schreyerite

InactiveCN106893856AImprove qualityImprove resource utilizationMagnetic separationFluidized bedResource utilization

The invention discloses a method and a system for treating schreyerite. The method comprises the following steps: the schreyerite is finely grinded to obtain schreyerite powder; the schreyerite powder is supplied into an oxidation roasting fluidized bed for oxidation roasting treatment to obtain an oxidation roasting product; coal powder is mixed with the oxidation roasting product to supply into a magnetic roasting fluidized bed for magnetic roasting treatment to obtain a magnetic roasting product; and the ore grinding-magnetic separation treatment is performed for the magnetic roasting product to obtain titanium slag and concentrates. The method for treating the schreyerite can effectively increase the resource utilization rate of the schreyerite, reduces the production cost and the energy consumption, and obtains high-quality concentrates and titanium slag.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Sintering method for sea sand vanadium-titanium-iron concentrate

The invention belongs to the field of metal smelting, and particularly relates to a sintering method for sea sand vanadium-titanium-iron concentrate. The technical problems that the sea sand vanadium-titanium-iron concentrate belongs to high titanium type schreyerite, the sintering performance is poor, the yield of sinter, the utilization coefficient and indexes like the drum index are poor compared with indexes of common ore are solved. According to the scheme, the sintering method of the sea sand vanadium-titanium-iron concentrate comprises the following steps that firstly, in the even mixing process before sintering, a calcium manganate aqueous solution is added into the sinter, and a mixture is prepared; and b, ignition is carried out, the mixture is sintered to obtain the sinter. The method is easy and convenient to operate, practical and suitable for industrialized production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method of regular furnace protection using schreyerite

The present invention relates to the field of steelmaking, and specifically to a method of regular furnace protection using schreyerite. The method of regular furnace protection using schreyerite comprises the following steps: step 1, for periodical repair of a blast furnace at an interval of 3-4 months, keeping a blast volume at 5800 m3 / min and an oxygen volume at 1500 m3 / h during a period from 48 hours before damping down to 8 hours before damping down, mixing schreyerite with coke nut and charging the mixture into the furnace, and keeping a temperature of liquid iron in the blast furnace within a range of 1510-1530 DEG C, a silicon content by mass percentage within a range of 0.6%-0.8% and an alkalinity within a range of 1.18-1.22; step 2, during a period from 8 hours before damping down to damping down, stopping adding the mixture of schreyerite and coke nut, and keeping the blast volume at 5800 m3 / min and the oxygen volume at 1500 m3 / h; step 3, reducing the temperature in the furnace below 1350 DEG C after damping down. The method of regular furnace protection using schreyerite is not only effective to long-term effective prevention of rising in the hearth wall temperature, and also significant to long-term stable smooth operation of the blast furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Melting and separating furnace reduction system and method for schreyerite

PendingCN106086283AMeet the needs of meltingSatisfy the conditions of high temperature reductionOxygenSchreyerite

The invention relates to a melting and separating furnace reduction system and method for schreyerite. The system comprises a reduction vertical furnace, a melting and separating furnace and an oxygen coal lance. The reduction vertical furnace comprises ore powder, a solvent feeding port, a discharging port and a smoke inlet. A baffle with the inclination angle capable of being adjusted is arranged in a hearth of the reduction vertical furnace, and the baffle and a supported rotating shaft are of a hollow structure. The melting and separating furnace comprises a feeding port, a smoke outlet and a discharging port, wherein the feeding port communicates with the discharging port of the reduction vertical furnace, and the smoke outlet communicates with the smoke inlet of the reduction vertical furnace. A spray lance head of the oxygen coal lance is arranged in the smelting and separating furnace. The oxygen coal lance stretches into the smelting and separating furnace from the furnace top of the smelting and separating furnace. According to the melting and separating furnace reduction system and method for the schreyerite, due to the fact that the baffle with the inclination angle capable of being adjusted is arranged in the reduction vertical furnace, the falling speed of and the staying time of the ore powder can be controlled, and the reduction effect of the ore powder is ensured.

Owner:SHENWU TECH GRP CO LTD

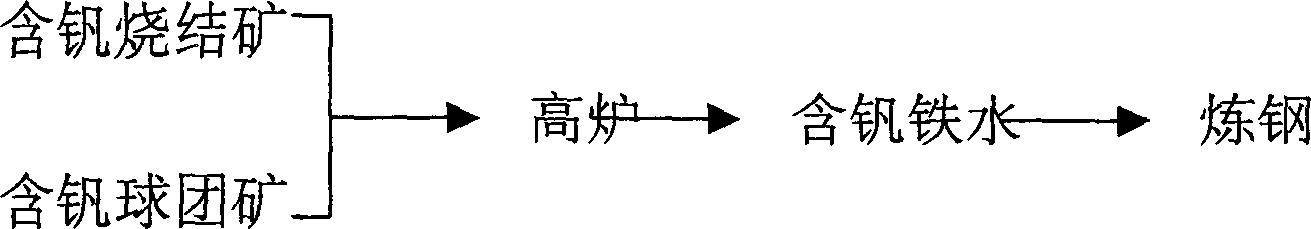

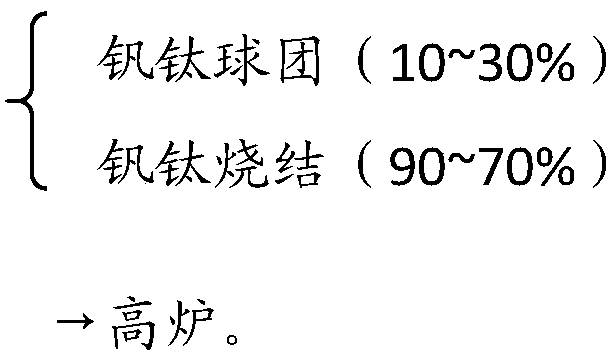

Process for smelting schreyerite by blast furnace with cooling block

The invention relates the technology of smelting schreyerite by high furnace, specially high pH value schreyerite sintered ore and acid schreyerite pellet ore. The method comprises the following steps: mixing the sintered ore containing vanadium and pellet ore containing vanadium, smelting them by modular high furnace to get iron melt containing vanadium, and carrying out steel production. The key points of the method are following: 1 improving standard speed; 2 reducing the foundry iron containing vanadium; 3 lowering the basic capacity of clinker. The invention makes the special type ore smelting technology requirement common. The main econo-technical indicators are good. The availability ratio is 2.23-2.84t / m3d, wind temperature is 705-988Deg.C and comprehensive coke ratio is 582-634kg / t.

Owner:HEBEI LUANHE IND GROUP

Slag form system for smelting vanadium-titanium magnetite with electric furnace

ActiveCN110438279ARealize comprehensive utilizationGood acid hydrolysisElectric furnaceElectric arc furnaceMagnetite

The invention discloses a slag form system for smelting vanadium-titanium magnetite with an electric furnace, and belongs to the field of comprehensive utilization of schreyerite. The slag form systemis characterized in that low-silicon vanadium-titanium magnetite concentrate is taken as a raw material; a pre-reduced product of the vanadium-titanium magnetite concentrate is fed into the electricfurnace for smelting; a calcium-containing and magnesium-containing solvent is added in a mass ratio of 0.6 to 1.0 of CaO to SiO2, and a molar ratio of 1.1 to 0.8 of MgO to TiO2 for regulating the slag composition; and a major titanium-containing phase in the slag refers to a magnesium metatitanate phase. Through adoption of the slag form system disclosed by the invention, the inclusion of molteniron in vanadium and the inclusion of slag in vanadium can be effectively controlled during smelting of the electric furnace; vanadium can be recovered from obtained vanadium-containing molten iron through vanadium extraction with a converter; the titanium-containing slag meets the requirement on a sulfate process titanium dioxide raw material; and the comprehensive utilization of iron, vanadium and titanium in the vanadium-titanium magnetite can be realized. in the smelting process, the vanadium-titanium trend is easy to control, and the smelting operation difficulty is low.

Owner:CENT SOUTH UNIV

Schreyerite smelting method

InactiveCN109082489ASuitable for processing technologyRaise the gradeBlast furnace detailsBriquetteUltimate tensile strength

The invention discloses a schreyerite smelting method, including the steps of producing schreyerite briquettes through the briquette production technology after separation of schreyerite; preparing sinter with low titanium dioxide content (not greater than 2%) from general mineral powder and in-plant circulating material by the sintering process; smelting raw materials, including 30-70% of schreyerite briquettes, 30-60% of sinter with low titanium dioxide content, 0-10% of high-grade general lump ore, in a blast furnace. According to researches, strength of sinter is in highly negative correlation with the content of TiO2 contained in the sinter, and schreyerite in Panxi region which has high content of MgO and low content of SiO2 is much adaptable to the briquette processing technology. To plants who utilize schreyerite in Panxi region which has high content of MgO and low content of SiO2 as the main ironmaking raw material, the schreyerite smelting method can improve the grade of thesinter and the comprehensive grade of as-fried ore in the blast furnace, improve technical economic index on sintering and blast-furnace processes remarkably and reduce product cost greatly.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Method and system for reducing schreyerite through coal pyrolysis gas

PendingCN107447068AHigh quality half focusHigh Metallization Rate Metallized PelletsShaft furnaceHeating furnaceGas heating

The present invention proposes a method and system for reducing vanadium-titanium ore with coal pyrolysis gas. The method includes the steps of: coal pyrolysis: adding raw coal from the coal pyrolysis furnace silo to the coal pyrolysis furnace, at a temperature of 700-900°C , pyrolysis to generate solid semi-coke and pyrolysis gas; pyrolysis gas heating: the pyrolysis gas enters the heating furnace through the pipeline to be heated to obtain a high-temperature reducing gas of 1000‑1100 °C; vanadium-titanium ore reduction: the high-temperature reducing gas is transported After entering the shaft furnace, react with semi-coke, and reduce vanadium-titanium ore to obtain reduced vanadium-titanium metallized pellets; wherein, the pressure of reducing gas entering the shaft furnace is 0.45MPa-0.9MPa, and the temperature is 950-1050 ℃. The invention organically combines coal chemical industry with metallurgical production, effectively utilizes H2O and CO2 in coal pyrolysis gas to oxidize semi-coke, so as to increase the content of reducing gas and reduce the production cost and energy consumption of vanadium-titanium direct reduction iron.

Owner:SHENWU TECH GRP CO LTD

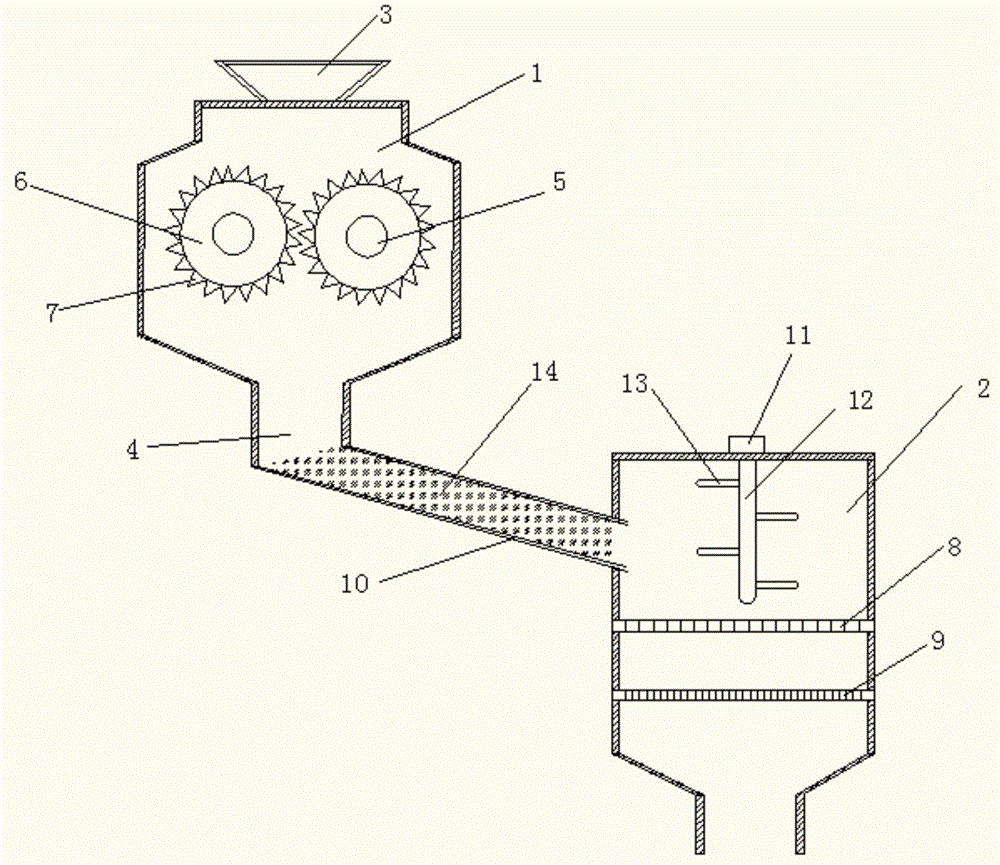

Schreyerite ore-dressing device

The invention relates to the field of mining machinery, in particular to a schreyerite ore-dressing device. In order to solve the technical problems, the invention provides the schreyerite ore-dressing device which is low in cost and is sufficient in ore-dressing. The schreyerite ore-dressing device comprises a grinding device and a screening device, and further comprises an inclination slot, wherein a charge hole is formed in the upper end of the grinding device; a discharge hole is formed in the lower end of the grinding device; rotary shafts are symmetrically arranged in the grinding device; rotor discs are arranged on the rotary shafts; tooth rollers are mounted on the rotor discs; a primary sieve plate is arranged inside the screening device; a secondary sieve plate is arranged below the primary sieve plate; the primary sieve plate and the secondary sieve plate are equipped with through holes which are densely arranged, and diameters of the through holes are sequentially reduced; one end of the inclination slot is connected with the discharge hole, and the other end of the inclination slot extends into the screening device; and the grinding device can be used for effectively grinding schreyerite ores, and small ground ores enter the screening device, so that schreyerite ores of different sizes are effectively screened out, screening is sufficient, production cost is reduced, and working efficiency is greatly improved.

Owner:攀枝花市仁通钒业有限公司

Method for smelting schreyerite in coke oven gas-based shaft furnace-electric furnace melt separation deep reduction

The invention belongs to the field of comprehensive utilization of schreyerite, and particularly relates to a method for smelting schreyerite in a coke oven gas-based shaft furnace and smelting deep reduction in an electric furnace, in particular to a method for smelting schreyerite in a coke oven gas-based shaft furnace and smelting deep reduction in an electric furnace. The vanadium-titanium pellets are reduced in the gas-based shaft furnace, and vanadium-titanium direct reduction iron is obtained; the vanadium-titanium direct reduction iron is subjected to melting reduction in an electric furnace to obtain vanadium-containing molten iron and titanium slag, the gas-based shaft furnace at least uses one coke oven gas as a gas source, and purified gas at the top of the gas-based shaft furnace exchanges heat with hot gas in a gas ascending pipe of the coke oven and then is mixed into high-temperature reducing gas generated by the coke oven gas to form furnace-entering reducing gas of the gas-based shaft furnace; and reducing gas is blown into the molten layer in the electric furnace, the reducing gas reacts with the vanadium and iron oxides to generate vanadium and iron metal liquid and titanium slag, and the vanadium and iron metal liquid enters the molten iron. Electric furnace smelting power consumption can be reduced, the influence of newly added materials of the electric furnace on the titanium slag grade is reduced, and efficient and reasonable utilization of different types of heat energy is achieved.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Iron preparation method and system

PendingCN106119456AGood effectImprove reduction efficiencyFluidised-bed furnacesIRON PREPARATIONSMagnetite

The invention discloses an iron preparation method and system. The method comprises the following steps: mixing vanadium titano-magnetite powder and carbon powder; treating the mixture by magnetizing roasting in nitrogen atmosphere so as to obtain magnetized ore powder; mixing the magnetized ore powder with pulverized coal and an adhesion agent to obtain a mixture; performing forming treatment on the mixture to obtain pellets; treating the pellets by reducing roasting to obtain metallized pellets; and then separating slag and iron in the metallized pellets so as to obtain iron and waste slag. According to the method, the vanadium titano-magnetite powder is subjected to magnetizing roasting treatment before the forming treatment, and the magnetized and roasted schreyerite can effectively inhibit the volume expansion caused by the conversion of crystal form in the ore during the reduction process, so that the problem of the volume expansion caused by the crystal form conversion in the reduction process of the vanadium titano-magnetite pellets can be solved; in addition, the magnetized and roasted schreyerite has a good effect on desulfurization.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

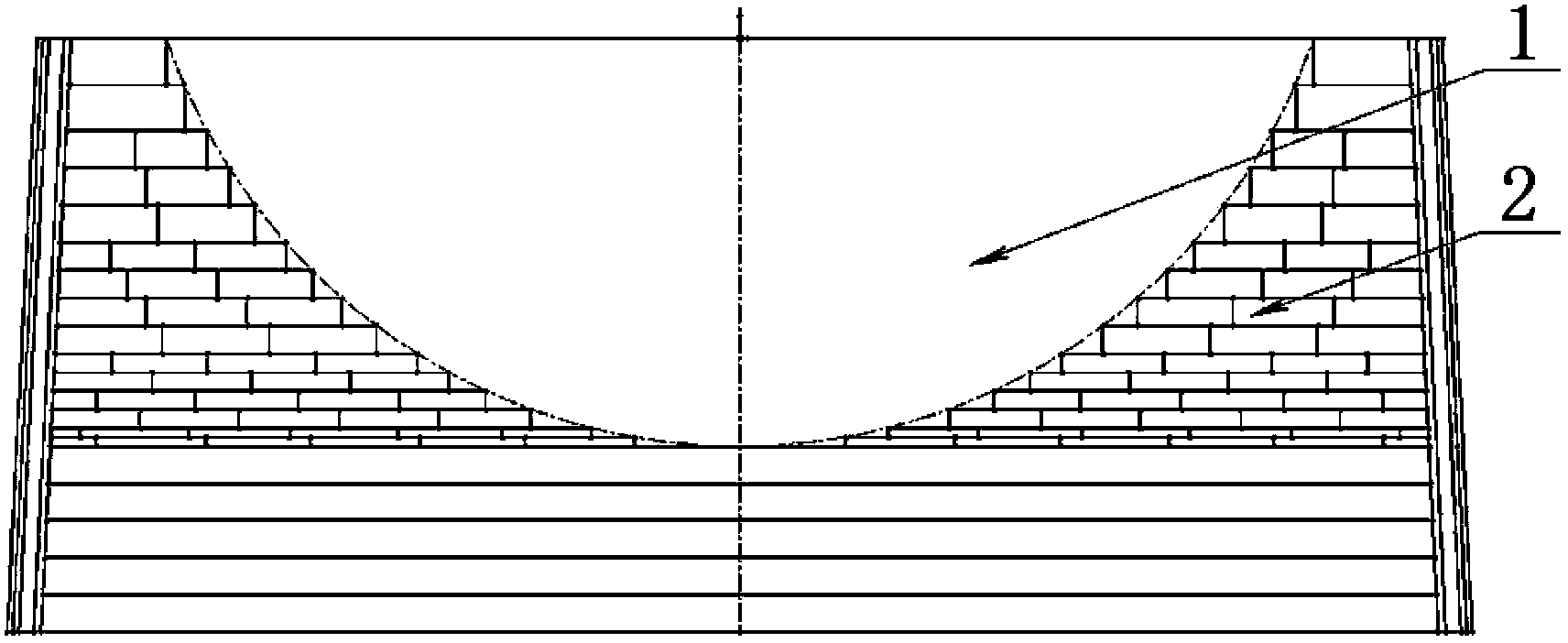

Long-life blast furnace hearth

InactiveCN103509899AAvoid erosionPrevent burn throughBlast furnace detailsInternal formsDaily operationBrick

The invention discloses a long-life blast furnace hearth including annularly layering carbon bricks, in the blast furnace hearth, the volume of a part from the furnace bottom to an iron notch is a spherical segment shape, the spherical centre of the spherical segment shape is located in the central axis of the blast furnace, the sphere radius of the spherical segment shape is R = (A<2>+ 4B<2>) / (8B), wherein A is the hearth diameter, B is the spherical segment height, namely the total height of the annularly layering carbon bricks of the hearth. "Elephant foot" erosion of the blast furnace hearth can be greatly inhibited, hearth breakout can be avoided as far as possible, and in the daily operation of a blast furnace, feeding of furnace protection materials such as schreyerite and the like can be cancelled, so that the cost of pig iron can be reduced, the development of varieties of rolled steel can be promoted.

Owner:ANGANG STEEL CO LTD

Coal pyrolysis, pyrolysis gas heating and schreyerite reduction coupled system and method

PendingCN107267701AIncrease metallization rateAvoid affecting the furnace conditionShaft furnaceShaft furnaceCoal pyrolysis

The invention relates to a system and method for coupling coal pyrolysis, ceramic radiant tube heating and vanadium-titanium ore reduction process. The system includes a coal pyrolysis furnace, a heating furnace and a shaft furnace; the coal pyrolysis furnace includes a coal pyrolysis charge bin and coal pyrolysis gas outlet; the heating furnace is a ceramic radiant tube gas heating device, which includes a coal pyrolysis gas inlet and a reducing gas outlet, and the coal pyrolysis gas inlet and the coal pyrolysis gas outlet pass through pyrolysis The gas pipeline is connected; the shaft furnace includes a gas injection port, a shaft furnace bunker and a shaft furnace discharge port, the shaft furnace bin is arranged on the top of the shaft furnace, and the gas injection port is arranged in the middle of the shaft furnace and connected to the shaft furnace The reducing gas outlet is connected. By organically combining coal chemical industry with metallurgical production, the present invention improves resource utilization, reduces production equipment, reduces the production cost and energy consumption of reducing gas semi-coke produced by vanadium-titanium DRI, low-quality coal, and medium-low rank coal, and improves production competitiveness.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

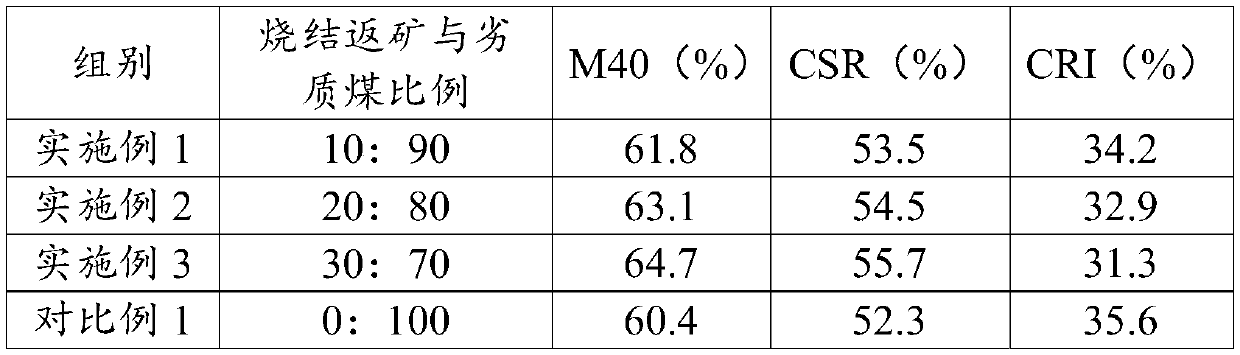

Iron coke preparation method by high titanium type schreyerite sintering return mine and prepared iron coke thereof

ActiveCN109097515AReduce processing costsImprove coking performanceBlast furnace detailsEconomic benefitsUltimate tensile strength

The invention provides an iron coke preparation method by high titanium type schreyerite sintering return mine and prepared iron coke thereof, and relates to the technical field of ferrous metallurgy.The iron coke preparation method by high titanium type schreyerite sintering return mine comprises the following steps that the high titanium type schreyerite sintering return mine is screened, and return mine with diameter less than 1mm is collected; the return mine with diameter less than 1mm is mixed with inferior coal and is added into a die for heat pressing forming to obtain coal-like materials; and the coal-like materials are mixed with high quality coal for coking to obtain the iron coke. The return mine with diameter less than 1mm is directly applied to iron coke production, and therefore the machining cost of return mine sintering can be greatly lowered, the inferior coal coking effect is obviously improved, intensity is significantly improved, and obvious application prospect and economic benefit for iron and steel metallurgical enterprises are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

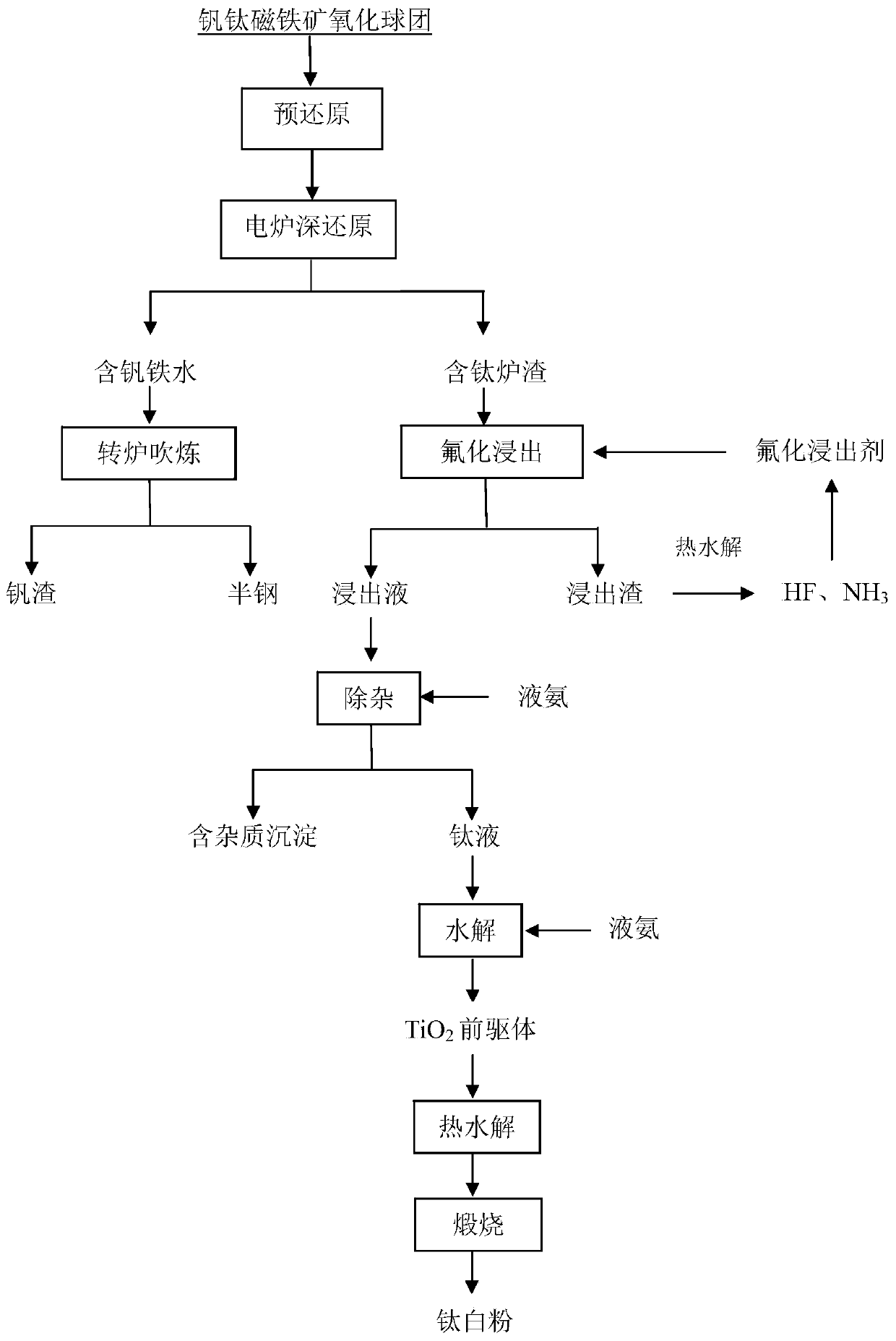

Process for comprehensively utilizing vanadium titano-magnetite via prereduction-electric furnace deep reduction-fluorination method

ActiveCN110484712ARealize comprehensive utilizationRaise the gradeTitanium dioxideProcess efficiency improvementMagnetiteTitanium oxide

The invention discloses a process for comprehensively utilizing a vanadium titano-magnetite via prereduction-electric furnace deep reduction-fluorination method. According to the process, a vanadium titano-magnetite pellet is firstly prereduced; the prereduced pellet is fed into an electric furnace for deep reduction so as to obtain vanadium-containing pig iron and titanium-containing slags; in the electric furnace smelting process, a calcium-containing flux is added for slag adjustment so as to ensure that the main titanium-containing phase of the slags are of a perovskite phase which is difficult to reduce, so that benefit is brought to restrain the reduction of the titanium oxides; and the titanium-containing slags which take perovskite as the main phase adopts a fluorination method toprepare titanium dioxide, and the vanadium molten iron adopts converter to extract vanadium, so that the comprehensive utilization of the vanadium titano-magnetite can be realized. Compared with the blast furnace process, the process disclosed by the invention is capable of realizing the full-schreyerite smelting, making the produced titanium slag taste high, recycling the titanium resources and decreasing the serious pollution processes such as sintering, coking, blast furnace and the like so as to have a relatively high environment-friendly advantage, and is capable of reducing the investment and production cost so as to have a relatively high economic advantage.

Owner:CENT SOUTH UNIV

Schreyerite furnace protection method and device

InactiveCN104073579AExtended service lifeEasy to moveBlast furnace componentsBlast furnace detailsMobile vehicleEngineering

The invention discloses a schreyerite furnace protection method and a device. According to the method and the device, a stocker containing schreyerite powder, which is disposed in a mobile vehicle, is pressurized by utilization of nitrogen so as to guarantee that the stocker is slightly pressurized, a feeder is opened, the concrete schreyerite powder is injected into a blast furnace by utilization of nitrogen through a tuyere, and the stocker is subjected to on-line real-time weighing control during injection. The stocker, a nitrogen bottle, the feeder and other auxiliary devices are installed on the mobile vehicle, the injection tuyere position is adjusted by moving the mobile vehicle, a discharging valve at the bottom of the stocker is connected to the feeder, and the lower part of the stocker is provided with a nozzle. The method and the device can inject the schreyerite to a specific area, movement is convenient and operation is simple. The method and the device achieve an effect of on-line furnace protection and prolong the service lifetime of the blast furnace. By setting the pressure of the schreyerite in the stocker and the pressure in the nitrogen bottle, the schreyerite injection amount is controlled quantitatively, and accurate control of blast furnace schreyerite-injection furnace protection can be achieved.

Owner:ANGANG STEEL CO LTD

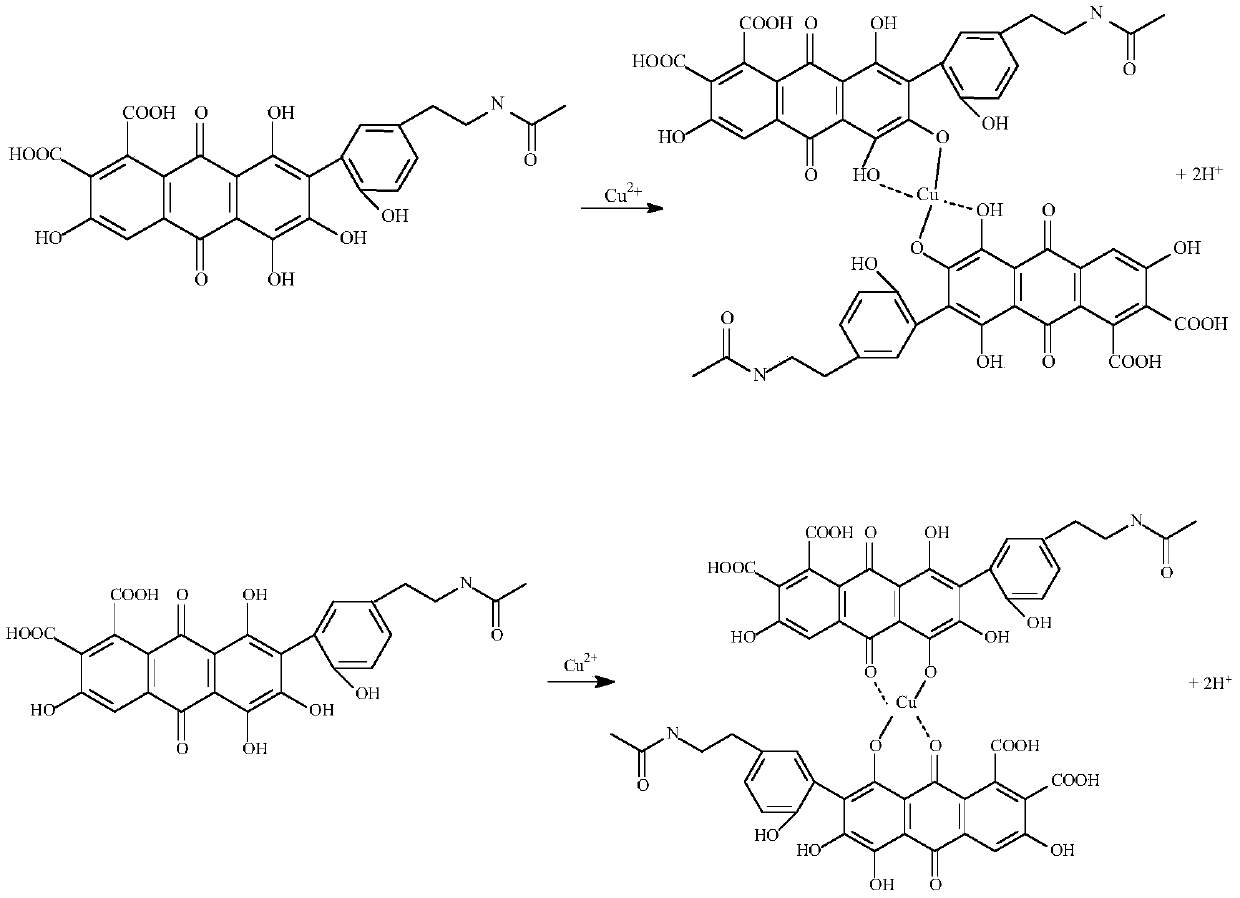

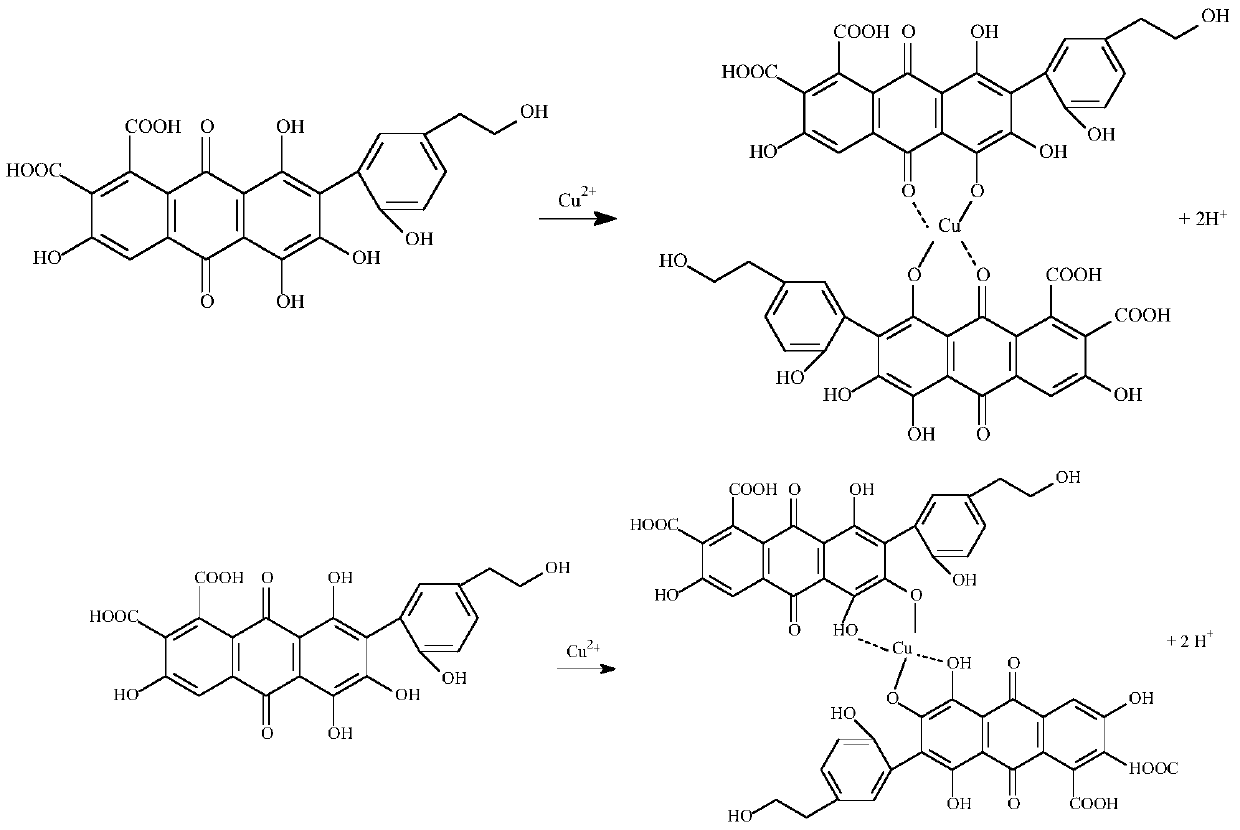

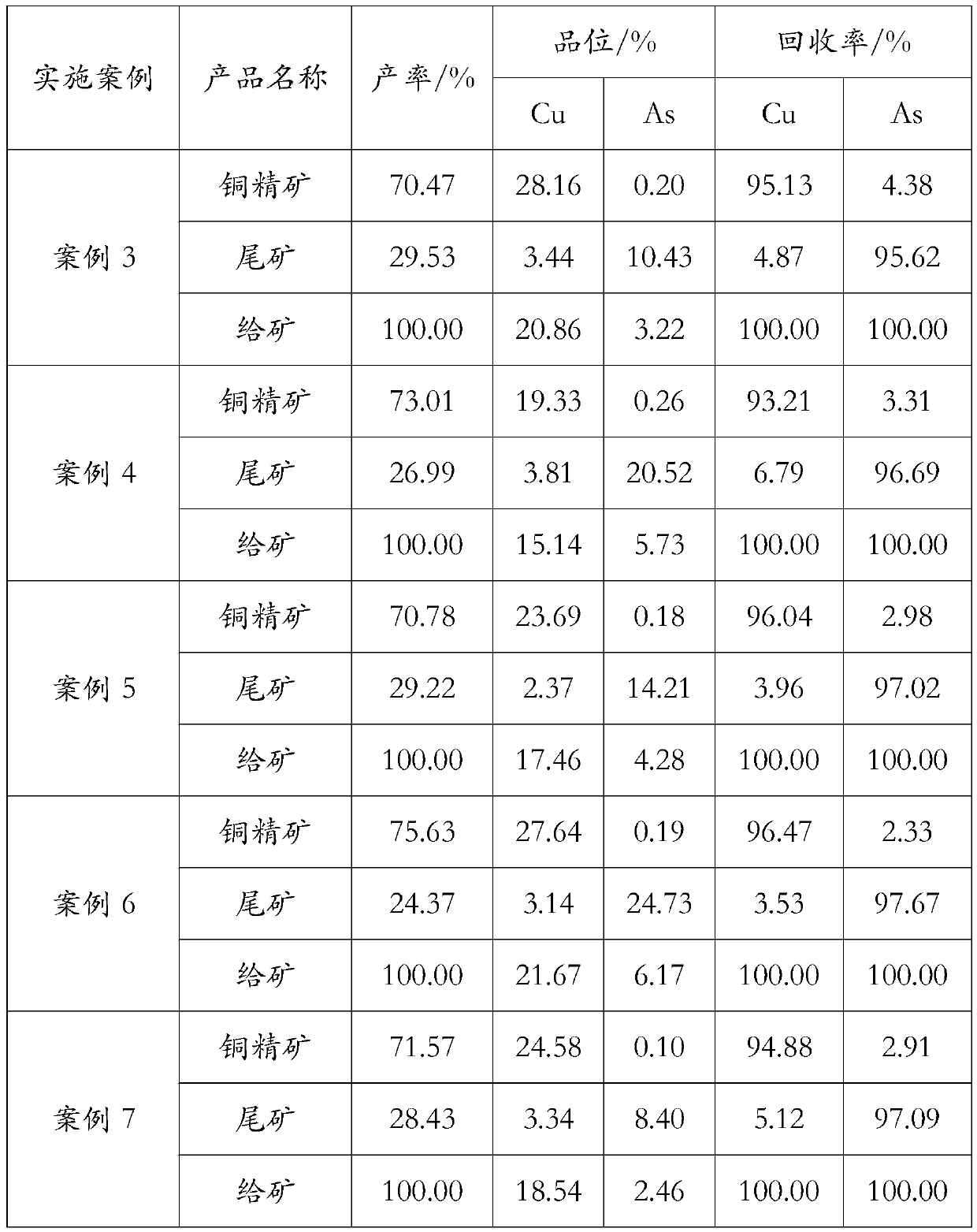

Arsenopyrite combined inhibitor and application thereof

The invention belongs to the technical field of flotation separation of arsenopyrite and copper sulfide ores, and particularly relates to an arsenopyrite combined inhibitor and an application thereof.The combined inhibitor comprises an organic inhibitor and an inorganic inhibitor. The organic inhibitor and Cu<2+> form a complex, and the complex is adsorbed on the surface of arsenopyrite, so the hydrophilicity of the surface of the arsenopyrite is enhanced, the floatability of the arsenopyrite is reduced, and the inhibition effect on the arsenopyrite is enhanced. Compared with single inhibitors, the combined inhibitor can greatly reduce the adsorbing capacity of a collecting agent on the surface of the arsenopyrite ore. The combined inhibitor has a high inhibition selectivity on arsenopyrite, and basically has no inhibition effect on the copper sulfide ore. The combined inhibitor has a high adaptability, and can effectively inhibit arsenopyrite in copper sulfide concentrate containingchalcopyrite and schreyerite. The combined inhibitor also has the advantages of small dosage, safety, non-toxicity, environmental friendliness, good stability, good water solubility, easiness in preparation and addition, convenience in use, effective achieving of flotation separation of the arsenopyrite and copper sulfide ores, and wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

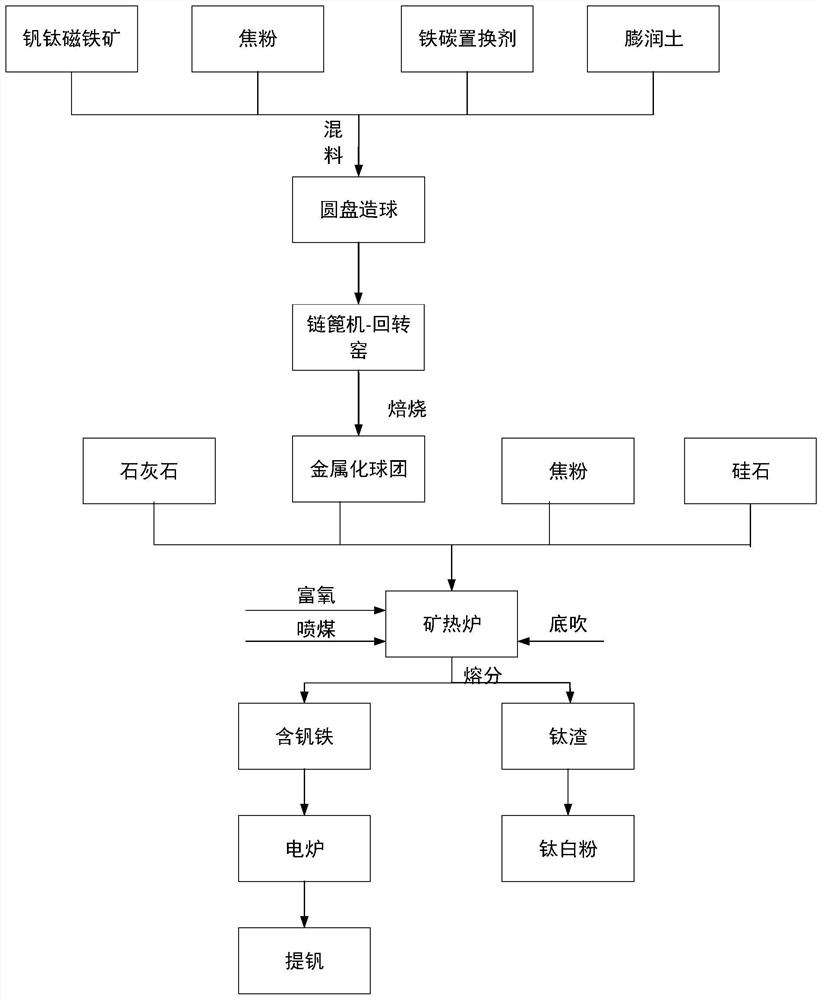

Smelting method for preparing pellet vanadium titano-magnetite by internally adding carbon

PendingCN113981214AReduced drop performanceReduced compressive strengthRotary drum furnacesProcess efficiency improvementMagnetiteCoke

The invention discloses a smelting method for preparing pellets from vanadium titano-magnetite by internally adding carbon, which is a method for comprehensively recovering vanadium, titanium and iron in the vanadium titano-magnetite, and comprises the following steps: firstly, adding coke powder, an iron-carbon displacer and bentonite into the vanadium titano-magnetite, making pellets of 8-12mm on a disc pelletizer, roasting the made pellets in a rotary kiln of a chain grate machine, producing metallized schreyerite, thermally charging the schreyerite in a submerged arc furnace or a high-temperature box-type furnace for reduction melting separation, realizing oxygen enrichment and pulverized coal injection in the submerged arc furnace, separating vanadium-containing molten iron and titanium slag, and preparing the titanium slag into titanium dioxide; and subjecting the separated vanadium-containing molten iron to oxygen blowing through an electric furnace to extract vanadium, separating vanadium slag and semi-steel molten iron out, and roasting and subjecting the vanadium slag to acid leaching to extract vanadium, so that recovery of vanadium, titanium and iron is achieved. The invention relates to a novel process for preparing pellet vanadium titano-magnetite by adding carbon and an iron-carbon displacer and realizing oxygen enrichment and pulverized coal injection smelting in a submerged arc furnace so as to overcome the technical problem of difficult schreyerite smelting in the prior art.

Owner:新疆葱岭钒钛有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com