Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "High impurity removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of preparing pectin from japanese premna leaf

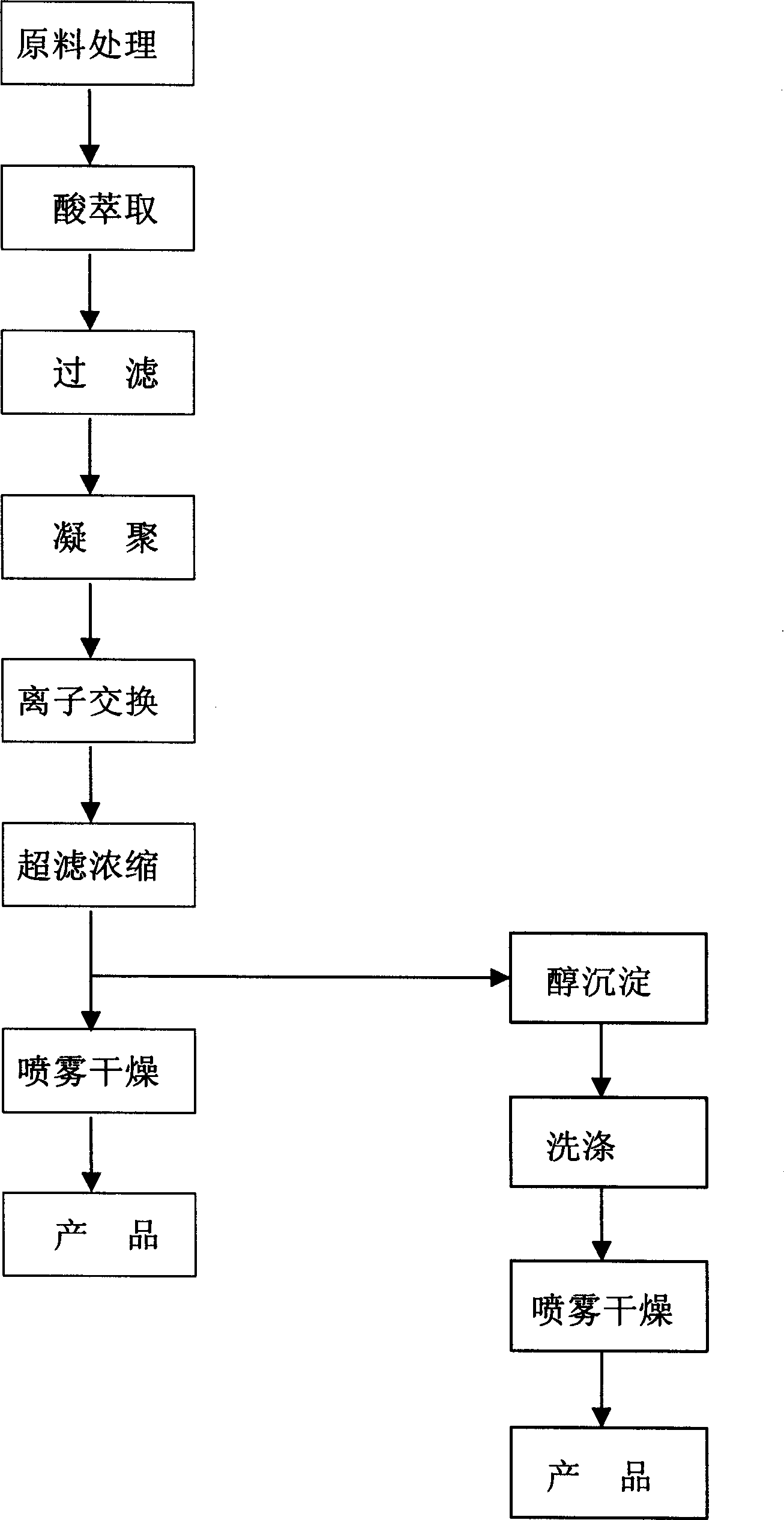

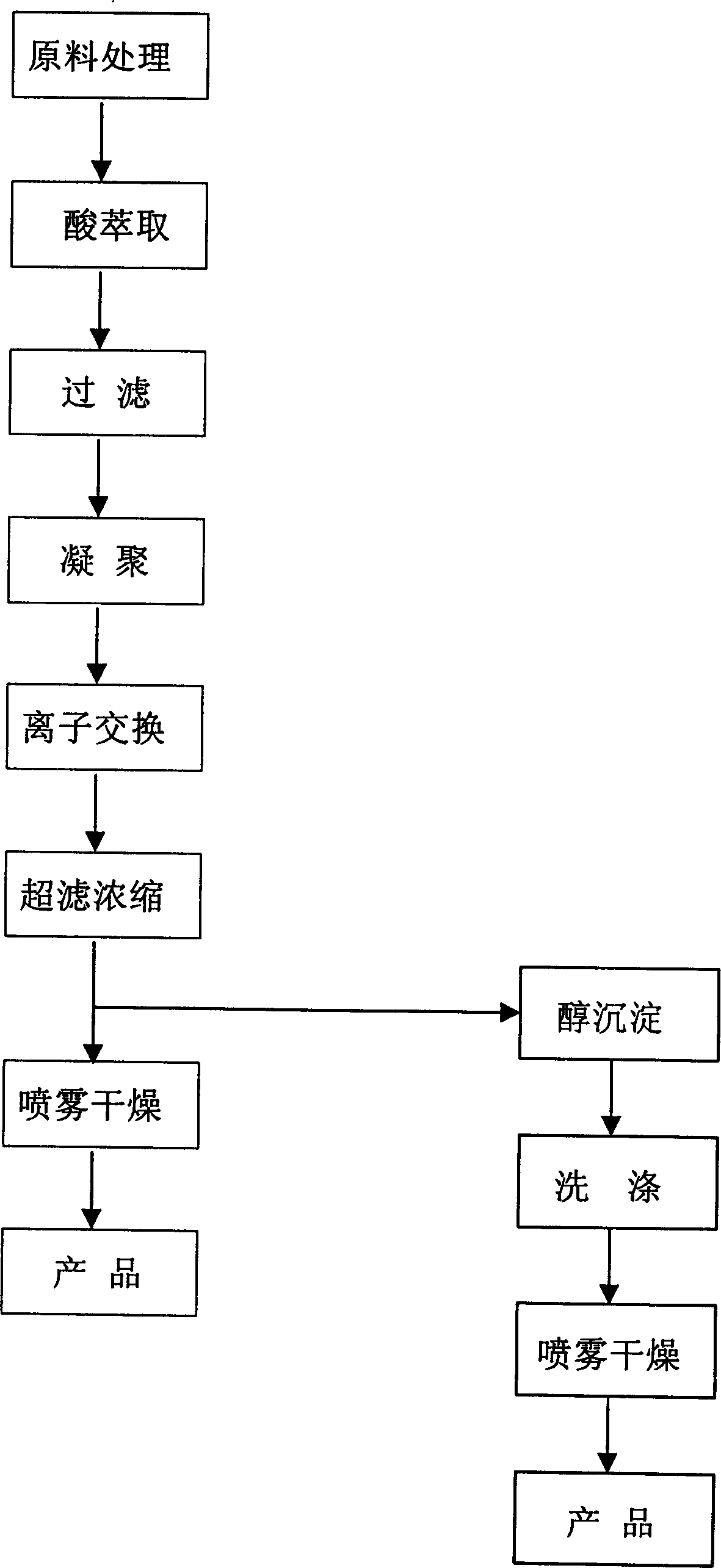

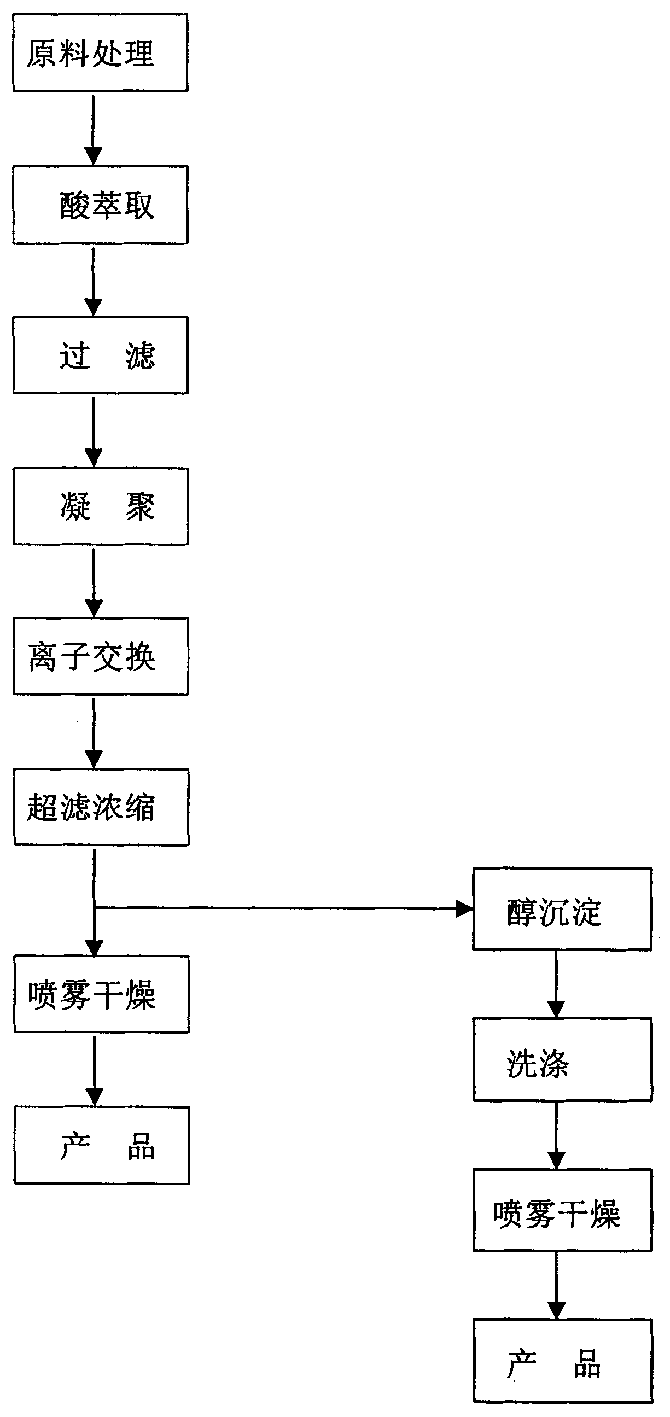

The preparation process of pectin by using premna microphylla leaf as raw material includes the following steps: treating raw material, acid extraction, filtration, decolouring and removing smell, spraying-drying to obtain pectin or after decolouring and removing smell, alcohol precipilation, washing and spraying-drying so as to obtain the pectin, in which the extract obtained after filtration is undergone the processes of coacervation, ion exchange and ultrafiltration and concentration to make decolorization, smell removed and desugarization, i.e. placing the polycoagulant whose concentration is 1% into the filtered extract, adding alkali to control pH value, precipitating to remove impurity and decolouring at twice, making the extract pass through the ion exchange resin column to make treatment.

Owner:WUHAN CHEM COLLEGE

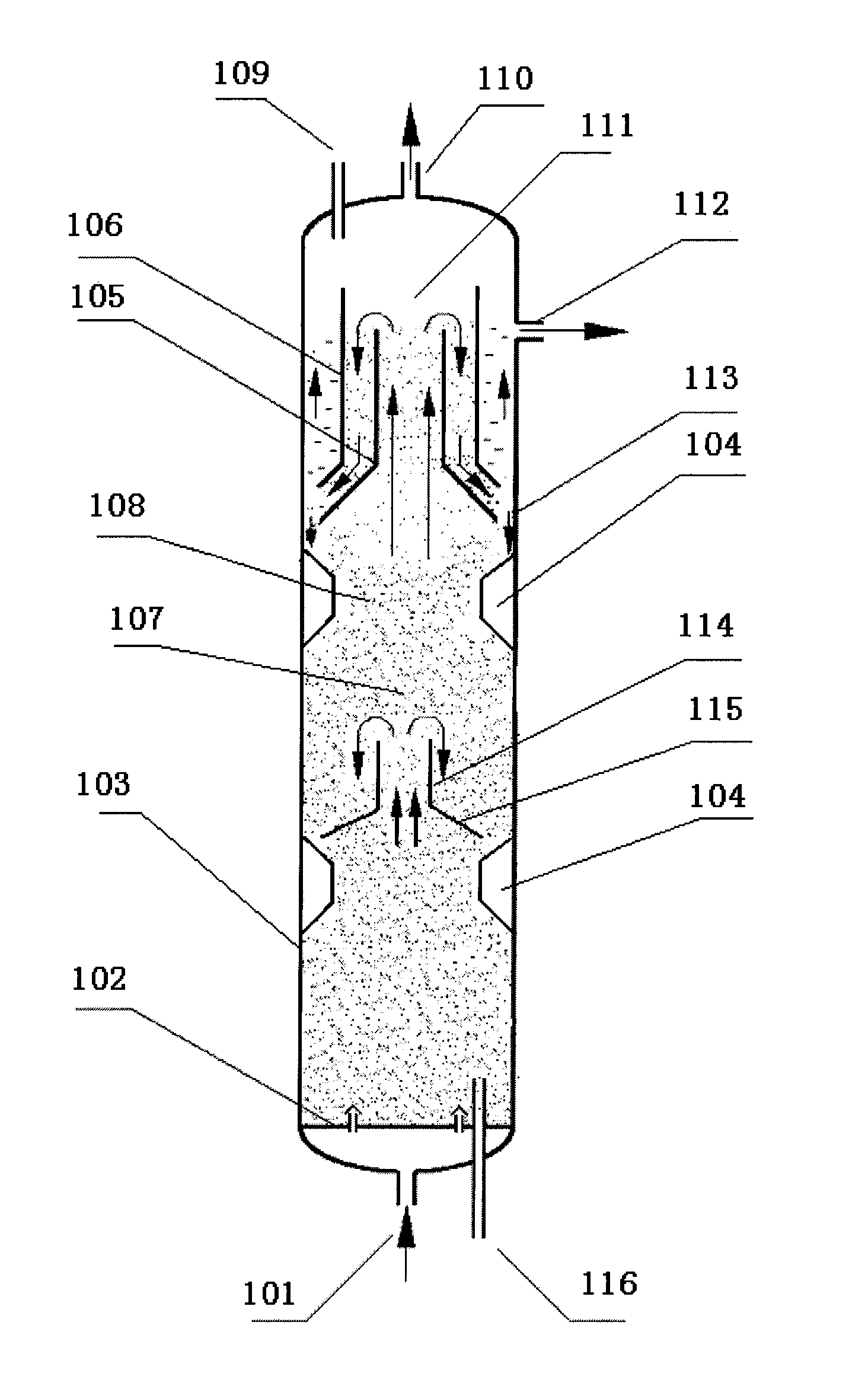

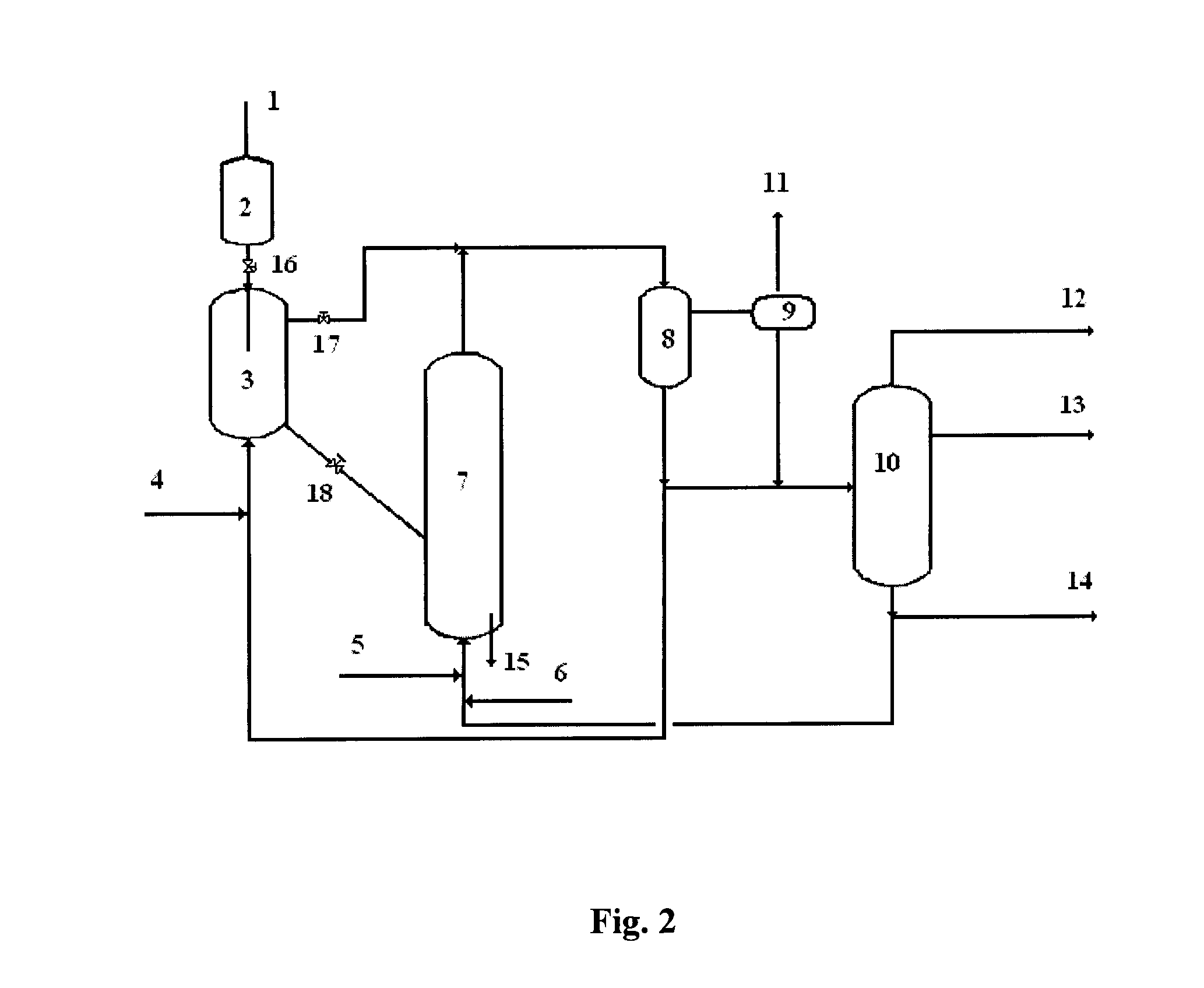

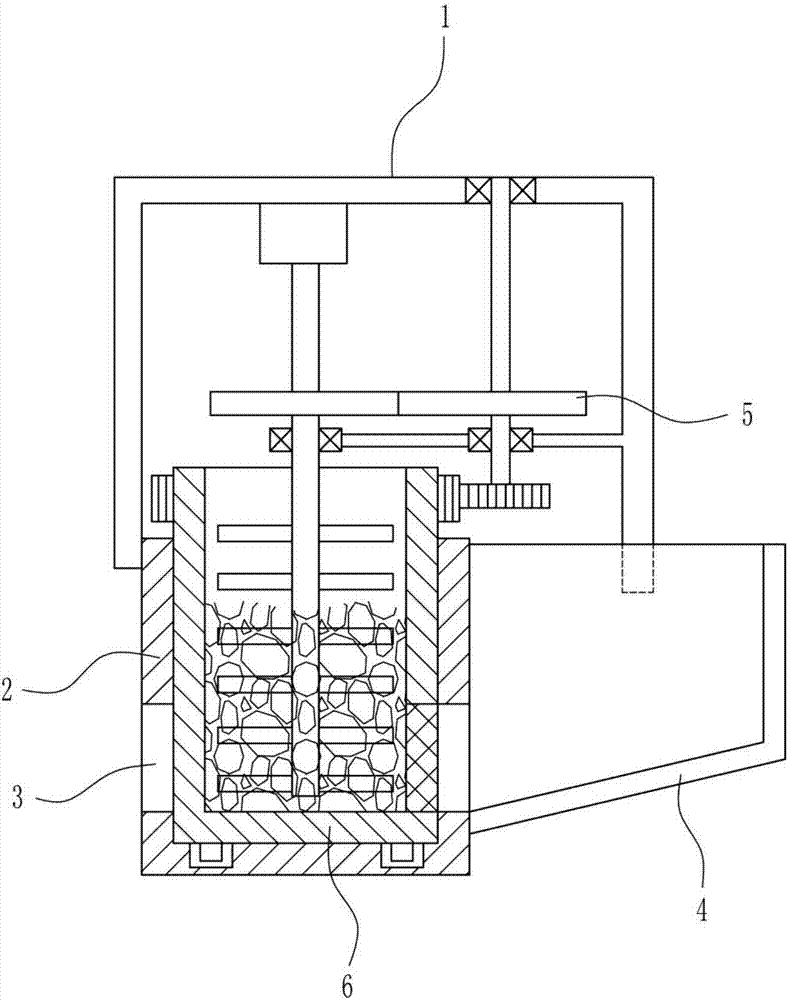

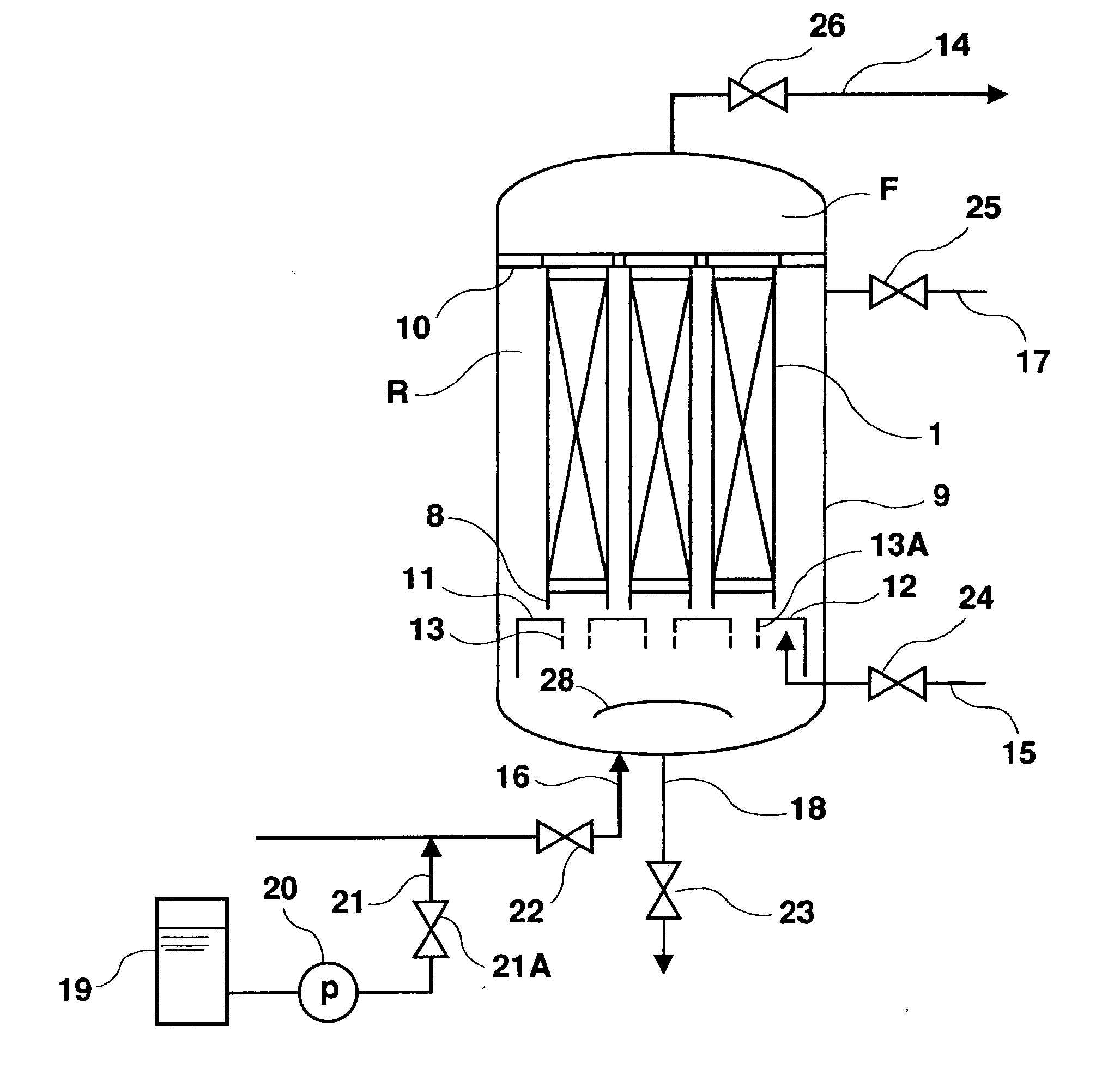

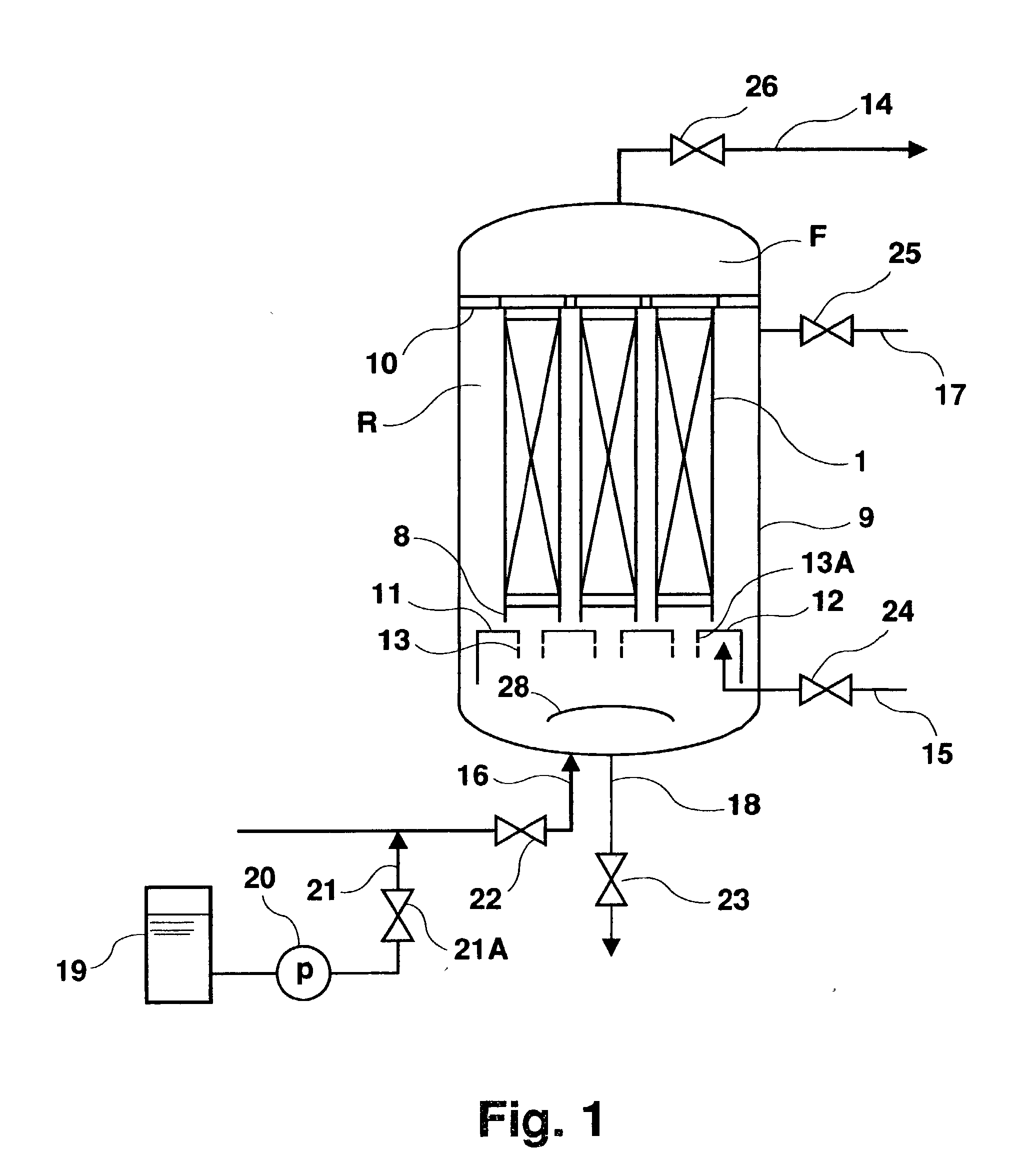

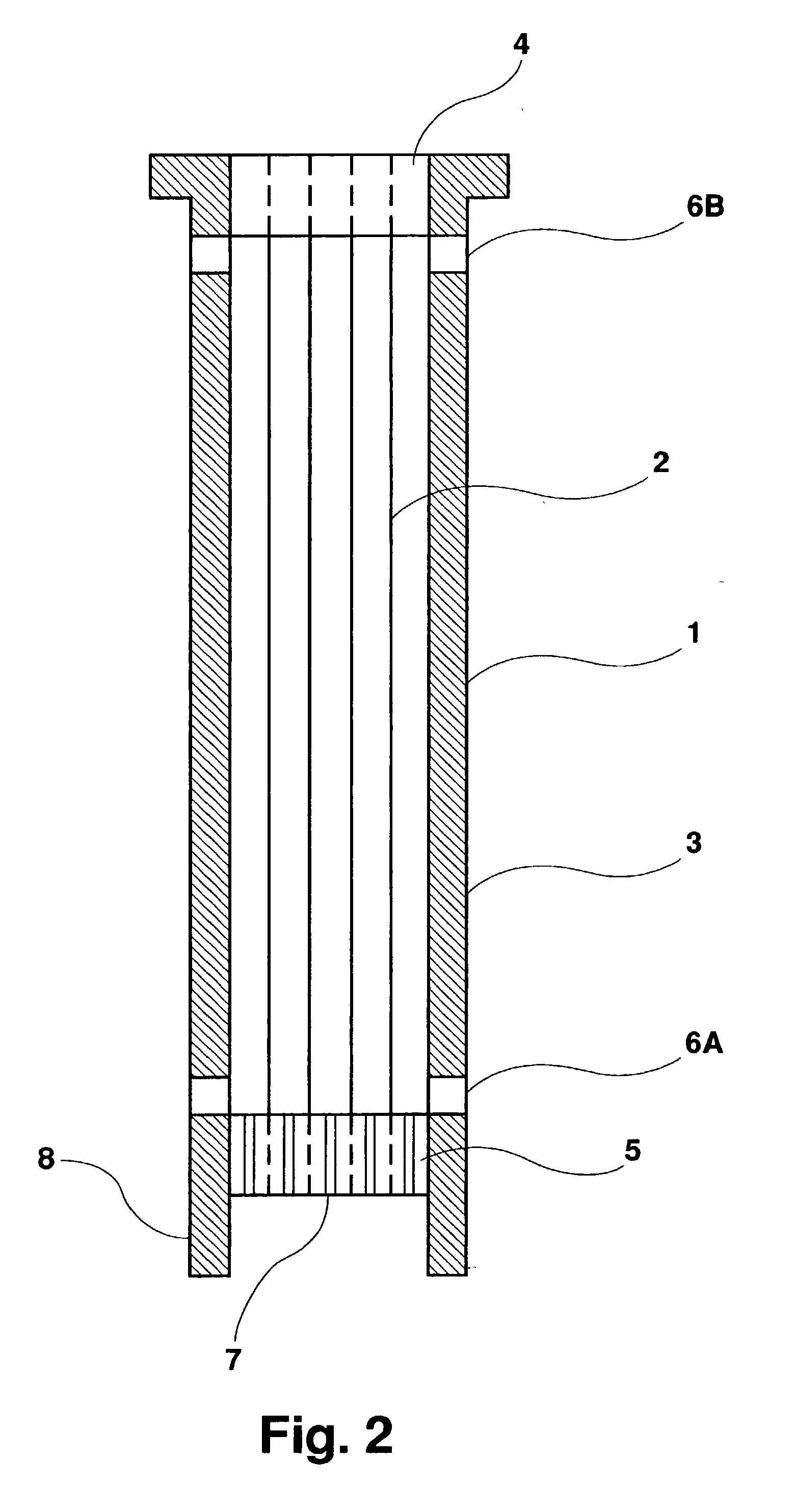

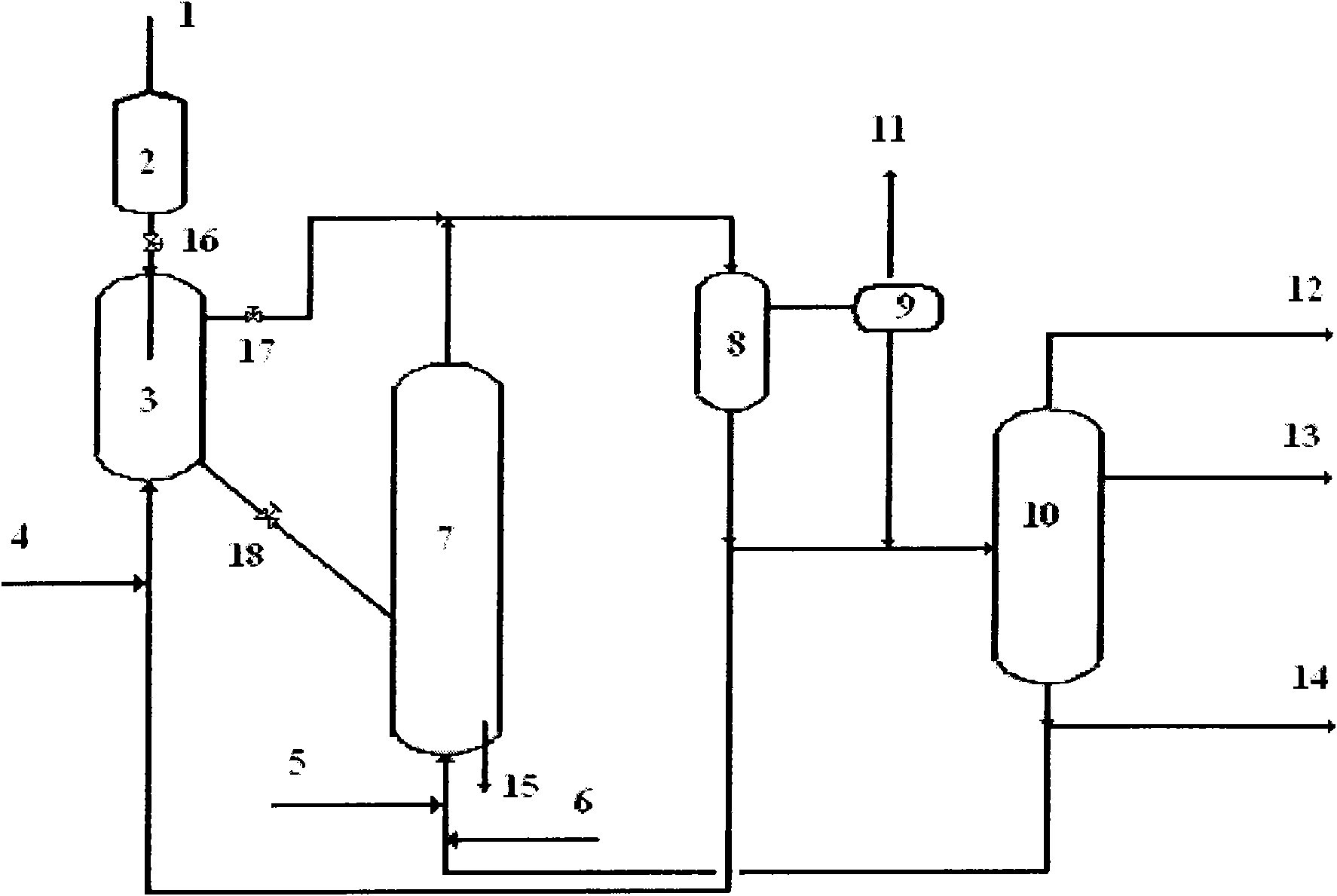

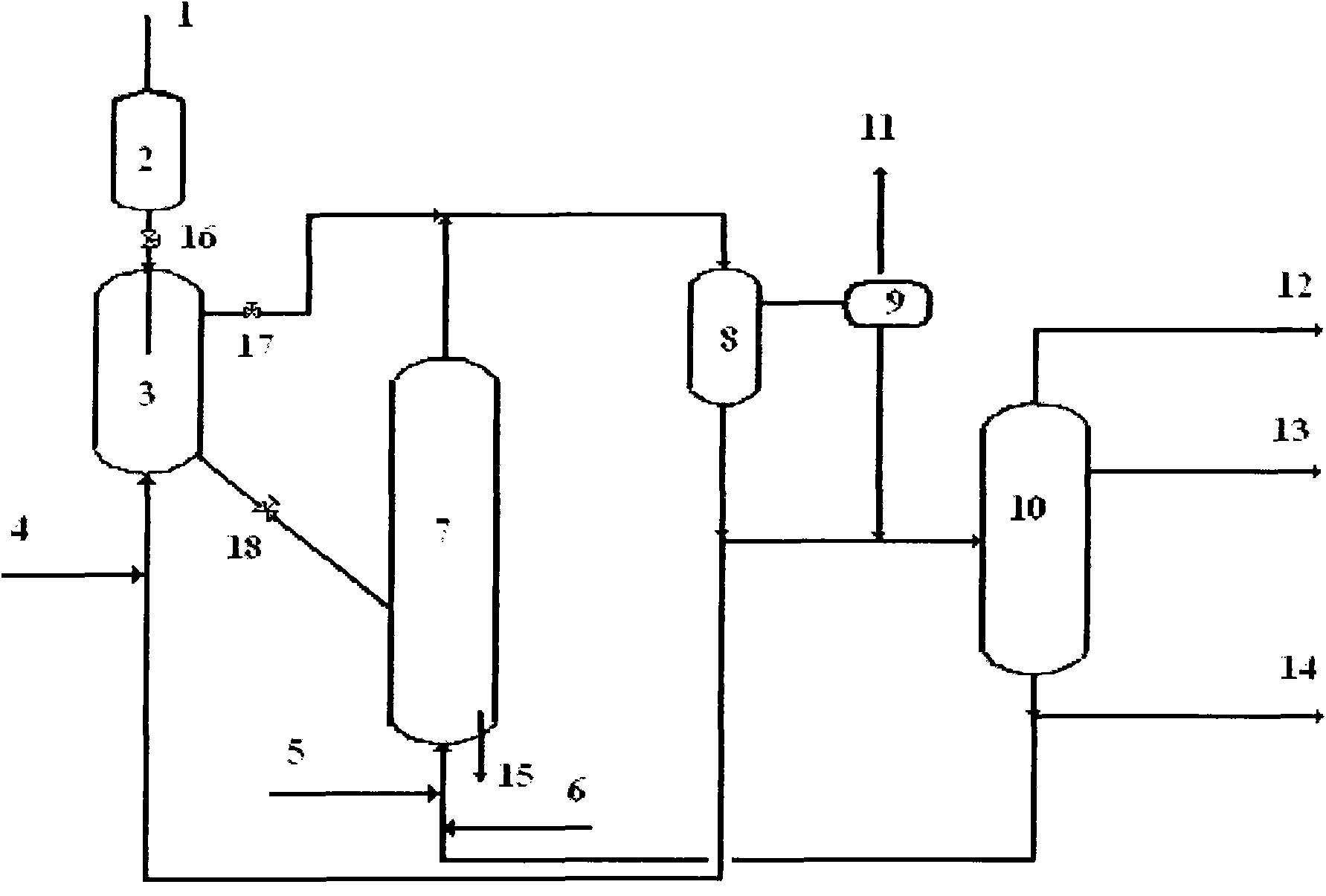

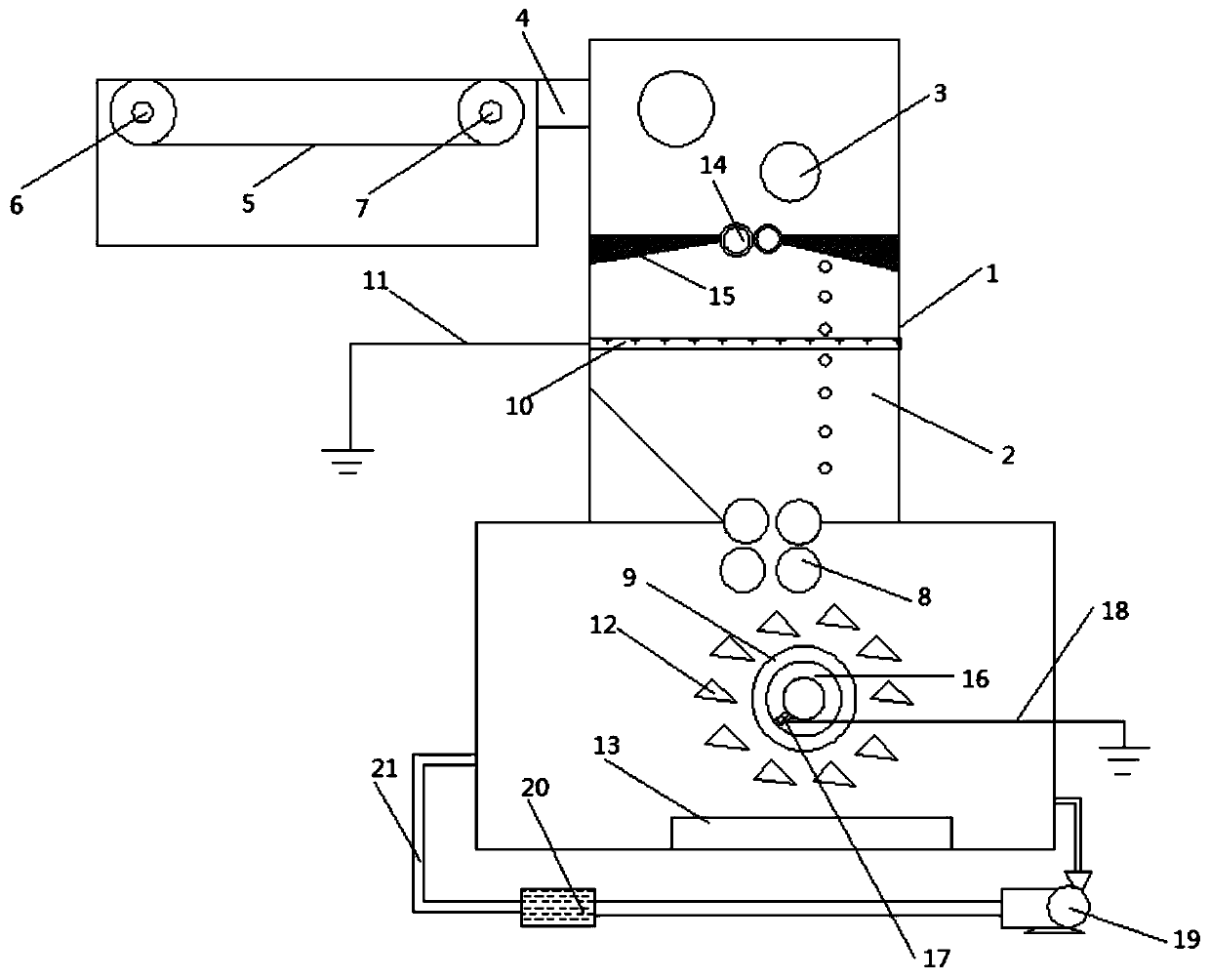

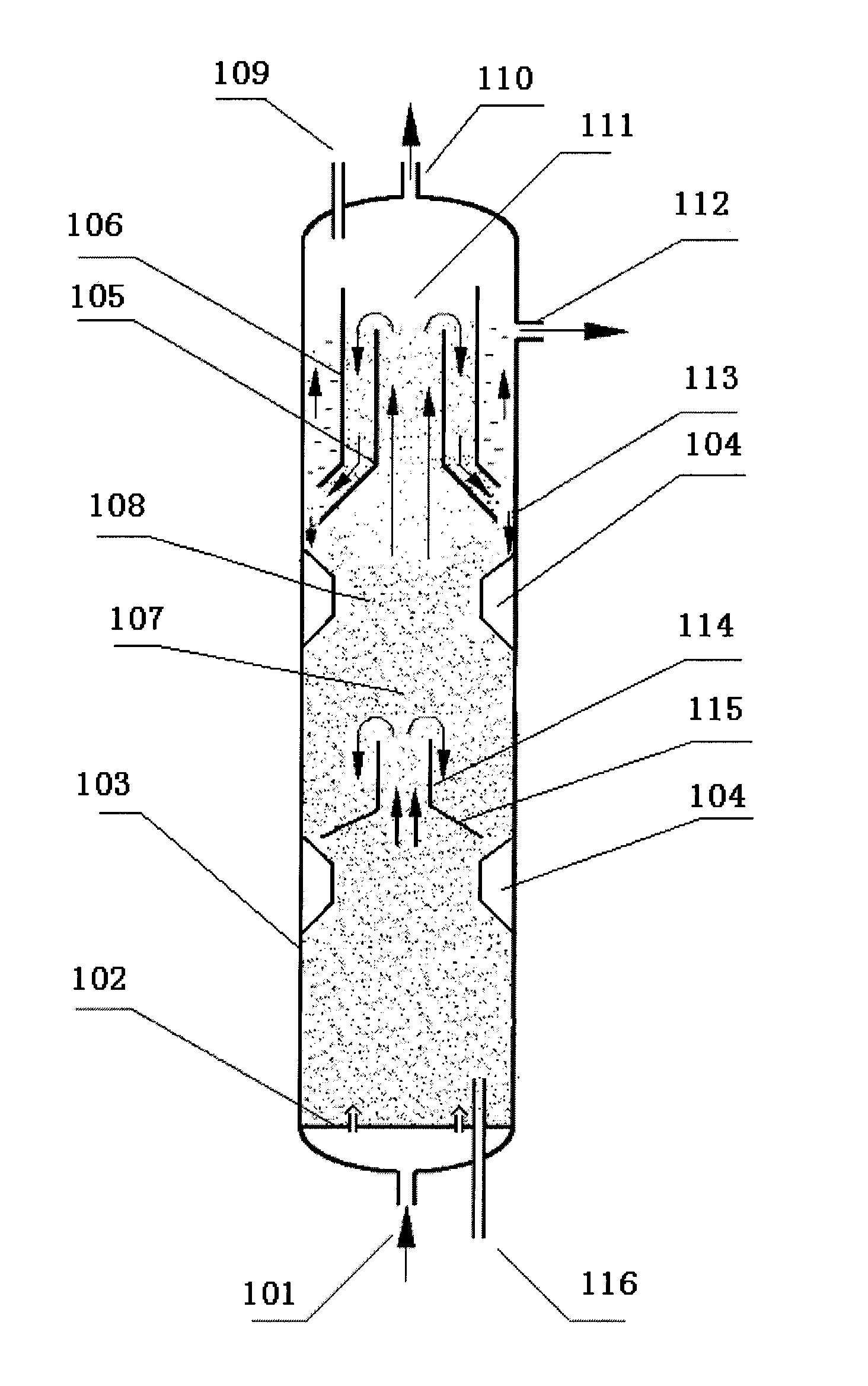

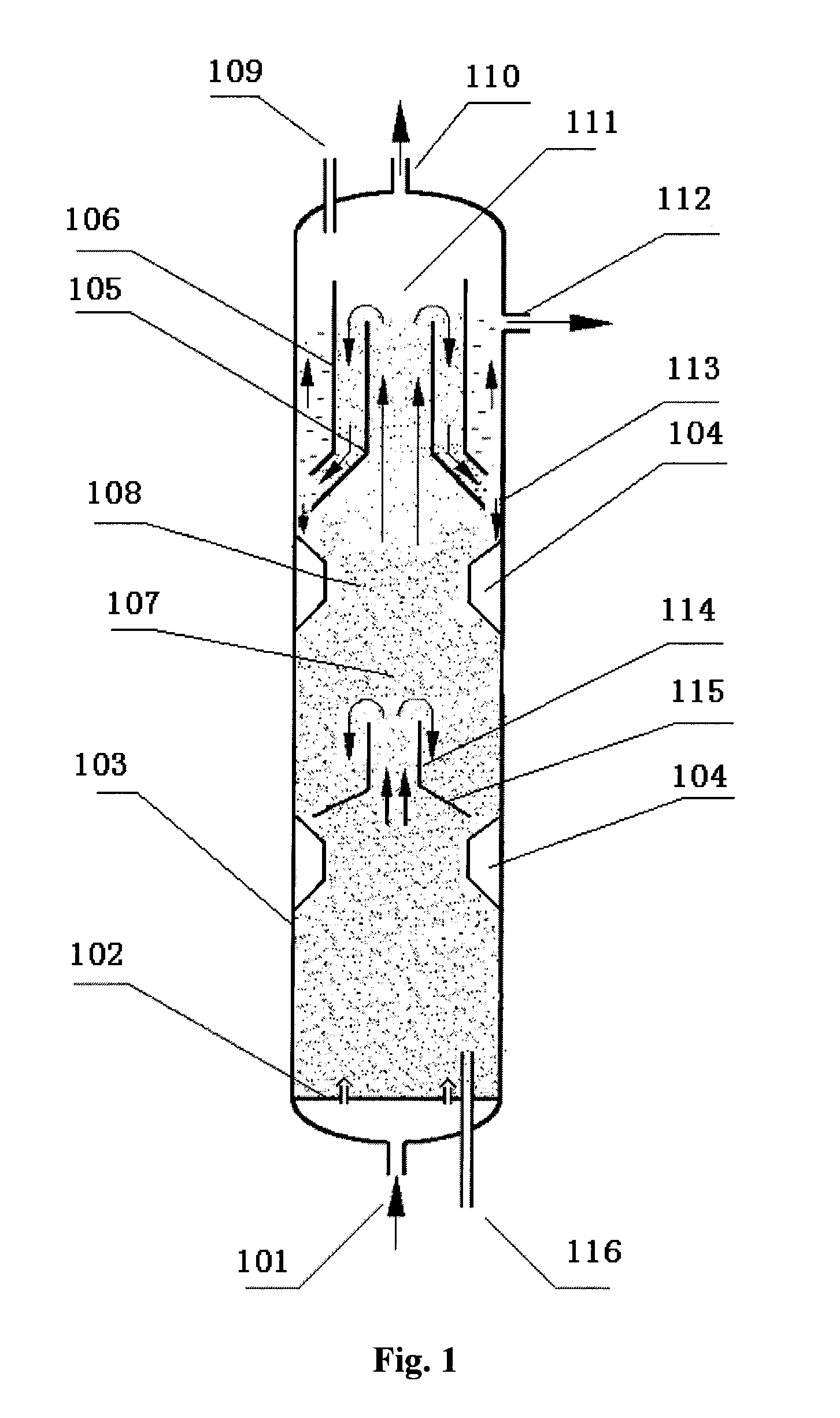

Fluidized-bed reactor and hydrotreating method thereof

ActiveUS20120205288A1Extended stayGood yieldLiquid hydrocarbon mixture productionHydrocarbon oil crackingFluidized bedProcess engineering

The invention relates to a fluidized bed reactor and a hydrogenation method thereof. The fluidized bed reactor (7) comprises a reactor shell (103) vertical to the ground and a phase separator (111) at the upper part of the shell (103). An inner circulation zone is provided under the phase separator (111), and comprises a cylinder (114), a tapered diffusion section (115) and a guiding structure (104). In the hydrogenation method using the fluidized bed reactor (7), an expanded bed reactor (3) is used to further hydrogenate part of the product from the fluidized bed reactor (7), and supply catalyst without influencing on the stable operation of the fluidized bed reactor (7).

Owner:CHINA PETROCHEMICAL CORP +1

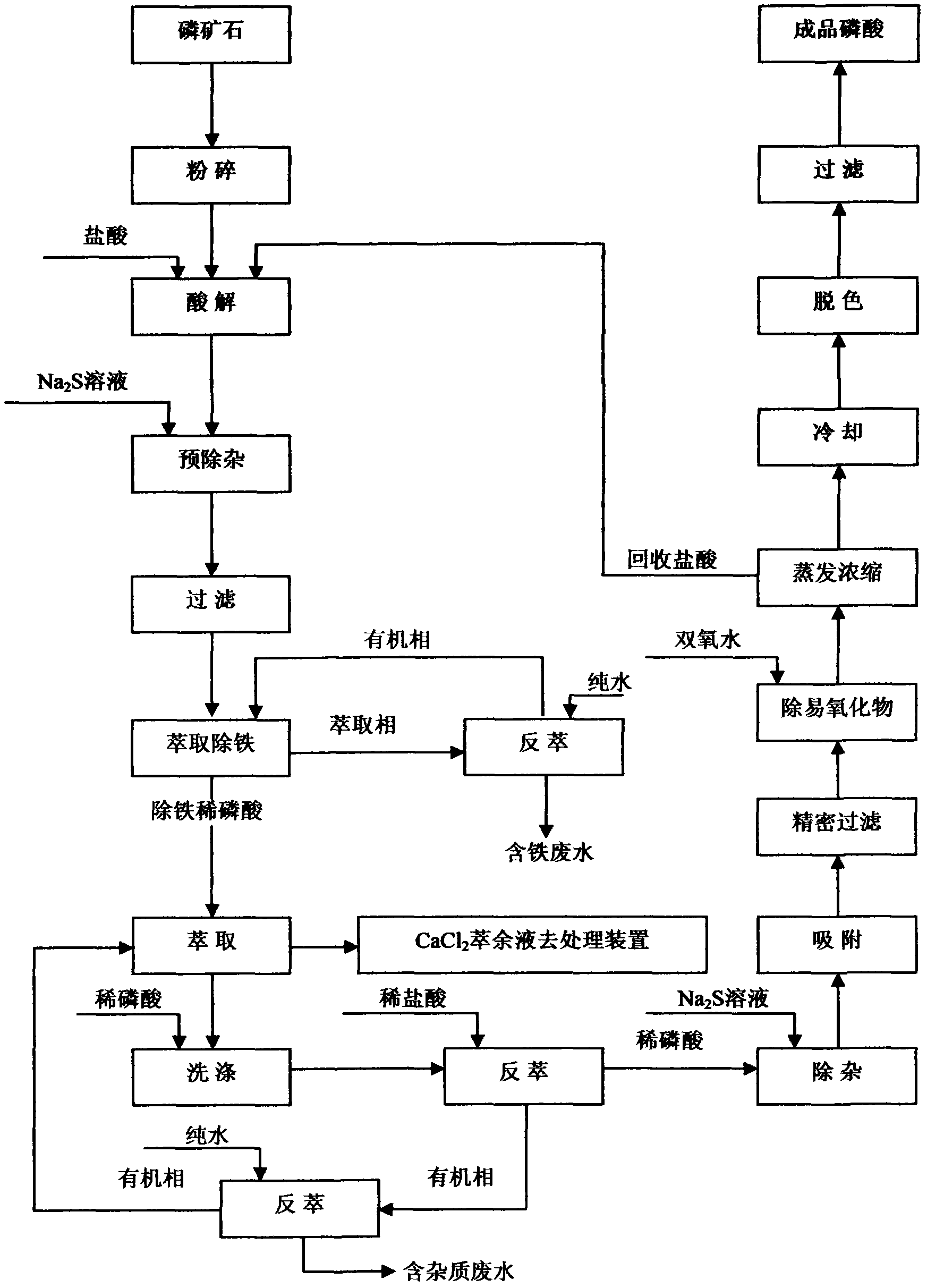

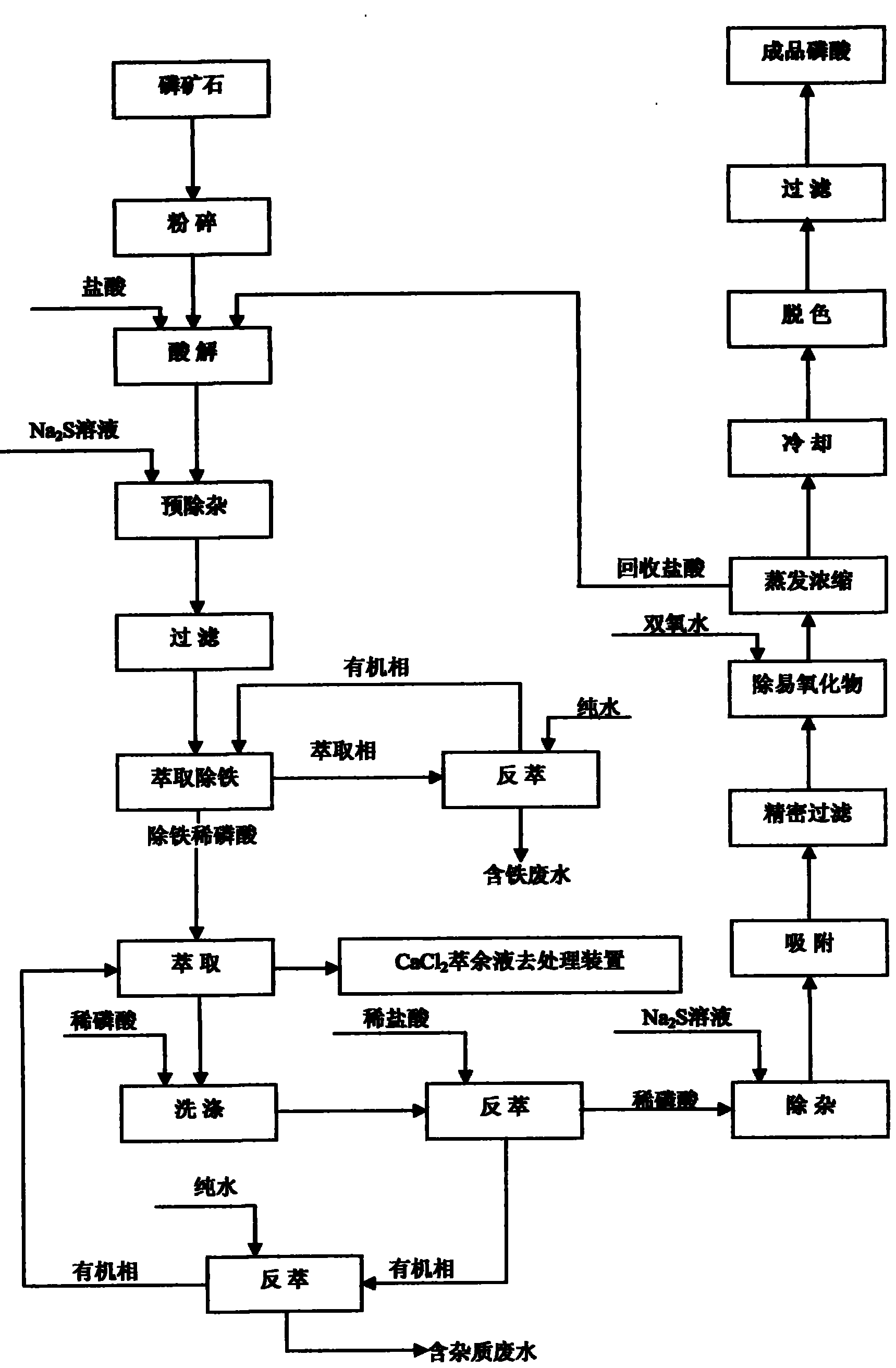

Production technology of food-grade phosphoric acid with hydrochloric acid method

ActiveCN102515134ASimple componentsControl impurity contentPhosphoric acidFood industrySimple component

The invention discloses a production technology of food-grade phosphoric acid with hydrochloric acid method. According to the invention, hydrochloric acid acidolysis process is used as a base, heavy metal impurities are removed by prepurification and subsequent purification, and simultaneously tributyl phosphate with simple components and stable property is used as an extractant to complete extraction, the extraction effect is good, and back extraction process of dilute hydrochloric acid is combined, the utilization rate of the extractant is high. The whole extraction and back extraction are completed at normal temperature, thus the technology is especially suitable for preparing food-grade phosphoric acid in industrial production. The liquid-liquid extraction technology has strong controllability, and high extraction rate and high impurity removal rate. The content of H3PO4 in a finished product of phosphoric acid reaches more than 75 wt%. The finished product of phosphoric acid has good quality and can be used in food industry without purification, and is suitable for lean phosphate rocks or rich phosphate rocks.

Owner:西安君正工程科技有限公司

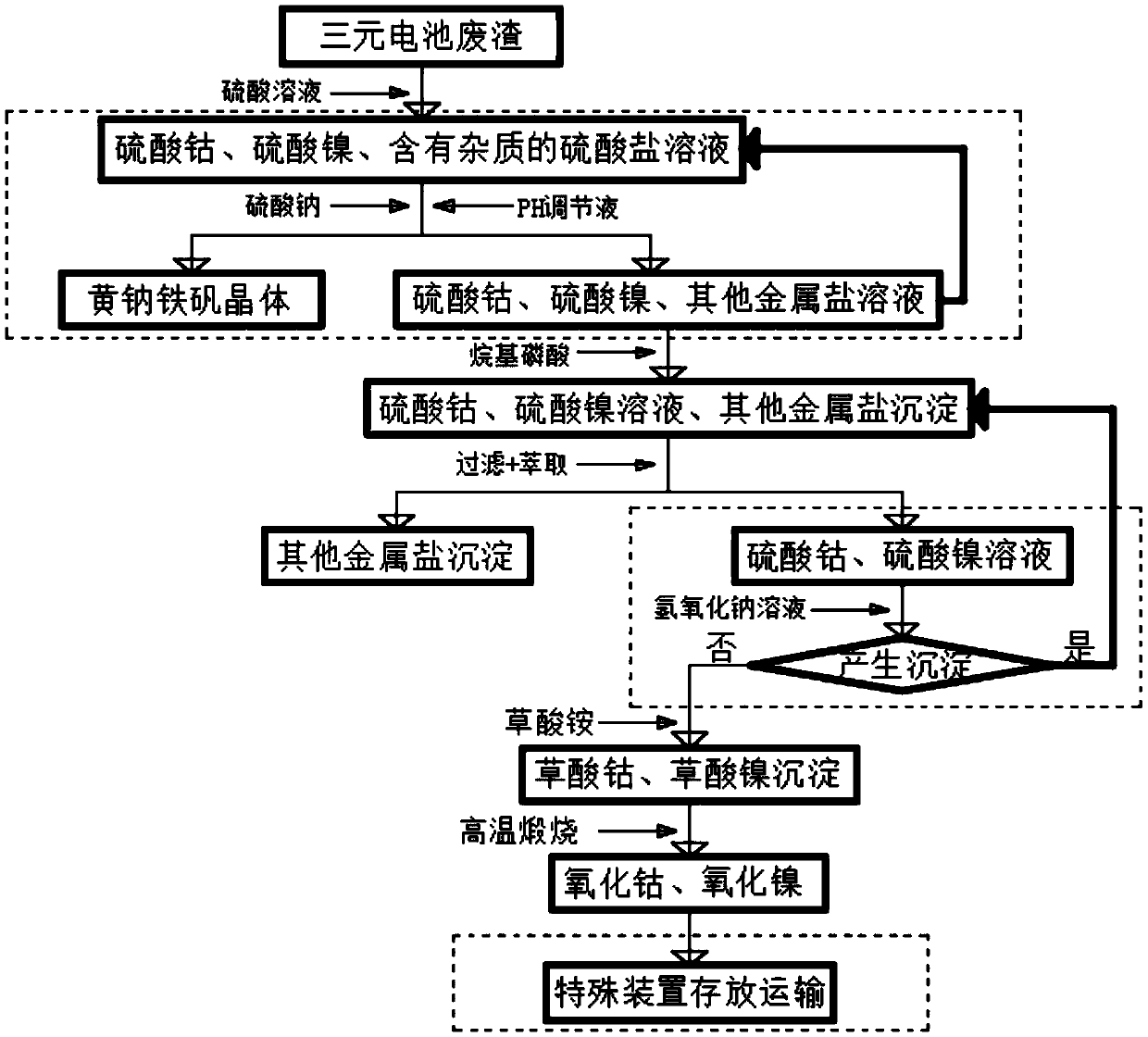

Cobalt and nickel purifying method based on waste battery metal recovery technology

InactiveCN109536724AHigh impurity removal rateImprove the efficiency of impurity removalProcess control/regulationChemical/physical/physico-chemical stationary reactorsFeedback effectMetal impurities

The invention discloses a cobalt and nickel purifying method based on a waste battery metal recovery technology, and belongs to the field of waste battery recovery. The cobalt and nickel purifying method based on the waste battery metal recovery technology comprises the step of recovery of ternary battery waste residues, the original waste battery metal recovery technology is improved, on the onehand, the impurity removal rate for iron ions can be higher than an impurity removal technology for the iron ions in the prior art, meanwhile, the impurity removal efficiency for the iron ions can beimproved, the recovery purity of cobalt and nickel is increased, the progress of the whole technology is accelerated, and the recovery efficiency is improved; on the other hand, compared with the prior art, the method has the advantages that detection of metal impurities in a solution after impurity removal operation is increased, the reaction phenomenon produced in the solution has the feedback effect, impurities can be removed more thoroughly, and the recovery purity of the metal cobalt and the metal nickel is further improved.

Owner:南通北新新能科技股份有限公司

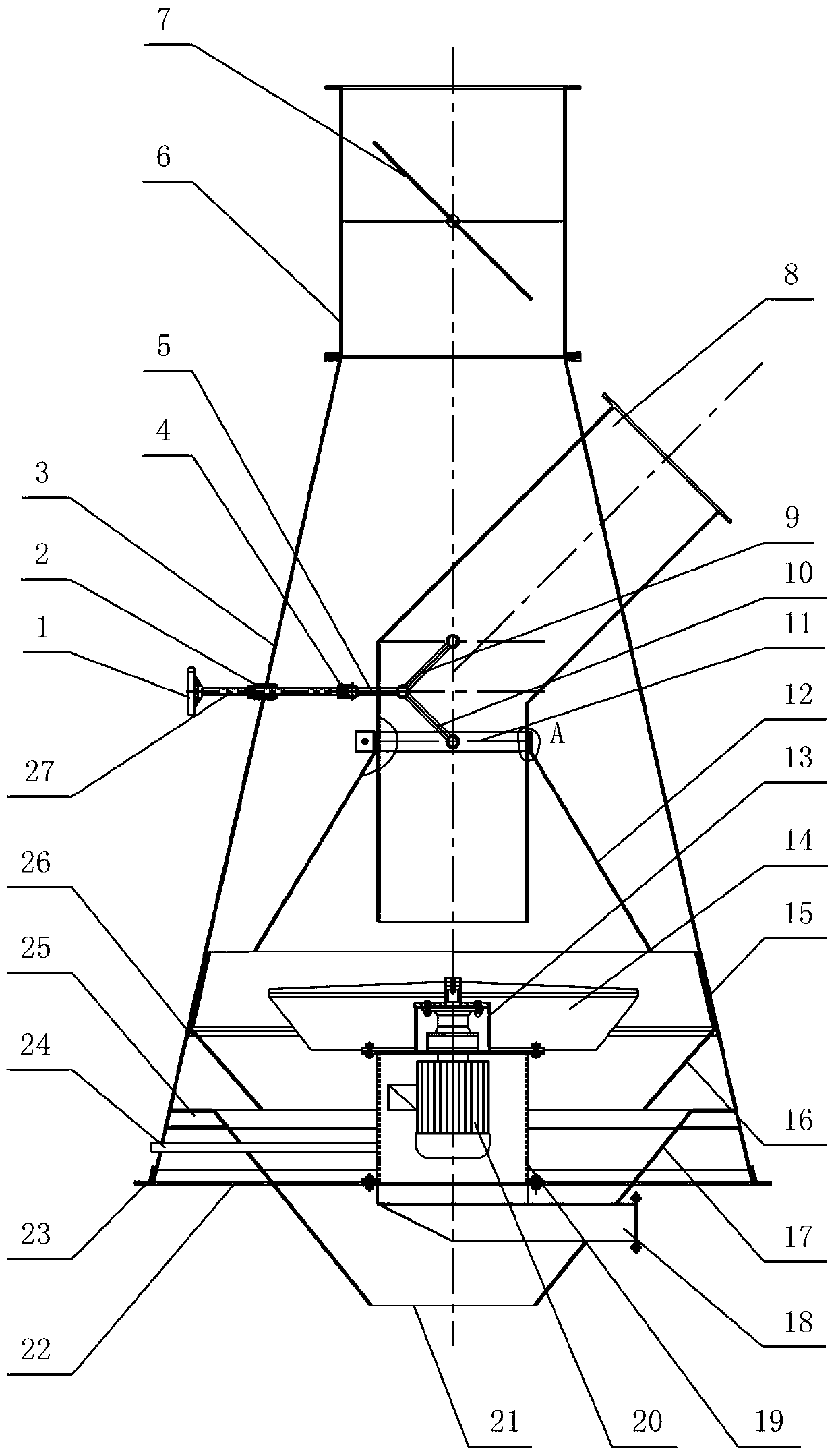

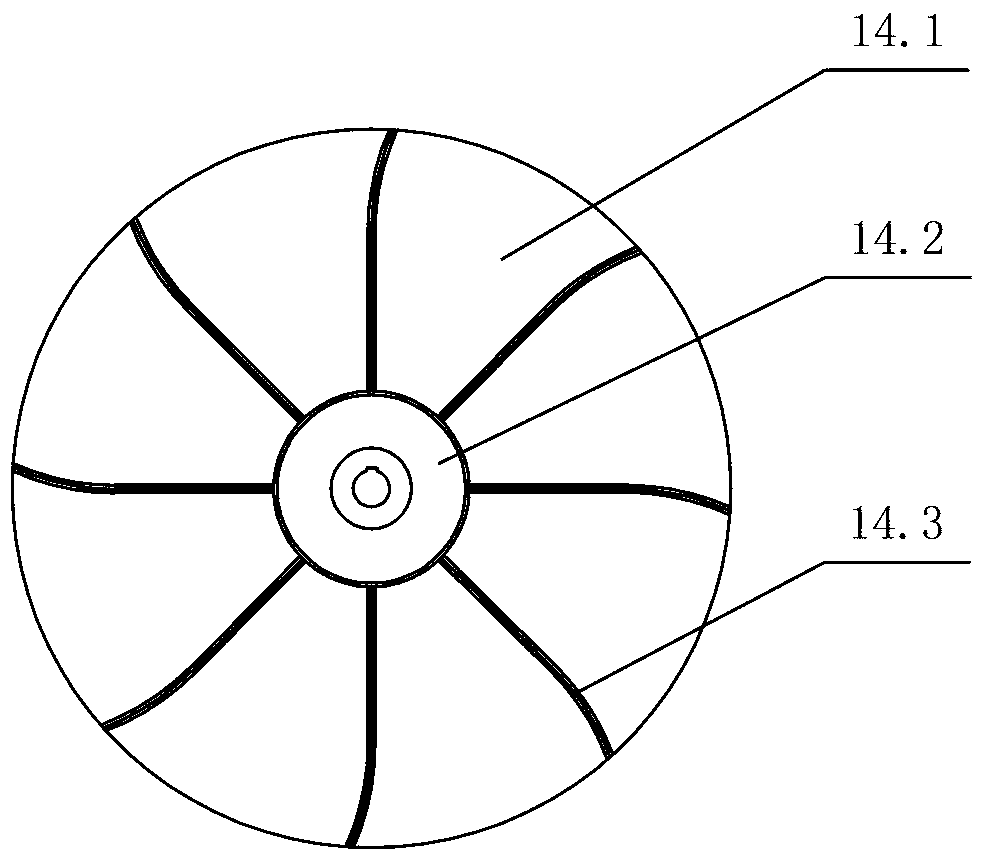

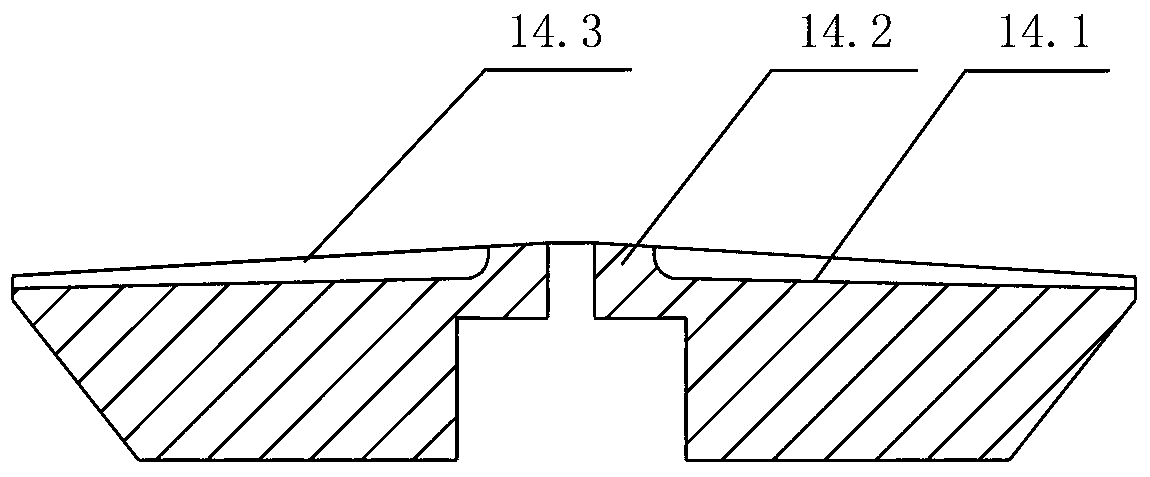

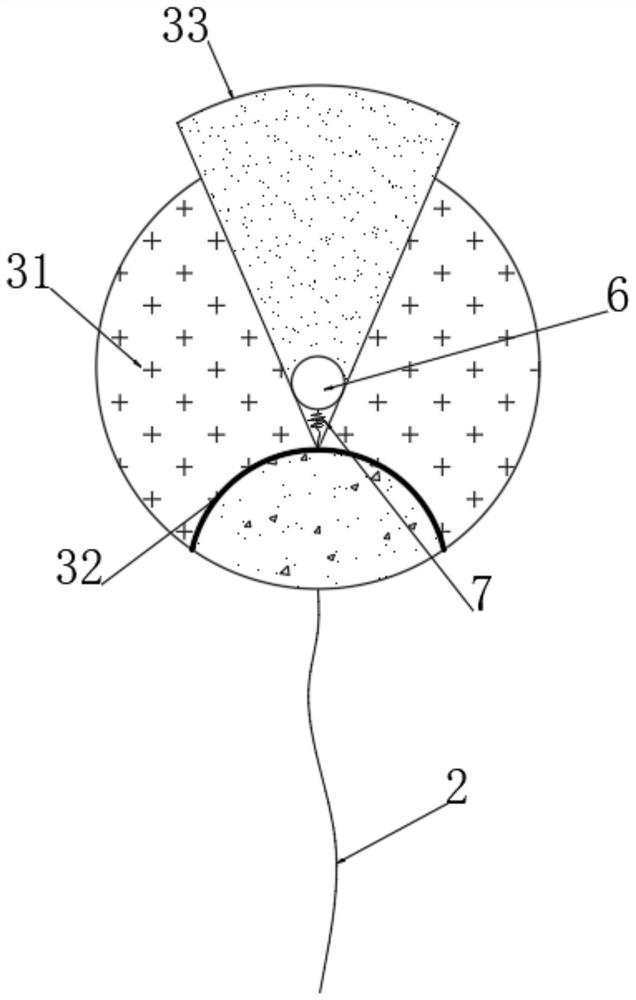

Rotary type grain separating device

ActiveCN103341445AConvenient and smooth flowReduce falling speedGas current separationEngineeringResidence time

The invention relates to a grain separating device, in particular to a grain winnowing separating device and belongs to the field of grain machinery. The rotary type grain separating device comprises a shell body, a rotary disc and a discharging tube. The rotary disc is arranged in the shell body; the discharging tube is arranged above the rotary disc; a motor is connected with the axial position of the rotary disc; a material collecting structure is arranged above the rotary disc; a winnowing region is formed among the rotary disc, the shell body and the material collecting structure; the opening portion of the shell body is connected with a wind power device. The rotary type grain separating device is reasonable in structure, small in size and occupied space, convenient to transport and suitable for application of a peasant household and small-sized operation. Grain is evenly distributed in the winnowing region, the residence time of the grain in the winnowing region is improved, the impurity removing efficiency is greatly improved, and the impurity removing efficiency is improved to 85% from 70%.

Owner:山东聚阳智能装备有限公司

Waste water aeration device used for water supply and drainage

ActiveCN107399866ASpeed up wastewater treatmentImprove work efficiencyWater treatment parameter controlSpecific water treatment objectivesPistonActivated carbon

The invention relates to an aeration device, and especially relates to a waste water aeration device used for water supply and drainage. The waste water aeration device is capable of realizing intermittent waste water injection, and realizing complete combination of active carbon in waste water with oxygen in the air. The waste water aeration device comprises a support; the left side of the bottom of the support is connected with a treatment pool; the right side of the bottom of the support is connected with a water storage pond; the lower part of the left wall and the lower part of the right wall of the treatment pool are provided with through holes; the water storage pond is communicated with the through hole on the left side of the treatment pool; the middle part of the lower part of the support is connected with a driving mechanism; the treatment pool is connected with an aeration mechanism; and the aeration mechanism is arranged on the lower part of the driving mechanism. The waste water aeration device used for water supply and drainage is capable of realizing intermittent discharging and collecting of waste water, increasing the quality of processed waste water, reducing waste water impurity, and increasing impurity removing efficiency via arrangement of a cylinder body and a piston.

Owner:亚太泵阀有限公司

Method for treating power plant heater drain water

InactiveUS20030128797A1High impurity removal rateGood removal effectMembranesWater contaminantsFiberPower station

Oxygen is mixed with heater drain water of power plant which contains fine particles of iron oxides such that the concentration of the dissolved oxygen in the heater drain water after the mixing of oxygen is in a range from 1 mug / liter to 20 mug / liter. The obtained heater drain water after oxygen mixing is filtered through a filter such as a hollow fiber filter to remove fine particles of iron oxides.

Owner:ORGANO CORP

Processes for the removal and recovery of minor elements in wet-process phosphoric acid

ActiveUS20150166343A1Minimal phosphate lossSuitable for productionCation exchanger materialsIon-exchanger regenerationMinor elementPhosphoric acid

In alternative embodiments, the invention provides processes and methods for the recovery or the removal of the so-called “Minor Elements” consisting of iron, aluminum and magnesium (expressed as oxides), from wet-process phosphoric acid using a continuous ion exchange approach. In alternative embodiments, use of processes and methods of the invention allows for the reduction of these Minor Elements with minimal phosphate losses and dilution in order to produce a phosphoric acid that is suitable for the production of fertilizer products such as world-class diammonium phosphate (DAP), merchant-grade phosphoric acid, superphosphoric acid, and other phosphoric acid products. Further, use of the invention would allow the use of lower grade phosphate rock or ore, which would greatly expand the potential phosphate rock reserve base for phosphate mining activities, and allow for better overall utilization of resources from a given developed mine site.

Owner:OCP

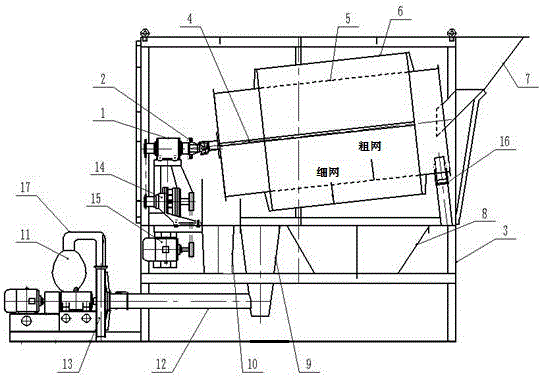

Compound impurity removing and sorting machine for crop seeds

PendingCN107520128AHigh impurity removal rateReduce energy consumptionSievingGas current separationAgricultural engineeringRockdust

The invention provides a compound impurity removing and sorting machine for crop seeds. Impurities such as leaves, bran hulls, dust and stones in the crop seeds can be removed. The compound impurity removing and sorting machine comprises a rack, a feeding hopper, discharging outlets, a filtering device and a dust removing device; the filtering device comprises a motor, a rotation shaft and drum screens, the motor is installed on the rack, the drum screens comprise a thick-net drum screen installed on the rack and a thin-net drum screen installed on the thick-net drum screen in a sleeving manner, the output end of the motor is connected with one end of the rotation shaft through a speed reducer, a pillow block bearing and a universal coupler, and one end of the rotation shaft is connected to the thick-net drum screen; and the discharging outlets comprise a coarse impurity discharging outlet, a clean grain discharging outlet and a fine impurity discharging outlet, wherein the coarse impurity discharging outlet is located at the end, far away from the feeding hopper, of the lower portion of the thick-net drum screen, the fine impurity discharging outlet is located under the thin-net drum screen, and the clean grain discharging outlet is located at the end, far away from the feeding hopper, of the lower portion of the thin-net drum screen and connected with the dust removing device.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Micro-pore filtration and purification stone and preparation method thereof

InactiveCN106747558AExpand the scope of filtration and purificationOvercome the defect of narrow filtering rangeDispersed particle filtrationTreatment involving filtrationFiltrationWater soluble

The invention relates to a micro-pore filtration and purification stone and a preparation method thereof. The micro-pore filtration and purification stone is prepared from the following raw materials in parts by weight: 70-85 parts of sand, 14-20 parts of mineral powder, 1-2 parts of binder powder and 1.656-1.84 parts of water, wherein the melting point of sand is greater than that of mineral powder, and binder powder is a water-soluble binder. The preparation method comprises the following steps: (1) uniformly stirring the sand, the mineral powder and the binder powder, adding water and mixing and stirring the mixture, so as to obtain mixed slurry; (2) placing the mixed slurry into a mould for molding, so as to obtain a stone blank; and (3) firing the stone blank to enable the stone blank to be molded and generate structure holes through which liquid or gas can pass, so as to obtain the micro-pore filtration and purification stone. According to the micro-pore filtration and purification stone, both a liquid working medium and a gas working medium can be filtered; the micro-pore filtration and purification stone is high in strength, corrosion-resistant and high-temperature-resistant; the stone can be prepared into various applicable shapes according to filtration requirements and is high in universality, strong in adsorbability and high in impurity removing efficiency; and the pore size can be adjusted.

Owner:FENGXIAN LYVKANG WATER PURIFICATION TECH CO LTD

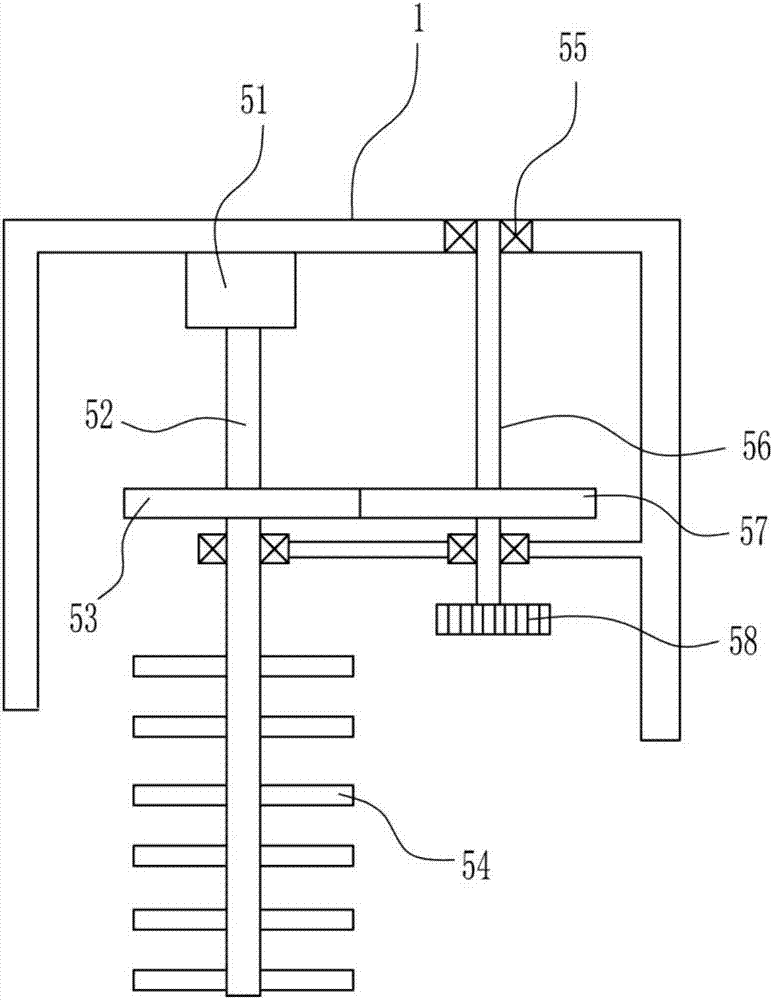

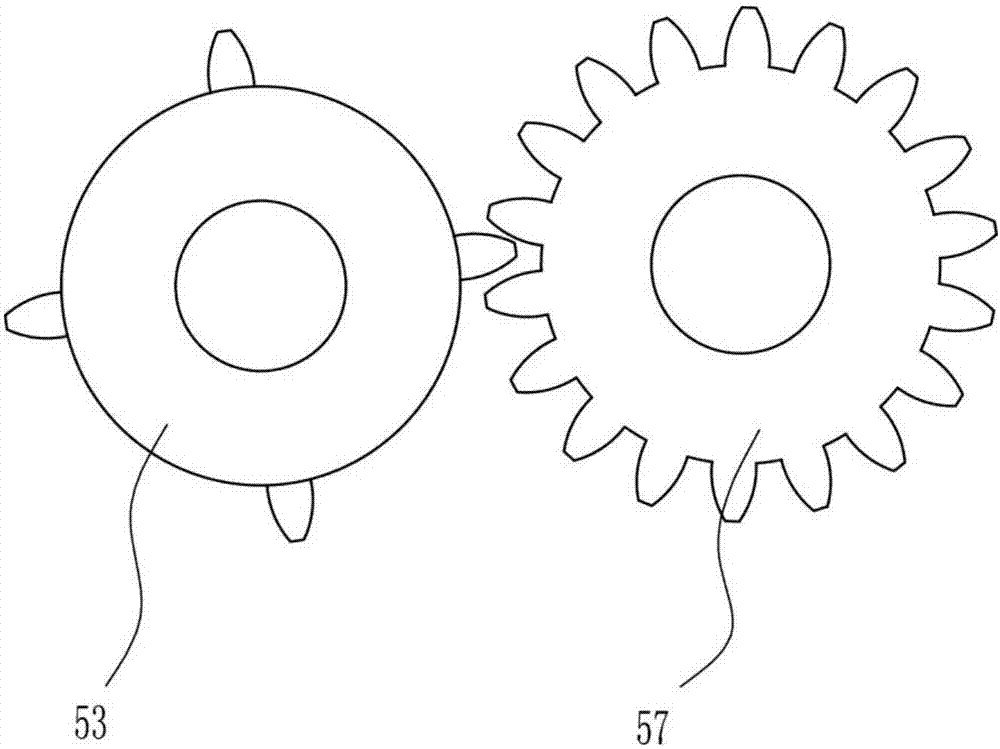

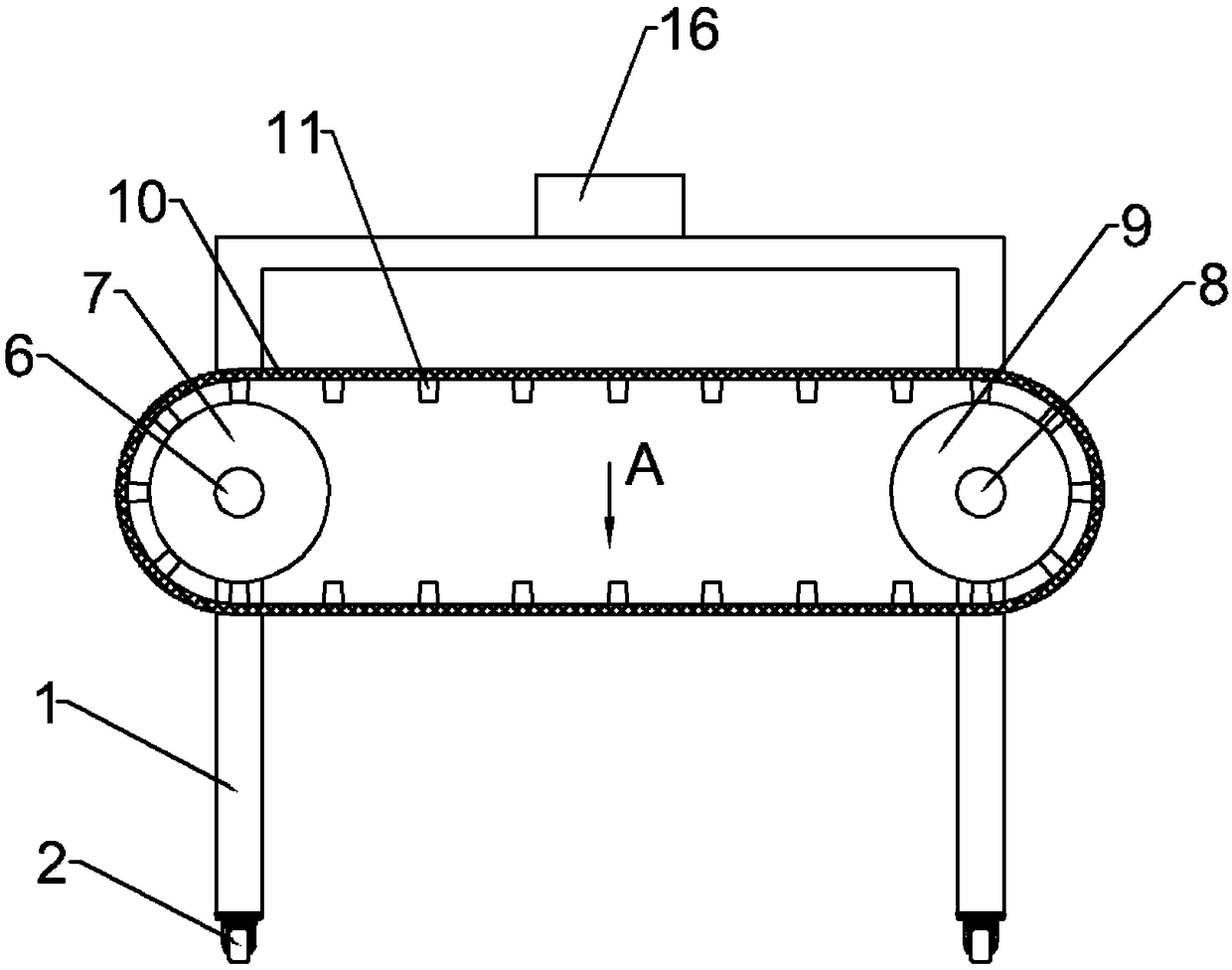

Material screening and impurity removing device

The invention discloses a material screening and impurity removing device comprising a support. A bearing seat is fixedly connected to the rear side of the support. A motor is fixedly connected to theupper portion of the bearing seat. A coupling is fixedly connected to the output end of the motor. A left rotary shaft is fixedly connected to the front end of the coupling and is rotationally connected with the left side of the support. A left rotary wheel is fixedly connected to the outer side of the left rotary shaft. A right rotary shaft is rotationally connected to the right side of the support. A right rotary wheel is fixedly connected to the outer side of the right rotary shaft. The left rotary wheel and the right rotary wheel is sleeved with a conveying belt. The outer side of the conveying belt is provided with a plurality of air holes. A plurality of conveying lugs are fixedly connected to the inner side of the conveying belt. The front sides of the left rotary wheel and the right rotary wheel are sleeved with front baffles. Compared with the prior art, the material screening and impurity removing device has the beneficial effects that the structure is simple, use is convenient, light impurities in materials can be screened out and removed during use, then pure materials are obtained, and the impurity removing rate is high.

Owner:HUIAN KELIAN AGRI TECH CO LTD

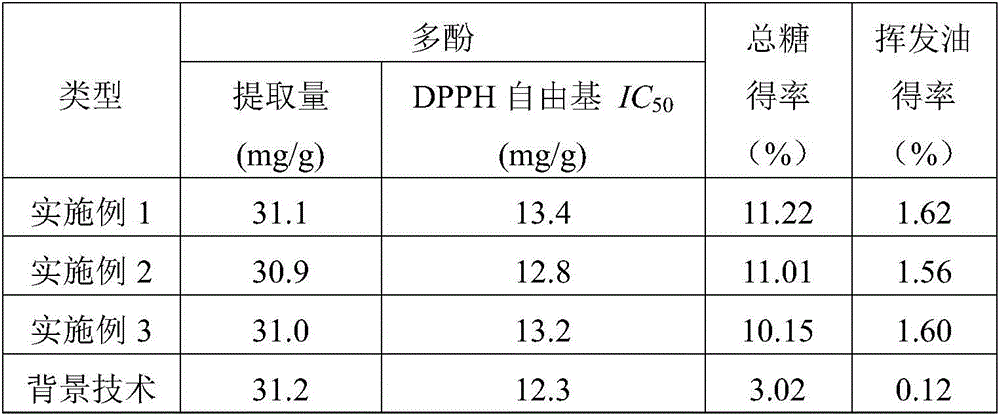

Preparation method of Baccaurea ramiflora extract

The invention discloses a preparation method of Baccaurea ramiflora extract. The Baccaurea ramiflora extract is prepared from Baccaurea ramiflora fruits as a raw material by grinding by a colloid grinder, performing enzymolysis by cellulase and pectinase, extracting by ultrasonic, performing ethyl alcohol reflux, performing water extracting, performing membrane filter and polyamide column purification and the like. The preparation method effectively solves the technical problems of the prior art that composition is single, a lot of effective components such as total sugar and volatile oil in Baccaurea ramiflora fruits cannot be reserved, and extraction rate and efficiency are low.

Owner:GUILIN MINGXING BIOTECH

Method for purifying and recovering solvent NMMO (N-methylmorpholine oxide) in lyocell fiber production process

InactiveCN110760948AExtend cycle lifeEasy to change screenArtificial filament recoveryTextile/flexible product manufactureNanofiltrationSmall particle

The invention discloses a method for purifying and recovering a solvent NMMO in a lyocell fiber production process, which comprises the steps: firstly, carrying out coarse filtering with a filter screen to remove solid impurities in NMMO; secondly, performing micro-filtration treatment with a hydrophobic polymer membrane to remove small particular solid impurities, bacteria and macromolecular colloid; thirdly, treating the NMMO with a micelle enhanced ultrafiltration method again to remove degraded residual chains in the NMMO, and carrying out micelle enhanced adsorption on metal ions in the NMMO; and fourthly, carrying out nanofiltration treatment to remove other impurities in the NMMO. The method of the invention is simple, no flocculants are needed, and the impurity removal rate and recovery rate of NMMO can be obviously increased.

Owner:SHANDONG YINGLI IND

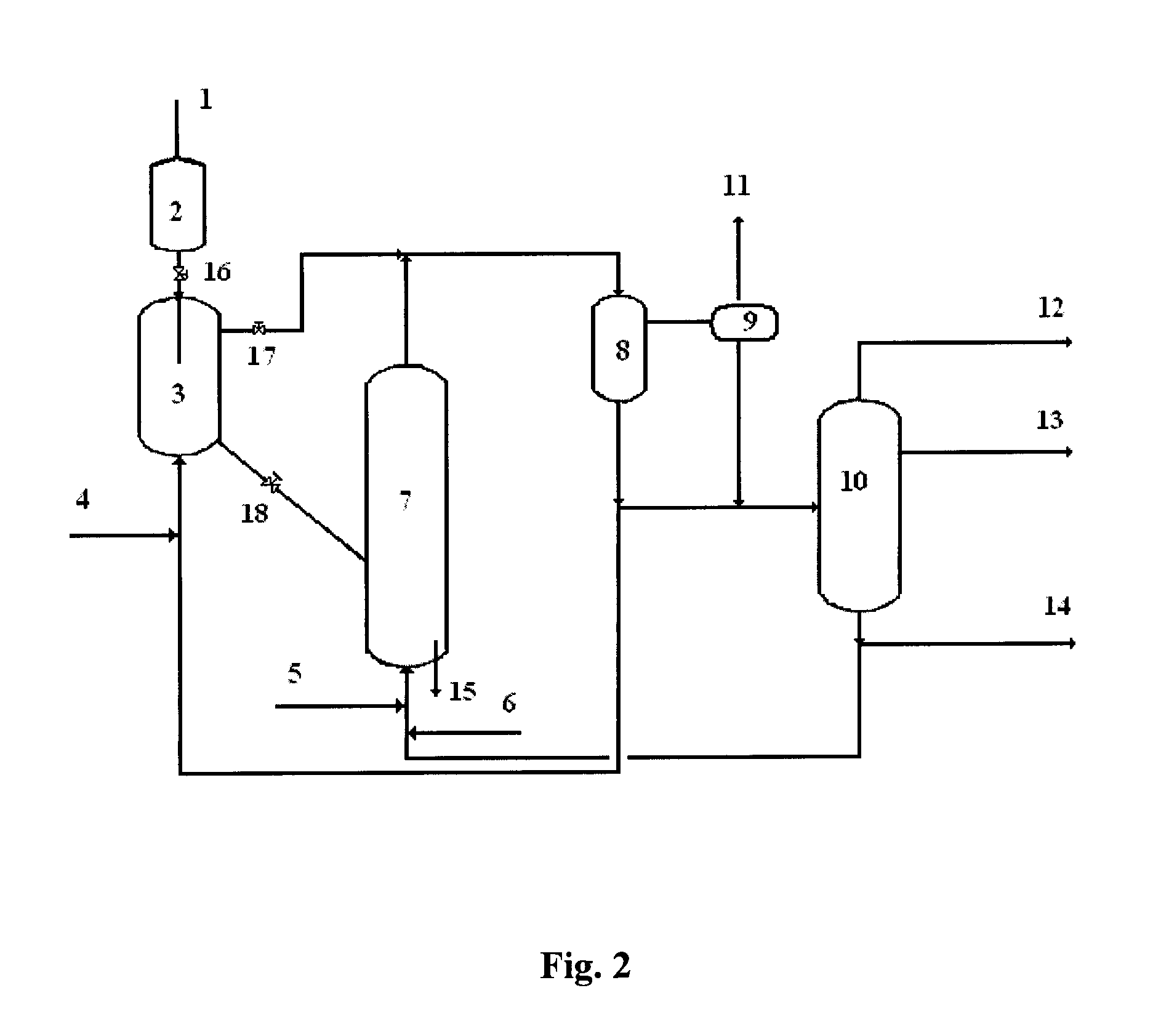

Hydrogenation treatment method for inferior feedstock oil

ActiveCN102061192AEasy to operateOvercome temperatureTreatment with hydrotreatment processesFluidized bedLiquid phase

The invention discloses a hydrogenation treatment method for inferior feedback oil. In the method, a fluidized bed reactor and an expanded bed reactor are combined to form a novel combined process, wherein the expanded bed reactor can not only perform further hydrogenation treatment on a liquid phase effluent of the fluidized bed reactor to improve product quality, but also supplement a catalyst for the fluidized bed reactor without affecting the smooth operation of the fluidized bed at the same time. The hydrogenation treatment method can ensure the long-period smooth operation of a device on the premise of bringing the wide raw material applicability of fluidized bed hydrogenation technology into full play.

Owner:CHINA PETROLEUM & CHEM CORP +1

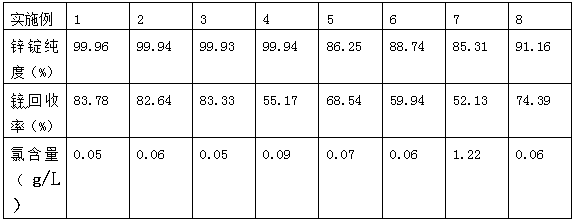

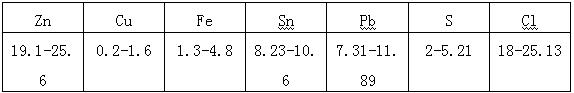

Process for extracting metal zinc from high-chlorine-content and high-zinc-content soot

ActiveCN109576500AAchieving zero emissionsLow costPhotography auxillary processesProcess efficiency improvementSootGoethite

The invention discloses a process for extracting metal zinc from high-chlorine-content and high-zinc-content soot. The process comprises the steps of zinc containing soot alkali washing dechlorinating, leaching, purification and impurity removal through a goethite-like method, copper salt deep dechlorination, three-segment purification, electrodeposition and casting. By means of the process, the wet alkali washing dechlorinating process is adopted, wastewater zero discharging is achieved, compared with a traditional pyrogenic process, the dechlorination process is simple, and the chlorine removal rate is high; through the specific leaching process, the zinc recovery rate is effectively increased; and the goethite-like method is adopted for purification and impurity removal, modified magnesium diboride is added, three-segment antimonic salt continuous purification treatment is achieved in combination, the impurity removal rate and the removal rate are effectively increased, and the zincrecovery efficiency and the grade are high.

Owner:江西新金叶实业有限公司

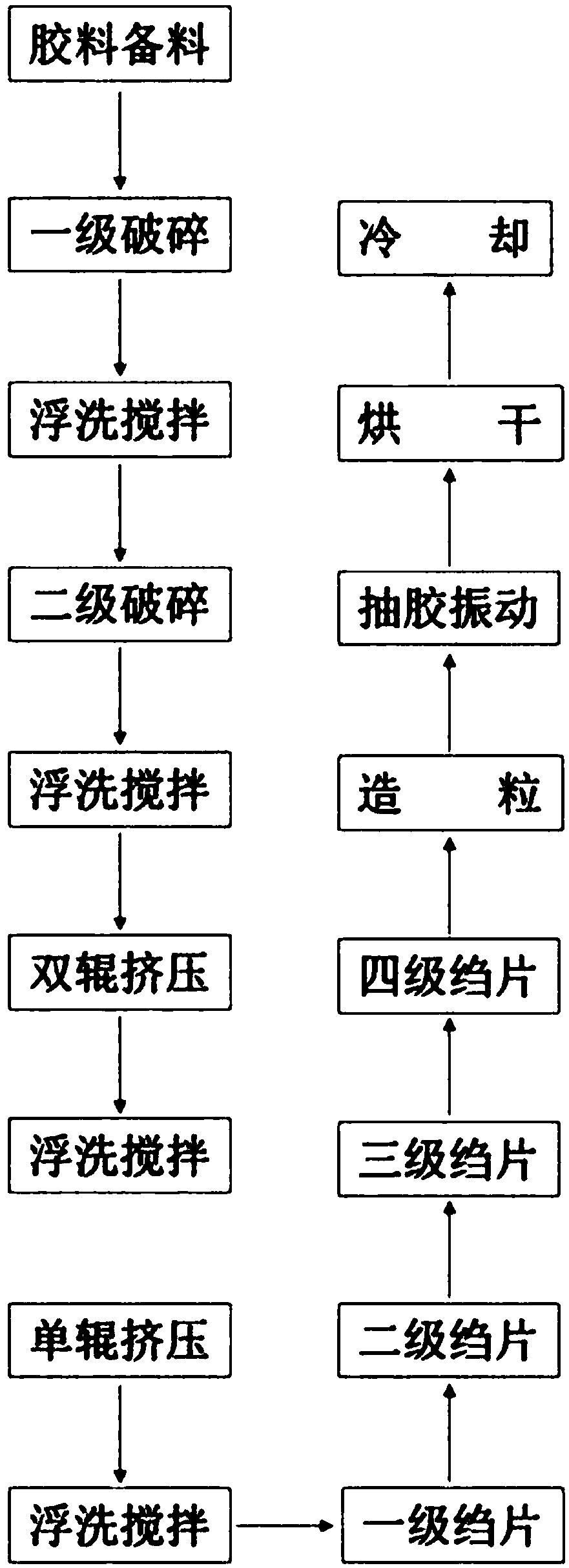

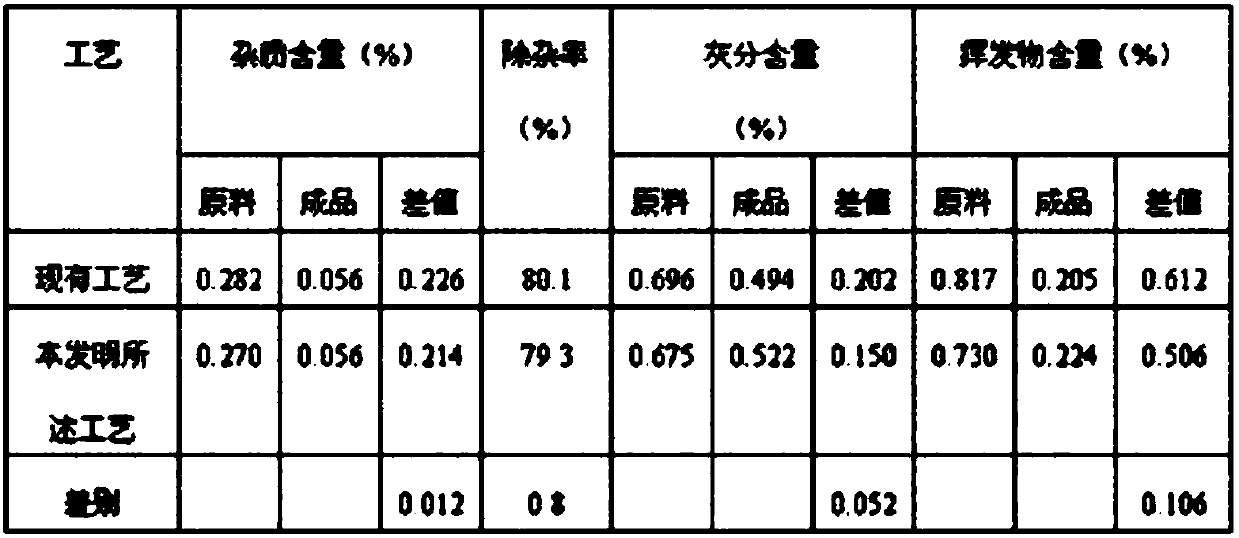

Processing technology for special rubber for radial tire

The invention discloses a processing technology of special rubber for radial tires. The process first divides the recovered rubber raw materials into two grades according to the evaluation results of the enterprise quality inspection standards, and breaks them into rubber blocks of 40cm×10cm×8cm~50cm×15cm×20cm respectively, and divides the graded rubber raw materials after removal of impurities by 1 ~3:1~3 weight ratio mixing. The mixed rubber material is crushed in the first stage, floated and stirred, and the secondary crushed, floated and stirred, the floating washing time must be ≥ 20min, and then the mixed rubber material is subjected to two-stage extrusion floating washing, and the floating washing time must be ≥ 12min, Make the rubber into a gelatinous mass. The rubber material is treated with one to four stages of creping to make the rubber material into a continuous sheet with a thickness of 6-12mm, and the creped rubber material is granulated to make rubber particles with a diameter of 6-12mm. The colloidal particles are pumped and vibrated, dried at 82-108°C according to the standard of 4-6t / h rubber material, and then cooled to room temperature. The process improves the impurity removal rate of the equipment, avoids damage to the rubber structure due to excessive processing, simplifies the equipment configuration of the production line, reduces the overall failure rate, reduces the amount of crushed rubber, and improves production efficiency.

Owner:南通通江橡胶制品有限公司

Preparation method of field muskmelon extract

InactiveCN106398855AHigh extraction rateImprove efficiencyFatty-oils/fats refiningFatty-oils/fats productionPectinaseCellulose

The invention discloses a preparation method of field muskmelon extract. The field muskmelon extract is prepared by taking field muskmelon fruit as raw material, and performing colloid mill grinding, enzymolysis process of cellulose and pectinase, ultrasound extracting process, microwave extracting technique, ethanol backflow, purifying technology of a filter membrane and a polyamide column. The extracting method can make field muskmelon remain many effective components such as oily matters, Vitamin E and carbohydrates, and also improve the extracting rate and efficiency of effective components of the field muskmelon.

Owner:GUILIN MINGXING BIOTECH

Method for extracting pectin from akebia trifoliata var australis peel

InactiveCN102093487AHigh purityReduce lossesPharmaceutical non-active ingredientsFood preparationFood additiveAlcohol

The invention discloses a method for extracting pectin from akebia trifoliata var australis peel, which comprises: picking akebia trifoliata var australis peel serving as a raw material; shearing, rinsing in hot water, deactivating enzyme and drying; and preparing pectin by acid leaching, filtering, decolorizing, precipitating in alcohol, centrifuging for separation, dying under vacuum and grinding. The method has the advantages of fewer steps, simple equipment, low cost, little energy consumption, suitability for industrial production and the like, and the prepared pectin is light in color, high in purity and easy to form into gel and can be directly used as feed additive or medicine auxiliary.

Owner:NANCHANG UNIV

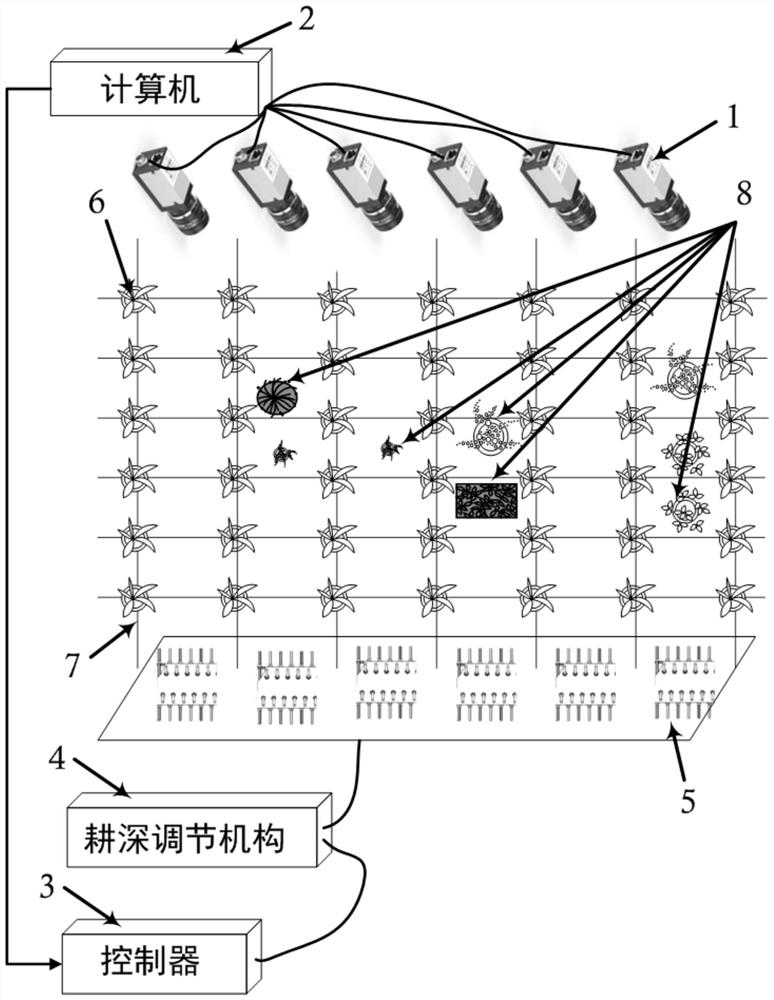

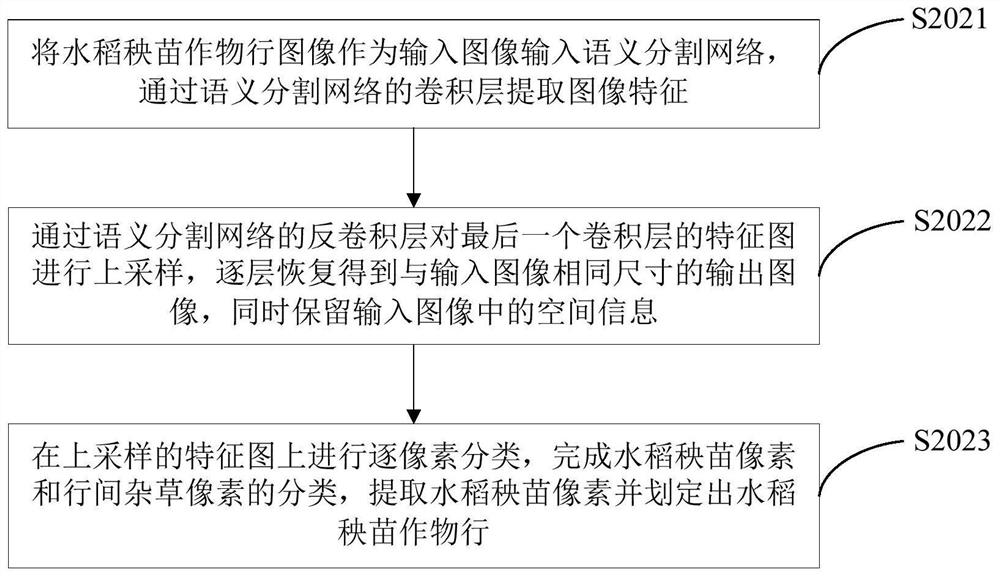

Weeding and tilling depth adjusting method, device and system, computer equipment and storage medium

PendingCN111639575AHigh impurity removal rateReal-time identificationSoil-working equipmentsCharacter and pattern recognitionAgricultural scienceAgricultural engineering

The invention discloses a weeding and tilling depth adjusting method, device and system, computer equipment and a storage medium, and the method comprises the steps: obtaining a rice seedling crop rowimage according to a time interval calculated according to the driving speed of an intertillage weeding machine; completing semantic segmentation of rice seedling pixels and inter-row weed pixels onthe rice seedling crop row image, and defining rice seedling crop rows according to the rice seedling pixels; grading the weed density according to the pixel values of the weeds in the rice seedling crop rows, and recording the position information of the weeds on the rice seedling crop row images; and controlling a tilling depth adjusting mechanism of the intertillage weeding machine to adjust the weeding tilling depth of the weeding part corresponding to the weed density grade according to the weed density grade and the position information. According to the invention, real-time identification of the density and position of weeds between rice seedling rows can be realized, corresponding weeding tilling depth adjustment is further realized, the impurity removal rate of the intertillage weeding machine is improved, and a foundation is laid for research and development design of the intelligent intertillage weeding machine between rice seedling rows.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

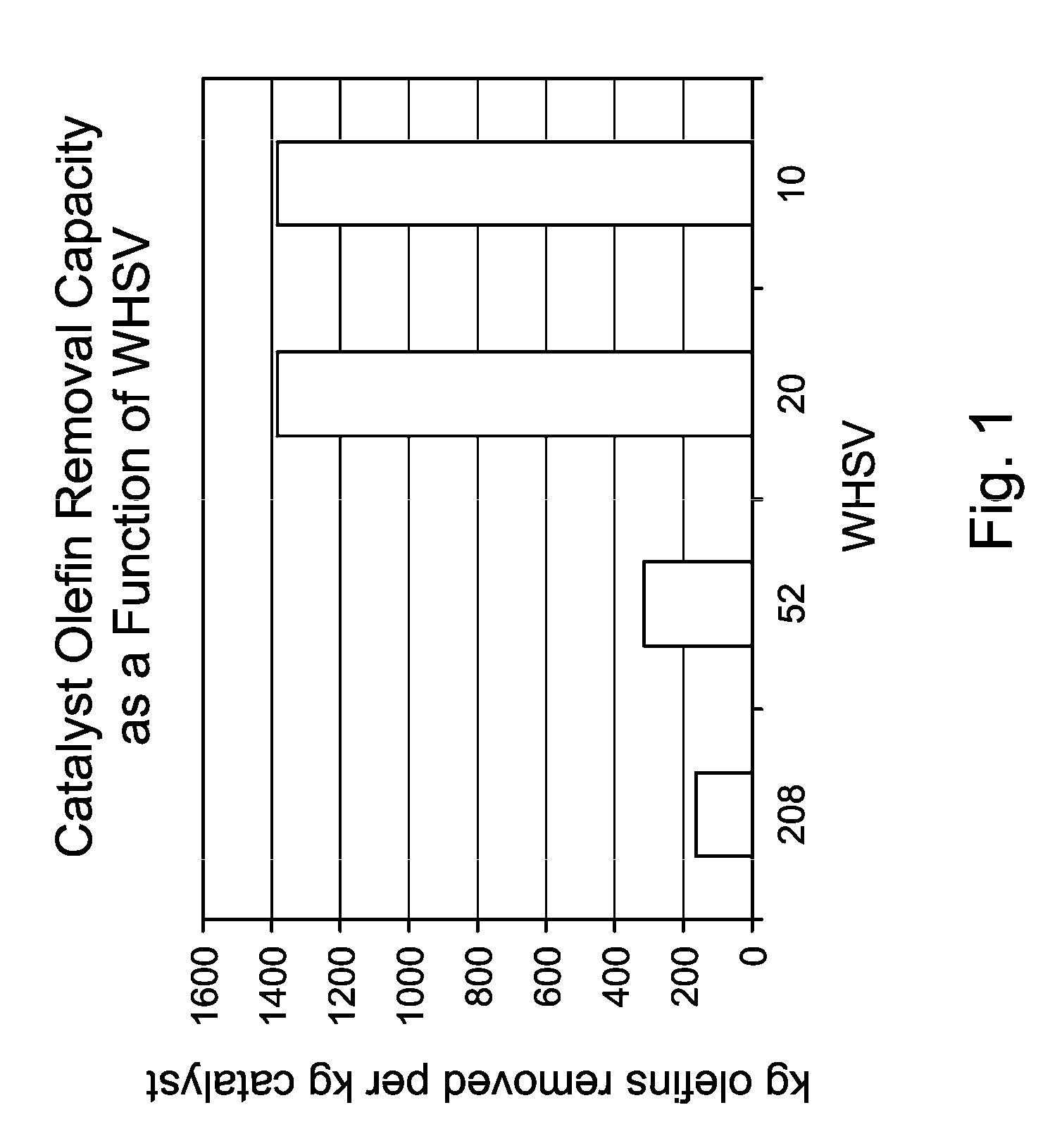

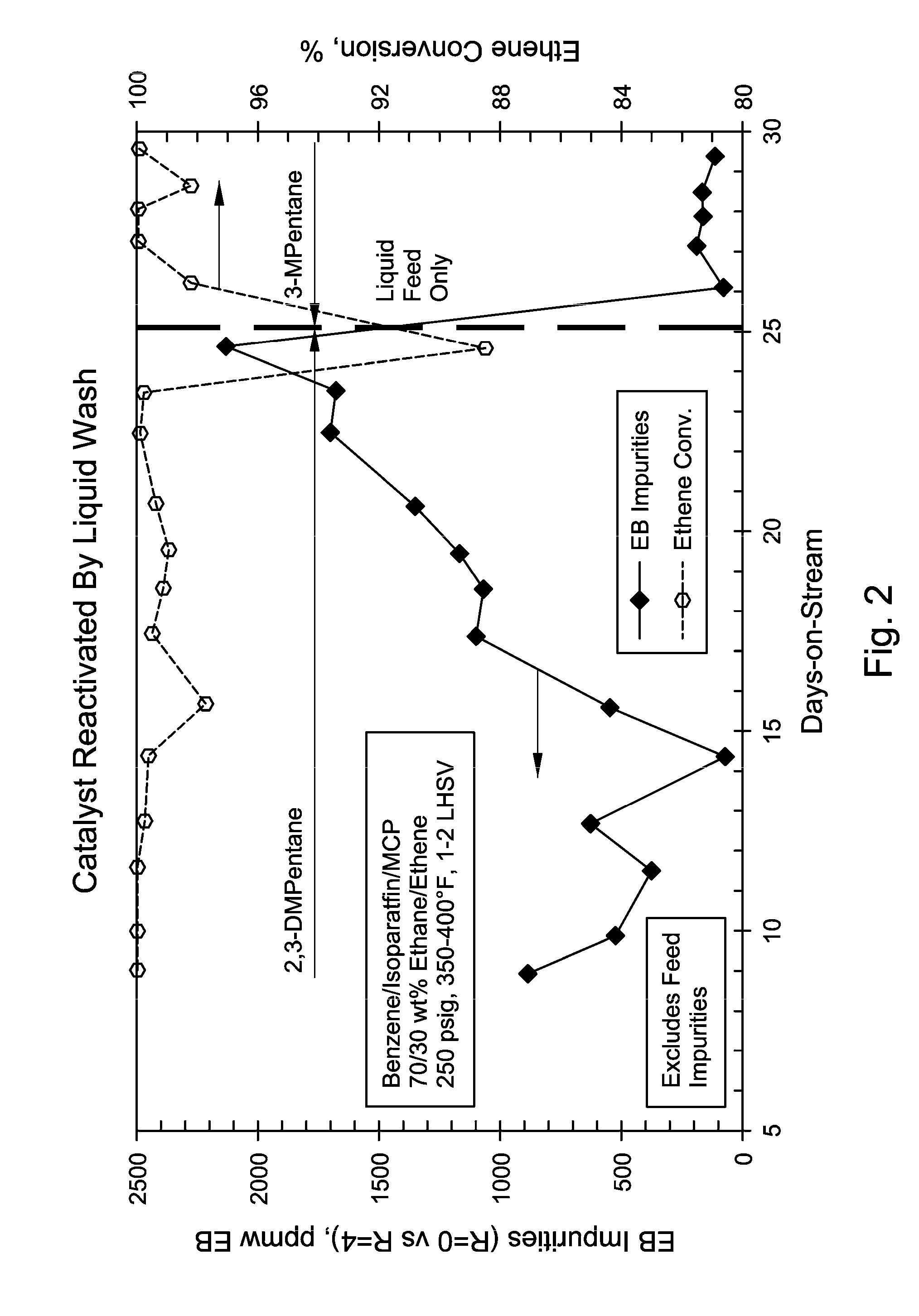

Removal of bromine index contaminants from aromatic streams

InactiveUS8216450B2Increase the lengthHigh impurity removal rateRefining with metalsHydrocarbon by hydrogenationBromineAromatic plants

According to the invention, trace olefins and dienes are removed from aromatic plant feedstocks by contacting the catalyst using conditions outside the ordinary range used for this application today.

Owner:EXXONMOBIL CHEM PAT INC

Process of preparing pectin from japanese premna leaf

The preparation process of pectin by using premna microphylla leaf as raw material includes the following steps: treating raw material, acid extraction, filtration, decolouring and removing smell, spraying-drying to obtain pectin or after decolouring and removing smell, alcohol precipilation, washing and spraying-drying so as to obtain the pectin, in which the extract obtained after filtration is undergone the processes of coacervation, ion exchange and ultrafiltration and concentration to make decolorization, smell removed and desugarization, i.e. placing the polycoagulant whose concentration is 1% into the filtered extract, adding alkali to control pH value, precipitating to remove impurity and decolouring at twice, making the extract pass through the ion exchange resin column to make treatment.

Owner:WUHAN CHEM COLLEGE

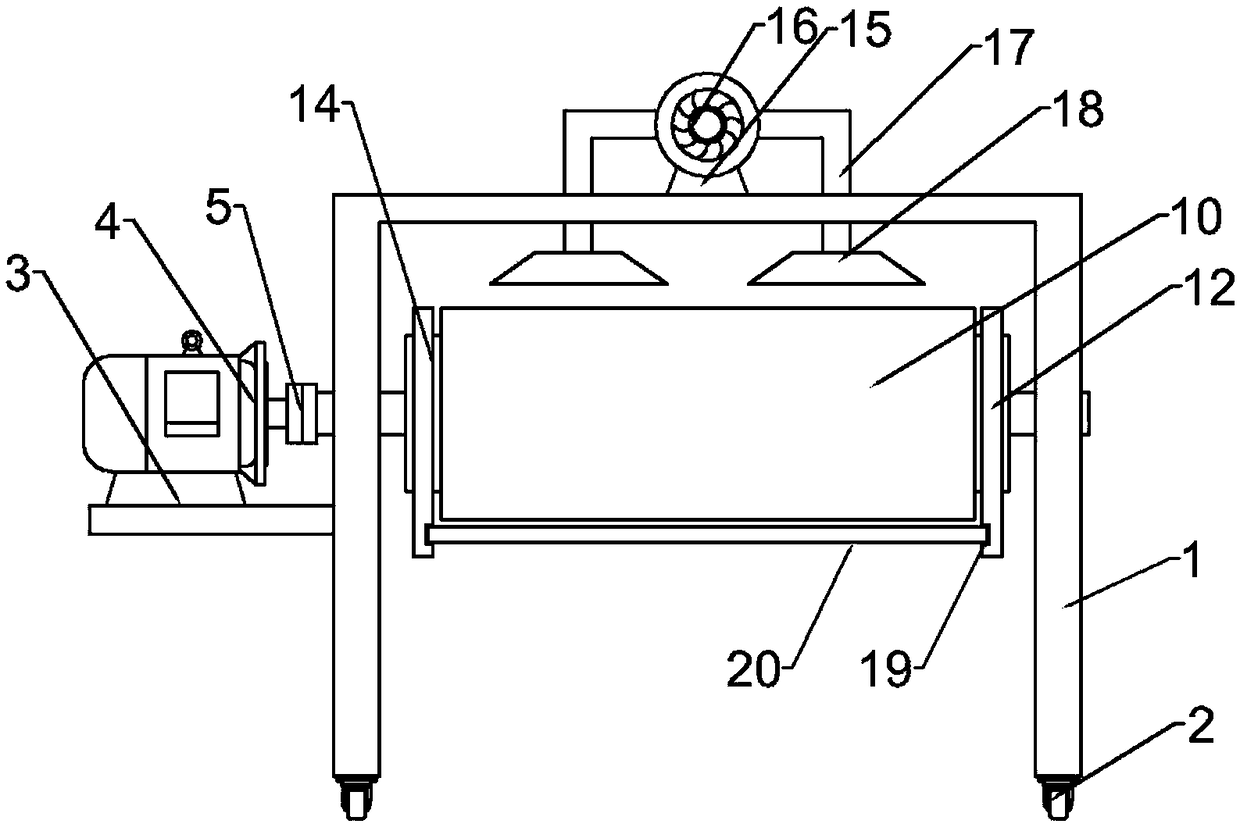

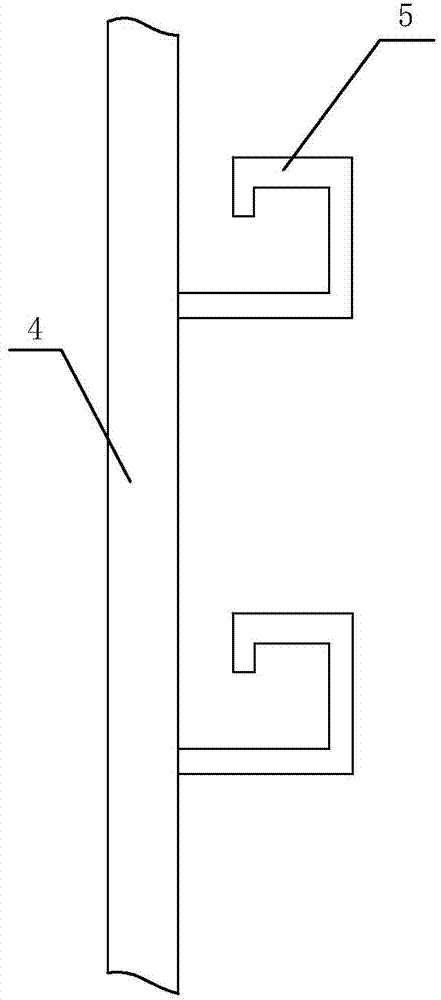

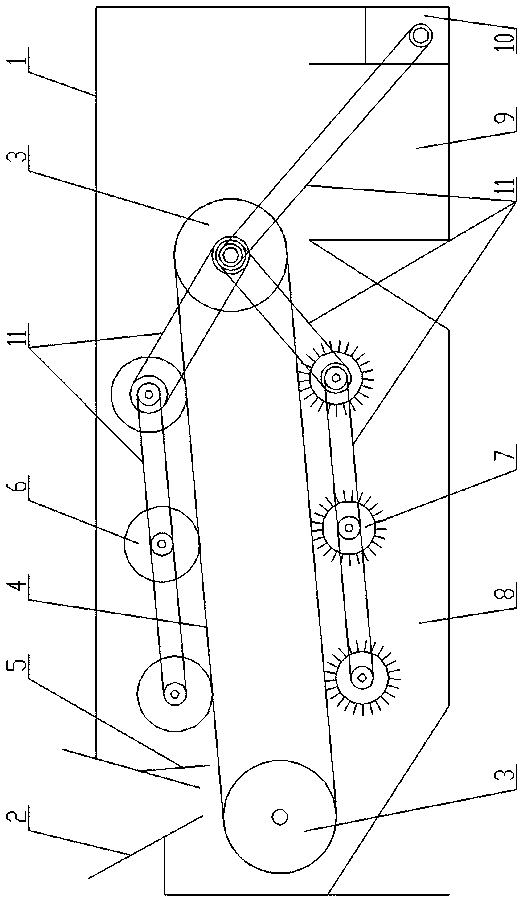

Novel multifunctional opener

InactiveCN110714241AEasy to operateReduce homeworkFibre cleaning/opening by beater armsFibre cleaning/opening machinesElectric machineryDrive motor

A novel multifunctional opener comprises a rack, a cotton conveyor device and a stand hopper; a condenser is arranged above the stand hopper and provided with a cotton inlet; the cotton conveyor device is connected with the cotton inlet and comprises a conveyor belt, a drive roll, a driven roll and a drive motor, the conveyor belt is connected with the driven roll and the drive roll, the drive motor is also connected with the drive roll and the driven roll, and the drive motor refers to a semi-servo motor; feeding rollers and opening beaters are arranged under the stand hopper sequentially; anelectrostatic eliminating net is arranged in the stand hopper, and one end of the electrostatic eliminating net is grounded through a ground wire.

Owner:邳州市苏鲁粮种繁育专业合作社

Production process of high purity silver by high frequency electrolysis

ActiveCN105274567AColor stableHigh impurity removal rateElectrolysis componentsPhotography auxillary processesElectrolysisFiltration

The invention relates to a production process of high purity silver by high frequency electrolysis. Through the special design of silver-containing mineral powdering purification, electrolytic oxidation treatment, high frequency oscillation filtration treatment and activation treatment process steps and special optimization of relevant parameters, the technical problems of complex impurity species, incapability to effective recovery of silver, poor fineness of recovered silver, many chemical reagents, easy pollution and the like are overcome, and the production process provided by the invention realizes the advantages and effects of wide application range of treatment scale, simple equipment, small floor space, applicability to existing process transformation, small investment and quick effect, low treatment cost, multi-step purification, high impurity removal rate, good product quality and stable fineness, etc.

Owner:嘉善凝溪建设有限公司

Preparation method of oxytotin injection

InactiveCN109010796ALow impurity contentIncrease the step of refrigerating and removing impuritiesPeptide/protein ingredientsPharmaceutical delivery mechanismHydrogenImpurity

The invention discloses a preparation method of oxytotin injection. The preparation method comprises the following steps: (1) adding hot water for injection into a preparation device 1; then adding anoxytotin solution and uniformly stirring and cooling; (2) adding the hot water for injection into a preparation device 2; then adding a preservative and uniformly stirring; (3) after cooling a solution in the preparation device 2, transferring the solution into the preparation device 1; uniformly stirring and regulating the pH (Potential of Hydrogen) value to be 3.4 to 3.6; (4) adding water for injection and making the volume constant; then removing bacteria and filtering; (5) refrigerating at 2 to 5 DEG C for 16 to 24h; (6) removing bacteria and filtering; (7) filling. According to a new discovery that small molecular active peptide can be precipitated and separated out in a refrigerating process and oxytotin is not precipitated, a refrigerating and impurity removal step is increased inan existing production technology of the oxytotin injection; meanwhile, the corresponding pH, temperature and time are controlled, and the content of impurities in the oxytotin injection can be reduced; the impurity removal rate is 50 to 70 percent.

Owner:CHENGDU HAITONG PHARMA

Air duct device having adjusting display device

InactiveCN104707798AFlexible useHigh impurity removal rateGas current separationAir volumeDisplay device

The invention relates to an air duct device having an adjusting display device. A discharge pipe is arranged on a shell; the lower part of the discharge pipe is in cup joint with an adjusting plate; an annular air duct is defined by the adjusting plate and the shell; a frame body is arranged at one side of the shell; multiple hanging hooks are arranged on the frame body from top to bottom; the top of the adjusting plate is connected with one end of a lower connecting rod; the other end of the lower connecting rod is connected with one end of an upper connecting rod; the other end of the upper connecting rod is clamped into the hanging hooks after penetrating through the shell; and a wind speed sensor and a wind volume sensor are arranged in the shell, and are connected with a display screen. The air duct device has the advantages that the air duct section can be changed and further the air speed and the air volume can be adjusted, so that the wind speed and the wind volume can be adjusted according to the practical material flows and material batches; the device is flexible to use and the actual impurity removal rate is largely improved; the air duct device has the advantages of simple structure, wide application, level type control and convenience for use; and the wind speed and the wind volume in the shell can be detected at any time by the wind speed sensor and the wind volume sensor, and are output through the display screen.

Owner:SHANDONG YIKAI STORAGE ENG

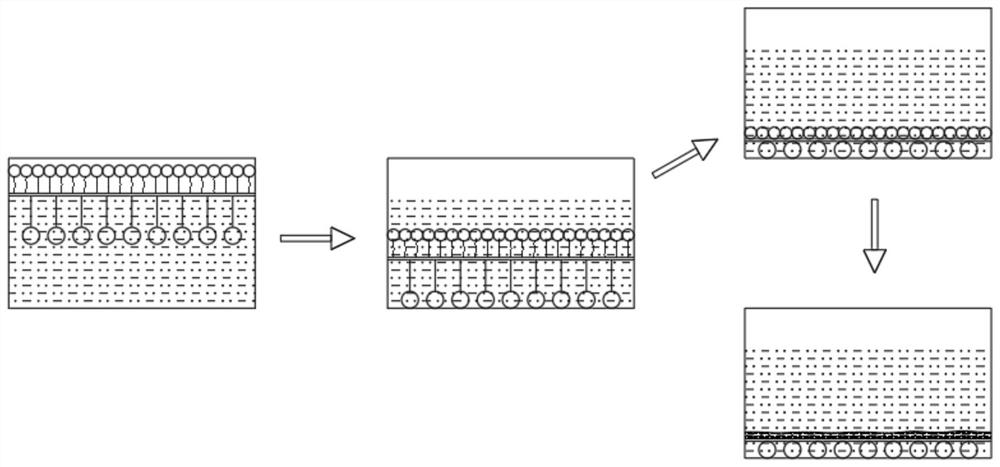

Wrapping isolation type lubricating oil regeneration process

ActiveCN113462460AImprove regeneration efficiencyAvoid driftingGeneral water supply conservationLubricant compositionThermodynamicsPetroleum engineering

The invention discloses a wrapping isolation type lubricating oil regeneration process, and belongs to the field of lubricating oil. According to the wrapping isolation type lubricating oil regeneration process, a ball net plate is arranged, downward pushing is conducted from top to bottom, so that lubricating oil and impurities are forced to be layered, and compared with the prior art, only standing flocculation impurity removal is conducted, so that the regeneration efficiency of the lubricating oil is remarkably improved; after a ball aligning screen plate touches the bottom, along with continuous pushing, a thermal collapse floating ball gradually gets close to the middle of the ball aligning screen plate and is tightly attached to the upper portion of the ball aligning screen plate, in cooperation with heating operation, the thermal collapse floating ball gradually collapses and wraps the ball aligning screen plate, impurities and lubricating oil are effectively separated, and scattering of impurities of layering, caused when the lubricating oil is separated and vibrates, is effectively avoided so the content of the impurities in the regenerated lubricating oil is effectively reduced, the quality of the regenerated lubricating oil is improved, the impurity extraction rate is higher, meanwhile, when the collapsed thermal collapse floating ball is solidified, the impurities at the boundary of a part of the layering can be fixed, and the impurity removal rate is further improved.

Owner:武汉市时代金鸡石油制品有限公司

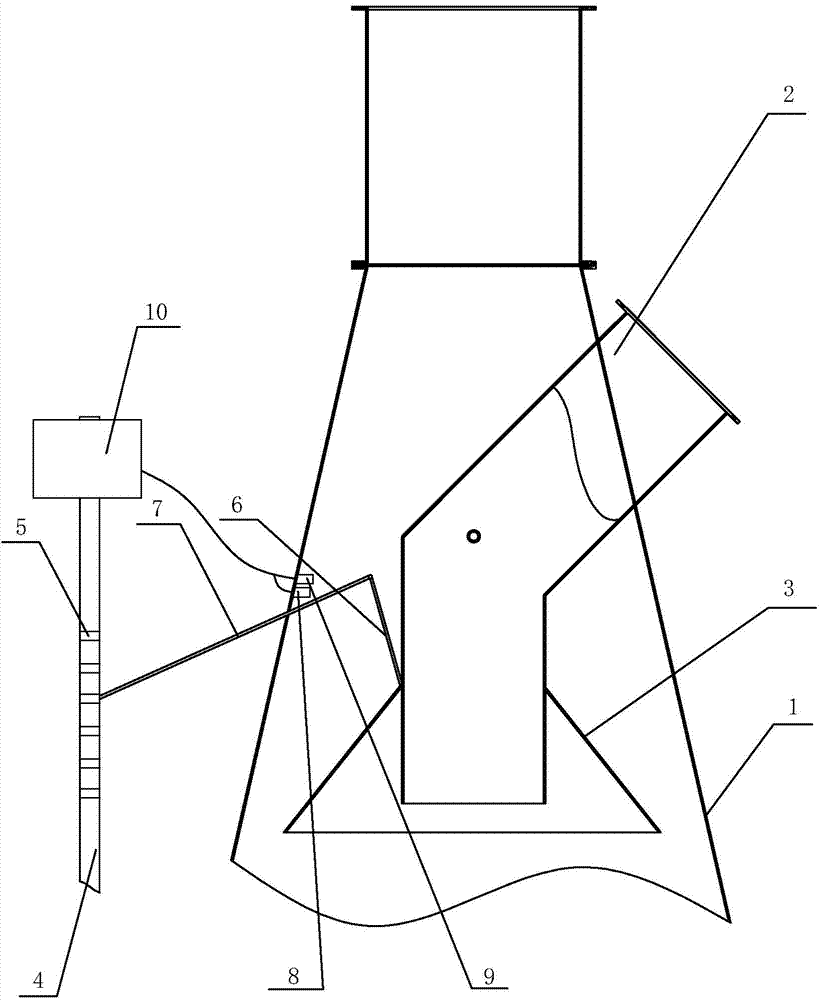

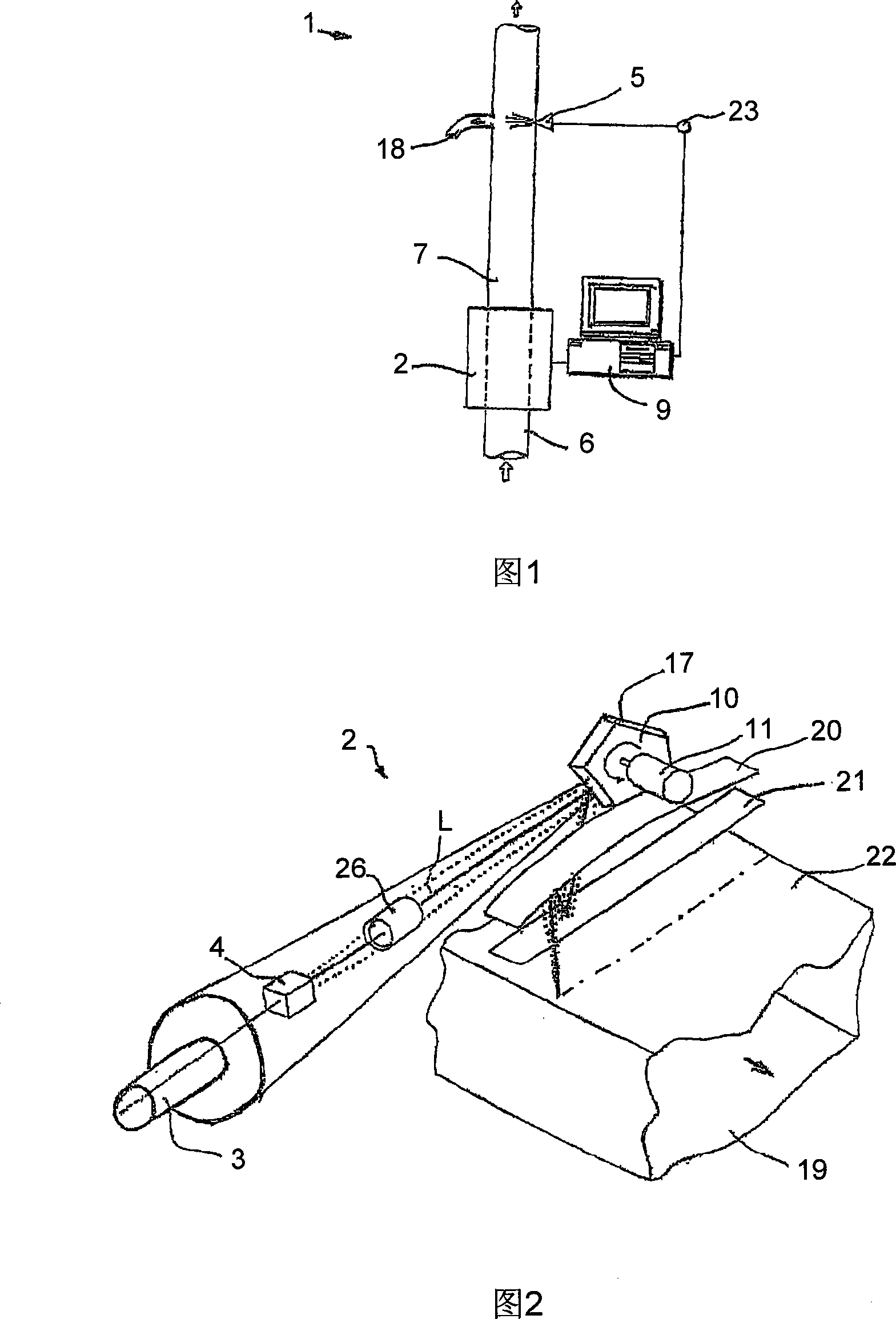

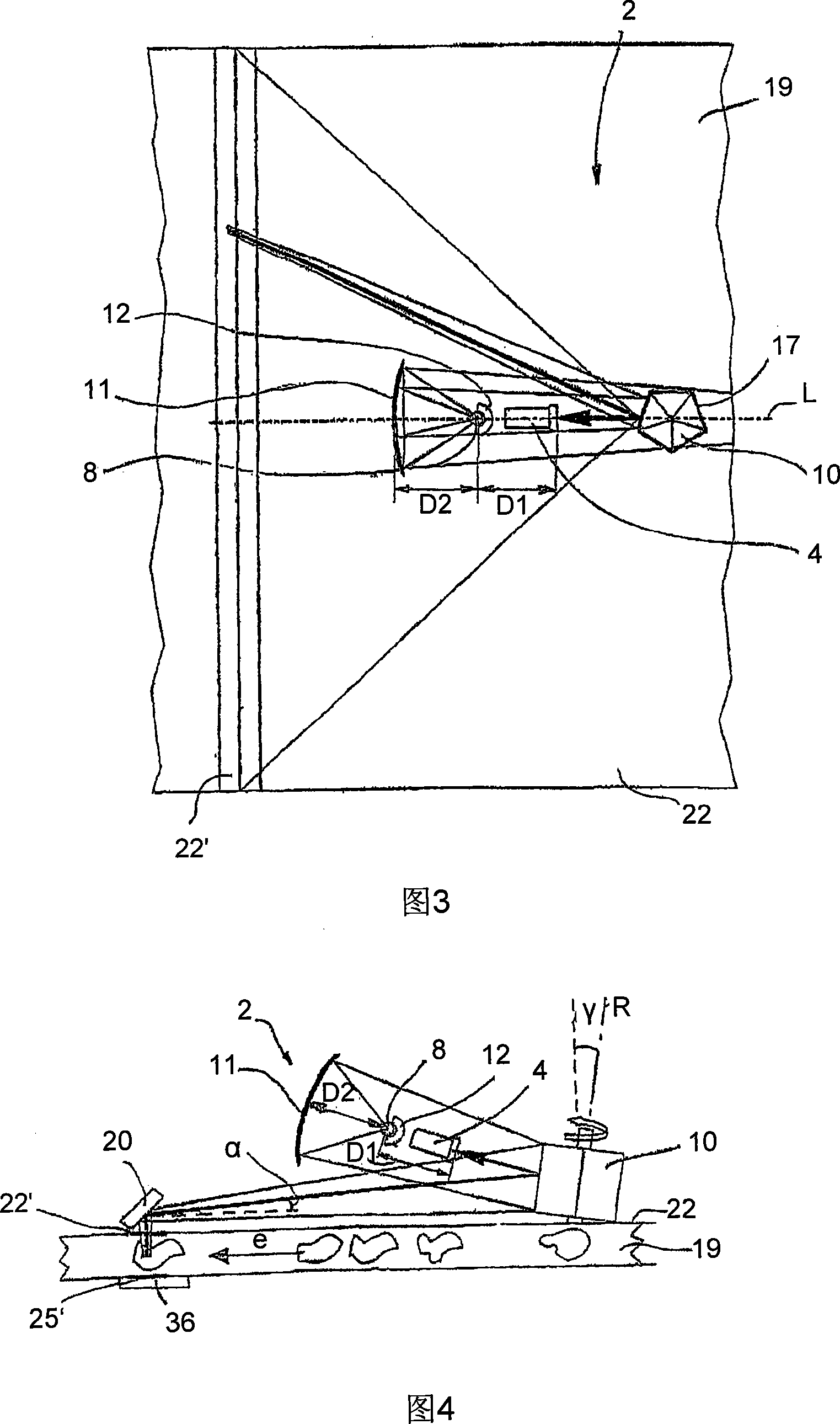

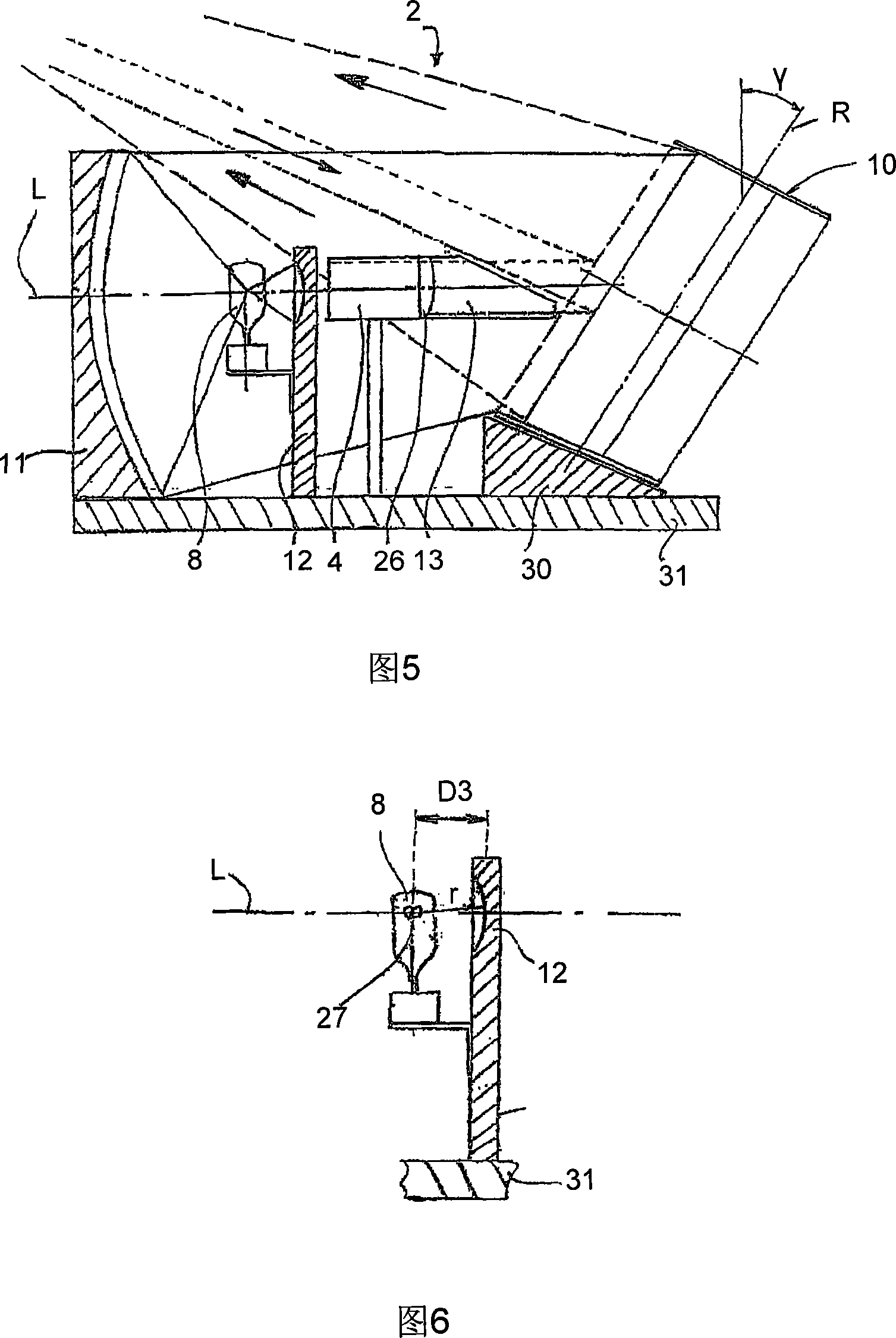

Device for detecting and removing foreign matter

InactiveCN101250772AImprove optical efficiencyHigh impurity removal rateSafety devices for fibre treatmentFibre cleaning/openingMedical physicsForeign matter

The invention provides a device for detecting and separating impurities in a material flow, including a radiation mechanism (3) for radiating the material flow and at least one a sensor device (4) for detecting the radiated impurities in the material flow. A rotatable polygonal mirror (10) for scanning the material flow row by row is provided, radiation of the radiation mechanism (3) can be deflected to the material flow and the radiation reflected by the material flow can be deflected to the sensor device (4) both by utilizing the polygonal mirror. The radiation mechanism (3) and the sensor device (4) are arranged coaxially with one being in front and the other being back with regard to an optical irradiation shaft (L). The radiation mechanism (3) mainly comprises a radiation source (8), a concave reflecting mirror (11) for collimate the radiation to the polygonal mirror (10) along the optical irradiation shaft (L), and a back reflector (12), by which back side of the radiation can be guided toward the concave reflecting mirror (11).

Owner:USTER TECHNOLOGIES

Fluidized-bed reactor and hydrotreating method thereof

ActiveUS9162207B2Extended stayHigh yieldLiquid hydrocarbon mixture productionHydrocarbon oil crackingFluidized bedProcess engineering

The invention relates to a fluidized bed reactor and a hydrogenation method thereof. The fluidized bed reactor (7) comprises a reactor shell (103) vertical to the ground and a phase separator (111) at the upper part of the shell (103). An inner circulation zone is provided under the phase separator (111), and comprises a cylinder (114), a tapered diffusion section (115) and a guiding structure (104). In the hydrogenation method using the fluidized bed reactor (7), an expanded bed reactor (3) is used to further hydrogenate part of the product from the fluidized bed reactor (7), and supply catalyst without influencing on the stable operation of the fluidized bed reactor (7).

Owner:CHINA PETROCHEMICAL CORP +1

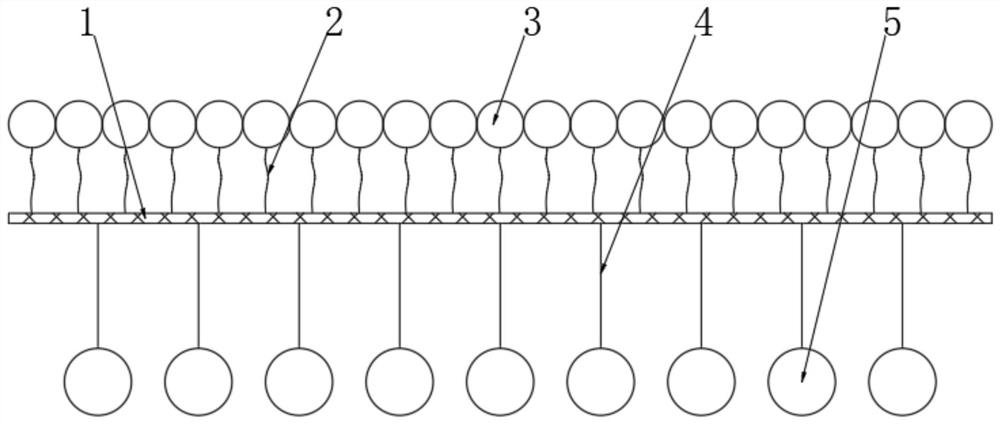

Adhesive impurity removing device for cleaning oats

The invention relates to an adhesive impurity removing device for cleaning oats. The device comprises a shell; a feed hopper is arranged at the top of the shell; a conveying belt is arranged in the shell; a material scraping plate is arranged above the conveying belt; materials are distributed on the conveying belt in an equal-thickness layer through contact of a bottom edge of the material scraping plate and the materials; a layer of cotton material is adhered to a surface of the conveying belt; a plurality of rubber rollers are arranged above the conveying belt; a plurality of brush rollersare arranged below the conveying belt; and an outer peripheral surface of each rubber roller is pressed on the upper surface of the conveying belt. Impurities in the materials are adhered to the uppersurface of the conveying belt by extrusion of the rubber rollers and cooperation of the cotton material, so that oat grains in the materials slide off one side of the conveying belt along a conveyingdirection, and the impurities are conveyed to a lower surface of the conveying belt. The impurities fall off from the lower surface of the conveying belt when the brush rollers rotate to brush the lower surface of the conveying belt. An impurity collecting box and a grain collecting box are arranged on a bottom surface of the shell; and a motor for driving belt pulleys, the rubber rollers and thebrush rollers to synchronously rotate is also arranged on the bottom surface of the shell.

Owner:HENAN UNIV OF SCI & TECH

Method for removing iron ion impurities in copper salt at high efficiency

The invention provides a method for removing iron ion impurities in copper salt at high efficiency. The method comprises the following steps of: firstly, adding hydrogen peroxide of which the weight is 1-3% as heavy as that of a copper salt water solution into the copper salt water solution to be treated, adding metastannic acid of which the weight is more than 0.12% as heavy as that of the copper salt water solution, and carrying out absorbing, filtering, evaporating, cooling crystallization, separating and drying to obtain a product. According to the method for removing iron ion impurities provided by the invention, the metastannic acid is taken as a sinking agent, and the metastannic acid is large in specific surface and high in adsorption capacity, so that the iron ion oxidized by the hydrogen peroxide in the copper salt water solution is absorbed in the manner of ferric hydroxide. Compared with the existing deironing technology, the whole impurity-removing technology has the characteristic of being simple to operate, high in impurity removal rate, low in cost, and less in environment pollution. The iron ion impurity content of the copper salt treated by the method provided by the invention can be reduced to be less than 5ppm, so that the method is suitable for being used in the electronic industry and the printed circuit board industry.

Owner:GUANGDONG GUANGHUA SCI TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com