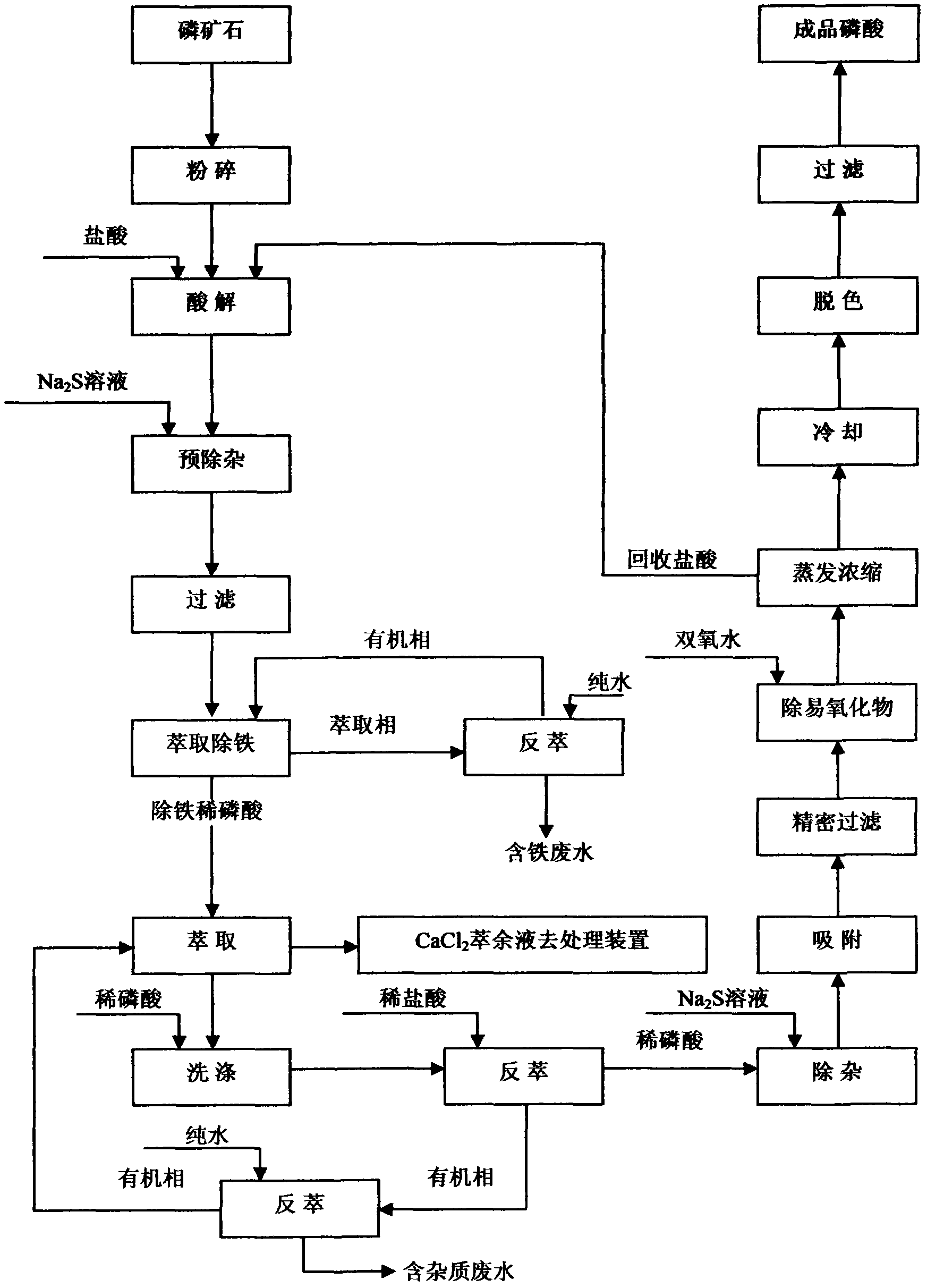

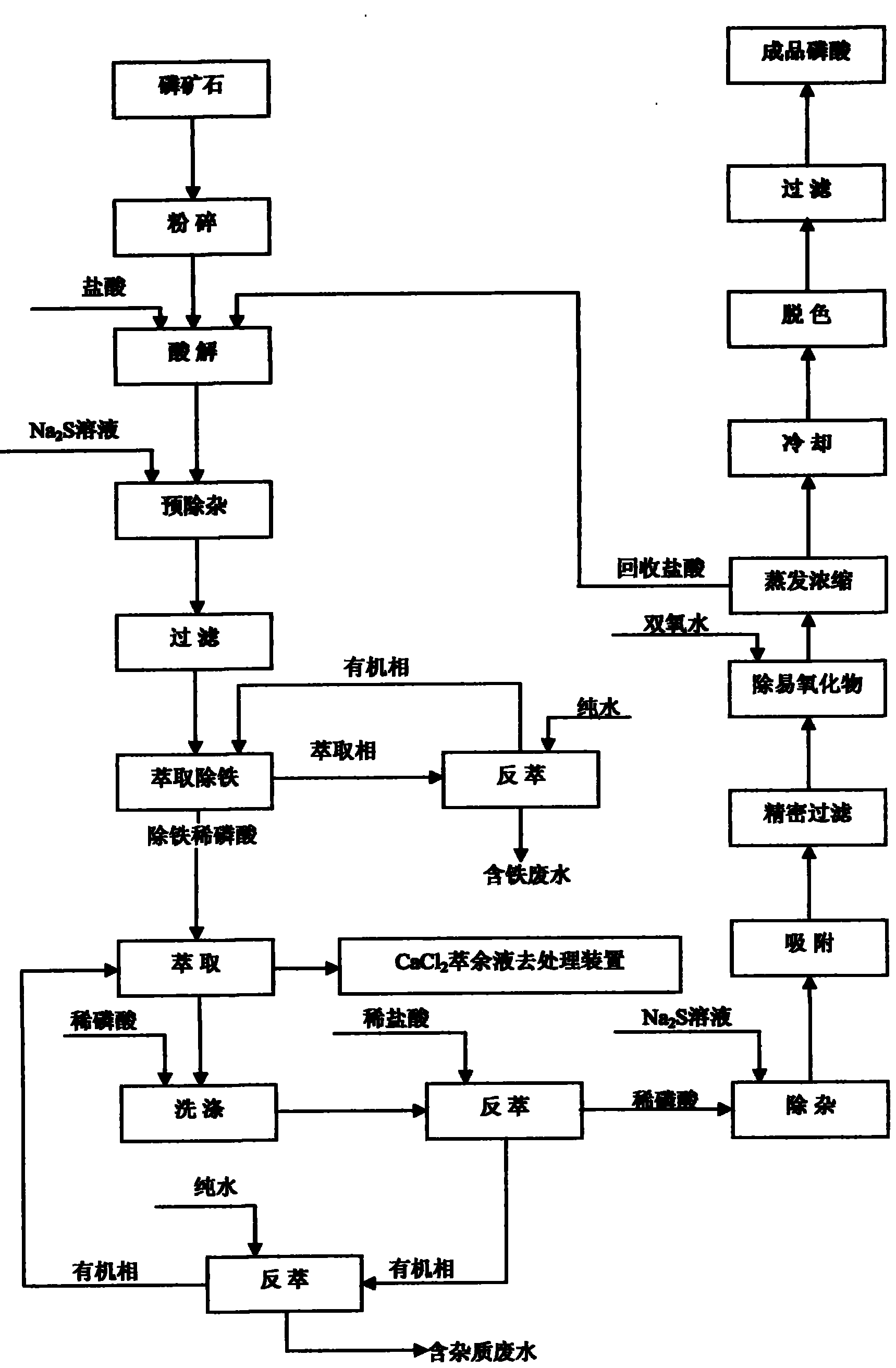

Production technology of food-grade phosphoric acid with hydrochloric acid method

A production process, food-grade technology, applied in the direction of phosphoric acid, phosphorus oxyacid, phosphorus compounds, etc., can solve the problems of unseen industrialized production, difficult filtration, poor washing effect, etc., achieve easy transportation and processing, simple removal process, High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take 200g with P 2 o 5 About 20% of the poor phosphate rock, crushed to more than 20 mesh and added to the beaker; add 400ml of 23wt% hydrochloric acid and a part of water, react under stirring conditions for 20 minutes, then add 6wt% Na 2 S solution 14ml carries out pre-removal of impurities, then adds 0.1wt% flocculant 10ml flocculation precipitation, then filters with filter paper; Carry out extraction to remove iron, extraction temperature is 20~30 ℃, extraction phase: water phase=1: 1, gained raffinate water phase is the dilute phosphoric acid of iron removal; Then, use the mixed solvent of tributyl phosphate and kerosene as extractant to Deferric dilute phosphoric acid carries out ten-stage extraction, extraction temperature is 20-30 ℃, by volume ratio, tributyl phosphate: kerosene=1: 1, water phase during extraction: organic phase=1: 4; Then, to extraction, obtain The organic phase carries out five-stage washing with the dilute phosphoric acid solution of 15wt%...

Embodiment 2

[0056] 100 kg of crushed phosphate rock powder, P 2 o 5 The content is about 20%, put it into the reaction tank, add 0.2m hydrochloric acid with a mass fraction of 23% 3 Carry out acidolysis, add 7L mass fraction after 20 minutes under stirring condition and be the Na of 6% 2 S solution carries out pre-removal of impurities, then adds 0.1wt% flocculant 3.5L flocculation precipitation, then filters; With volume percentage, N235: isooctyl alcohol: kerosene=15%: 15%: 70% mixed solvent is carried out to filtrate Extraction and iron removal, extraction temperature is 20~30 ℃, extraction phase: water phase=1:1, the obtained raffinate water phase is dilute phosphoric acid for iron removal; then, by volume ratio, tributyl phosphate: kerosene=1:1 Mixed solvent carries out ten-stage extraction to dilute phosphoric acid for iron removal, and extraction temperature is 20~30 ℃, and water phase during extraction: organic phase=1: 5; Carry out five-stage washing to the organic phase that e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com