Preparation method of Baccaurea ramiflora extract

A wood milk fruit and extract technology is applied in the field of preparation of wood milk fruit extract, which can solve the problems of low extraction rate and efficiency, single component and the like, and achieve the effects of uniform particle size, prolonging storage period and improving impurity removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

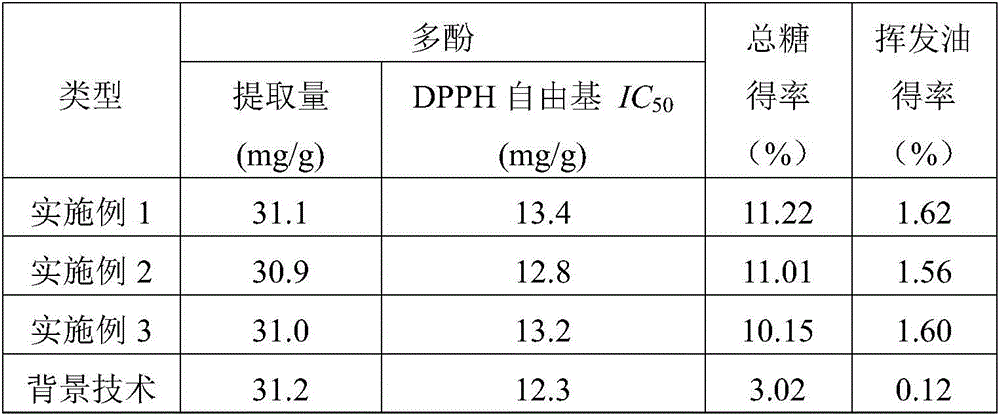

Examples

Embodiment 1

[0030] A preparation method of cayenne fruit extract, comprising the following steps:

[0031] 1) Wash and sterilize the air-dried sakigo fruit, crush it into 120 meshes, and dry it at 60°C for 18 minutes, add 70% ethanol that is 8 times the weight of the dried sakigo fruit and stir, stir for 8 minutes and use colloid Grinding for 35 minutes;

[0032] 2) Keep the feed liquid obtained in step 1) at a temperature of 45° C., and adjust the pH to 5. At the same time, add a compound enzyme that accounts for 0.3% of the weight of the fruit after drying for 1.5 hours, wherein the compound enzyme is composed of 4 wt. Parts of cellulase and 3 parts by weight of pectinase are mixed;

[0033] 3) Keep the enzymolysis solution obtained in step 2) at 105°C for 8 minutes to sterilize, then place it at an ultrasonic frequency of 45kHz and a temperature of 35°C for ultrasonic extraction, extract for 15 minutes, and filter to obtain filtrate 1 and filter residue 1, which are set aside;

[003...

Embodiment 2

[0042] A preparation method of acacia fruit extract, comprising the following steps:

[0043]1) Wash and sterilize the air-dried sakigo fruit, crush it into 100 meshes, and dry it at 60°C for 15 minutes, then add 60% ethanol that is 5 times the weight of the dried sakigo fruit and stir, stir for 5 minutes, and use colloid Grinding for 30 minutes;

[0044] 2) Keep the feed liquid obtained in step 1) at a temperature of 40° C., and adjust the pH to 4. At the same time, add 0.2% of the weight of the dried fruit of Mumilia fruit for enzymolysis for 1 hour, wherein the compound enzyme is composed of 3 parts by weight Cellulase and 2 parts by weight of pectinase are mixed;

[0045] 3) Keep the enzymolysis solution obtained in step 2) at 100°C for 6 minutes to sterilize, then place it at an ultrasonic frequency of 40kHz and a temperature of 30°C for ultrasonic extraction, extract for 10 minutes, and filter to obtain filtrate 1 and filter residue 1, which are set aside;

[0046] 4) ...

Embodiment 3

[0054] A preparation method of cayenne fruit extract, comprising the following steps:

[0055] 1) Wash and sterilize the air-dried sakigo fruit, crush it into 120 meshes, and dry it at 60°C for 20 minutes, add 80% ethanol which is 10 times the weight of the dried sakigo fruit and stir, stir for 10 minutes and use colloid Grinding for 40 minutes;

[0056] 2) Keep the feed liquid obtained in step 1) at a temperature of 50° C., and adjust the pH to 6, and simultaneously add 0.4% of the weight of the dried fruit of Mumilia fruit for enzymolysis for 2 hours, wherein the compound enzyme is composed of 5 parts by weight Cellulase and 4 parts by weight of pectinase are mixed;

[0057] 3) Keep the enzymolysis solution obtained in step 2) at 110°C for 10 minutes to sterilize, then place it at an ultrasonic frequency of 50kHz and a temperature of 40°C for ultrasonic extraction, extract for 20 minutes, and filter to obtain filtrate 1 and filter residue 1, which are set aside;

[0058] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com