Preparation method of ganoderma lucidum polysaccharide with high yield

A high-yield technology of ganoderma polysaccharides, applied in the field of preparation of ganoderma polysaccharides, can solve the problems of not considering the recovery of water-soluble ganoderma polysaccharides, limited extraction rate, waste of resources, etc., and achieve high yield, low extraction temperature and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

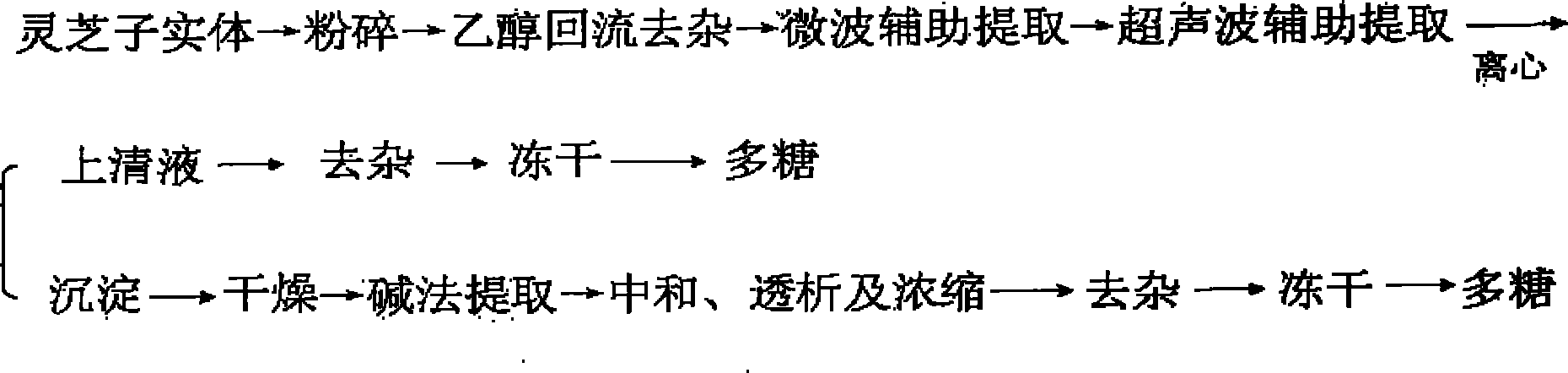

Method used

Image

Examples

Embodiment 1

[0038] (1) Use red ganoderma lucidum fruiting bodies as raw materials to carry out ultrafine pulverization treatment to obtain red ganoderma powder with a particle size of about 150 meshes. Red ganoderma powder is refluxed twice with 90% ethanol at 80° C. for 3 hours each time. The ratio of solid to liquid is 1:15 (g / ml), then centrifuged to remove the supernatant, and the resulting precipitate is dried in an oven at 60°C for 5 hours to obtain Ganoderma lucidum from which alcohol-soluble components, some monosaccharides, oligosaccharides and lipid substances have been removed pink.

[0039] (2) Accurately weigh 5g of red Ganoderma lucidum powder, wherein the moisture content of red Ganoderma lucidum powder is 13.26%, with water as solvent, the solid-liquid ratio of red Ganoderma lucidum powder and water is 1: 25 (g / ml), first use microwave assisted Hot water extraction followed by ultrasonic-assisted hot water extraction of water-soluble Ganoderma lucidum polysaccharides. Amo...

Embodiment 2

[0042] (1) Use red ganoderma lucidum fruiting body as raw material to carry out superfine pulverization treatment to obtain red ganoderma powder with a particle size of about 200 mesh. The ratio of solid to liquid is 1:20 (g / ml), then centrifuged to remove the supernatant, and the resulting precipitate is dried in an oven at 60°C for 5 hours to obtain Ganoderma lucidum from which alcohol-soluble components, some monosaccharides, oligosaccharides and lipid substances have been removed pink.

[0043] (2) Accurately weigh 5g of red Ganoderma lucidum powder, wherein the moisture content of red Ganoderma lucidum powder is 13.26%, with water as solvent, the solid-liquid ratio of red Ganoderma lucidum powder and water is 1: 20 (g / ml), first adopt microwave-assisted Hot water extraction followed by ultrasound-assisted hot water extraction of water-soluble Ganoderma lucidum polysaccharides. Among them, the microwave extraction conditions are: microwave power 400W, extraction time 4min...

Embodiment 3

[0046] (1) Use red ganoderma lucidum fruiting body as raw material to carry out ultrafine pulverization treatment to obtain red ganoderma powder with a particle size of about 100 mesh, red ganoderma powder is refluxed with 95% ethanol at 75°C for 2 times, each time for 3 hours, the mixture of red ganoderma powder and ethanol The ratio of solid to liquid is 1:18 (g / ml), then centrifuged to remove the supernatant, and the resulting precipitate is dried in an oven at 60°C for 5 hours to obtain Ganoderma lucidum from which alcohol-soluble components, some monosaccharides, oligosaccharides and lipid substances have been removed pink.

[0047] (2) Accurately weigh 5g of red Ganoderma lucidum powder, wherein the moisture content of red Ganoderma lucidum powder is 13.26%, with water as solvent, the solid-liquid ratio of red Ganoderma lucidum powder and water is 1: 15 (g / ml), first adopt microwave-assisted Hot water extraction followed by ultrasound-assisted hot water extraction of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com