Weeding and tilling depth adjusting method, device and system, computer equipment and storage medium

An adjustment method and weeding machine technology, applied in the field of weeding and tillage depth adjustment, can solve the problems of feedback, failure to realize automatic identification of weed density and position in the field, etc., so as to improve the efficiency of weeding, reduce the intensity of manual operation, and improve the rate of weed removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

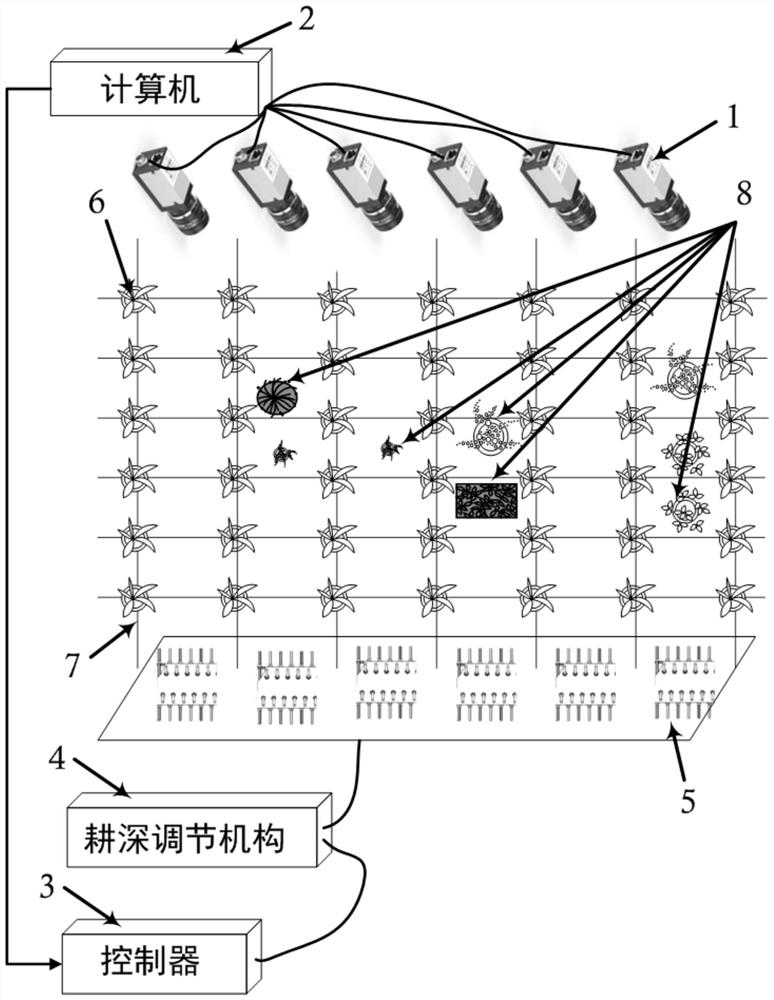

[0062] Such as figure 1 Shown, the present embodiment provides a kind of weeding depth adjustment system, and this system is applied to cultivating weeder, and it comprises industrial camera 1, speed sensor (not shown in the figure) and computer 2, industrial camera 1, speed sensor and The computer 2 realizes the machine vision detection technology. The industrial camera 1 and the speed sensor are installed at the front of the cultivator and weeder, and are respectively connected to the computer 2. The working camera 1 is used to capture images of rice seedling crop rows, and the speed sensor is used to detect the intertillage and weeding Whether the machine is walking or not and the speed of the cultivator and weeder, the computer 2 is used to process the image of the rice seedling crop row to obtain the weed density and position information; Camera 1 can still shoot normally, and this system can also comprise ring light source (not shown in the figure), and this ring light s...

Embodiment 2

[0084] Such as Image 6 As shown, the present embodiment provides a device for adjusting the depth of tillage for weeding. The device includes an acquisition module 601, a delineation module 602, a division and recording module 603 and an adjustment module 604. The specific functions of each module are as follows:

[0085] The acquiring module 601 is configured to acquire crop row images of rice seedlings at time intervals calculated according to the driving speed of the cultivator weeding machine.

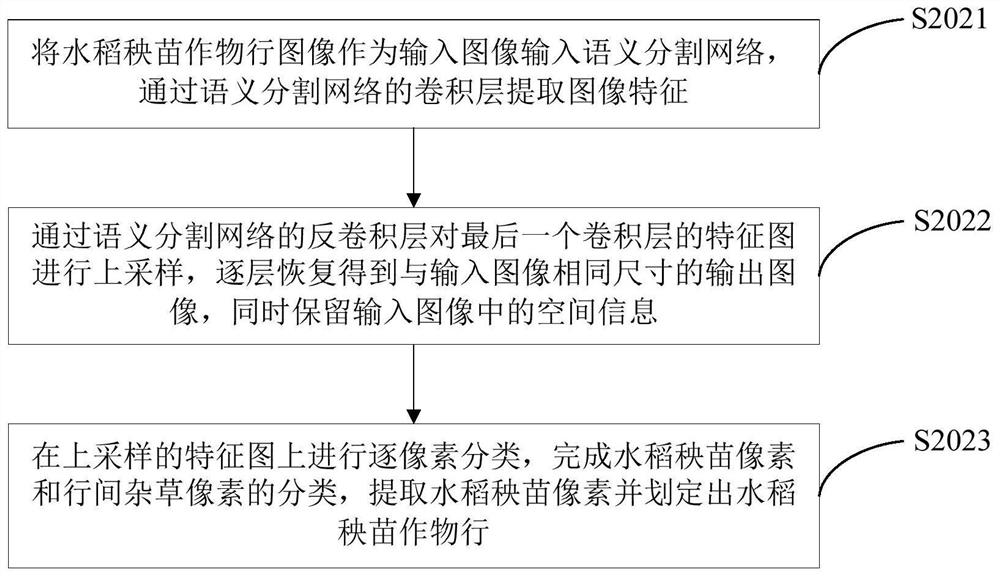

[0086] The delineation module 602 is used to complete the semantic segmentation of rice seedling pixels and inter-row weed pixels on the rice seedling crop row image, and delineate the rice seedling crop rows according to the rice seedling pixels.

[0087] The division and recording module 603 is used to classify the density of weeds according to the weed pixel value in the rice seedling crop row, and record the position information of the weeds on the rice seedling crop row image...

Embodiment 3

[0095] This embodiment provides a computer device, which can be a computer, such as Figure 8 As shown, a processor 802, a memory, an input device 803, a display 804 and a network interface 805 are connected through a system bus 801, the processor is used to provide computing and control capabilities, and the memory includes a non-volatile storage medium 806 and an internal memory 807, the non-volatile storage medium 806 stores an operating system, a computer program, and a database, the internal memory 807 provides an environment for the operation of the operating system and the computer program in the non-volatile storage medium, and the processor 802 executes the During computer program, realize the weeding deep-plow adjustment method of above-mentioned embodiment 1, as follows:

[0096] According to the time interval calculated by the driving speed of the cultivator and weeder, the image of the rice seedling crop row is obtained;

[0097] Complete the semantic segmentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com