Wrapping isolation type lubricating oil regeneration process

A lubricating oil and isolation technology, applied in the field of lubricating oil, can solve the problems of low quality of regenerated lubricating oil, slow impurity flocculation process, low regeneration efficiency, etc., to ensure the removal rate of impurities, avoid the content of impurities, and improve the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

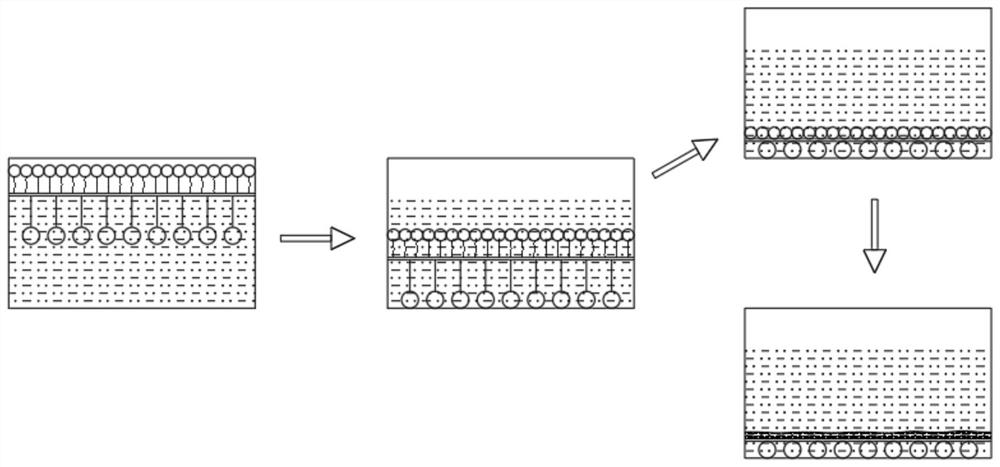

[0046] see figure 1 , a wrapping isolation type lubricating oil regeneration process, comprising the following steps:

[0047] S1. First add the recovered lubricating oil to the flocculant, and then let it stand for 0.5-1h;

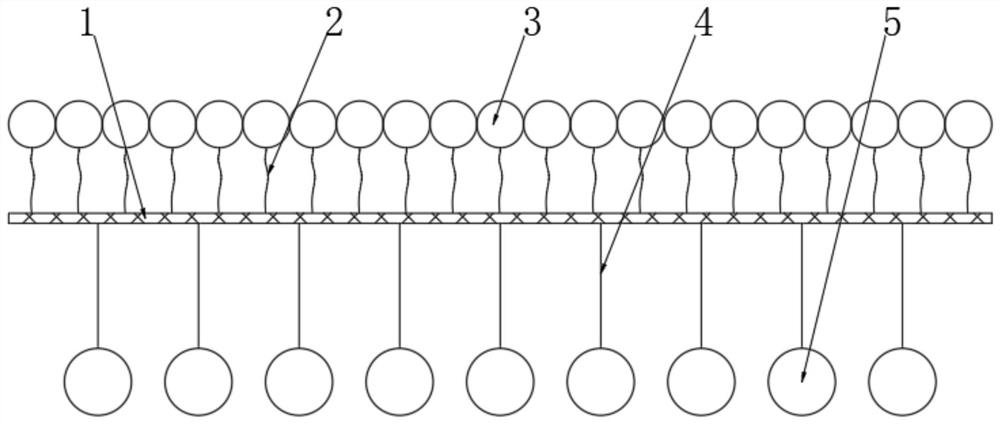

[0048] S2. Place the counter-ball net plate on the lubricating oil liquid surface, and press down, so that the counter-ball net plate gradually approaches the bottom of the lubricating oil. During the second process, the impurities in the lubricating oil are gradually squeezed and concentrated at the bottom;

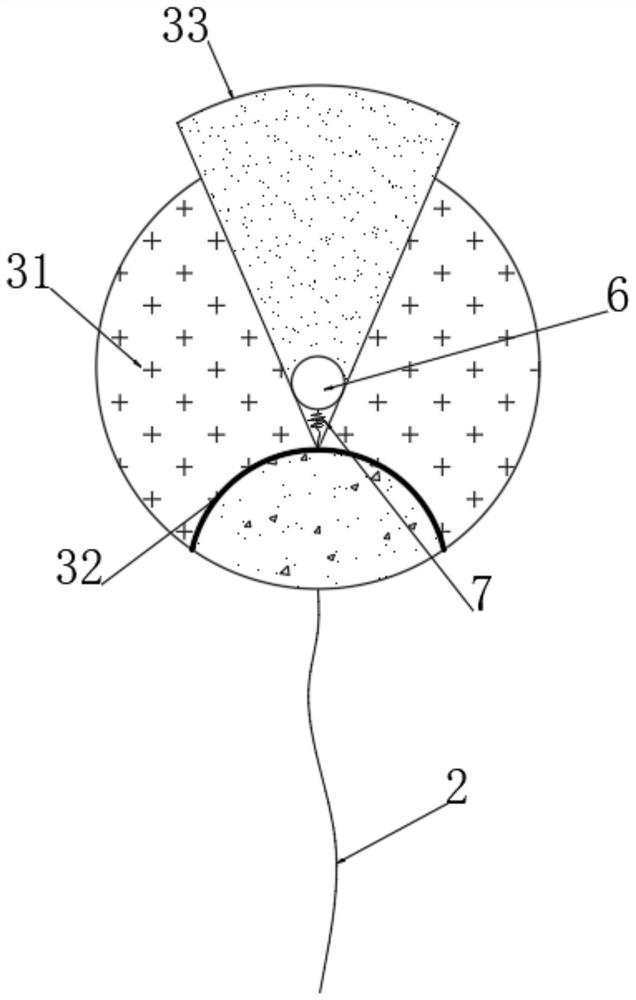

[0049] S3. When the opposing net plate touches the bottom, continue to press down until the multiple hot-collapsed floating balls on the opposing net plate gradually approach the middle of the opposing net plate and cling to the top of the opposing net plate;

[0050] S4. Heating the lubricating oil, causing the hot-collapsed floating ball to gradually collapse and wrap it on the opposing net plate, so that the lubricating oil and the impurities in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com