Method for recovering iron, vanadium and titanium from schreyerite through shaft furnace reduction and electric furnace smelting and separating deep reduction

A technology for vanadium-titanium ore and iron recovery, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of long reduction time, road transportation pressure, economic waste, etc., achieve high smelting efficiency, reduce dependence, and improve recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

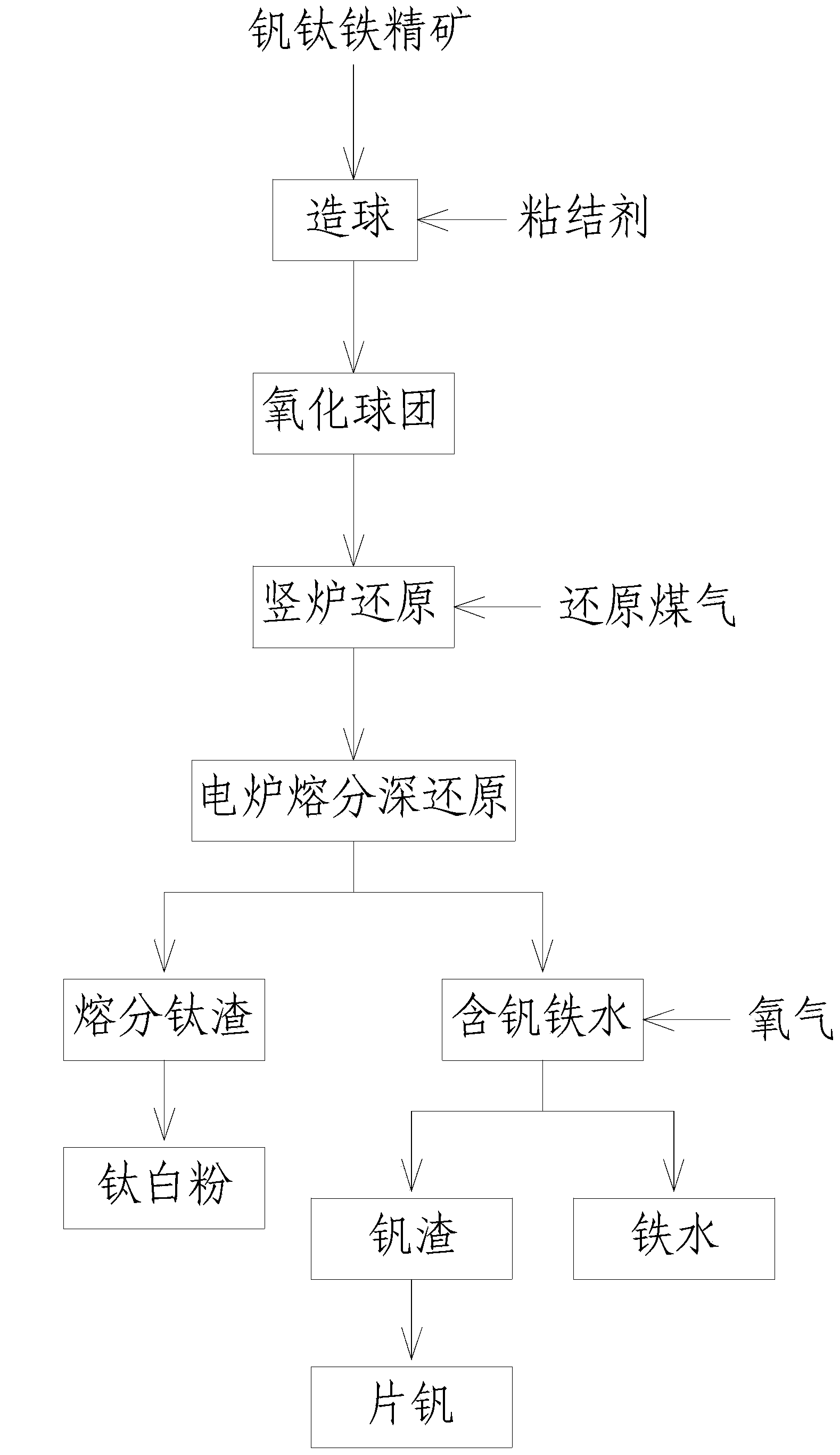

[0020] Embodiment 1: As shown in the figure, the method of shaft furnace reduction of vanadium-titanium ore in this embodiment-electric furnace melting deep reduction to recover iron, vanadium and titanium includes the production of vanadium-titanium oxide pellets, direct reduction of vanadium-titanium oxide pellets, metal Melting pelletizing electric furnace, extracting vanadium from molten iron containing vanadium, melting titanium slag to produce titanium dioxide and vanadium slag to produce V 2 o 5 ,

[0021] a. Production of vanadium-titanium oxide pellets: mix vanadium-titanium iron concentrate with binder and water to form pellets, in terms of mass percentage: vanadium-titanium iron concentrate with a particle size of less than 0.074 mm accounts for 80% %, in the mixed pelletizing raw material composed of vanadium-titanium iron concentrate, binder and water: binder accounts for 1.0%, water accounts for 6.5%; the diameter of the pellets is 10mm, and the pellets are preh...

Embodiment 2

[0033] Embodiment 2: The method of shaft furnace reduction of vanadium-titanium ore in this embodiment-electric furnace melting deep reduction to recover iron, vanadium and titanium, including production of vanadium-titanium oxide pellets, direct reduction of vanadium-titanium oxide pellets, and electric furnace melting of metallized pellets Extraction of vanadium from molten iron containing vanadium, melting titanium slag to produce titanium dioxide and vanadium slag to produce V 2 o 5 ,

[0034] a. Production of vanadium-titanium oxide pellets: Mix vanadium-titanium iron concentrate with binder and water to form pellets. In terms of mass percentage: vanadium-titanium iron concentrate with a particle size of less than 0.074 mm accounts for 82.5% of the vanadium-titanium iron concentrate %, in the mixed pelletizing raw material composed of vanadium-titanium iron concentrate, binder and water: binder accounts for 1.5%, water accounts for 7%; the diameter of the pellets is 15mm...

Embodiment 3

[0046] Embodiment 3: The method of shaft furnace reduction of vanadium-titanium ore in this embodiment-electric furnace melting deep reduction to recover iron, vanadium and titanium, including production of vanadium-titanium oxide pellets, direct reduction of vanadium-titanium oxide pellets, electric furnace melting of metallized pellets Extraction of vanadium from molten iron containing vanadium, melting titanium slag to produce titanium dioxide and vanadium slag to produce V 2 o 5 ,

[0047] a. Production of vanadium-titanium oxide pellets: Mix vanadium-titanium iron concentrate with binder and water to form pellets. In terms of mass percentage: vanadium-titanium iron concentrate with a particle size of less than 0.074 mm accounts for 85% %, in the mixed pelletizing raw material composed of vanadium-titanium iron concentrate, binder and water: binder accounts for 2.0%, water accounts for 7.5%; pellets;

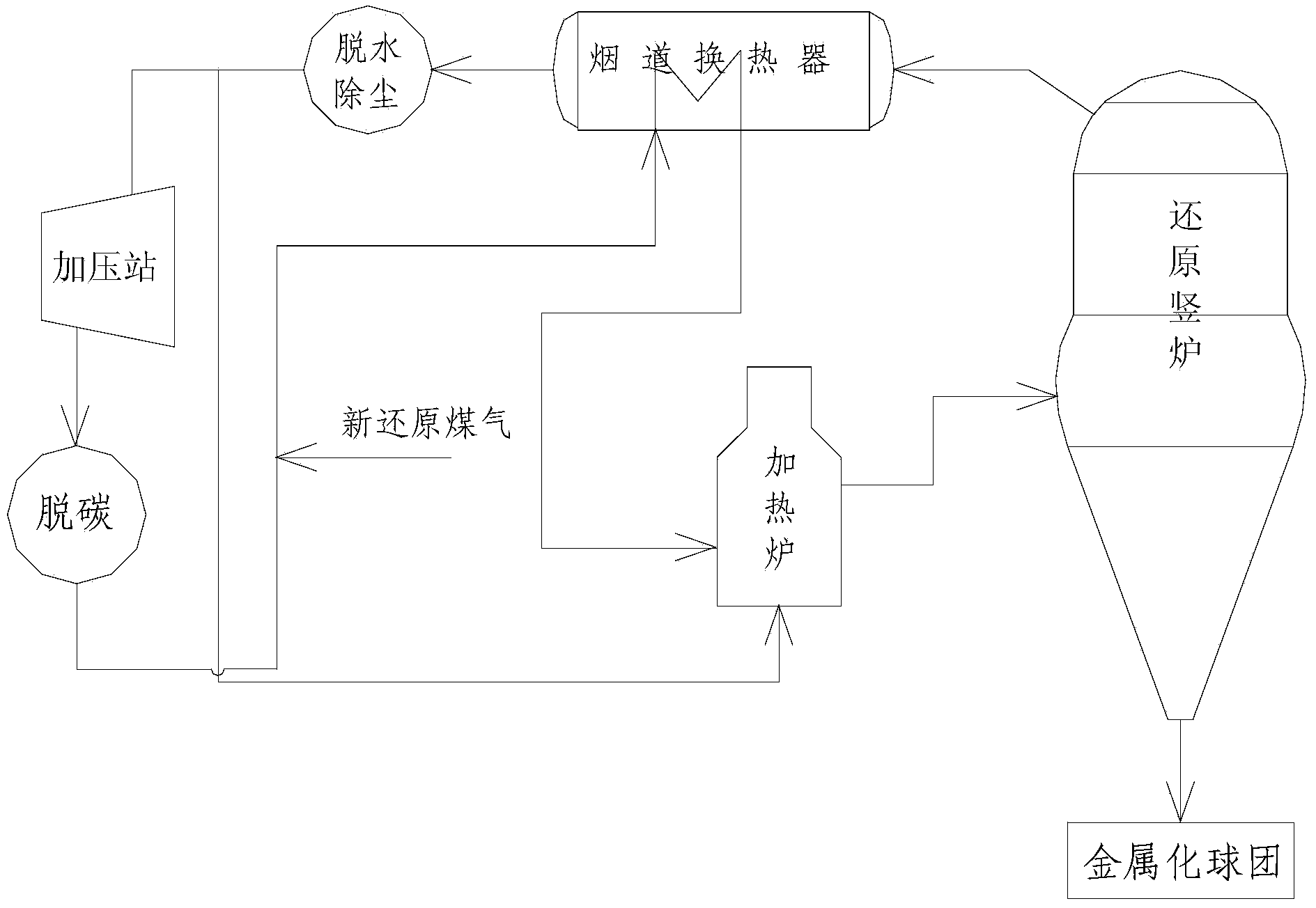

[0048] b. Direct reduction of vanadium-titanium oxide pellets: load ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com