Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Prevent burn through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

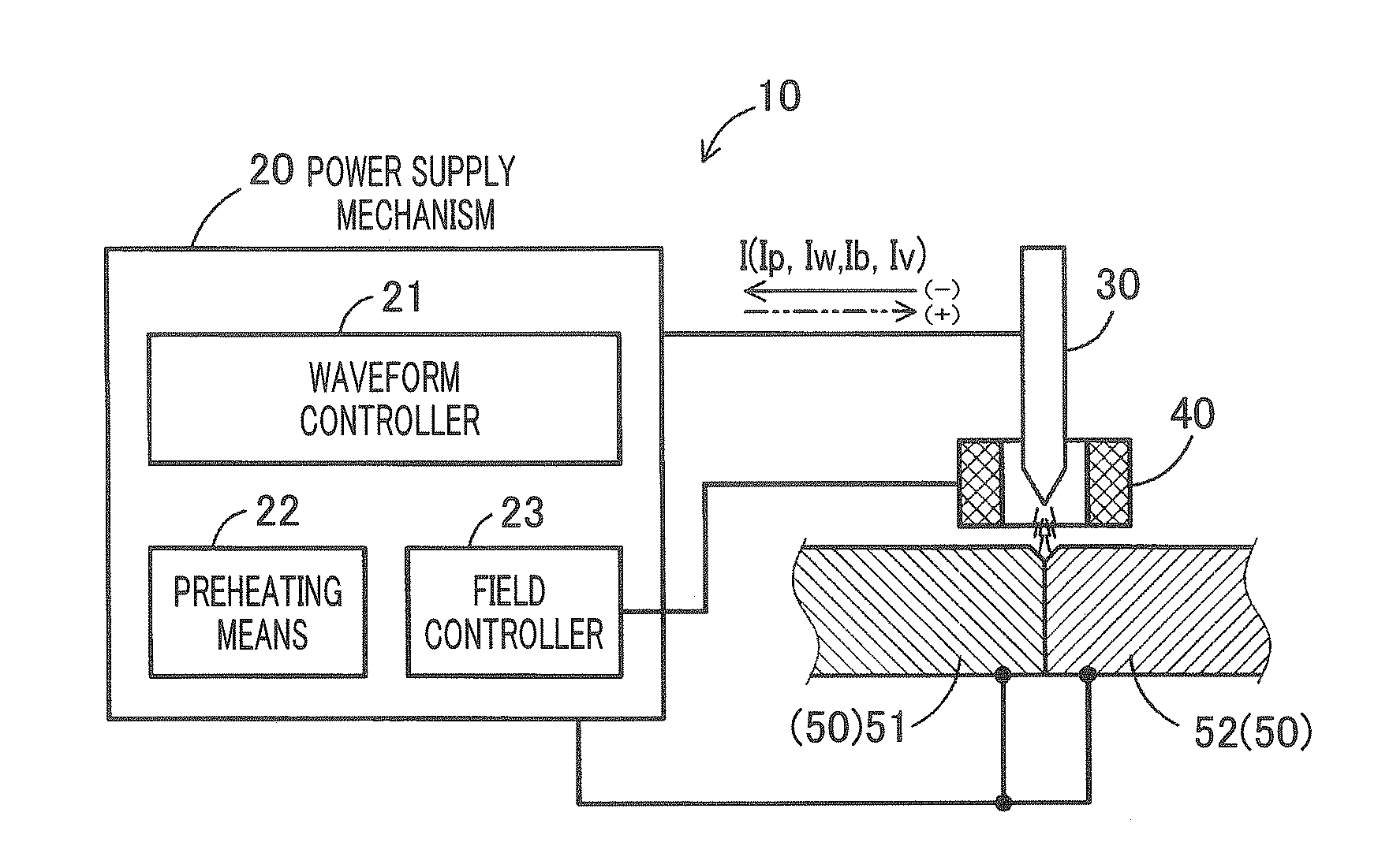

Arc welding method and arc welding apparatus

InactiveUS20110248007A1Suppress generationPrevent burn-throughArc welding apparatusWelding/soldering/cutting articlesElectric arcMetallic materials

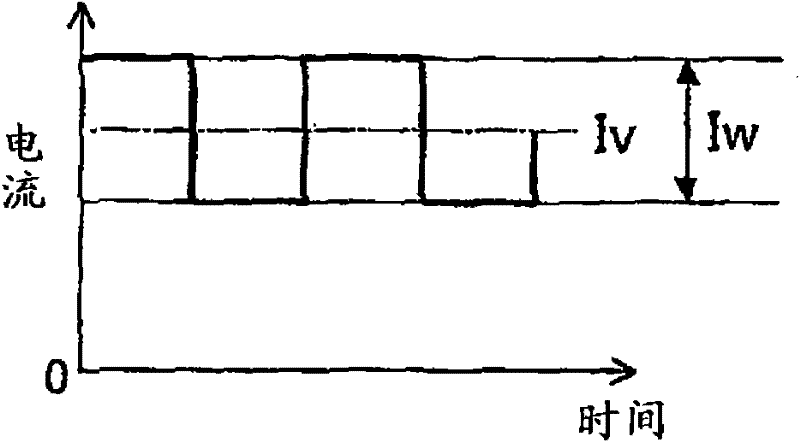

A base metal composed of a plurality of metallic materials having an oxygen content of 10 ppm is first preheated partly or overall. Then AC (alternating current) current is made to pass through the preheated base metal and an electrode so as to generate an arc for welding the metallic materials. The waveform of the current is changed with time between a peak current value and a base current value excluding a current of zero value only in one of plus and minus polarity sides of the current. A current ratio defined by dividing a current amplitude between the peak and base current values by a current average of the alternating current is a range of 0.5 to 2.0. The alternating current has a frequency of 500 Hz or higher.

Owner:DENSO CORP

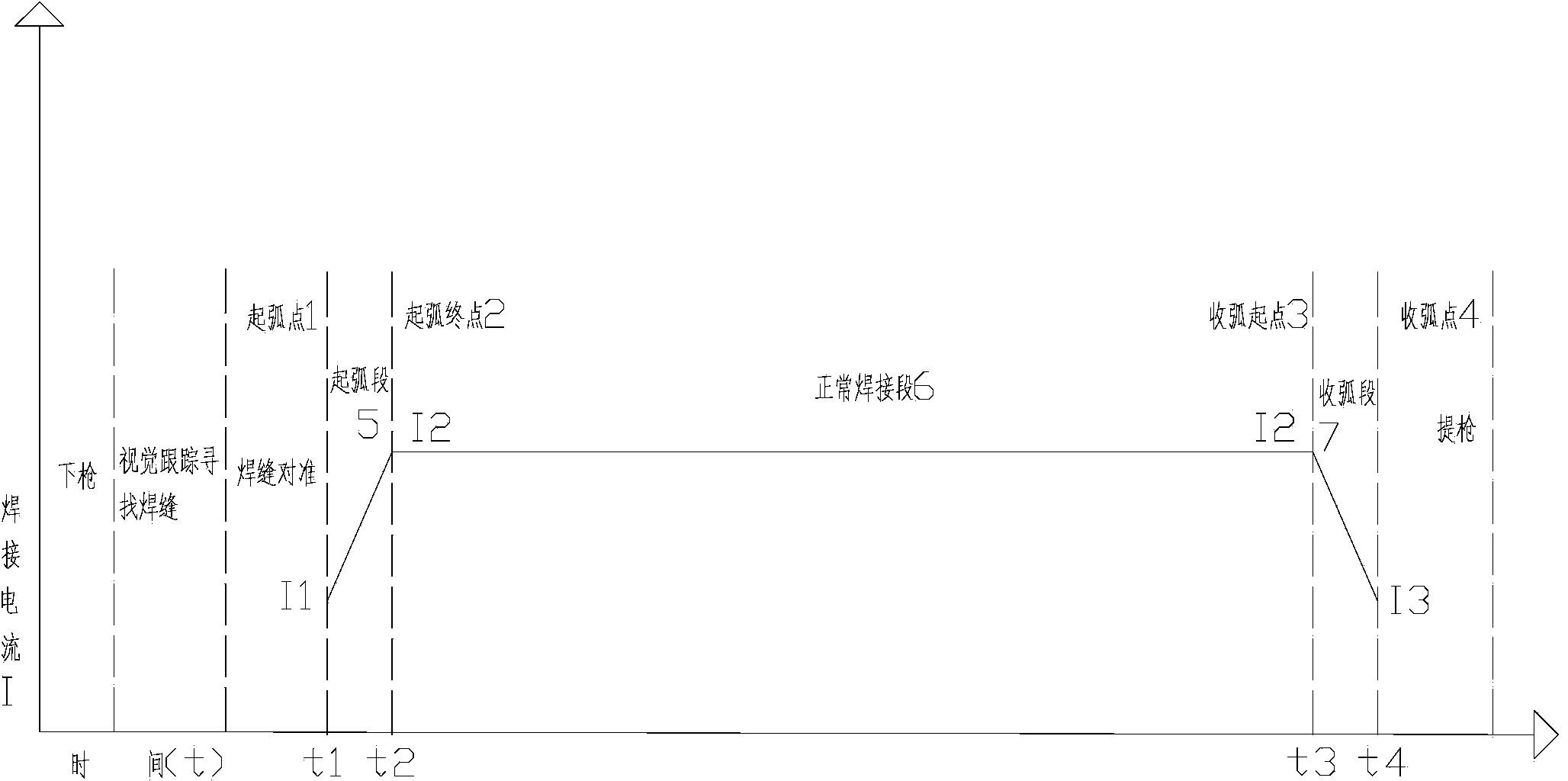

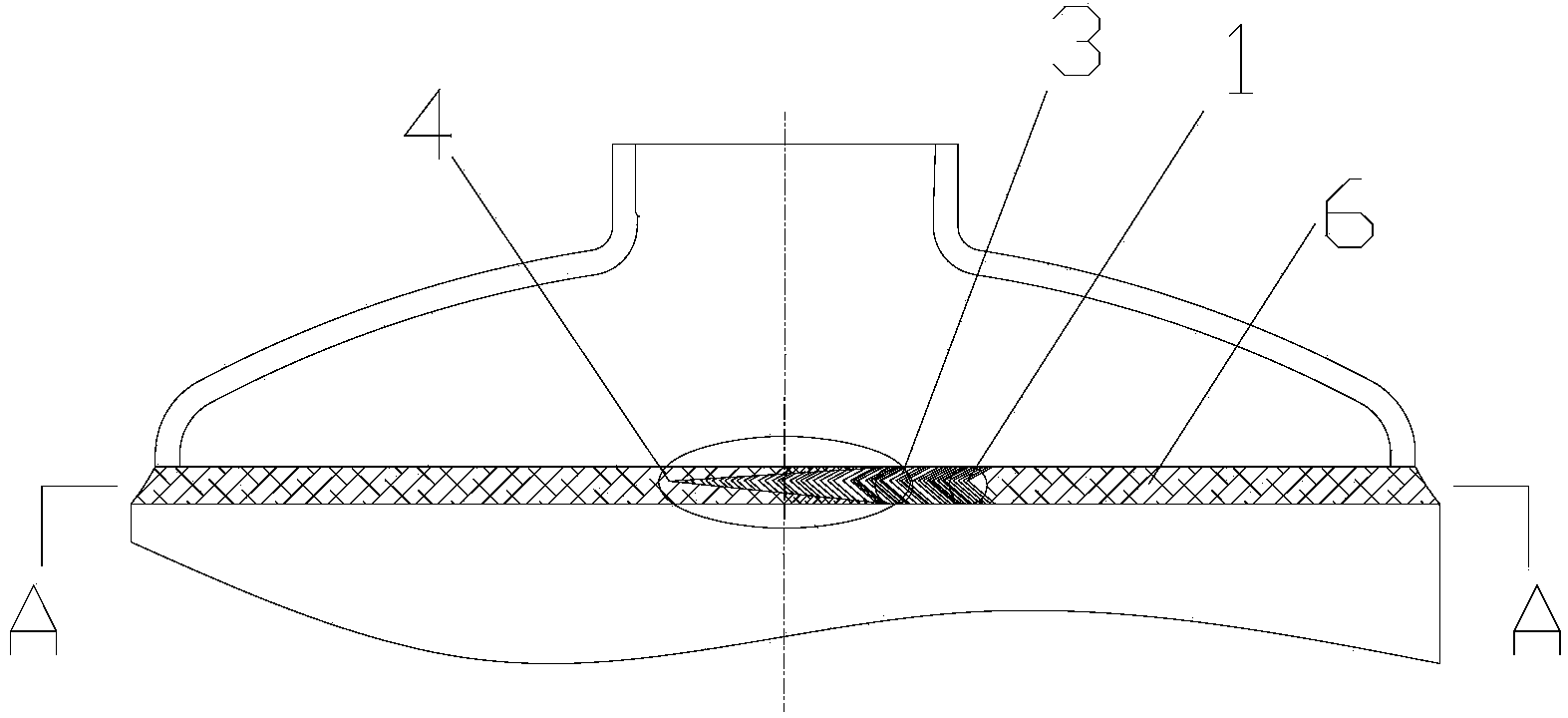

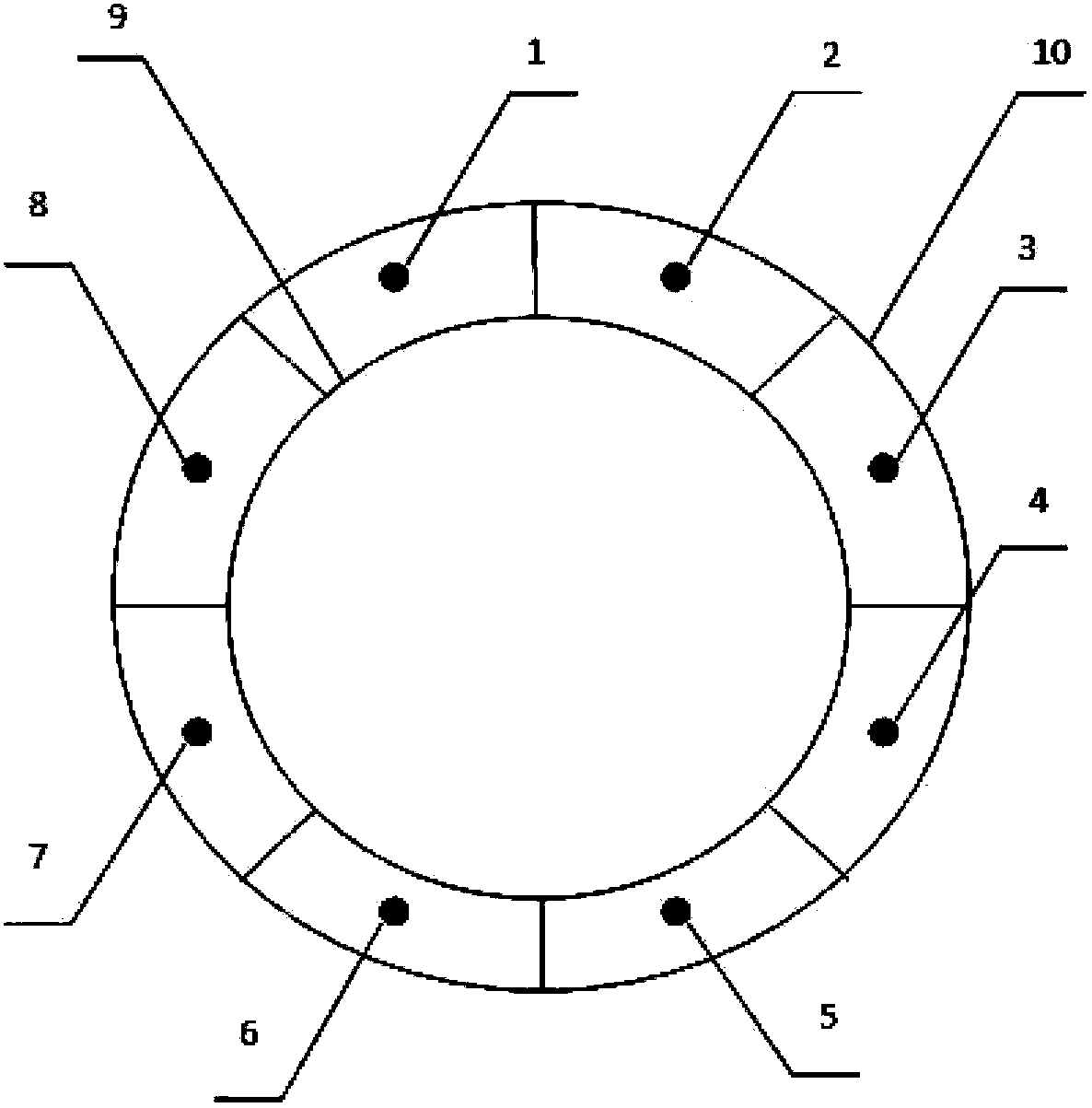

Annular welding method

ActiveCN103846528AQuality improvementGuaranteed weld tightnessElectrode supporting devicesPlasma welding apparatusEngineeringMechanical engineering

The invention relates to an annular welding method. A welding gun is adopted to realize welding; a welding line of a workpiece is annular. The annular welding method is characterized in that welding comprises arc striking, normal welding and arc stopping; the welding current of an arc striking section between an arc striking point and an arc striking end point and the welding current of an arc stopping section between an arc stopping start point and an arc stopping point are lower than that of the normal welding; furthermore, the welding line of the welding line from the arc striking point to the arc stopping point rotates around an angle which is larger than 360 degrees. Due to a research, the quality of the annular welding line is greatly improved by changing welding technical parameters by the adoption of soft arc striking and soft arc stopping, so that the welding sealing property of end-to-end overlapped sections of the welding line formed in the arc striking and the arc stopping is guaranteed; the problem of welding missing is avoided; meanwhile, the phenomenon of burnthrough during welding is avoided, and the end-to-end overlapped section of the welding line is smoothly transitioned. The annular welding method is particularly suitable for welding on a barrel body or a pipe body with a high sealing requirement.

Owner:佛山晓世科技服务有限公司

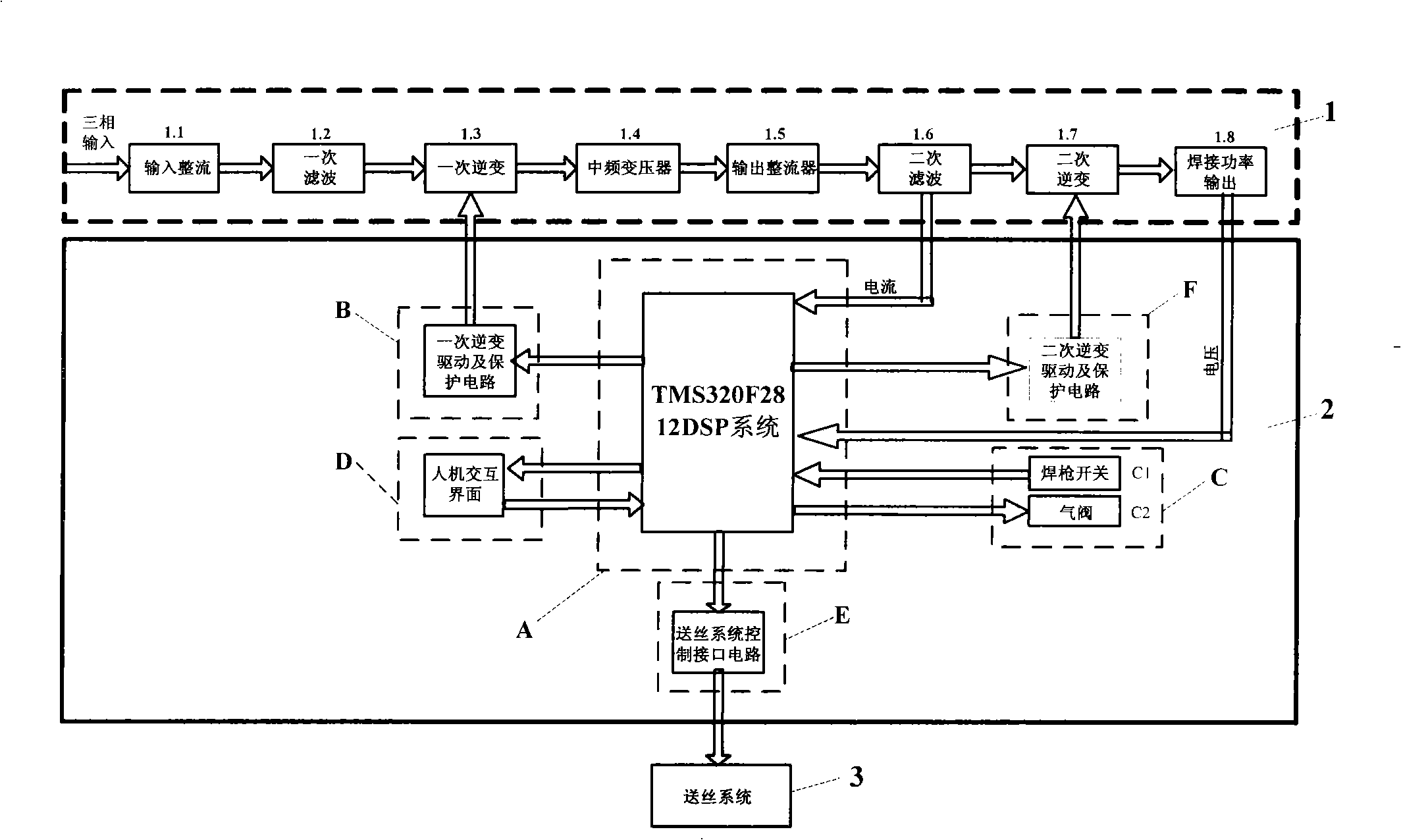

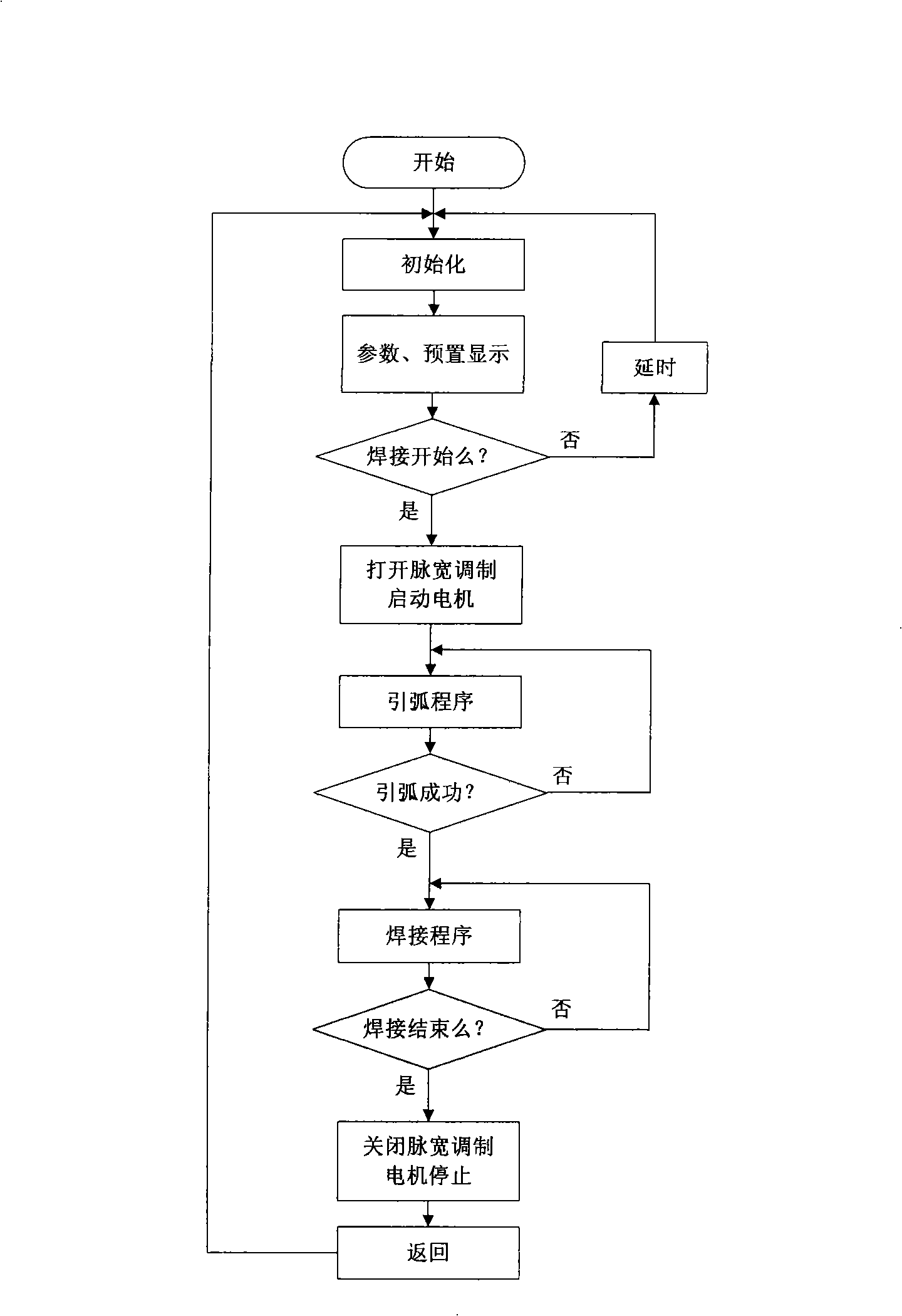

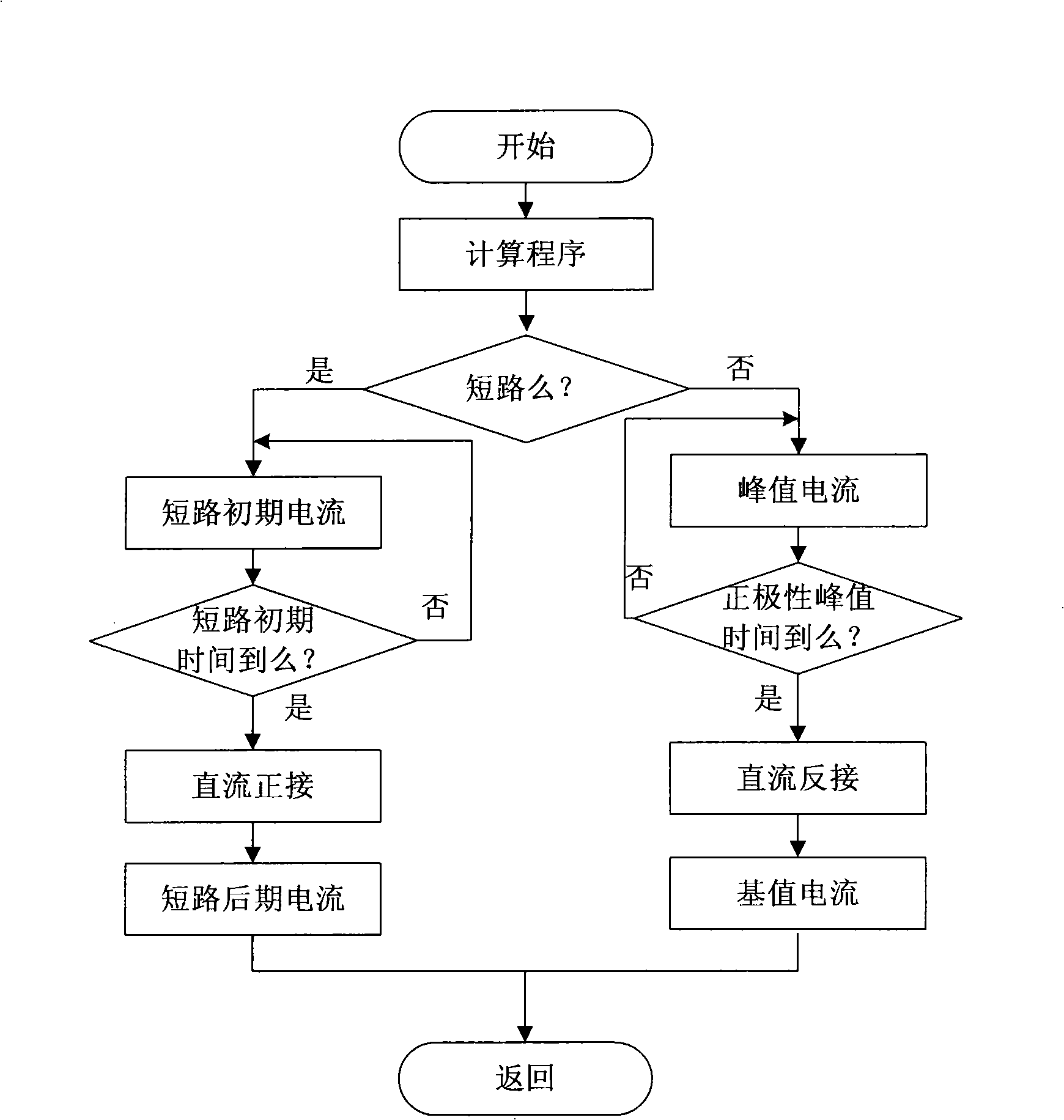

AC arc welding system and method thereof

InactiveCN101524781AReduce energy inputSimple and reliable processArc welding apparatusInterface circuitsWelding power supply

The invention relates to an AC arc welding system and a method thereof, belonging to the welding equipment and automation field. The system adopts a wire feeding mode of wire pushing and drawing. A power supply adopts an AC output mode. The system concretely comprises a welding power system and a wire feeding system. The welding power system mainly comprises a main circuit part (1) for providing power output for welding and a control circuit part (2) for controlling the output power of the main circuit. The wire feeding system adopts an AC servo motor as a wire feeding motor and controls an interface circuit (E) by the wire feeding system to receive signals sent by a DSP system (A). The wire feeding motor reciprocates to realize the wire pushing and drawing. Simultaneously, a welding power judges that the welding is in the short circuit / arcing state according to the feedback voltage to change the output polarity of the power. The droplet short circuiting transfer is finished under the function of welding pumpback tension. A small short circuit current is adopted. In addition, the straight polarity direct current is adopted at the arcing initial stage. More arc energy can be distributed to welding wires, and the heat input of base metal is lowered greatly.

Owner:BEIJING UNIV OF TECH

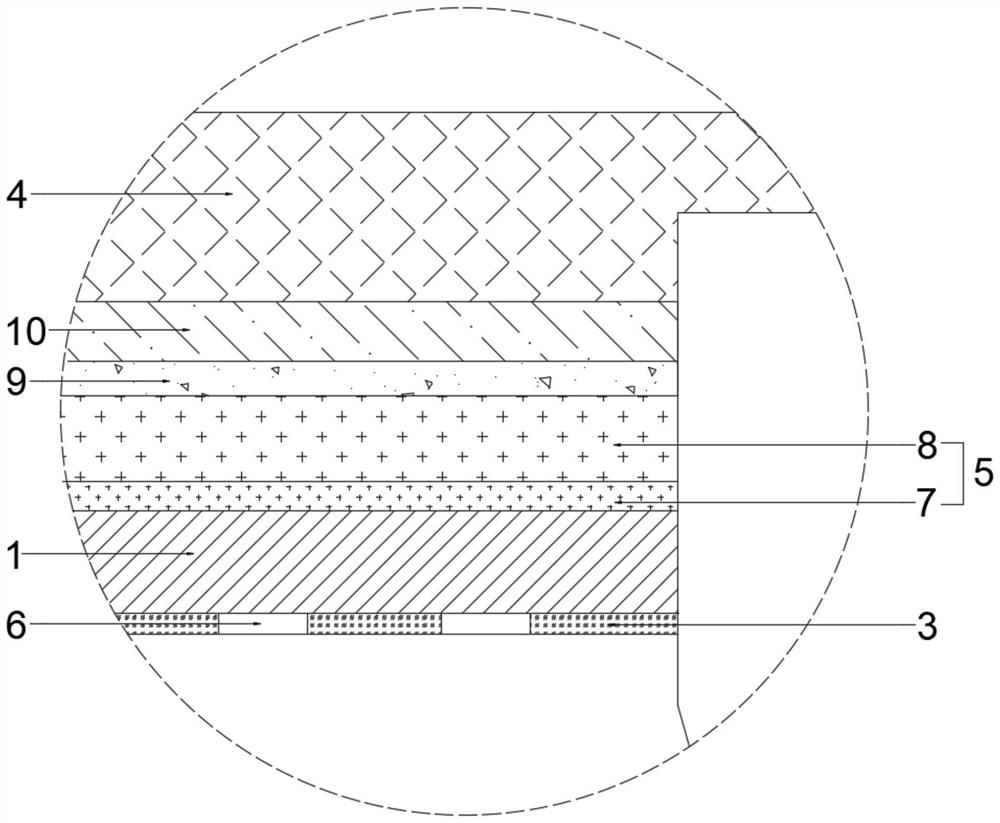

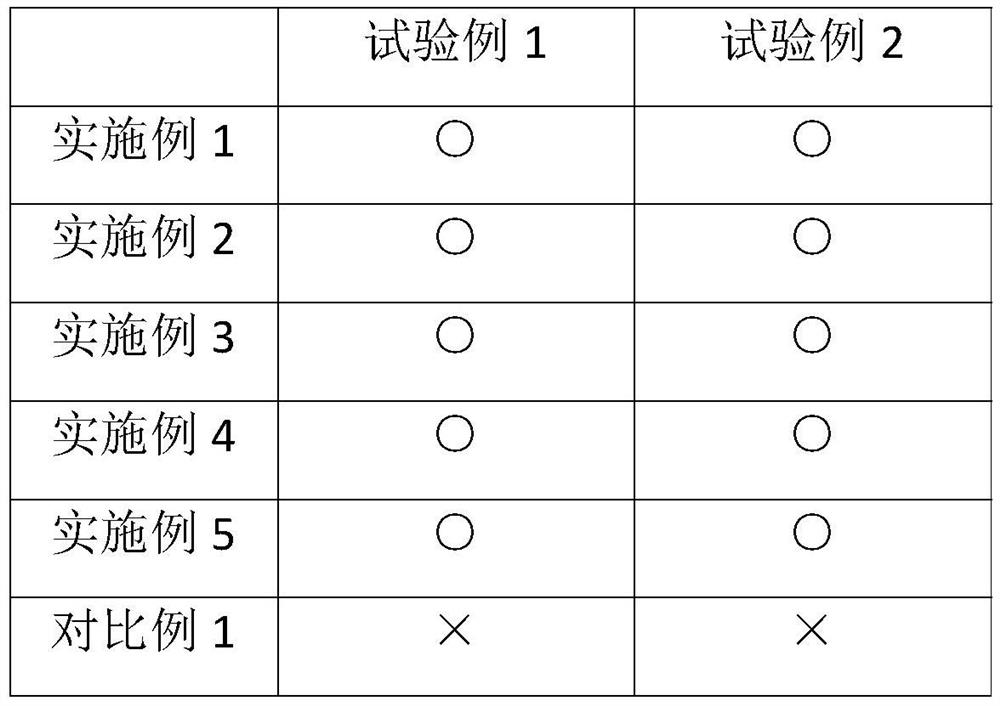

Front electrode silver paste of crystalline silicon solar battery and preparation method for front electrode silver paste

ActiveCN103021511AControl the degree of corrosionControl thicknessNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetallurgy

The invention provides front electrode silver paste of a crystalline silicon solar battery and a preparation method for the front electrode silver paste. The silver paste comprises the following components in reference to the total weight of the silver paste: 75 to 90 percent of silver powder, 1 to 3 percent of first glass powder, 1 to 5 percent of second glass powder and 6 to 25 percent of organic component, wherein the softening point of the first glass powder is 350 to 550 DEG C; the softening point of the second glass powder is 550 to 650 DEG C; and a difference between the softening point of the first glass powder and the softening point of the second glass powder is at least 70 DEG C. The invention also provides the preparation method for the electrode silver paste. The electrode silver paste can be sintered at a relatively wide sintering temperature range; and the obtained solar battery is low in series resistance and high in photoelectric conversion rate.

Owner:BYD CO LTD

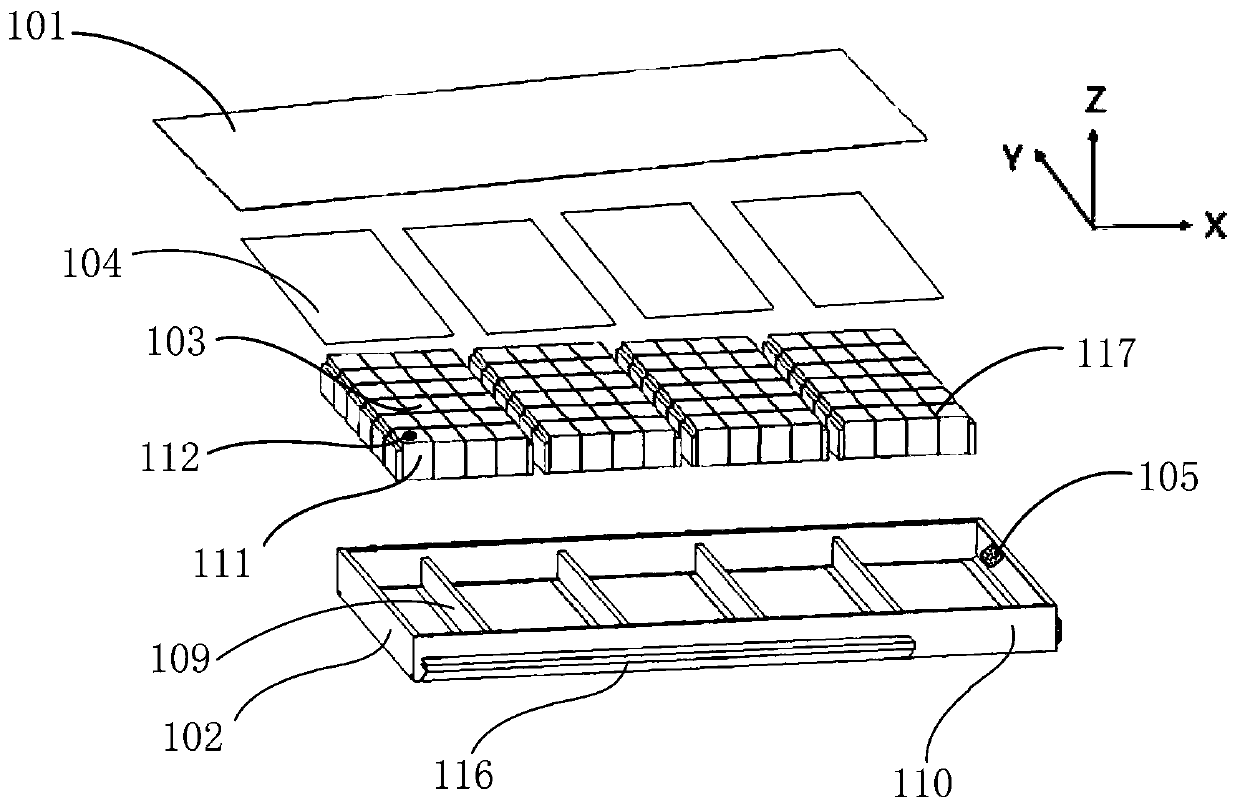

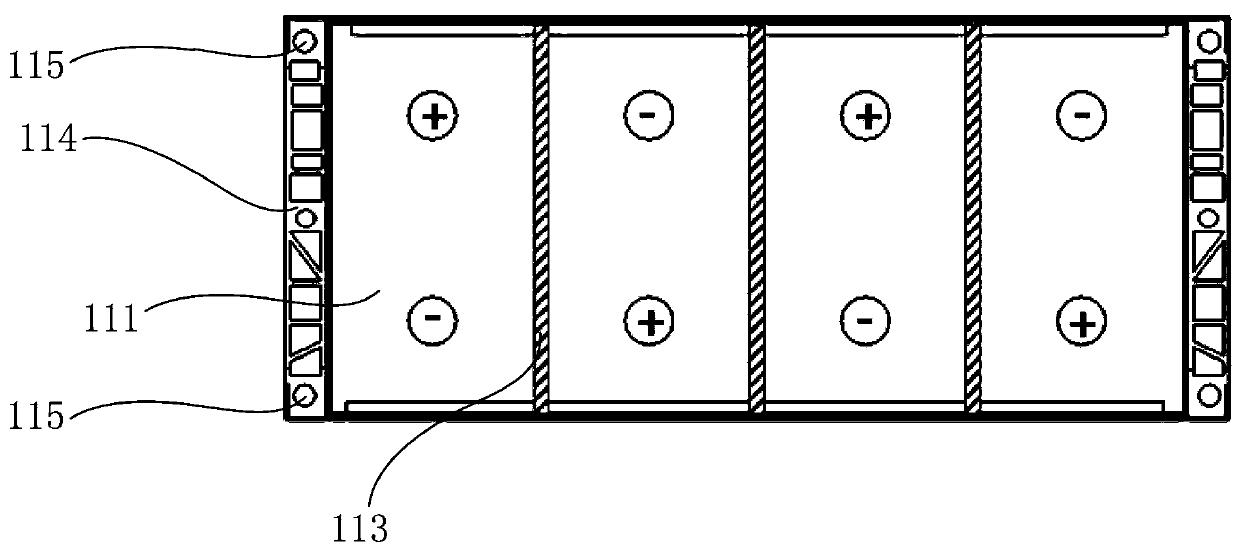

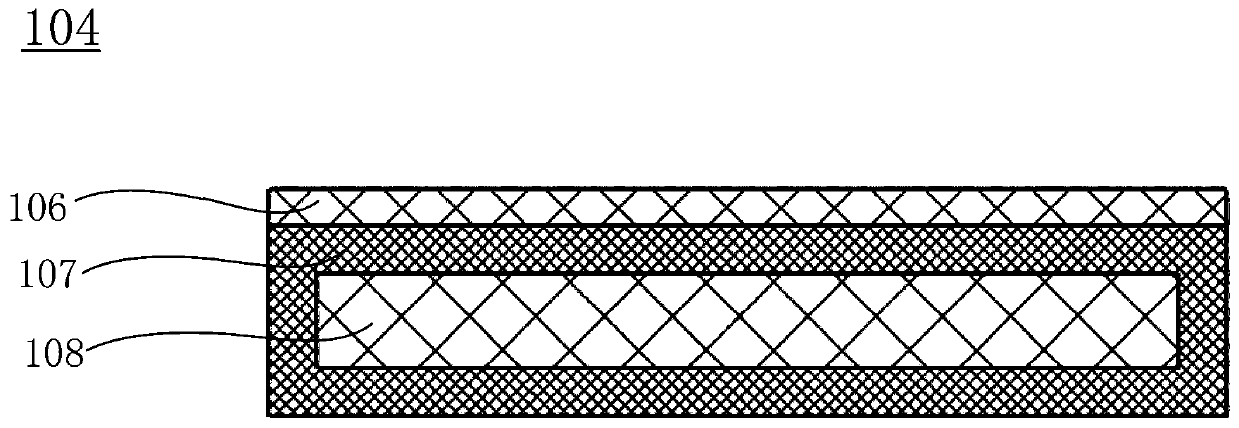

Power battery thermal protection system

PendingCN110828747AAvoid direct contactAvoid short circuit failureSecondary cellsFire rescueThermal runawayThermal insulation

The invention provides a power battery thermal protection system, which is used for carrying out thermal protection on a power battery pack. The power battery pack comprises an upper cover, a lower housing and a plurality of module integration modules which are located between the upper cover and the lower housing and are arranged in the first direction. The power battery thermal protection systemcomprises fireproof thermal insulation pads, which are arranged between the upper cover and the module integration modules, wherein the fireproof thermal insulation pads are in one-to-one correspondence with the module integration modules; and a battery pack explosion-proof valve, which is arranged on the inner side of at least one side edge, in the second direction, of the lower housing, whereinthe second direction is perpendicular to the first direction. The system realizes prolonging of time before the fire of a battery core breaks through a power battery housing when the battery core issubjected to thermal runaway due to heating, thereby leaving enough escape time for passengers, and guaranteeing the safety of the passengers.

Owner:AIWAYS AUTOMOBILE CO LTD

Manual arc welding bottoming layer Z-shaped arc extinction method and application thereof in Q460 high-strength steel horizontally-fixed steel pipe butt welding

ActiveCN102922085AFusion wellNo accumulationArc welding apparatusTubular articlesShielded metal arc weldingButt welding

The invention discloses a manual arc welding bottoming layer Z-shaped arc extinction method and application of the manual arc welding bottoming layer Z-shaped arc extinction method in Q460 high-strength steel horizontally-fixed steel pipe butt welding. An arcing point is located at a position of a root part of a groove 2 to 3mm close to a truncated edge, an electric arc is lightly led to an oblique rear part of a fusing tank along the groove after being struck and then transversely swung to the other side of the groove after a pause, act extinction is carried out towards the oblique rear part of an arcing point after fusing of the groove at the side is good through observation, and a running track of an end of a welding rod is Z-shaped. As the fusing tank can be well observed in a welding process, welding defects of a bottoming layer can be reduced and technical support is provided to ensure welding quality of the bottoming layer of a butt joint. With the adoption of the arc extinction method, shaping of the root part of a welding seam can be effectively controlled and a good welding seam structure can be obtained.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

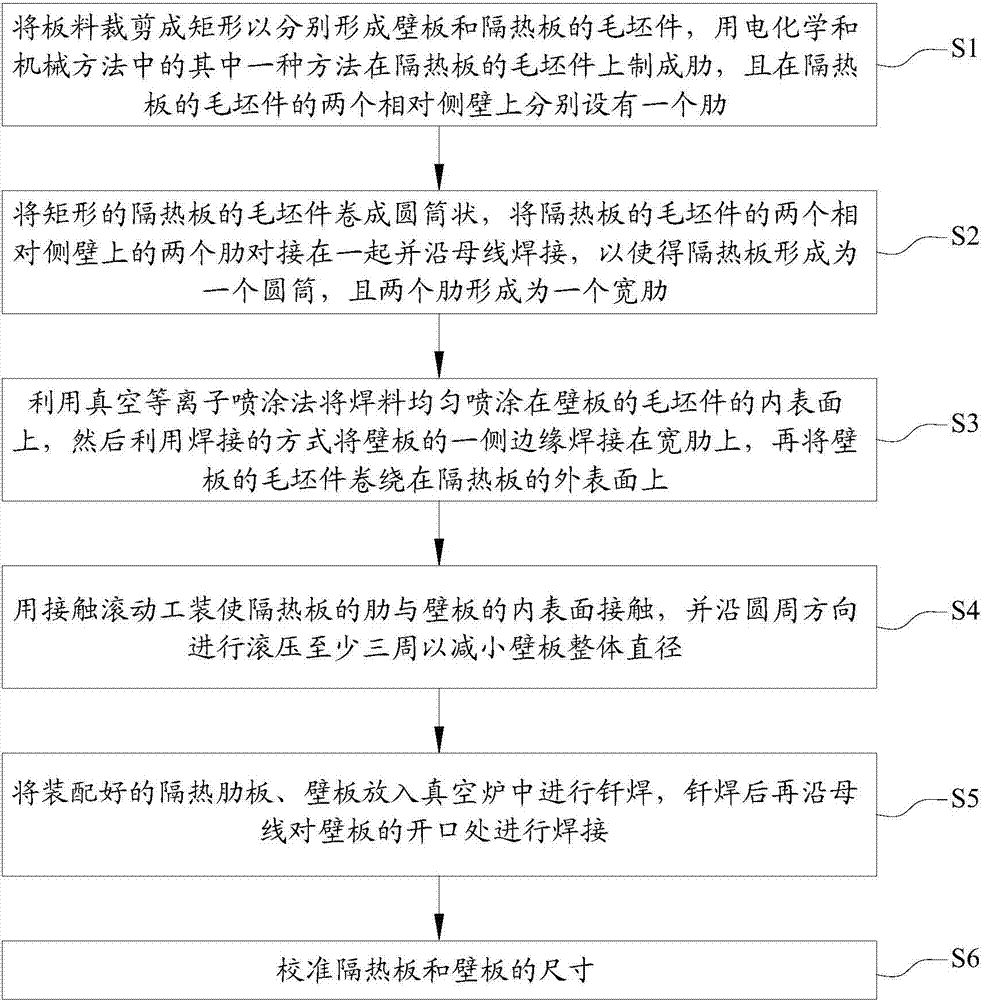

Method for producing aviation gas turbine engine combustion chamber burner inner liner

The invention discloses a method for producing an aviation gas turbine engine combustion chamber burner inner liner. The method comprises the following steps: S1, forming a blank part of a wall board and a blank part of a heat insulation board, and manufacturing ribs on the blank part of the heat insulation board; S2, rolling the blank part of the heat insulation board to be in a cylinder shape, enabling the two ribs on the two opposite side walls of the blank part of the heat insulation board to be in butt joint and be welded to from a wide rib; S3, spraying a welding flux on the inner surface of the wall board, welding one side edge of the wall board on the wide rib, and winding the blank part of the wall board on the outer surface of the heat insulation board in a rolling mode; S4, using a contact rolling tool for enabling the ribs of the heat insulation board to be in contact with the inner surface of the wall board; S5, placing the assembled heat insulation board and the wall board into a vacuum furnace to be brazed, and then welding the position of an opening in the wall board along the generatrix; S6, correcting the size of the heat insulation board and the size of the wall board. According to the method, a slot can be prevented from being decreased and even blocked, and the burner inner liner can be prevented from being burnt ablated and even burnt through due to overheating.

Owner:BEIJING POWER MACHINERY INST

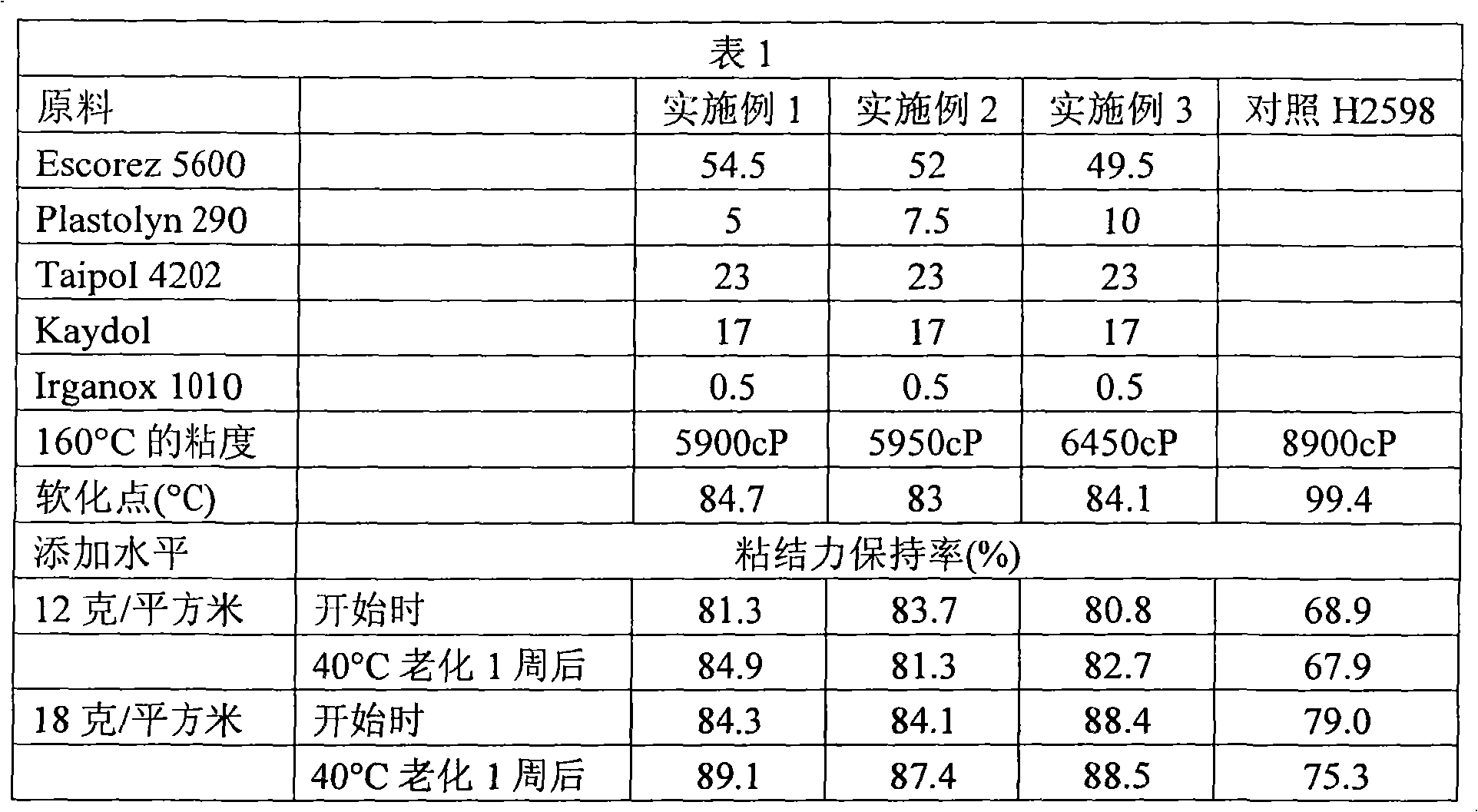

High styrene sbs hot melt adhesive

Multipurpose hot melt adhesive compositions which are suitable for use as both a construction and elastic attachment adhesive for disposable soft goods, such as disposable diapers, feminine sanitary napkins, surgical drapes, hospital pads, and adult incontinent products. The multipurpose hot melt adhesive compositions have a high level of creep resistance, high bond strength, and relatively low viscosity, and are composed of endblock resin in combination with a linear styrene- butadiene-styrene (SBS) copolymer wherein the copolymer has a styrene content greater than about 35% by weight, and preferably about 38% to about 50% by weight.

Owner:BOSTIK INC

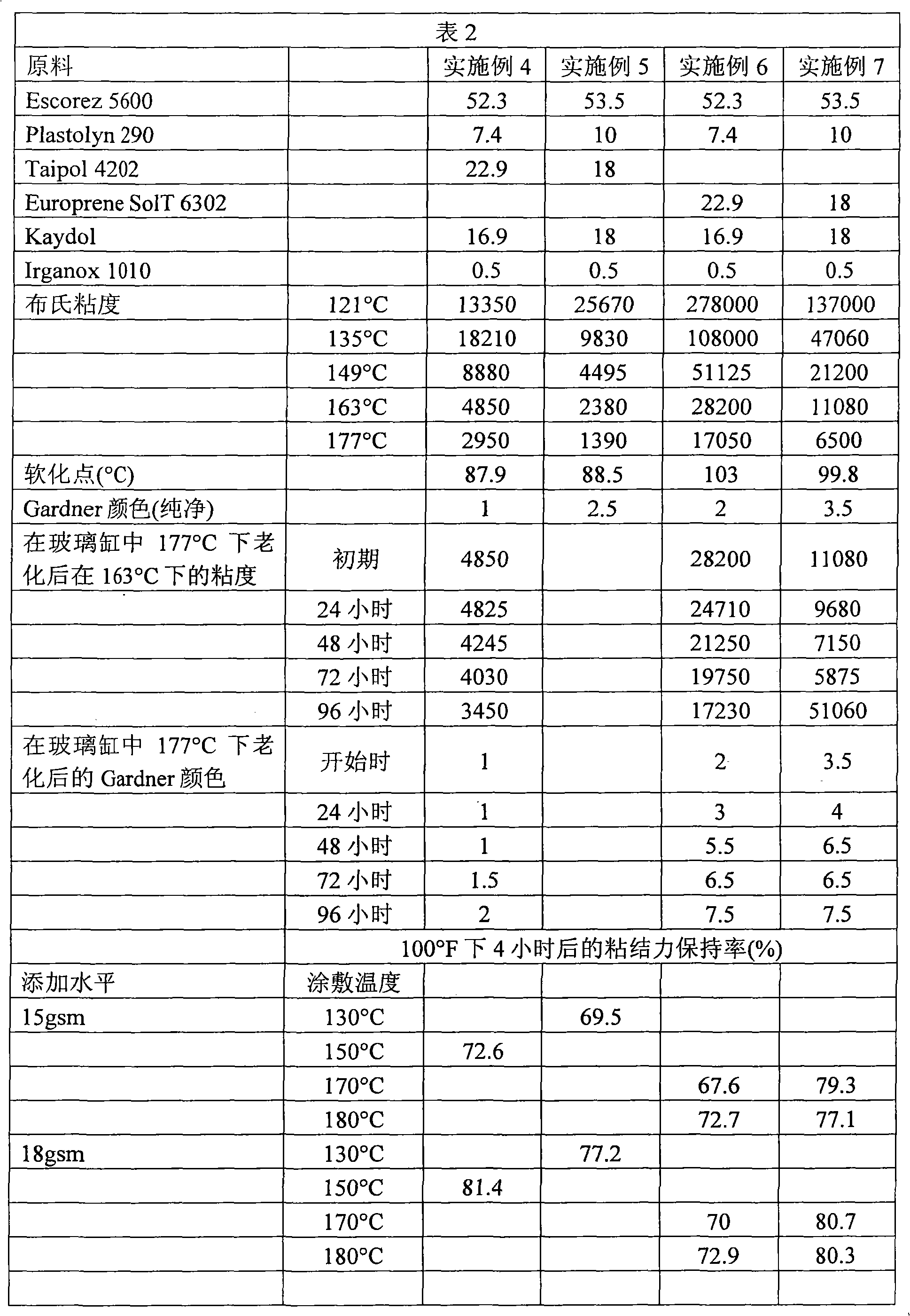

Cold air type argon-arc welding gun

InactiveCN101085489AEffective isolationAvoid isolationElectrode supporting devicesCold airHeat-affected zone

The invention relates to the argon cold air arc welding machine. It has top and down air chamber through the screen current and connected to the nozzle, and separated by rigid air lens with intersected through holes. The air lens is divided into top and down air chambers, forming effective isolation air multi layer post screening the current. It forms multi layer protective layer current. It has concentrated electric arc temperature, small thermal input, quick speed, and less thermal influence. It solves existing technical issues, avoids the location limitation of vacuum argon filling welding equipment. It realizes welding under natural conditions.

Owner:郭光耀

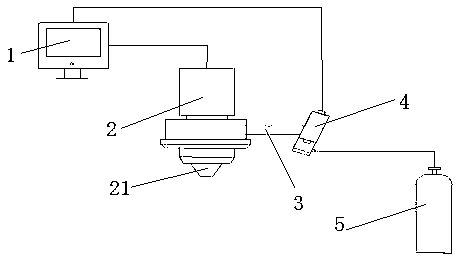

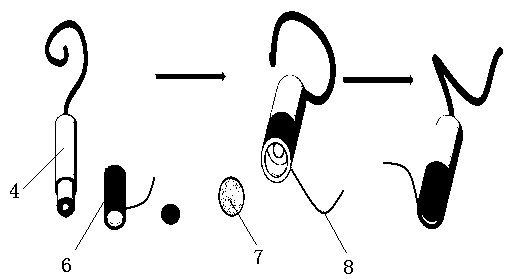

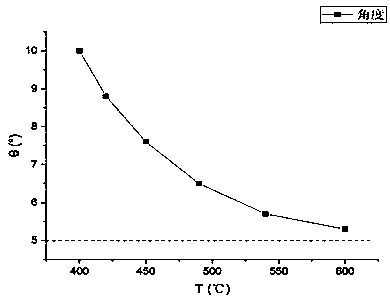

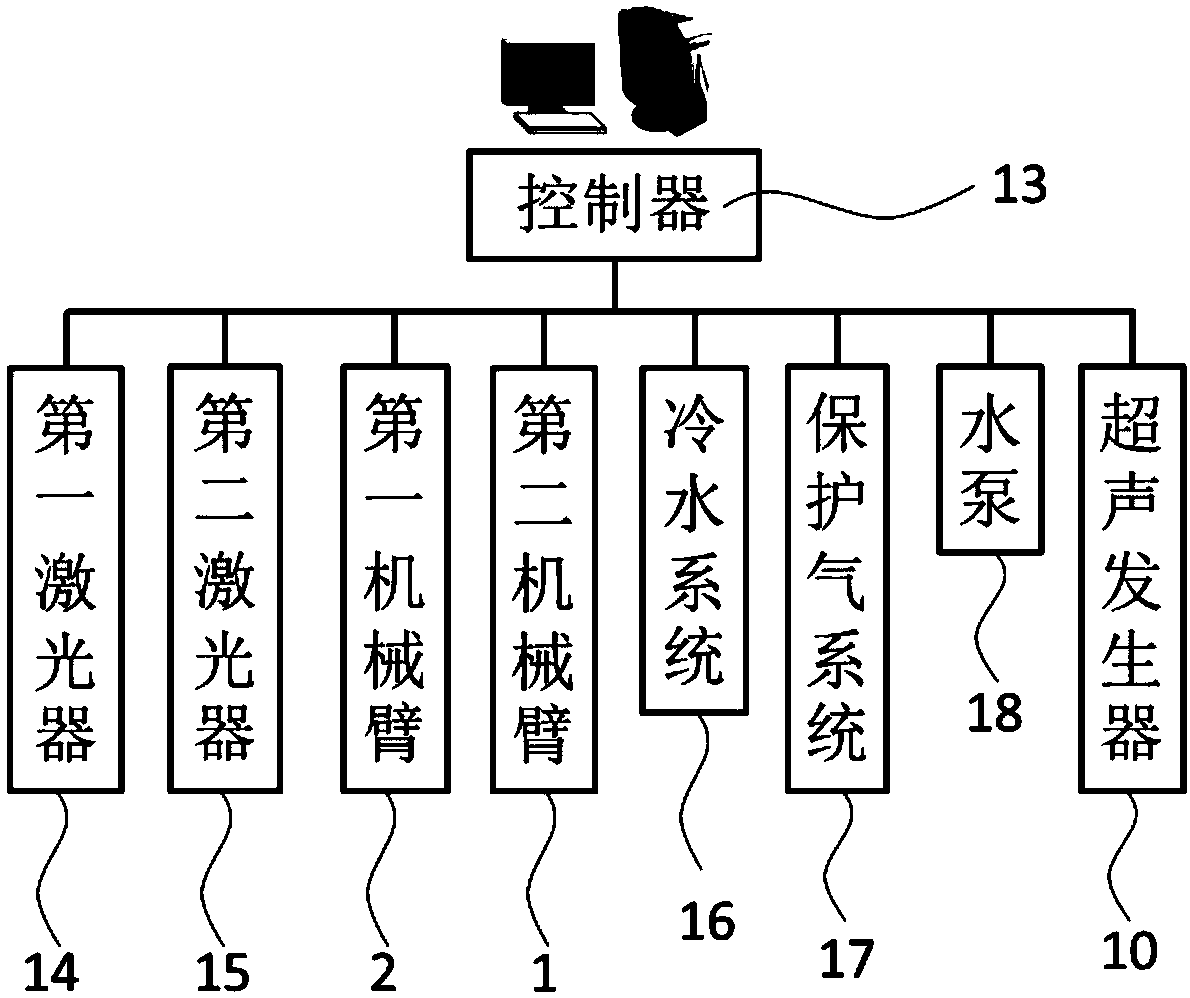

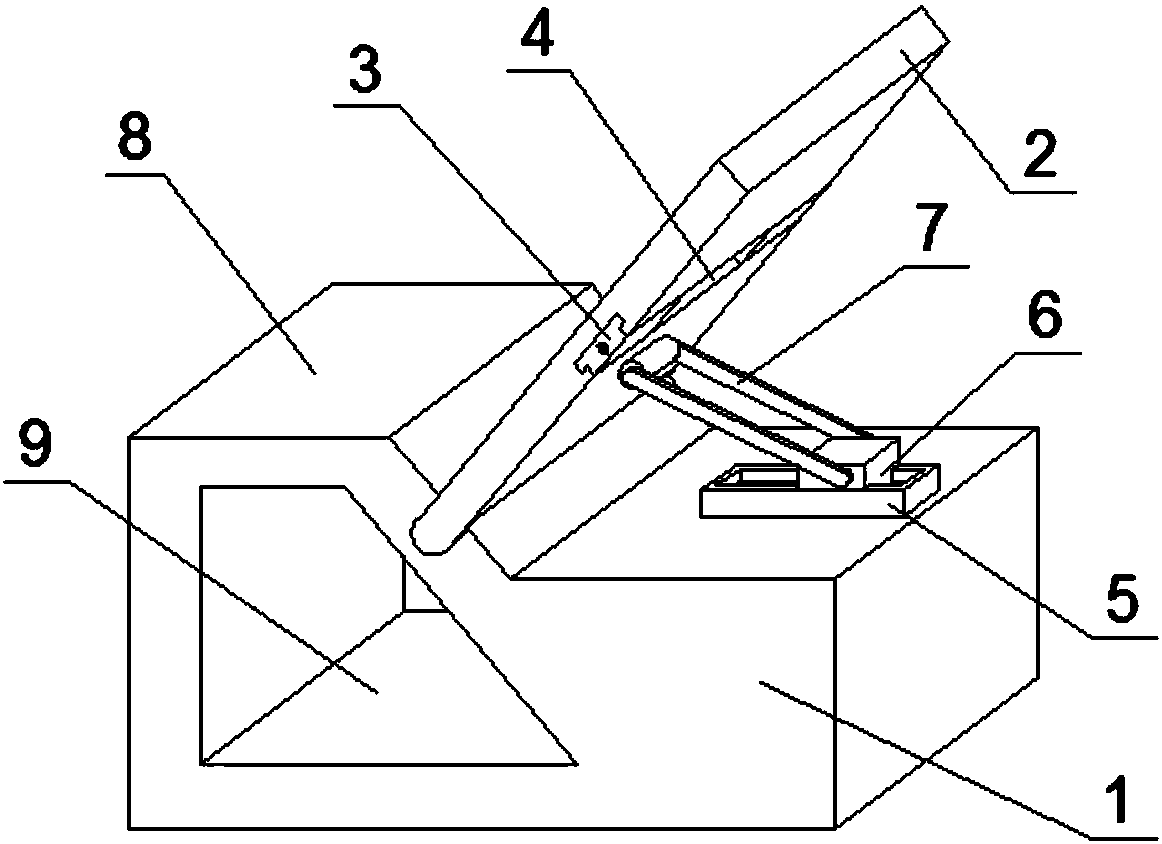

Laser welding incident angle real-time regulating and controlling system based on temperature feedback and welding method

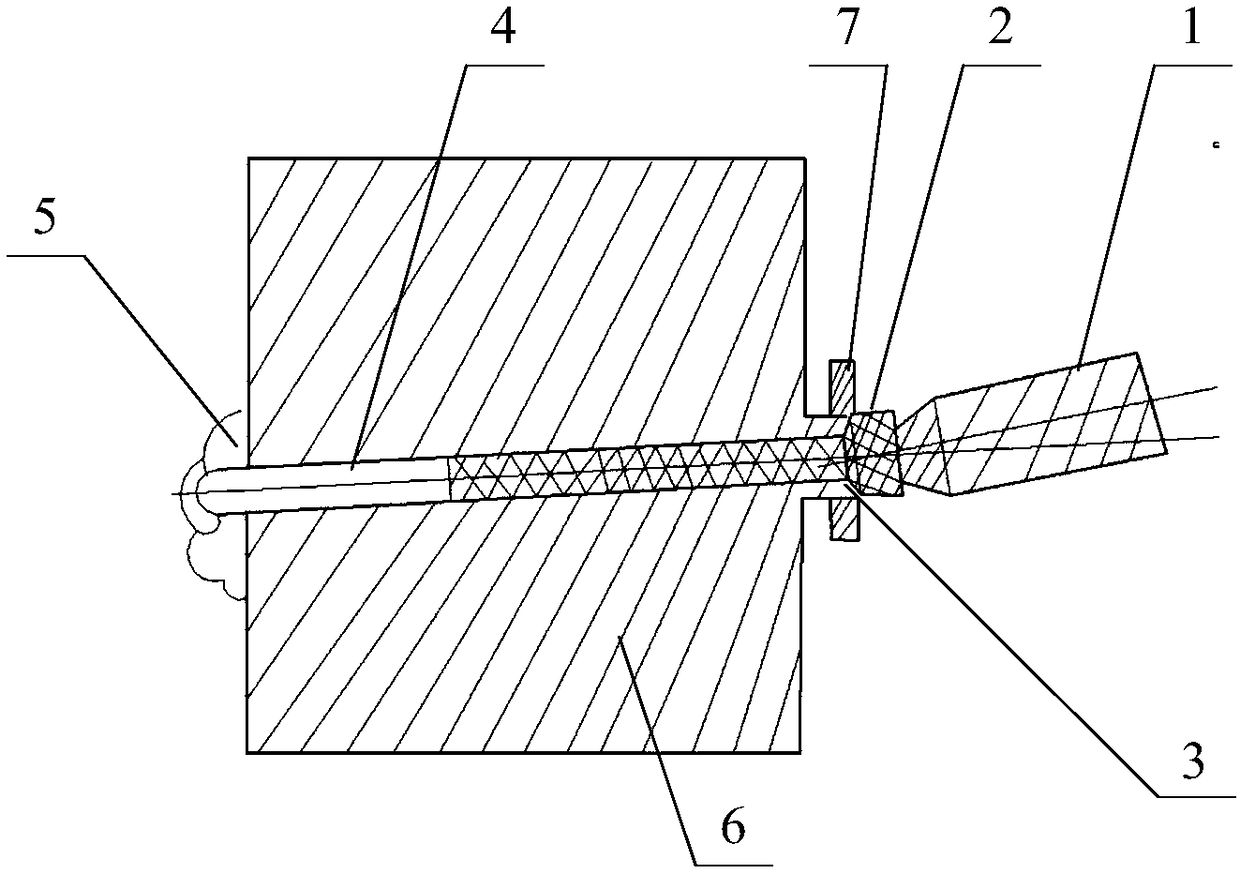

ActiveCN109454328AIncrease the incident distancePrevent burn-throughLaser beam welding apparatusEngineeringControl system

The invention discloses a laser welding incident angle real-time regulating and controlling system based on temperature feedback and a welding method of the laser welding incident angle real-time regulating and controlling system. The welding system comprises a laser welding module, a welding control module, a clamper and an infrared temperature feedback module, wherein the clamper and the infrared temperature feedback module are arranged on the side wall of the laser welding module, one end of the clamper is fixed on the side wall of the laser welding module, and the other end of the clamperis connected with the infrared temperature feedback module; and the angle of the infrared temperature feedback module is adjusted through the clamping end of the clamper, so that an infrared thermometer can conveniently measure the temperature of a specific area. According to the laser welding incident angle real-time regulating and controlling system based on temperature feedback and the weldingmethod, the average temperature of the specific area can be detected in real time through the real-time regulating and controlling system; if the temperature is too high, the system correspondingly makes feedback, the incident angle of laser welding is adjusted, the incident distance of lasers in the material is increased, and the burnthrough phenomenon is effectively prevented. The system and method are particularly suitable for welding thin cover plate structures such as aluminum and a magnesium alloy.

Owner:JIANGSU UNIV OF SCI & TECH

Method for improving blast furnace hearth cooling efficiency

ActiveCN103882169AImprove cooling effectReduce reactive power consumptionBlast furnace detailsCooling devicesWeight coefficientCooling effect

The invention discloses a method for improving blast furnace hearth cooling efficiency. The method comprises the following steps: dividing the periphery of a blast furnace into (iend+1) symmetrical vertical section areas, calculating the hearth temperature changes and temperature gradients of 2*(iend+1) points in the periphery of the blast furnace; carrying out grading evaluation on the hearth, wherein the temperatures can be divided into three grades: abnormally high temperature, abnormally low temperature, and normal temperature; finally calculating the occurrence numbers of the three situations and the ratios of the points with three temperature grades in all points, and re-adjusting the flow distribution of hearth cooling water according to weight coefficients sigma H, sigma M, and sigma L. According to the corrosion situation in hearth, the cooling water distribution in hearth can be dynamically adjusted to strength the cooling effect in heavy corrosion areas, at the same time, the cooling water consumption is reduced, the cooling performance of the blast furnace cooling system is improved, and the blast furnace heart is prevented from being burnt through.

Owner:ANGANG STEEL CO LTD

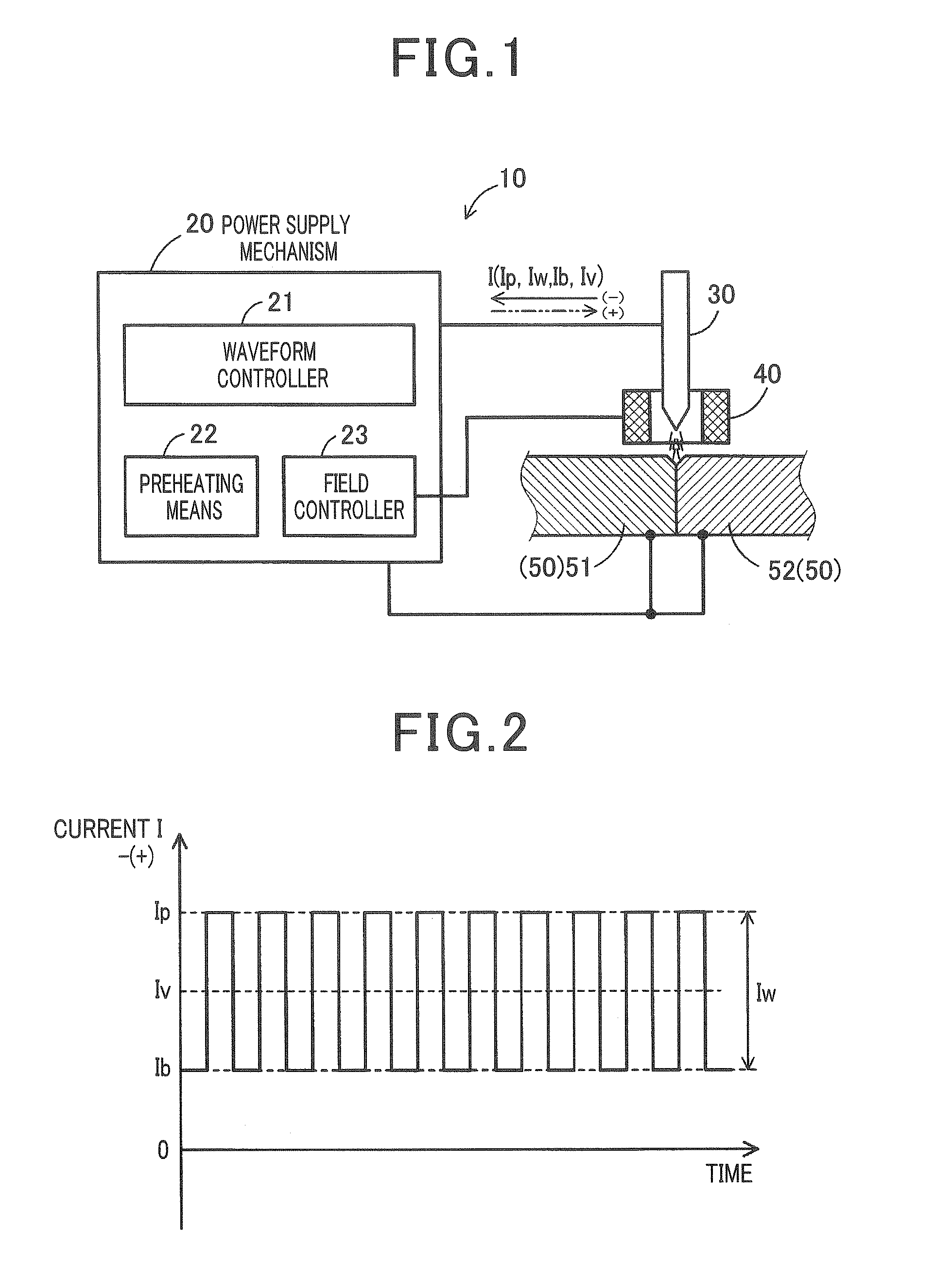

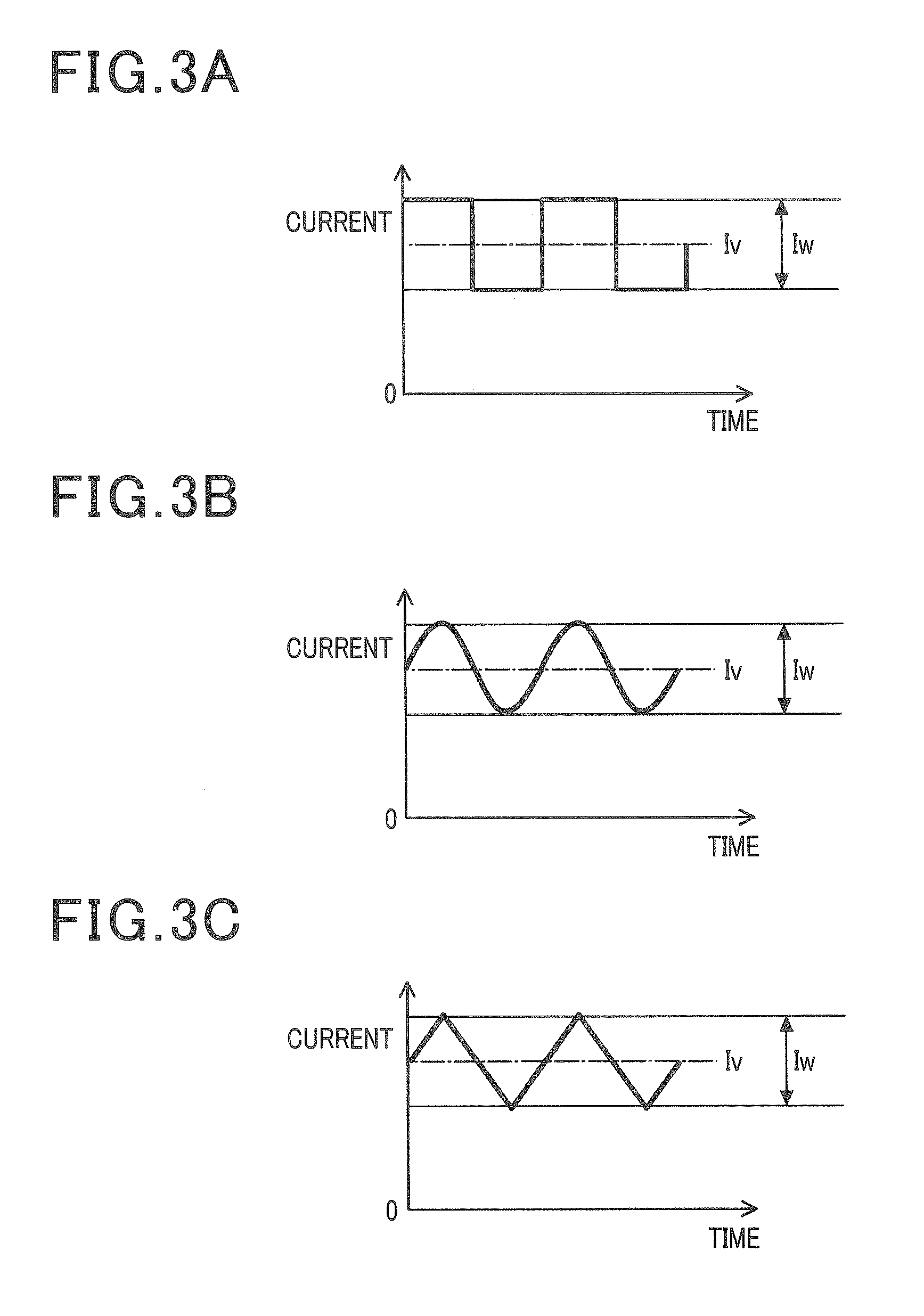

Arc welding method and arc welding apparatus

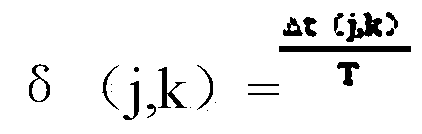

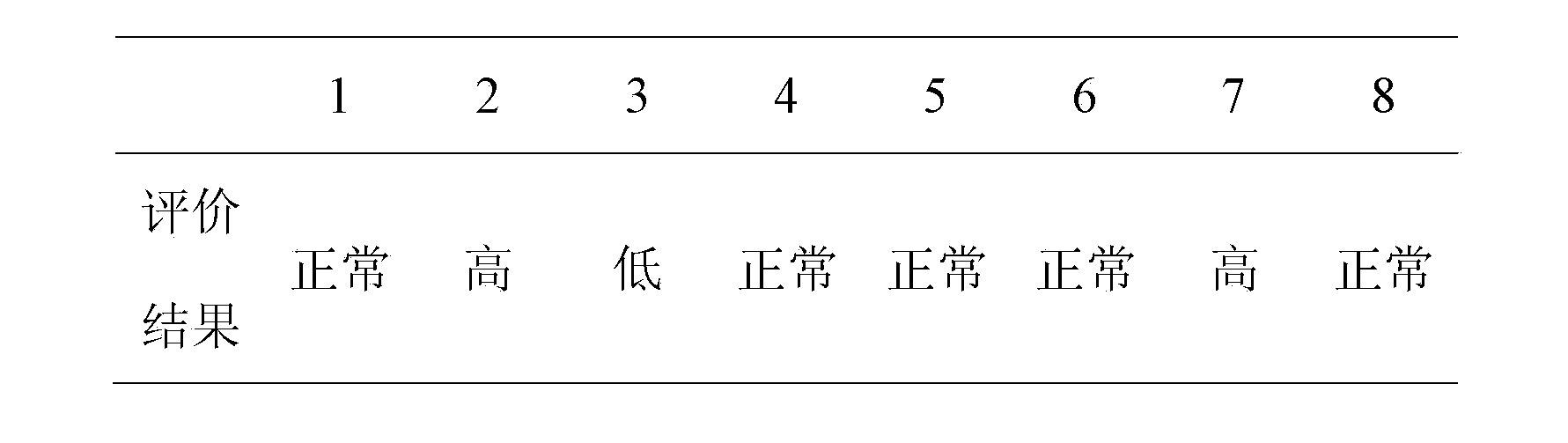

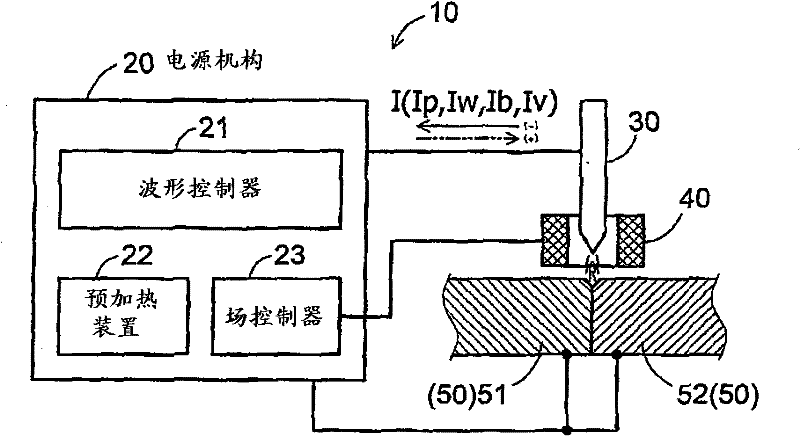

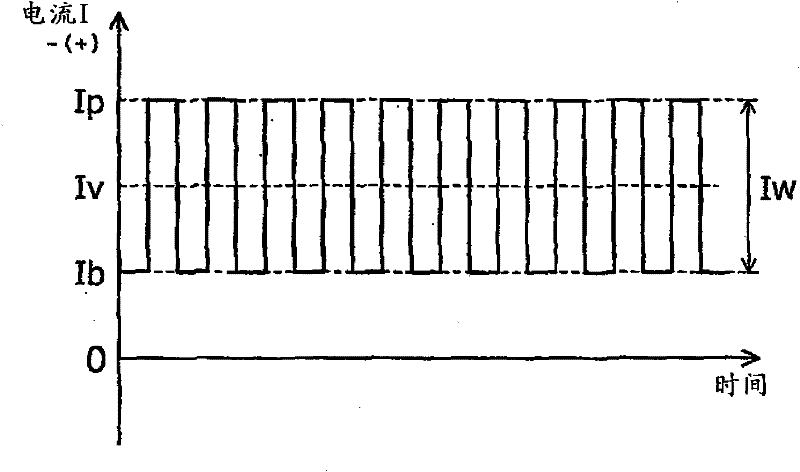

InactiveCN102211238AShorten the time frameStable build pathWelding/soldering/cutting articlesWelding accessoriesMetallic materialsPeak current

The invention discloses an arc welding method and an arc welding apparatus. A base metal 50 composed of a plurality of metallic materials 51, 52 having an oxygen content of 10 ppm is first preheated partly or overall. Then AC (alternating current) current (I) is made to pass through the preheated base metal and an electrode (30) so as to generate an arc for welding the metallic materials. The waveform of the current is changed with time between a peak current value (Ip) and a base current value (Ib) excluding a current of zero value only in one of plus and minus polarity sides of the current. A current ratio defined by dividing a current amplitude (Iw) between the peak and base current values (Ip, Ib) by a current average (Iv) of the alternating current is a range of 0.5 to 2.0. The alternating current has a frequency of 500 Hz or higher.

Owner:DENSO CORP

Welding method for CO2 gas shielded welding for super-strength thick steel plate

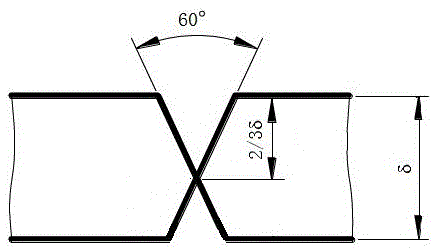

ActiveCN105643061ASimple welding processLow wire strengthArc welding apparatusWelding/soldering/cutting articlesThick plateSheet steel

The invention relates to a welding method for CO2 gas shielded welding for a super-strength thick steel plate. According to the technical scheme of the welding method, a groove is machined in the blanked to-be-welded super-strength thick steel plate and is in an asymmetric X shape; and bottoming layer welding and filling layer welding are sequentially conducted through a CO2 gas shielded welding method, nondestructive testing is conducted on a welding line through ultrasonic waves, and mechanical performance testing is conducted on a welding connector. According to bottoming layer welding, a welding stick of the 500-600 MPa level is used for performing welding, and the thickness of a bottoming layer ranges from 2 mm to 8 mm; and according to filling layer welding, a welding stick with the strength equal to the strength of base metal is adopted for welding. The strength of the to-be-welded super-strength thick steel plate is larger than or equal to 890 MPa, and the thickness of the to-be-welded super-strength thick steel plate ranges from 25 mm to 30 mm. The welding method has the beneficial effects of being simple in technology, low in manual strength, low in welding cost and high in welding efficiency. The welding connector formed through the welding method obtains the good comprehensive mechanical performance and is suitable for super-strength large thick plate structural steel with strength being larger than or equal to 890 MPa.

Owner:WUHAN UNIV OF SCI & TECH

Method for avoiding metal taphole of blast furnace from burning through

ActiveCN108342534APrevent burn throughDoes not affect normal productionBlast furnace componentsBlast furnace detailsHigh pressureHot blast

The invention discloses a method for avoiding a metal taphole of a blast furnace from burning through. The method comprises the following steps: drilling a blind hole in the metal taphole by using a drill bit of a tapping machine; thoroughly purging the blind hole by utilizing high-pressure compressed air; uniformly mixing a corundum casting material and a nano sol binder to obtain a first castingmaterial capable of flowing and a second casting material capable of being molded; under the condition that a clay sleeve of the metal taphole is complete and clean, filling the blind hole with the first casting material; thoroughly eliminating the stemming in a gun head of a hydraulic clay gun, and filling the gun head with the second casting material; tightly pressing the gun head of the hydraulic clay gun on the clay sleeve of the metal taphole by adopting the operation of plugging the metal taphole, pressing the second casting material in the gun head into the blind hole by utilizing thethrust force of the hydraulic clay gun, suppressing the clay tapping pressure of the hydraulic clay gun to the upper limit of the plugging operation pressure, and keeping the pressure; and removing the hydraulic clay gun, and baking the clay sleeve region of the metal taphole by adopting naked flame. The processing steps can be performed during operation of the blast furnace without affecting normal production; and the involved equipment is less, and the processing steps are simple.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Ferritic stainless steel sheet for plasma arc welding and welding method therefor

ActiveUS10272513B2Increase volumeImprove thermal conductivityArc welding apparatusPlasma welding apparatusMetallurgyPlasma arc welding

The ferritic stainless steel sheet contains, in mass%, C: 0.020% or less, Si: 0.6% or less, Mn: 0.5% or less, P: 0.04% or less, S: 0.010% or less, Al: 0.015% or more and 0.20% or less, Cr: 17.0% or more and 24.0% or less, Ni: less than 0.6%, N: 0.020% or less, Ca: 0.0002% or more and 0.0020% or less, and O: 0.0050% or less and further contains one or two selected from Ti: 0.01% or more and 0.45% or less and Nb: 0.01% or more and 0.55% or less, with the balance being Fe and unavoidable impurities. The ferritic stainless steel sheet satisfies (Ti+Nb×48 / 93) / (C+N)≥8.0 (where Ti, Nb, C, and N represent the contents (% by mass) of these elements, respectively).

Owner:JFE STEEL CORP

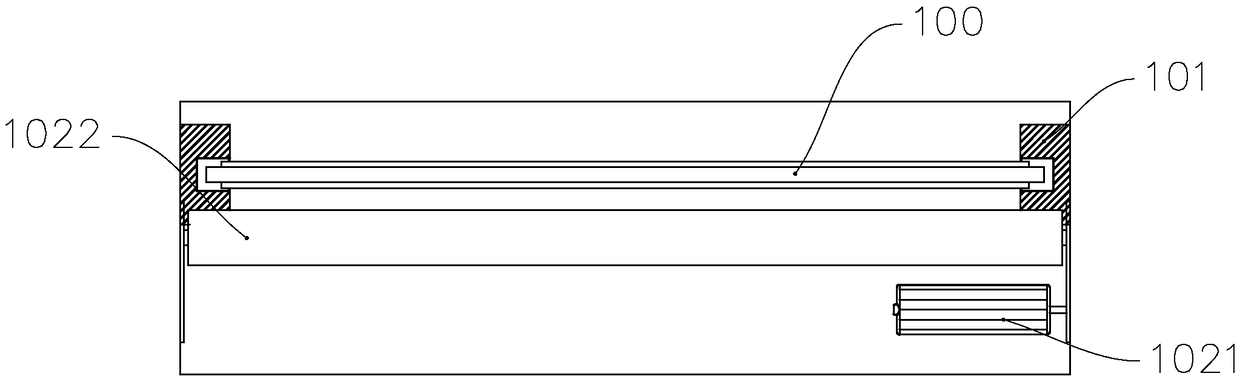

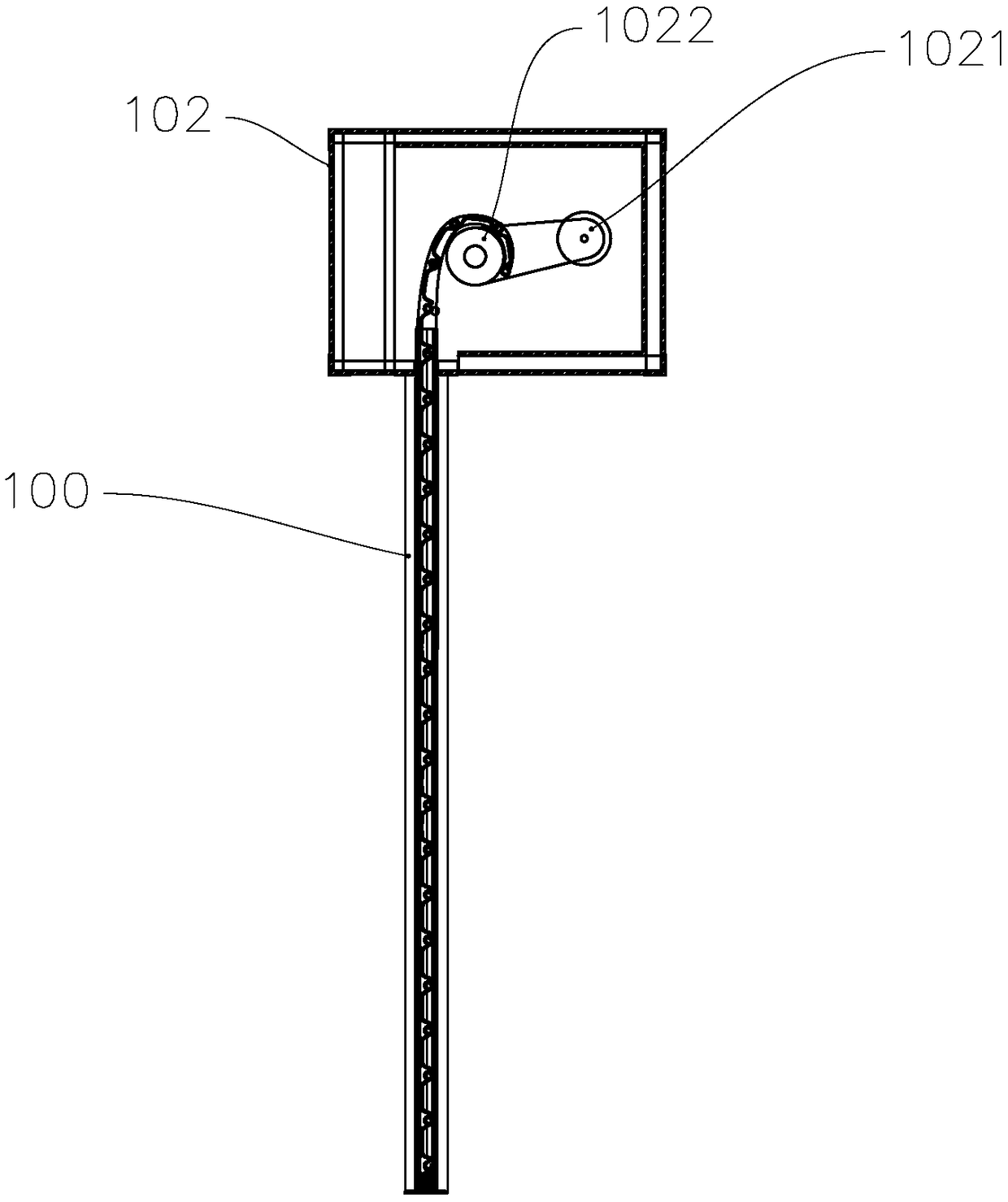

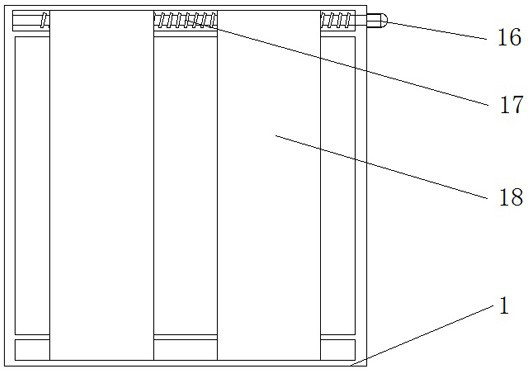

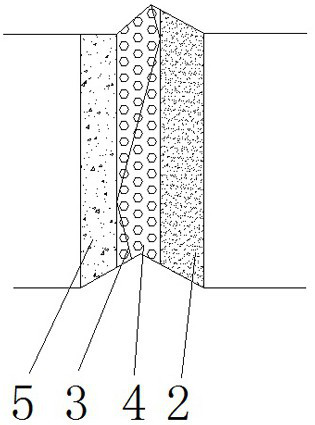

fire shutter door

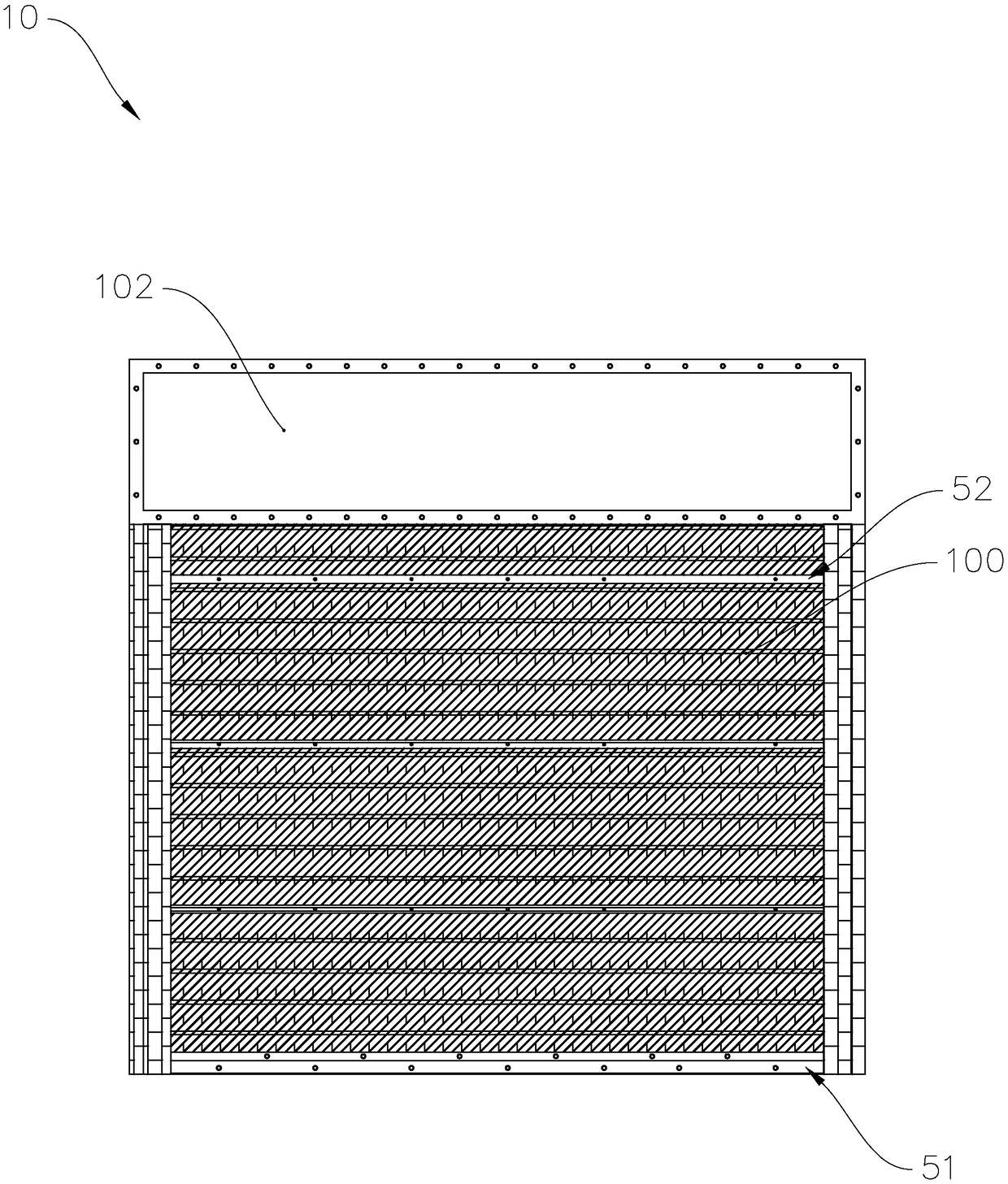

ActiveCN107386941BImprove integrityGood heat insulationShutters/ movable grillesFireproof doorsFiberWinding machine

The invention provides a fireproof rolling shutter door. The fireproof rolling shutter door comprises a guide rail, a shutter body and a winding device; the shutter body is positioned in the guide rail; the winding device comprises a door winding machine and a winding shaft; a driving shaft of the door winding machine drives a rotating shaft of the winding shaft; the winding shaft is fixedly connected with the shutter body; the shutter body comprises a support piece, a first shutter surface, a second shutter surface, a fireproof bar and a bottom beam; the first shutter surface is outwards provided with a first inorganic fiber cotton, first inorganic fiber cloth and first silica gel cloth in sequence from the support piece; the second shutter surface is outwards provided with a second inorganic fiber cotton, second inorganic fiber cloth and second silica gel cloth in sequence from the support piece; the first shutter surface and the second shutter surface are respectively positioned on two sides of the support piece; the fireproof bar is arranged between the support piece and the first shutter surface; the fireproof bar is arranged between the support piece and the second shutter surface; and the bottom beam is connected between the bottom of the first shutter surface and the bottom of the second shutter surface. The fireproof rolling shutter door has the advantages of simple structure, excellent fire resistance, thermal insulation and flame isolation effect and excellent fire resistance.

Owner:新富利消防工程有限公司

Ferritic stainless steel sheet for plasma arc welding and welding method therefor (as amended)

ActiveUS20170266751A1Reduce generationQuality improvementArc welding apparatusPlasma welding apparatusFerricPlasma arc welding

The ferritic stainless steel sheet contains, in mass %, C: 0.020% or less, Si: 0.6% or less, Mn: 0.5% or less, P: 0.04% or less, S: 0.010% or less, Al: 0.015% or more and 0.20% or less, Cr: 17.0% or more and 24.0% or less, Ni: less than 0.6%, N: 0.020% or less, Ca: 0.0002% or more and 0.0020% or less, and O: 0.0050% or less and further contains one or two selected from Ti: 0.01% or more and 0.45% or less and Nb: 0.01% or more and 0.55% or less, with the balance being Fe and unavoidable impurities. The ferritic stainless steel sheet satisfies (Ti+Nb×48 / 93) / (C+N)≧8.0 (where Ti, Nb, C, and N represent the contents (% by mass) of these elements, respectively).

Owner:JFE STEEL CORP

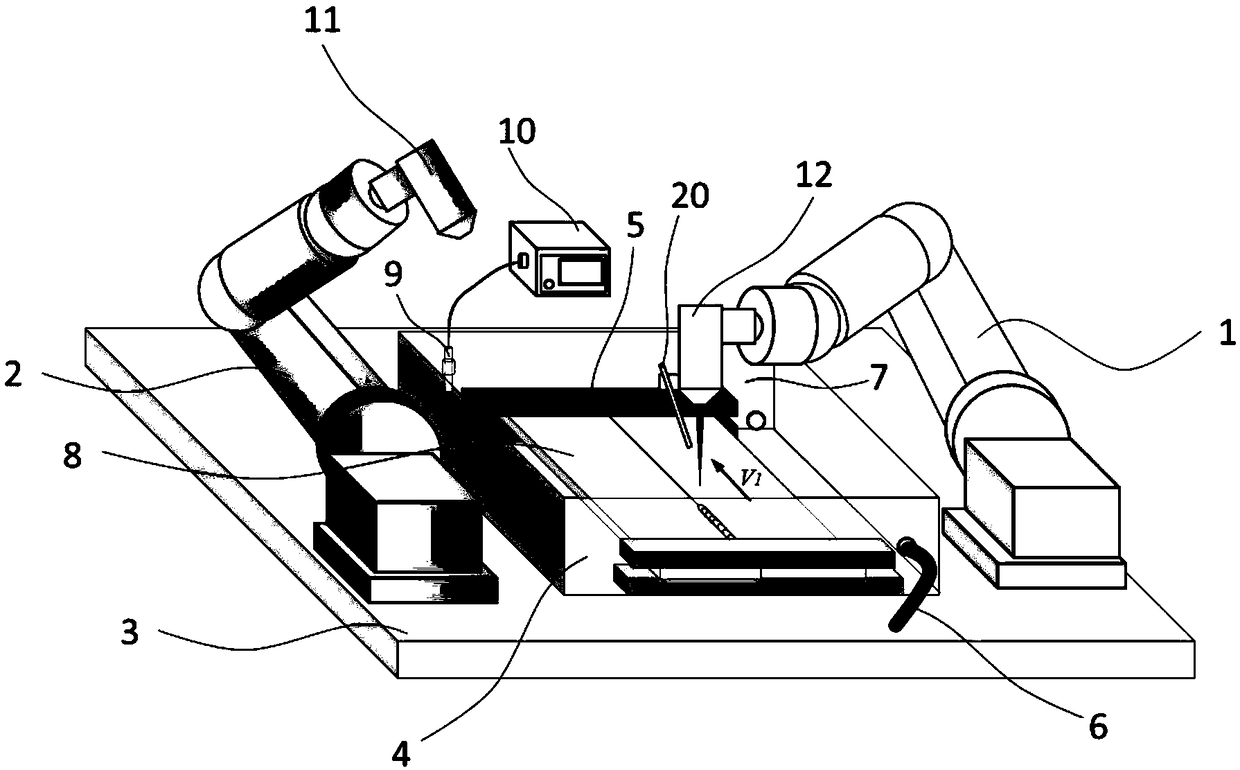

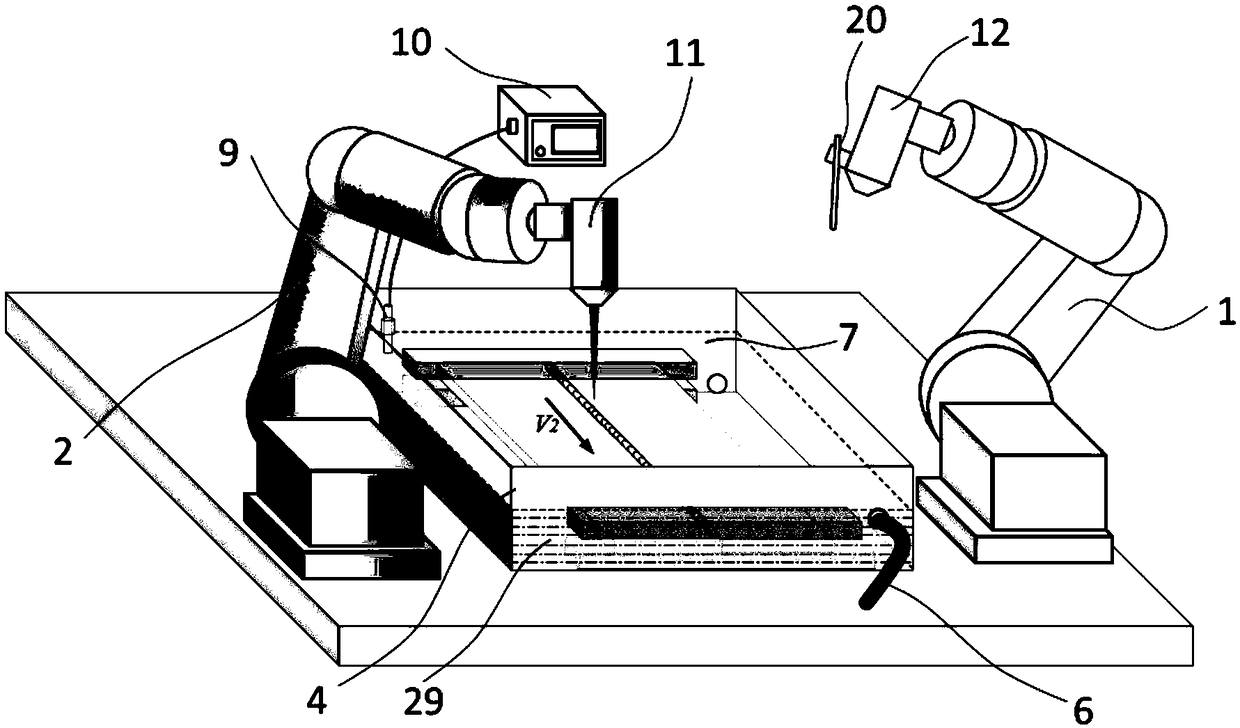

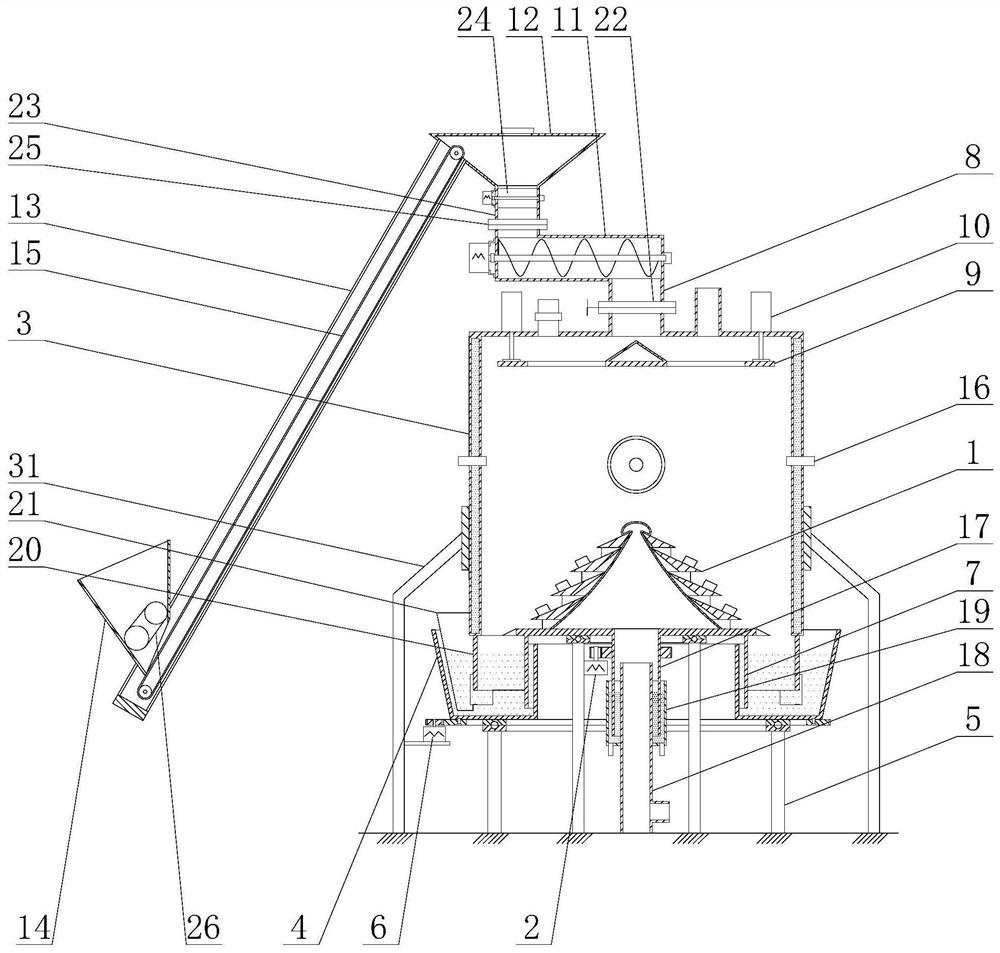

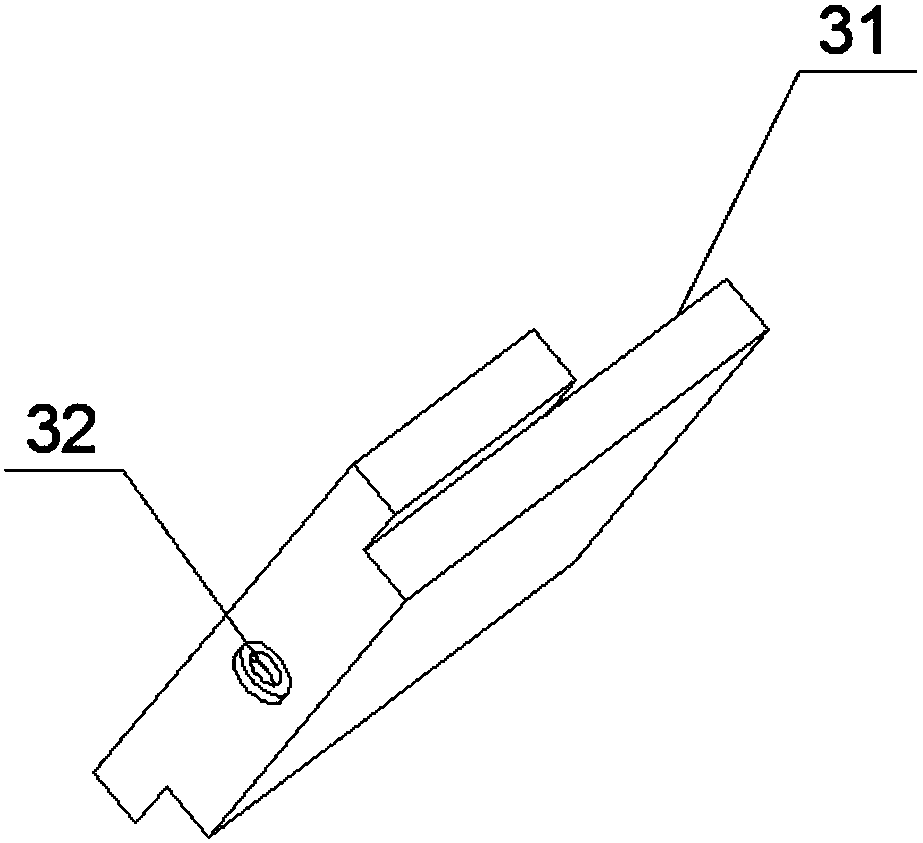

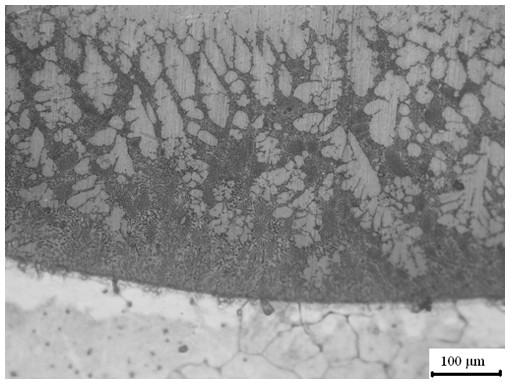

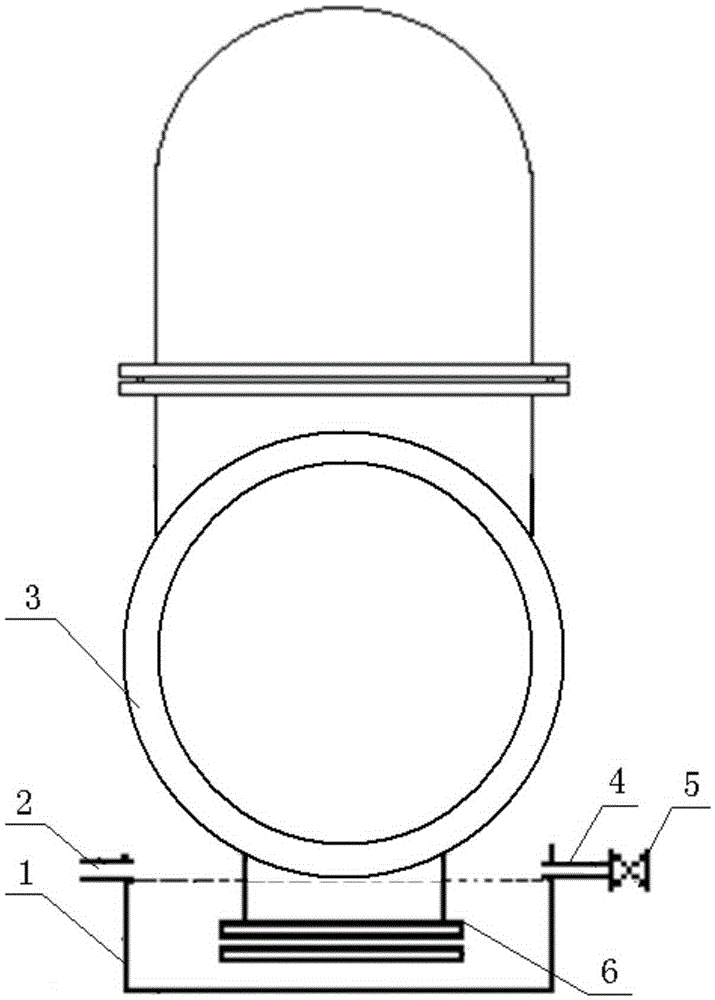

Aluminum alloy non-penetration laser welding strengthening platform and method

ActiveCN109079323AReduce flow ratePrevent burn throughLaser beam welding apparatusSurface layerButt joint

The invention discloses an aluminum alloy non-penetration laser welding strengthening platform and method. A first mechanical arm and a second mechanical arm are respectively provided with a first laser head and a second laser head; a processing chamber is respectively connected with a water inlet pipe and a water outlet pipe; welding plates in butt joint are clamped and positioned by fixtures inthe processing chamber; the water inlet pipe is connected with a water pump; an amplitude change rod is fixed on the inner wall of the processing chamber; a working head of the amplitude change rod ispositioned under a preset water level upper limit; a blind way is formed in the center of the butt joint end surfaces of the welding plates before welding, so that the flowing-down speed of molten metal on the front wall of a key hole during welding is effectively lowered, and the burnthrough of the back parts of the welding lines or the formation of full-penetration welding is prevented; and thelaser impact processing is performed after welding to effectively refine grains on the surface layer of an aluminum alloy layer welding joint, so that the mechanical performance of the joint is improved. In addition, the laser welding and the laser impact technology are fused on one platform, and the laser impact processing is performed after the welding operation, so that the secondary positioning and clamping of workpieces are prevented, and the production efficiency and the automation level are improved.

Owner:GUANGDONG UNIV OF TECH

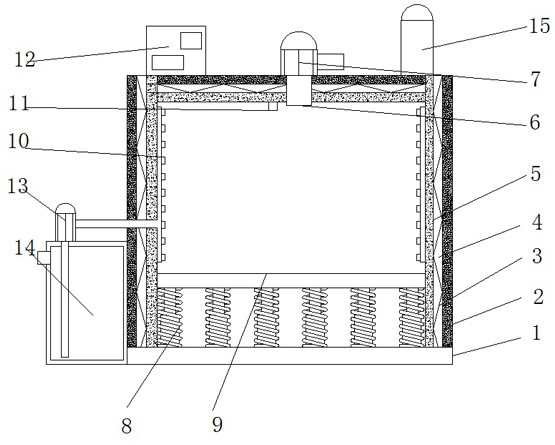

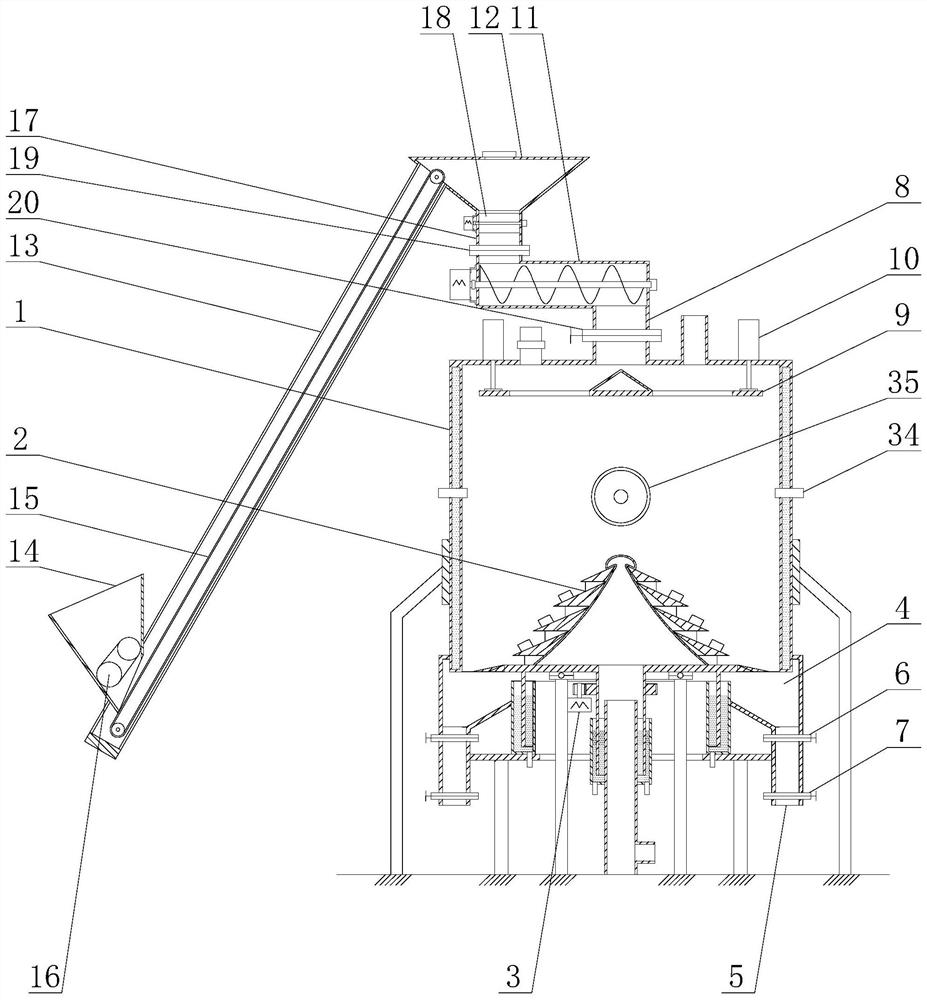

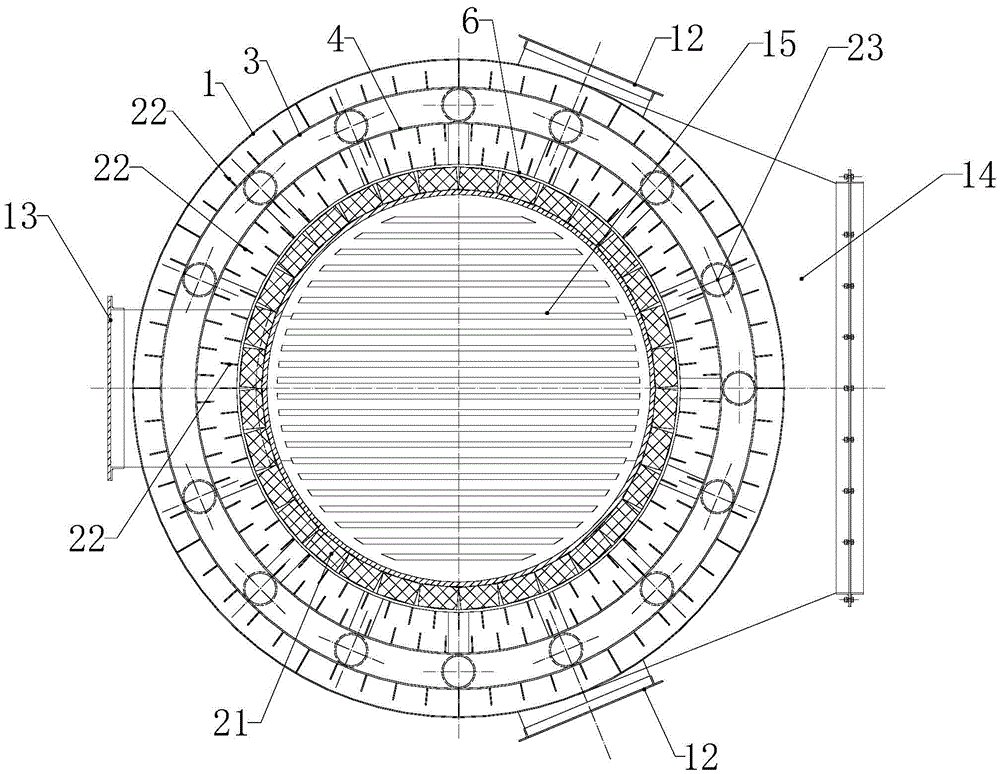

Differential rotating bed continuous feeding biomass gasification furnace

InactiveCN112126468AAdjustable speedNot easy to slaggingProductsGasifier feeding meansProcess engineeringBiomass gasifier

The invention discloses a differential rotating bed continuous feeding biomass gasification furnace, and mainly relates to the technical field of energy science. The furnace comprises a furnace body,an air distribution disc and an air disc driving device for driving the air distribution disc to rotate are arranged in the furnace body, the furnace body comprises a cylinder body and a cylinder bodysupport located on the outer side of the cylinder body and used for supporting the cylinder body, an ash bin is arranged on the lower side of the cylinder body, and an ash bin driving device for driving the ash bin to rotate is arranged on the cylinder body support. A blanking pipe is arranged at the top of the furnace body, a conical distributor is arranged on the lower side of the blanking pipe, a spiral sealing feeder is arranged at the top of the blanking pipe, a buffer bin is arranged at the top of the end, away from the blanking pipe, of the spiral sealing feeder, and a feeding barrel with the closed bottom end is obliquely arranged on one side of the buffer bin. The biomass gasification furnace can realize continuous sealed feeding in the gasification process, can effectively prevent partial burning deviation and burning through, is easy to control the thickness of an ash layer, can enhance the disturbance of biomass in the furnace, and improves the gasification strength.

Owner:山东信科环境科学研究院有限公司

Welding and repairing method and device for thin-walled part

ActiveCN108406223AAvoid deformationPrevent burn-throughAdditive manufacturing apparatusWelding/cutting auxillary devicesLatent heatRepair method

The invention discloses a welding and repairing method and device for a thin-walled part. The welding and repairing method comprises the following steps: performing preheating and overheat preventingtreatment on the the thin-walled part, rolling or adhering a low-melting-point sheet metal to the back side of at the welded part of the thin-wall part, and using a melt fusing phase transformation latent heat unsteady efficient heat absorption principle to realize local efficient cooling of the thin-walled part to further prevent the phenomenon that the thin-walled part is excessively heated to cause deformation or burnthrough in the welding process.

Owner:成都瑞合科技有限公司

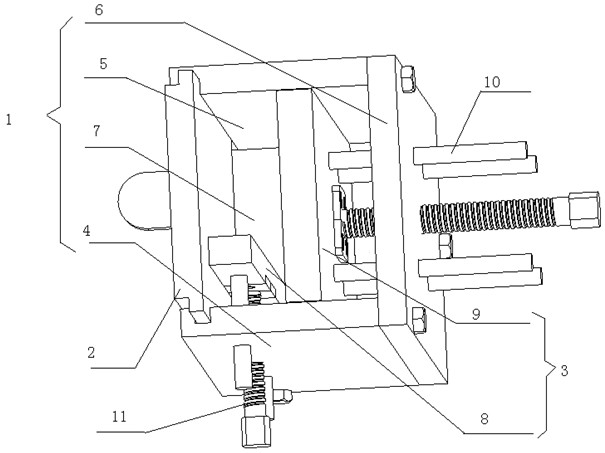

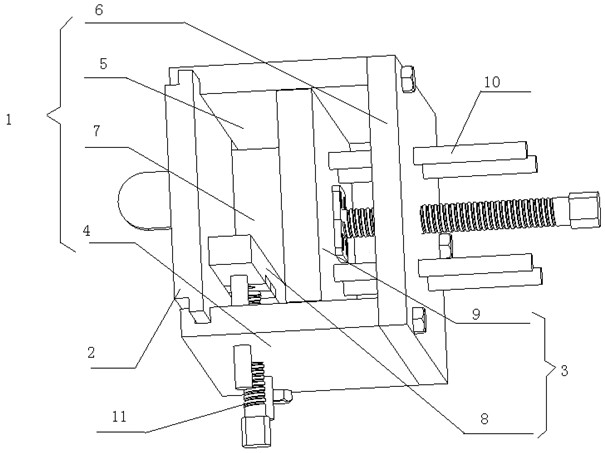

Die for casting aluminum-clad magnesium alloy composite material

The invention discloses a die for casting an aluminum-clad magnesium alloy composite material, which comprises a die seat (1), a movable insert plate (2) and a side surface clamping mechanism (3). The die seat is formed by connecting a baseplate (7) with side plates (4), (5) and (6) through fastening bolts. Grooves are processed on the side plates (4) and (5), which are in clearance fit with the movable insert plate (2), threaded holes are processed on the side plates (4) and (6), which are connected with the side surface clamping mechanism, and the side surface clamping mechanism is formed by connecting a clamping plate with a threaded push rod. By adopting the die for casting an aluminum-clad magnesium alloy composite cast ingot, the bottom surface and the peripheral side surfaces of an aluminum-clad box are well jointed with the die, uniform heat radiation of the composite cast ingot is realized, and burning through can be effectively prevented. In addition, the requirement on processing precision of dimension of the aluminum-clad box is low, and the cast ingot is convenient to detach and the like.

Owner:SOUTHWEST UNIVERSITY

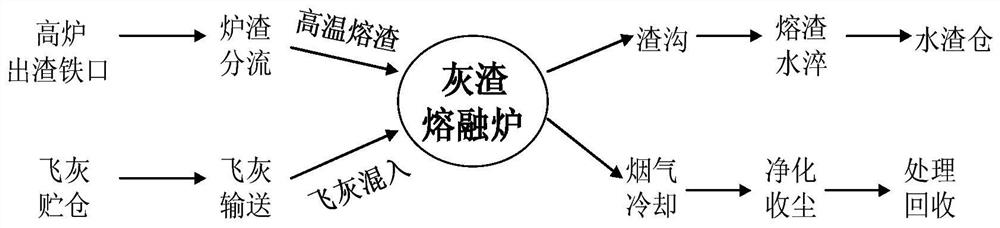

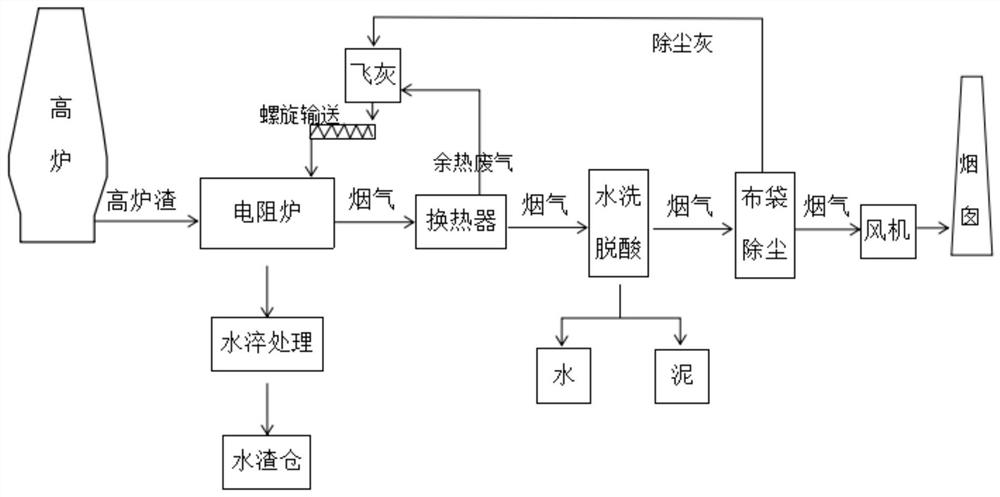

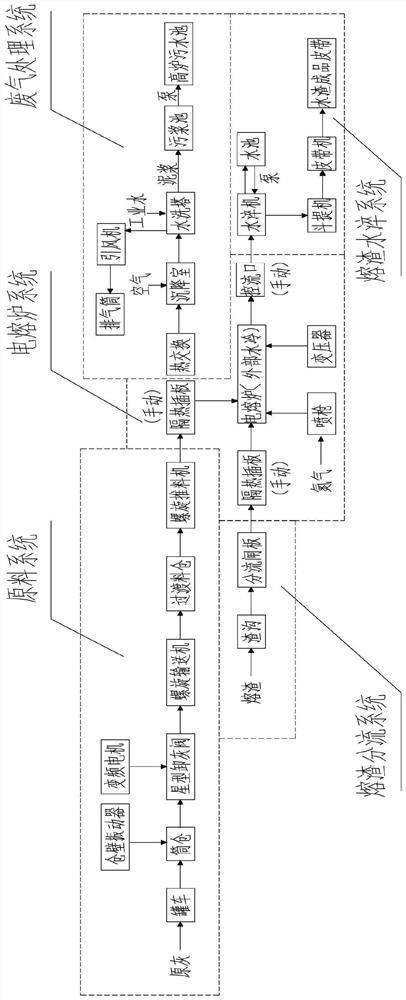

Method and device for disposing waste incineration fly ash in low-energy-consumption, recycling and environment-friendly manner

PendingCN112441759AReduce energy consumptionReduce disposal costsSolid waste managementIncinerator apparatusAggregate (composite)Fly ash

The invention discloses a method and device for disposing waste incineration fly ash in a low-energy-consumption, recycling and environment-friendly manner. The method comprises the following steps that: 1) 1480-1510 DEG C blast furnace slag is added into a melting furnace, fly ash is simultaneously or subsequently added, and an obtained mixture is fully stirred, and the addition amount of the flyash accounts for not more than 25% of the total mass of the blast furnace slag and fly ash; 2) the temperature of the composite slag in the melting furnace is kept at 1400-1450 DEG C, and the reaction time is kept for 20-40 minutes under the temperature; and 3) deslagging, cooling, and water quenching treatment are carried out to obtain powdery water granulated slag, and the powdery water granulated slag is used as cement aggregate after being subjected to fine grinding.

Owner:BAOSHAN IRON & STEEL CO LTD

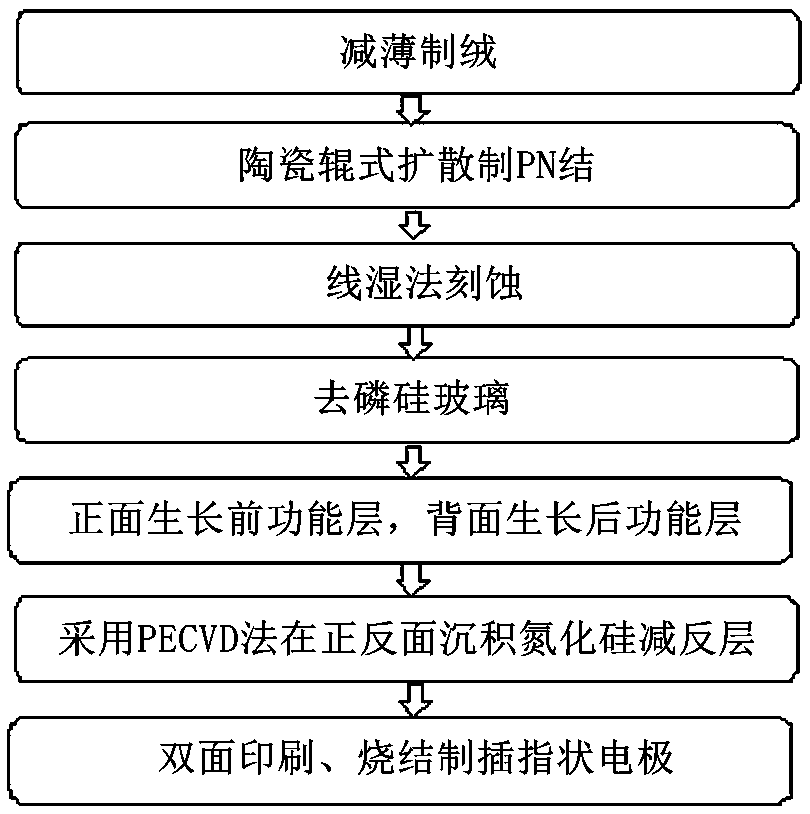

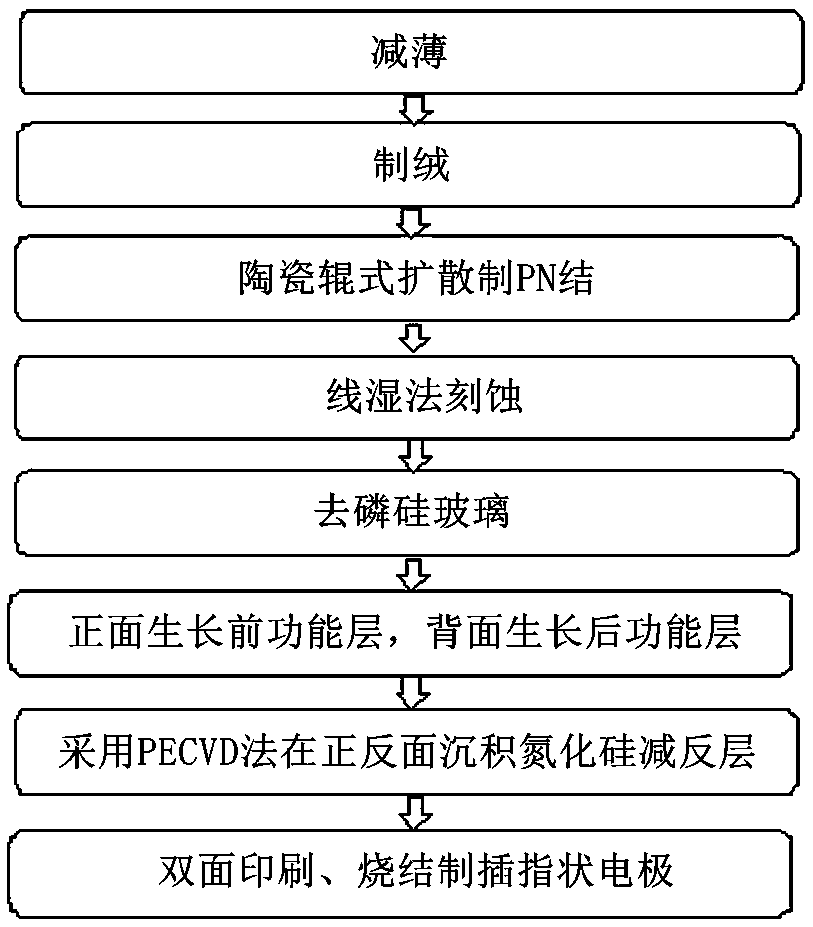

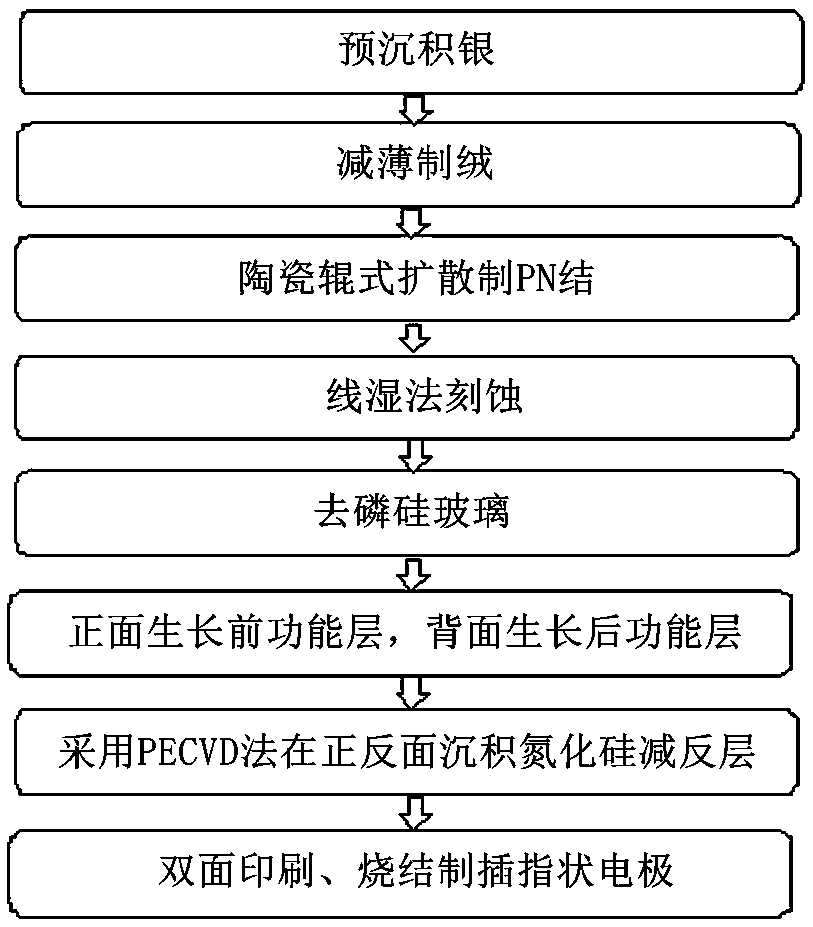

Method for preparing ultrathin crystalline silicon double-sided solar cell

ActiveCN109802009AImprove light energy utilizationIncrease light dwell timeFinal product manufacturePhotovoltaic energy generationPhosphoric acidSilicon nitride

The invention provides a method for preparing ultrathin crystalline silicon double-sided solar cell. The method comprises steps of: firstly thinning a polycrystalline silicon substrate to 90-120[mu]mat 18-25 degrees centigrade for 2000-2300s by using a mixed solution of HF, H2O2 and an additive, wherein a textured structure is formed on the surface of the substrate during the thinning process; preparing a PN junction by roll diffusion, and using ultrasonic atomization of phosphoric acid, thereby being nontoxic and nonpolluting, and achieving a uniform diffusion junction; and disposing siliconnitride antireflection layers on the front and back sides of the substrate; finally forming finger electrodes on the front and back sides by a silk-screen printing and sintering process. The method is suitable for the production technology of polycrystalline silicon 90-120[mu]m thick. Compared with a method for preparing a conventional polycrystalline silicon cell 180[mu]m thick, the method can reduce the thickness of the cell under the premise of ensuring a fragmentation rate, ensures battery efficiency, is simple in process, and low in cost. The method also solves the problem that the thincell is likely to be bent and is fragile, and can be industrialized by experimental verification.

Owner:HEBEI UNIVERSITY

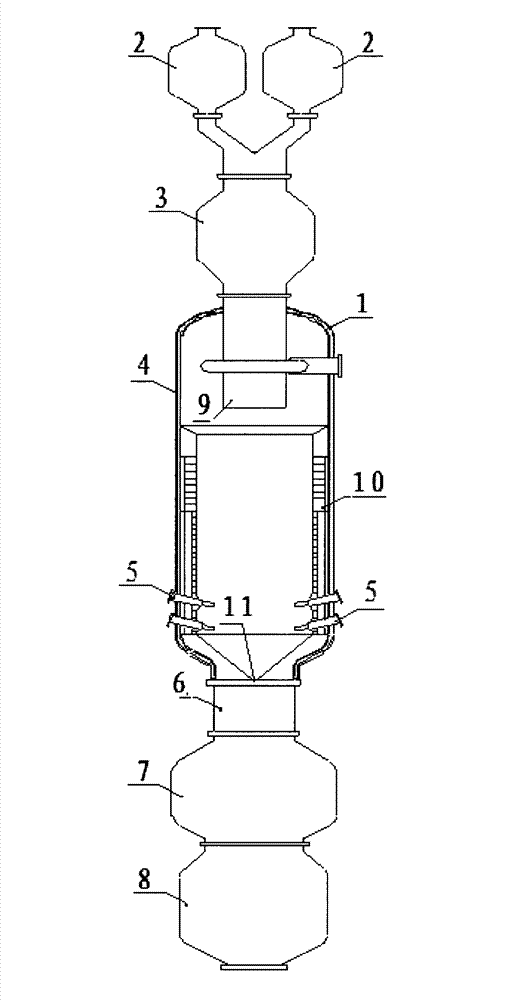

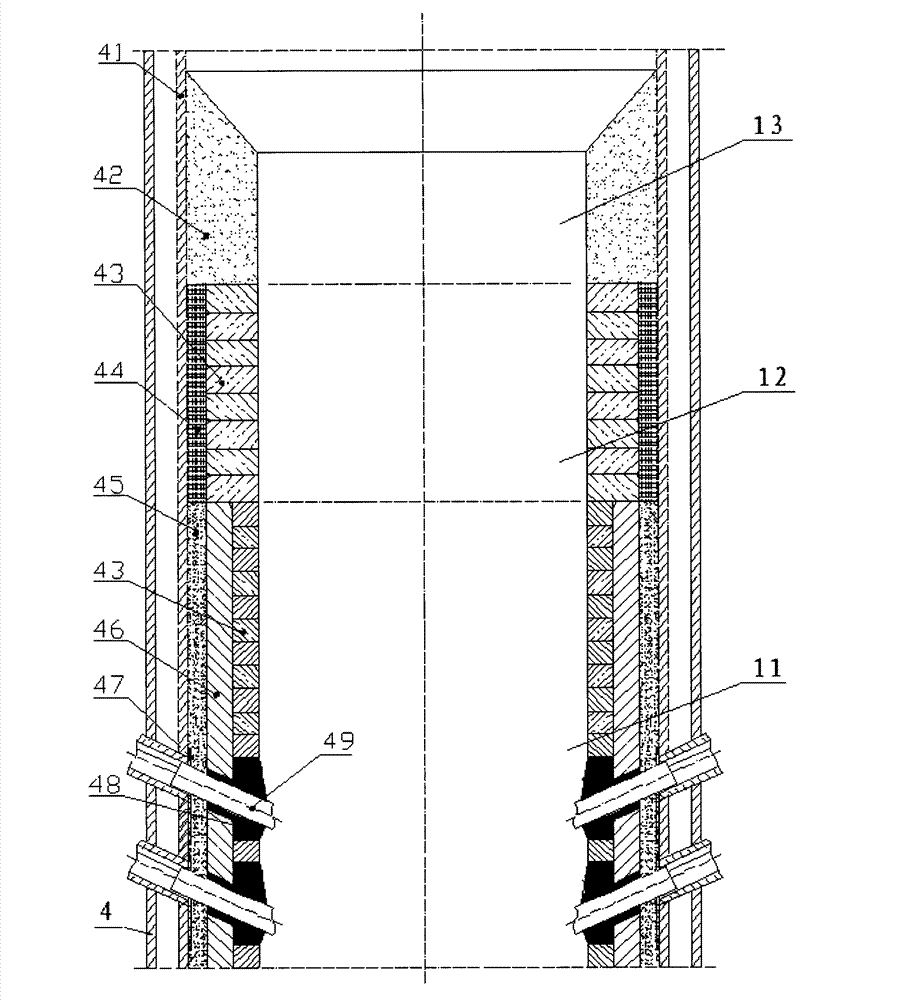

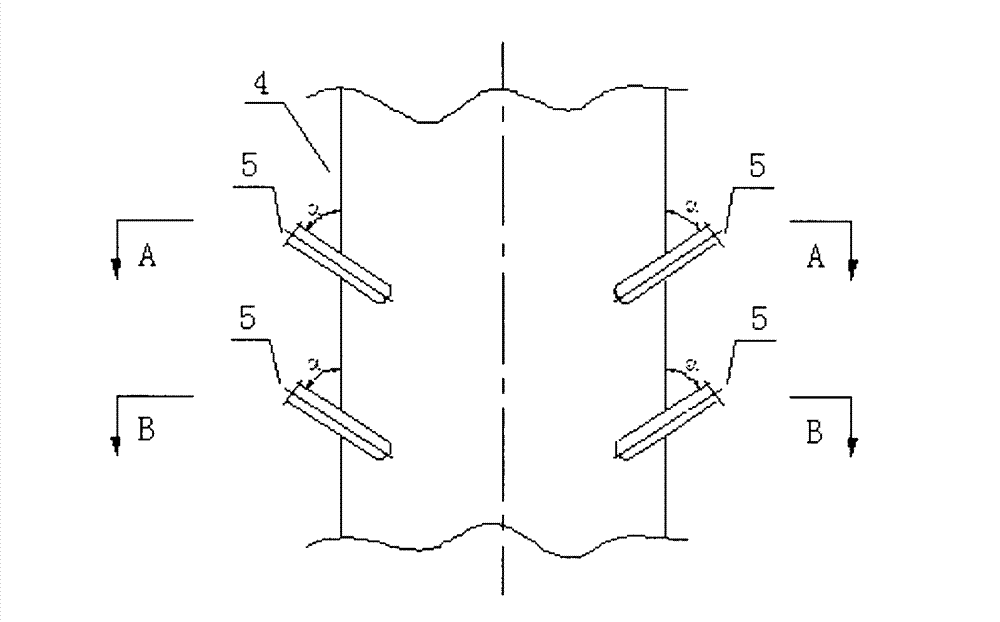

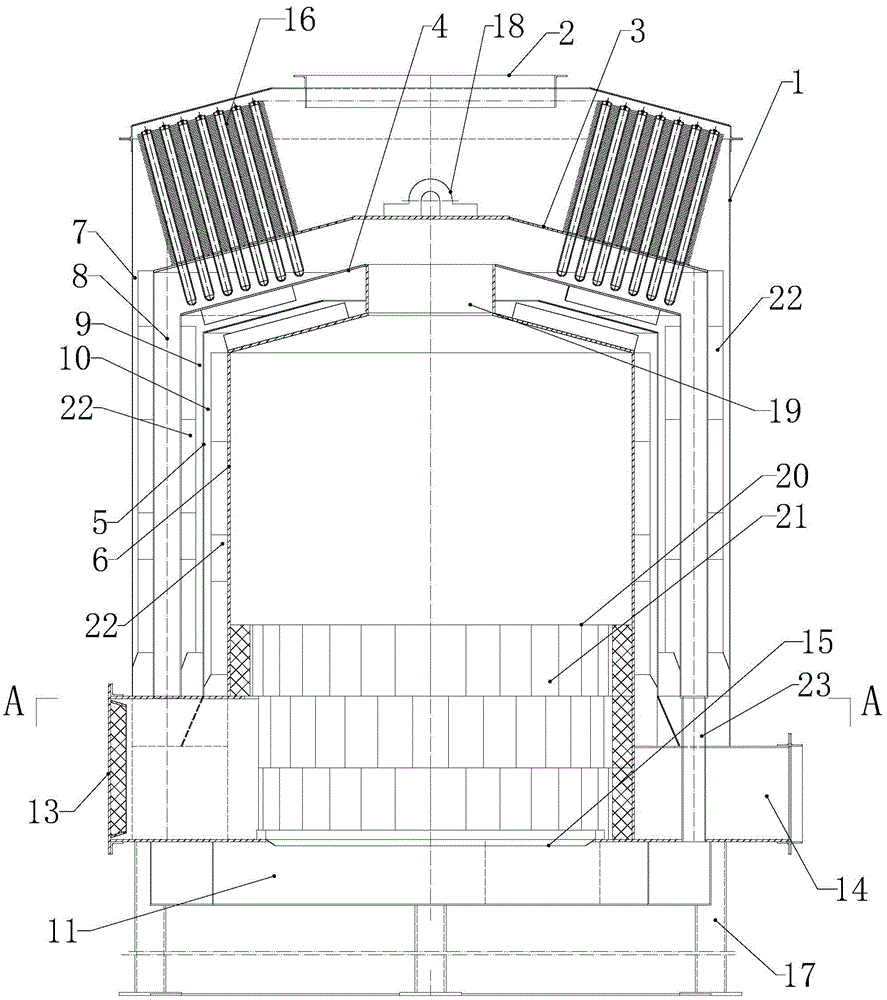

Fixed bed slag gasification furnace

ActiveCN102041098BSolve the burning problemReduce maintenance timesCombustible gas productionSlagFixed bed

The invention relates to a fixed bed slag gasification furnace. The inner wall of a furnace body (4) is provided with a composite furnace lining (10), the furnace body (4) is divided into a lower and slag bath region (11), an upper and middle region (12) and a top region (13), wherein the lower and slag bath region (11) is provided with a nozzle (49), the composite furnace lining (10) in the top region (13) is in a two-layer structure, the composite furnace lining (10) in the upper and middle region (12) is in a three-layer structure, and the composite furnace lining (10) in the lower and slag bath region (11) is in a four-layer structure. The invention has the advantages of reasonable design structure, good safety performance and good gasification effect and can solve the problems that furnace lining is seriously burnt and damaged, service life of the gasification furnace is short and gasification effect is poor in the prior art.

Owner:云南煤化集团工程技术有限公司 +1

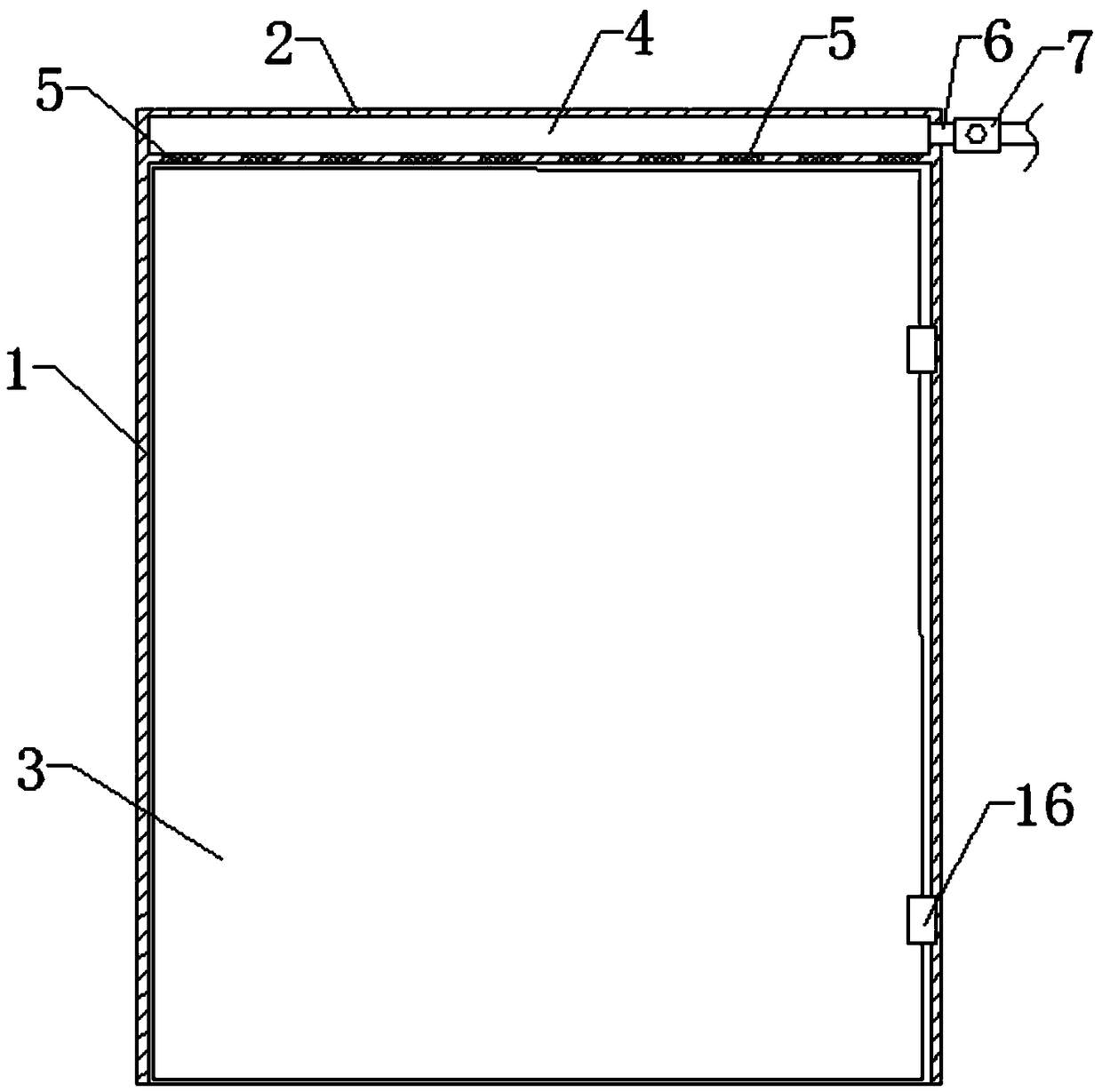

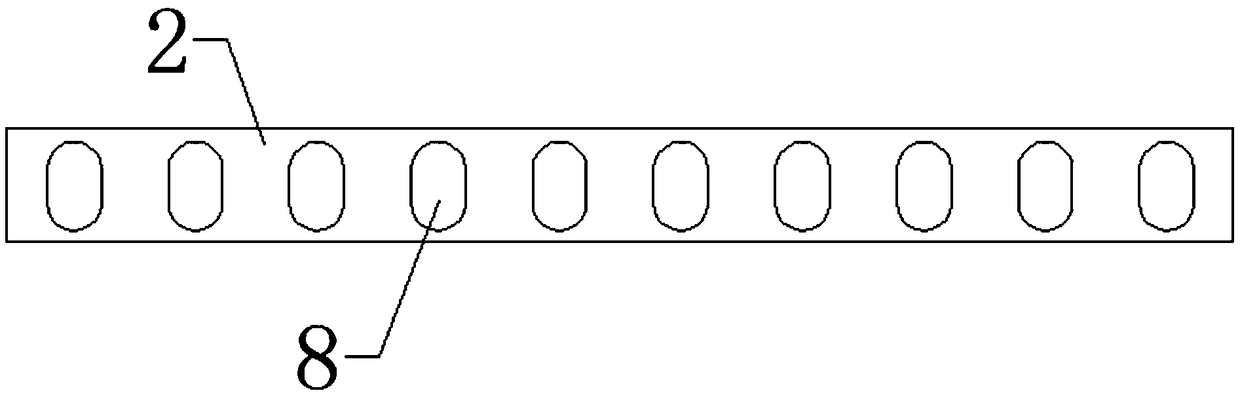

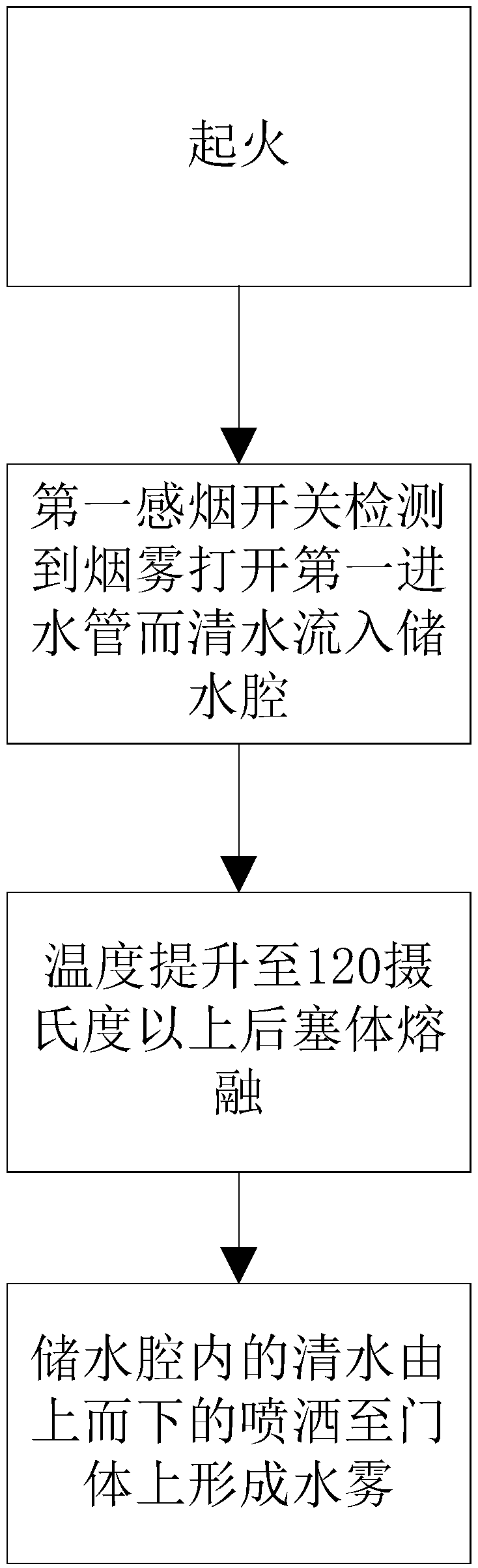

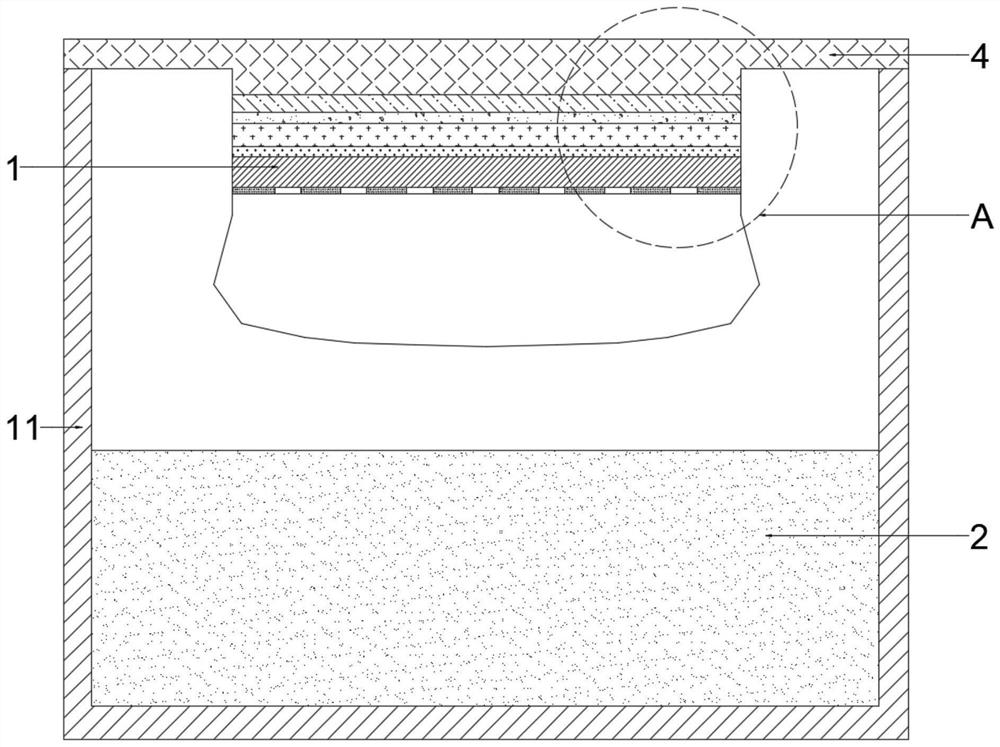

Fireproof door capable of realizing automatic door body cooling

InactiveCN108915542AImprove fire resistanceIncreased chance of survivalFireproof doorsFire rescueFire hazardPlastic materials

The invention discloses a fireproof door capable of realizing automatic door body cooling. The fireproof door comprises a door frame, a door head and a door body, wherein the door head is transverselyerected on the door frame; the door body is hinged to one side of the door frame; a water storage cavity in transverse arrangement is arranged inside the door head; a plurality of water outlet holesare formed at the lower end surface of the door head; a plug body made of PE plastic materials is embedded in each water outlet hole; a first water inlet pipe and a first smoke sensing switch are arranged at one side of the door head; the first smoke sensing switch is used for controlling the break-and-make state of the first water inlet pipe after detecting the smoke information in an indoor position; after the indoor temperature rises to 120 DEG C or higher, the plug body is naturally molten and softened to expose the water outlet hole; water flow flowing out from the water outlet hole is poured onto the door body to cool the door body; water mist is formed, so that the smoke is prevented from passing through seams on the periphery of the door body; the inside of the door body is hollowand forms an accommodating cavity; a second water inlet pipe and a second smoke sensing switch are connected under the door body. By adopting the technical scheme, the door body can be automaticallycooled; the smoke entering is prevented; the survival possibility of people in fire hazards can be effectively improved.

Owner:唐珊珊

Sacrificial silicon carbide seed crystal protective film

ActiveCN113502540APrevent volatilizationPlay a protective effectPolycrystalline material growthFrom condensed vaporsCarbon filmGraphite

The invention provides a sacrificial silicon carbide seed crystal protective film which comprises a first silicon carbide polycrystalline film covering the front surface of the seed crystal and a second silicon carbide polycrystalline film covering the back surface of the seed crystal; nanoscale through holes are uniformly distributed in the first silicon carbide polycrystalline film; the second silicon carbide polycrystalline film is a double-layer composite film and sequentially comprises a first film layer and a second film layer; the back surface of the seed crystal is sequentially covered with the second silicon carbide polycrystalline film, a carbon film and graphite paper, and the second film layer is attached to the carbon film. As the defect density of the silicon carbide polycrystalline film is greater than that of the seed crystal, the silicon carbide polycrystalline film is volatilized preferentially in the heating process, and the generated gas is filled near the surface of the seed crystal, so that the volatilization speed of the surface of the seed crystal is delayed, and the seed crystal is protected. The carbon film is used for reducing the exposed area of the second film layer and delaying volatilization of the second film layer. The graphite paper has an isolation effect on the silicon carbide and the seed crystal tray, the stress of the seed crystal is reduced, and the seed crystal and the crystal are prevented from cracking.

Owner:SUZHOU UKING PHOTOELECTRIC TECH CO LTD

Fireproof device of electrical equipment

PendingCN111956979APrevent burn-throughMonitor operationFire rescueBoring toolsCombustible gasEngineering

The invention discloses a fireproof device of electrical equipment. The fireproof device comprises a box body, wherein a heat insulting plate is fixed to the outer wall of the box body, a mounting groove is formed in the box wall of the box body, a heat insulating net is fixed to the inner wall of the mounting groove, fine sand fills the inner wall of the mounting groove, asbestos are fixed to theinner wall of the box body, an exhaust hole is formed in the center position of the top of the box body, an exhaust pipe is fixed to the inner wall of the exhaust hole, and a suction pump is connected to the top end of the exhaust pipe. By using the heat insulating plate, the heat insulating net, the fine sand and the asbestos, the fireproof device not only plays a role of blocking a fire source,but also prevents a burnthrough phenomenon of the box wall of the box body. By using a water pump, a water tank and a high pressure spray head to extinguish a fire source, the equipment is preventedfrom being damaged again. By using an electrical motor, a bidirectional threaded rod and a sealing door, the box body can be sealed when a fire happens, and meanwhile, vacuumizing is carried out directly by means of the exhaust pipe and the suction pump, combustible gas is blocked and extracted to achieve a fire-extinguishing effect.

Owner:湘潭市岳塘区通用电气设备厂

Dry deslagging continuous feeding biomass gasification furnace

The invention discloses a dry deslagging continuous feeding biomass gasification furnace, and mainly relates to the technical field of energy science. The dry deslagging continuous feeding biomass gasification furnace comprises a furnace body, an air distribution disc is arranged in the furnace body, a slag storage chamber is arranged on the outer side of the bottom of the air distribution disc and fixedly connected with the furnace body, a plurality of slag discharging pipes are arranged at the bottom of the slag storage chamber, upper inserting plates used for sealing the slag discharging pipes are arranged on the upper portions of the slag discharging pipes, and lower inserting plates used for sealing the slag discharging pipes are arranged on the lower portions of the slag dischargingpipes. Wherein a blanking pipe is arranged at the top of the furnace body, a conical distributor is arranged on the lower side of the blanking pipe, a spiral sealing feeder is arranged at the top of the blanking pipe, and a buffer bin is arranged at the top of one end, far away from the blanking pipe, of the spiral sealing feeder; continuous sealed feeding in the gasification process can be achieved, a material layer in the furnace body can be prevented from being fluffy, local partial burning deviation and burning through can be effectively prevented, the gasification strength can be improved, water consumption can be reduced, the ash utilization range can be enlarged, and overheating burning loss of the air distribution disc can be prevented.

Owner:山东信科环境科学研究院有限公司

Method for cooling air leaking flange of supporting plate of hot blast valve

InactiveCN106702063APrevent burn-throughReduce consumptionBlast furnace detailsHeating stovesDraining tubeCopper wire

The invention provides a method for cooling an air leaking flange of a supporting plate of a hot blast valve. The method comprises the following steps: winding an air leaking position by using a thin copper wire strand at first, and fastening and stressing through bolts of the flange; welding a cooling water tank to the lower part of the hot blast valve, and enabling the upper edge of the cooling water tank to be higher than the air leaking flange; respectively welding a water replenishing tube and a water draining tube to the upper part of the cooling water tank; connecting the water replenishing tube to a water tube through a ball valve and a cloth inserted hose, and meanwhile welding an overflow tube to the upper edge of the cooling water tank; then opening the ball valve on the water replenishing tube to carry out water replenishing; after water flows out from the water draining tube, adjusting the open degree of the ball valve, enabling water replenishing and water draining amount to be balanced, and cooling the flange submerged in cooling water through the flowing cooling water. The problem of rising of temperature caused by air leakage of the supporting plate of the hot blast valve can be controlled effectively, burn-through of the supporting plate is prevented, blast stopping accidents of a blast furnace are avoided, consumption of spare parts is reduced, repair costs are reduced, yield loss is avoided, and smooth production of the blast furnace is guaranteed.

Owner:ANGANG STEEL CO LTD

Multi-fuel indirect heating hot air stove with heat pipes

ActiveCN105466008AImprove thermal efficiencyIncrease the heat exchange areaAir heatersPlate heat exchangerProcess engineering

The invention relates to a multi-fuel indirect heating hot air stove with heat pipes. The multi-fuel indirect heating hot air stove is high in energy utilization rate and comprises an outer shield; a plate heat exchanger is arranged in the outer shield and comprises a first shell, a second shell arranged in the first shell, a third shell arranged in the second shell and a fourth shell arranged in the third shell; a first descending air flue is formed between the outer shield and the first shell, a smoke flue is formed between the first shell and the second shell, an ascending air flue is formed between the second shell and the third shell, a second descending air flue is formed between the third shell and the fourth shell, the first descending air flue is communicated with the ascending air flue, and the ascending air flue is communicated with the second descending air flue; the cavity of the fourth shell is communicated with the smoke flue, and a fire grate is arranged on the bottom surface of the cavity of the fourth shell; a hot air confluence cavity is formed in the lower part of the outer shield, a smoke box is arranged under the hot air confluence cavity, and a hot air outlet is formed in the back of the hot air confluence cavity; the multiple heat pipes are arranged on the top surface of the first shell.

Owner:SHANDONG SHUANGLI MODERN AGRI EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com