Fireproof door capable of realizing automatic door body cooling

An automatic cooling and fire door technology, applied in the field of fire doors, can solve problems such as bending deformation, physical health effects, and burning of fire doors, and achieve the effect of enhancing fire resistance and increasing the probability of survival.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

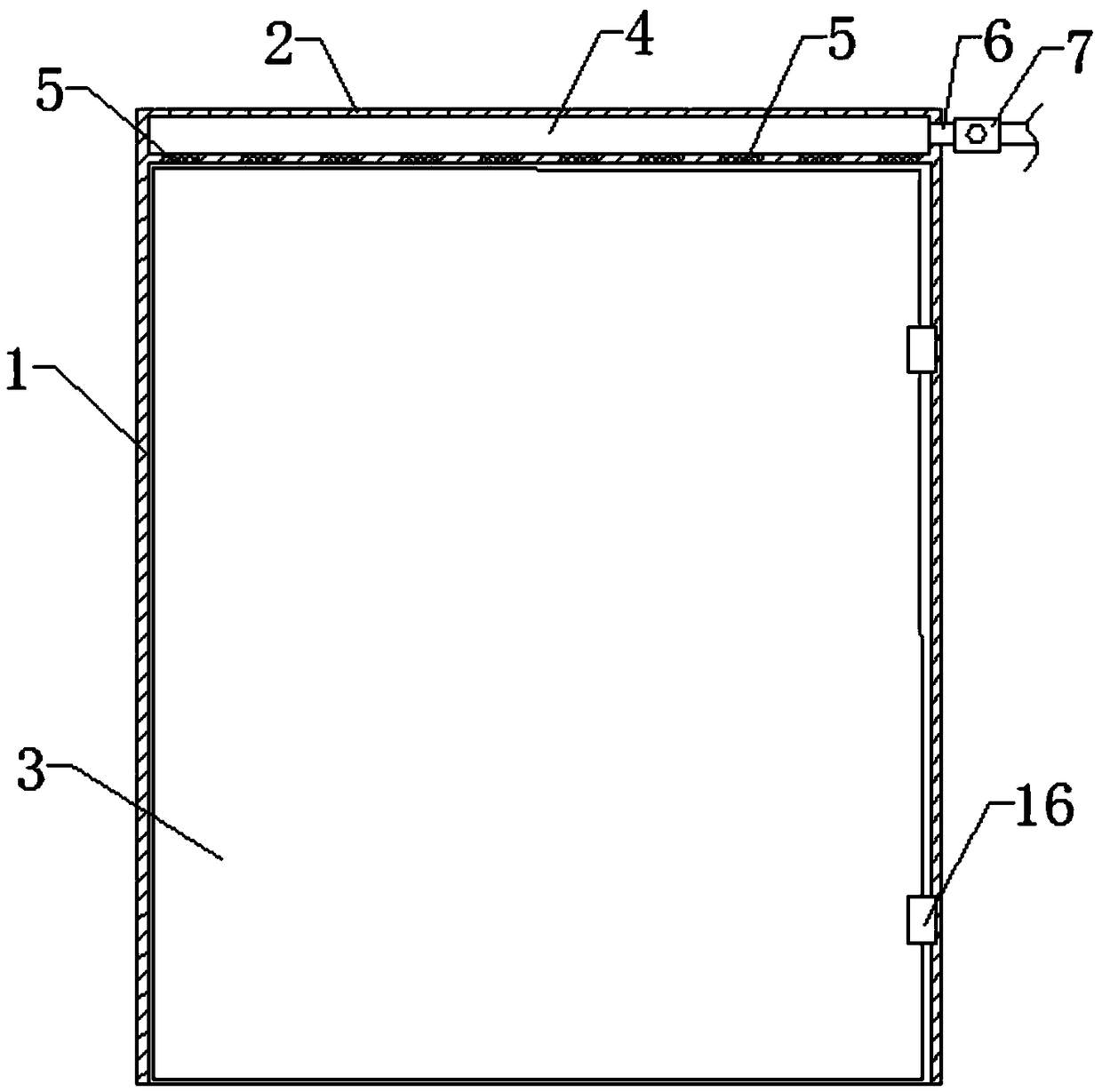

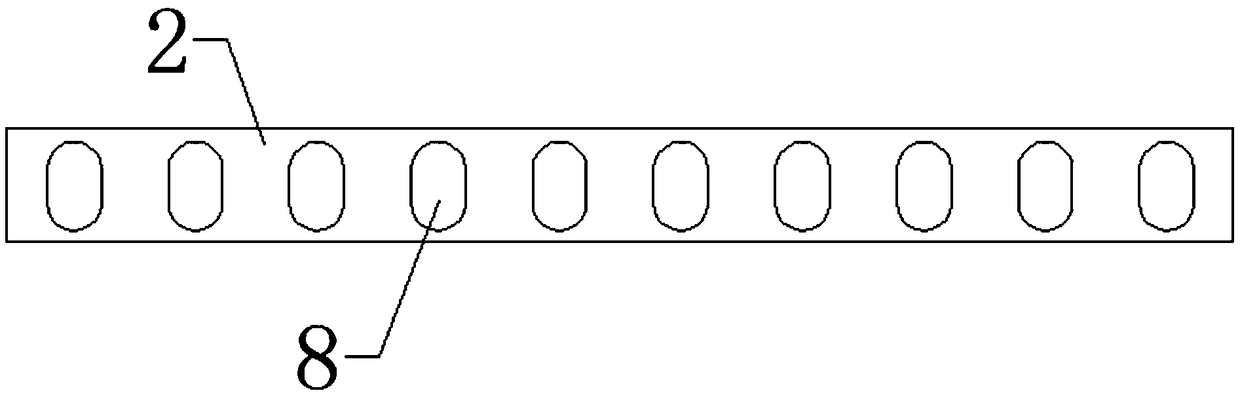

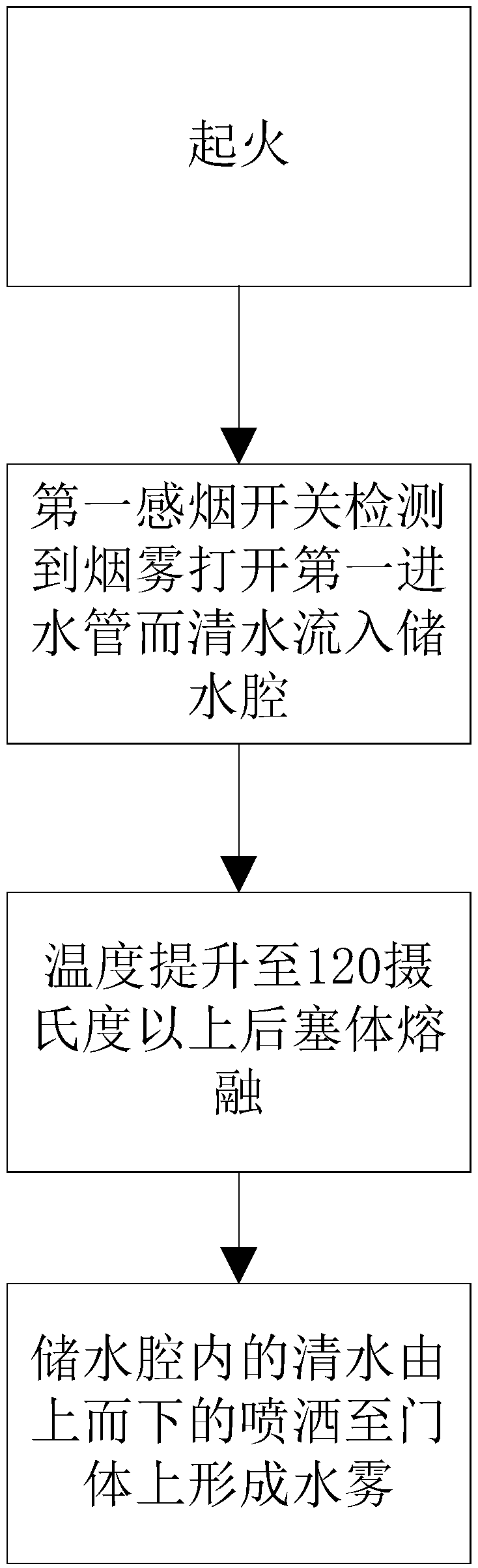

[0024] refer to figure 1 , is a schematic cross-sectional structure diagram of the first embodiment of the fire door capable of automatically cooling the door body; figure 2 , is the bottom view of the lintel in Embodiment 1 of the fire door capable of automatically cooling the door body; and image 3 , is a diagram of the operation steps of Embodiment 1 of the fire door capable of automatically cooling the door body.

[0025] Such as Figures 1 to 3 As shown in , the fire door capable of automatically cooling the door body provided by the present invention includes a door frame 1, a door lintel 2 crossed on the door frame 1, and a door body 3 hinged to one side of the door frame 1, wherein the door lintel 2 has a horizontally arranged The water storage chamber 4, and the lower end surface of the lintel 2 is arranged in an array along the length direction with a number of water outlet holes 8, and each water outlet hole 8 is embedded with a plug body 5 made of PE plastic ma...

Embodiment 2

[0030] refer to Figure 4 , is a schematic cross-sectional structure diagram of the second embodiment of the fire door capable of automatically cooling the door body; Figure 5 , is a diagram of the operation steps of Embodiment 2 of the fire door capable of automatically cooling the door body. Such as Figure 4 and Figure 5 As shown in , the fire door capable of automatically cooling the door body provided in this embodiment is basically the same as the first embodiment above, the difference is that a housing chamber 3 is formed in a hollow inside the door body 3, and a soft The pipe 10 is connected with a second water inlet pipe 12, and the second water inlet pipe 12 is equipped with a second smoke sensor switch 11, which is used to control the passage of the second water inlet pipe 12 after detecting the smoke information, and inject into the accommodating cavity 3 Water flow to enhance the fire resistance of the door body 3.

[0031] In a preferred embodiment, the hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com