Method for improving blast furnace hearth cooling efficiency

A technology for cooling efficiency and blast furnaces, applied in blast furnaces, cooling devices, blast furnace details, etc., to achieve the effects of improving cooling capacity, reducing reactive power consumption, and preventing burn-through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0049] Take the hearth cooling system of a large blast furnace as an example:

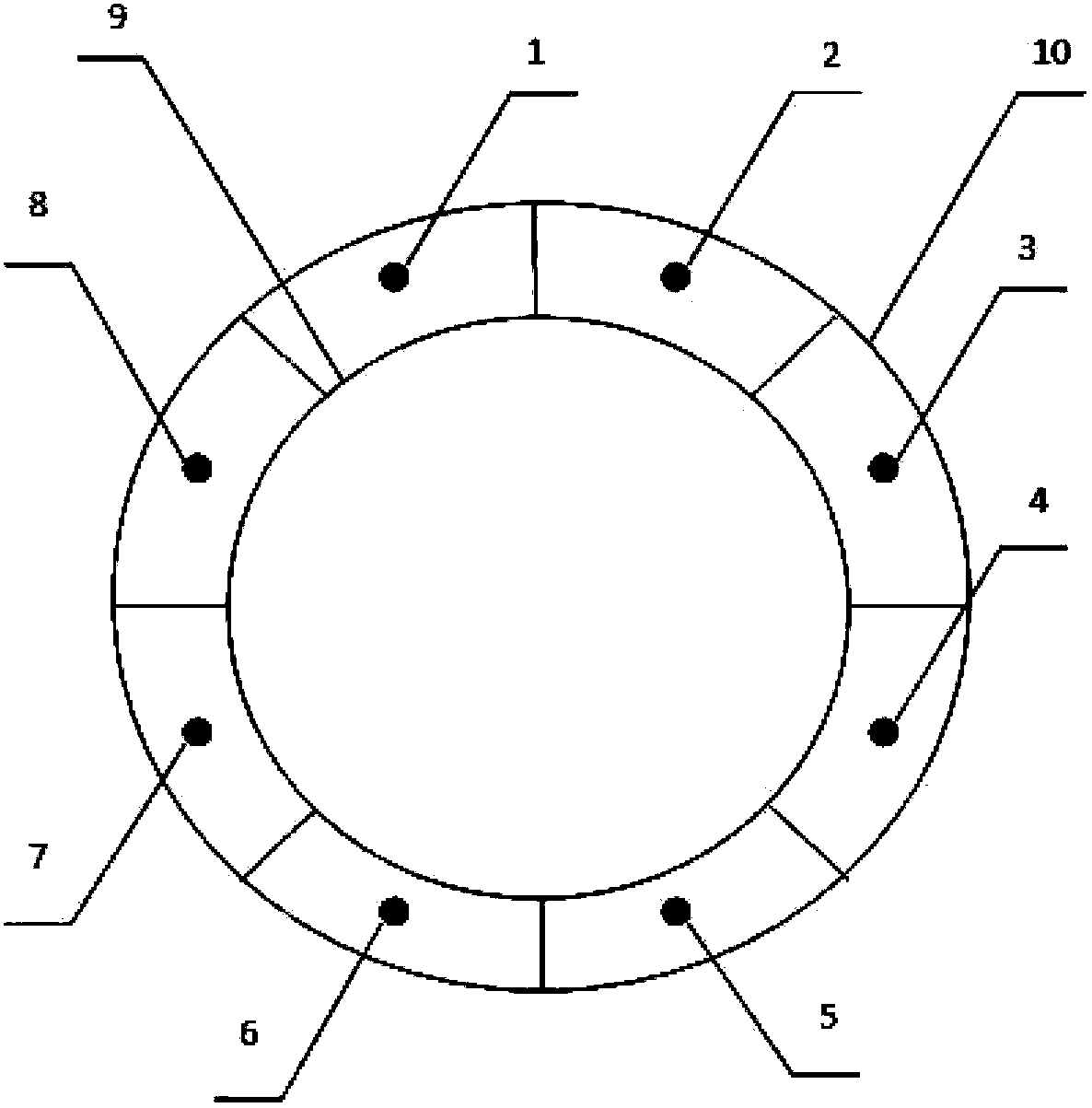

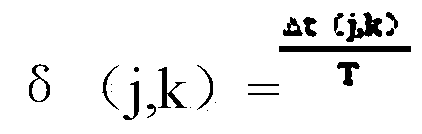

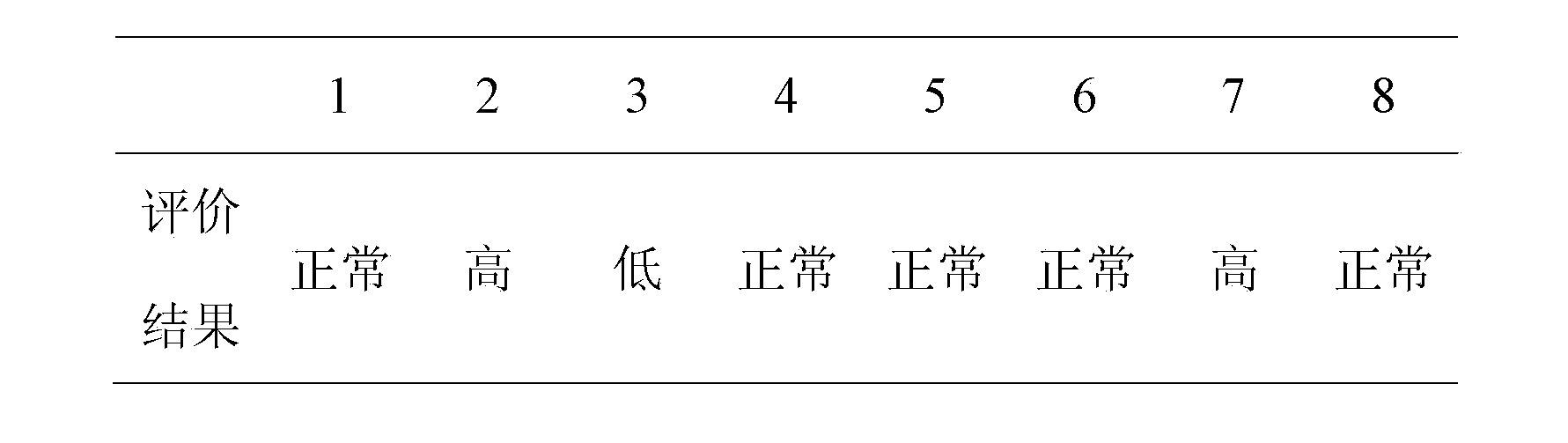

[0050] Step 1, such as figure 1 As shown, firstly, the blast furnace hearth is divided into 4 different symmetrical vertical section areas within the 360-degree circumference range, and the range of each area is calculated according to the following method: [0°+(i*α°),180°+ (i*α°)], where i=0, 1, 2, ...i end , α∈[0°,180°], and (i end +1)*α=180°. In this example, i end =3, α=45°, then the range of each area is: [0°,180°], [45°,225°], [90°,270°], [135°,315°], such as figure 1 , install thermocouples on the thermocouple installation points 1-8 respectively, and detect the temperature change of the furnace hearth. In this example, the cycle of collecting temperature is 0.5 hours, and the cycle of collecting temperature can also be adjusted according to the actual sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com