Gas-based shaft furnace direct reduction-electric furnace smelting separation process of vanadium titano-magnetite

A vanadium-titanium-magnetite and gas-based shaft furnace technology, which is applied in the direction of improving process efficiency, can solve the problems of high energy consumption and equipment investment, aggravated lining erosion of submerged arc furnace, high process investment and consumption, and achieves reduction of The effect of energy consumption and one-time investment in equipment, suitable for large-scale production, and effective clean separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

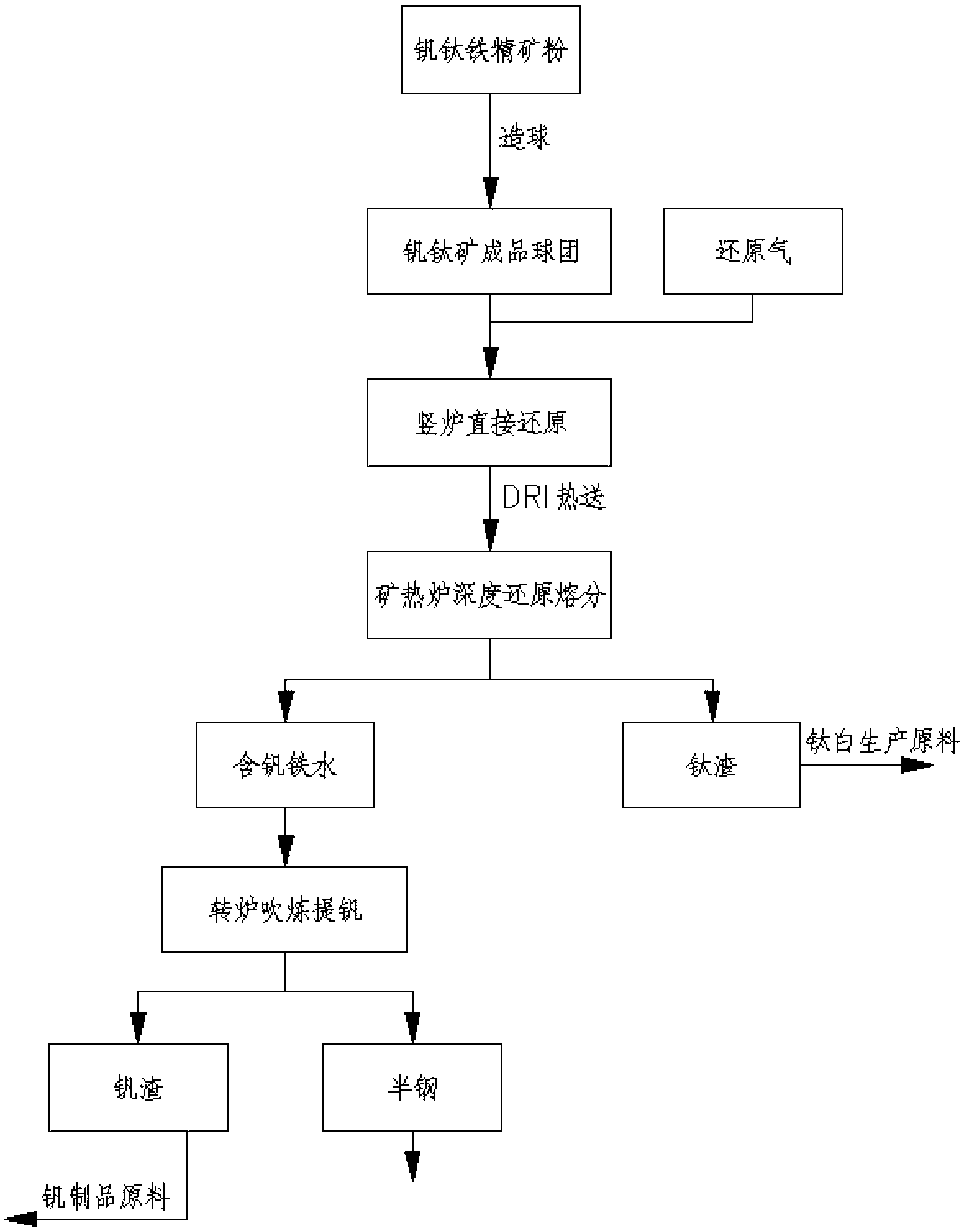

[0024] Such as figure 1 As shown, the gas-based shaft furnace direct reduction of the present embodiment-the process of electric furnace smelting vanadium-titanium magnetite comprises the following steps:

[0025] a. Finished product pellets: Mix 100% vanadium-titanium iron concentrate powder, bentonite and water in proportion to make green pellets; and dry and oxidize and roast to make finished vanadium-titanium ore pellets with a particle size of 8mm;

[0026] b. The finished vanadium-titanium ore pellets are loaded into the direct reduction shaft furnace as raw materials, and reducing gas is introduced into the shaft furnace to reduce the pellets to obtain hot direct reduced iron; the temperature of the reducing gas entering the shaft furnace is 900°C, Pressure 0.1MPa(G), reducing gas (CO+H 2 ) / (CO 2 +H 2 O)=9,CO+H 2 =80%,

[0027] c. The hot direct reduced iron is sent to the electric melting furnace for reduction and melting, and the titanium slag is separated to ...

Embodiment 2

[0035] Such as figure 1 As shown, the gas-based shaft furnace direct reduction of the present embodiment-the process of electric furnace smelting vanadium-titanium magnetite comprises the following steps:

[0036] a. Finished product pellets: Mix 100% vanadium-titanium iron ore concentrate powder, bentonite and water evenly in proportion to make pellets; and dry and oxidize and roast to make finished vanadium-titanium ore pellets with a particle size of 16mm;

[0037] b. The finished vanadium-titanium ore pellets are loaded into the direct reduction shaft furnace as raw materials, and reducing gas is introduced into the shaft furnace to reduce the pellets to obtain hot direct reduced iron; the temperature of the reducing gas entering the shaft furnace is 1100 °C, Pressure 0.4MPa(G), reducing gas (CO+H 2 ) / (CO 2 +H 2 O)=9.5,CO+H 2 =83%,

[0038] c. The hot direct reduced iron is sent to the electric melting furnace for reduction and melting, and the titanium slag is sep...

Embodiment 3

[0046] Such as figure 1 As shown, the gas-based shaft furnace direct reduction of the present embodiment-the process of electric furnace smelting vanadium-titanium magnetite comprises the following steps:

[0047] a. Finished product pellets: Mix 100% vanadium-titanium iron ore concentrate powder, bentonite and water evenly in proportion to make green pellets; and make finished vanadium-titanium ore pellets with a particle size of 12.5 mm after drying and oxidizing roasting;

[0048] b. The finished vanadium-titanium ore pellets are loaded into the direct reduction shaft furnace as raw materials, and reducing gas is introduced into the shaft furnace to reduce the pellets to obtain hot direct reduced iron; the temperature of the reducing gas entering the shaft furnace is 1000°C, Pressure 0.25MPa(G), reducing gas (CO+H 2 ) / (CO 2 +H 2 O)=9.2, CO+H 2 =81%,

[0049] c. The hot direct reduced iron is sent to the electric melting furnace for reduction and melting, and the tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com