Long-life blast furnace hearth

A blast furnace and longevity technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems such as blast furnace hearth erosion, hearth burn-through, etc., to reduce pig iron costs, promote development, and avoid hearth burn-through. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

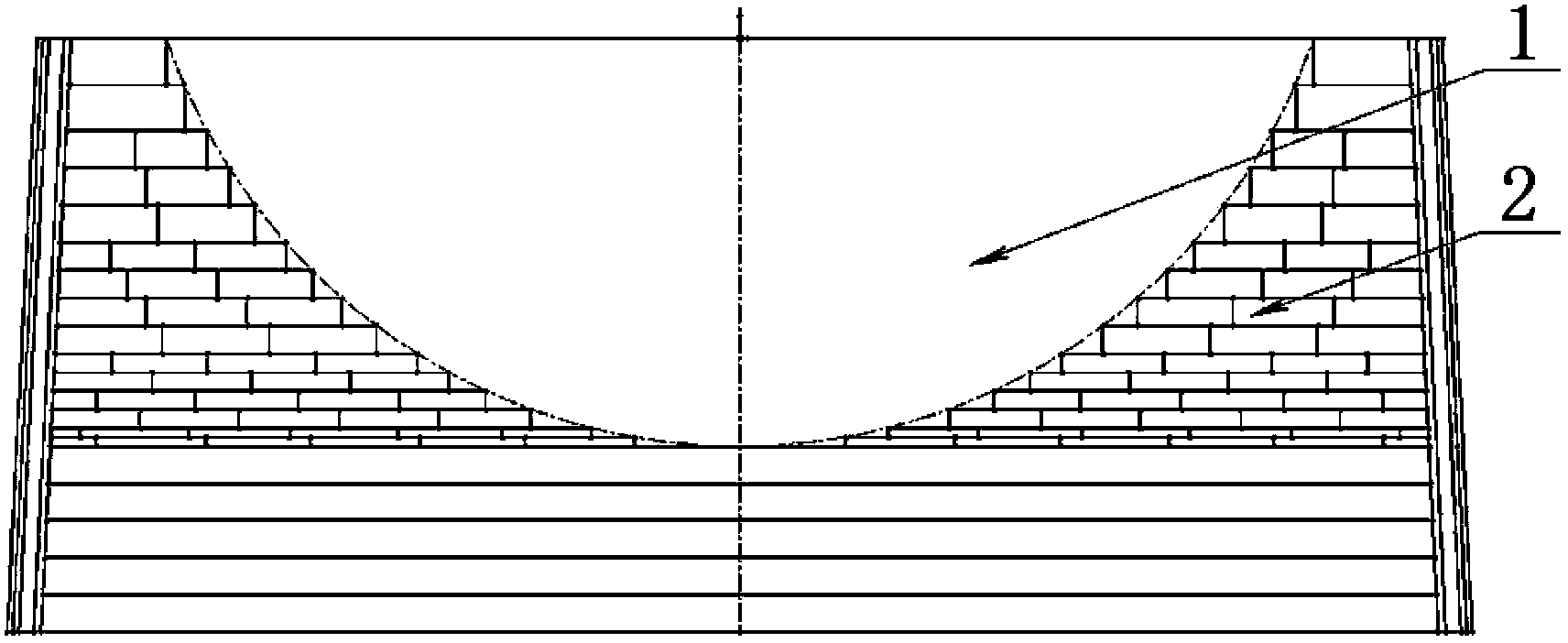

[0022] Take a certain 3200m 3 Take a blast furnace as an example, the diameter of hearth 1 of the blast furnace is 12.4m, and the height of the ball is 4.4m. According to the calculation formula given by the technical scheme, R = (A 2 +4B 2 ) / (8B), in the above formula, A is the diameter of the hearth, B is the height of the spherical gap, that is, the total height of the carbon bricks around the hearth, and the radius of the sphere can be obtained R = 6.57m;

[0023] Then according to the calculation formula given by the technical scheme, the hearth diameter of each layer of carbon bricks is: a=2(R 2 -(Σb) 2 ) 1 / 2 , in the above formula, R is the radius of the sphere, b is the thickness of the carbon brick, which is also the thickness of each layer; the hearth diameter of each layer of the hearth 1 and the ring of carbon bricks 2 can be obtained.

[0024] Table 1 shows the diameter of hearth determined by laying carbon bricks 2 on each layer of hearth 1, the number of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com