Method and system for treating schreyerite

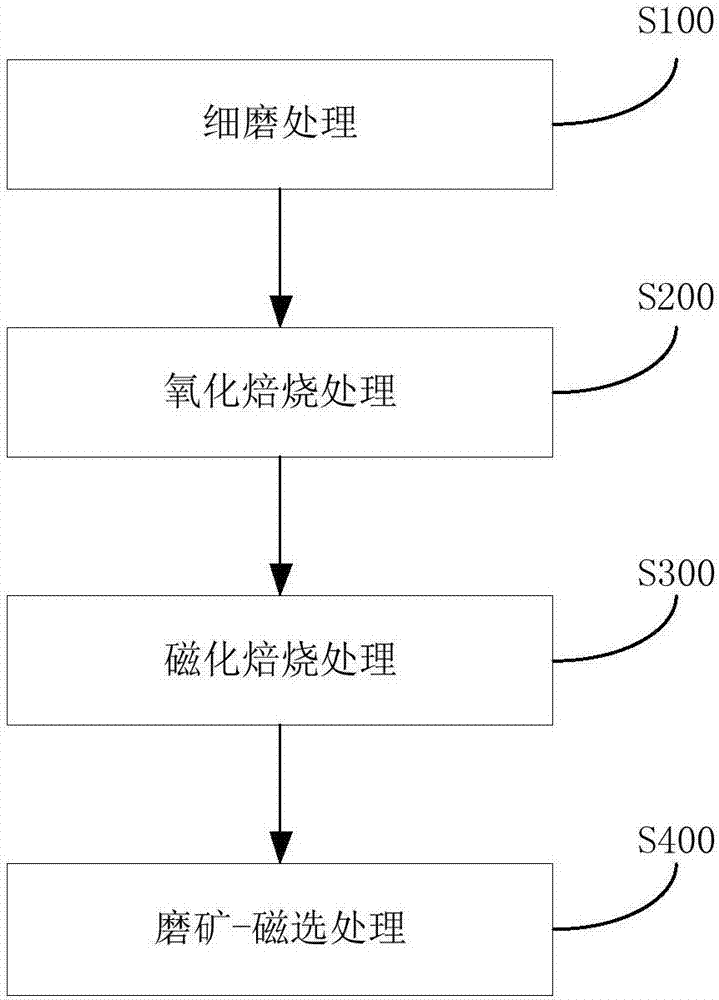

A vanadium-titanium ore grinding technology, applied in the field of metallurgy, can solve the problems of titanium resource loss, energy consumption, material consumption, high cost, difficulty in meeting high-efficiency, low-carbon, green production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

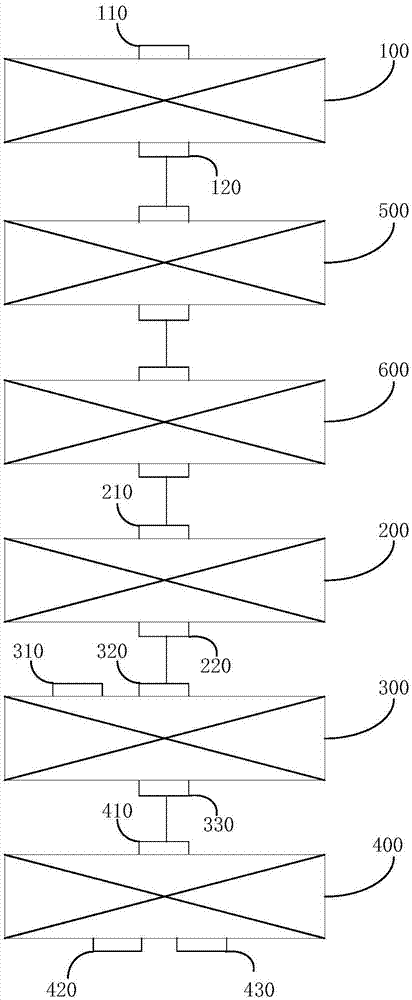

[0070] The raw ore is crushed and finely ground until the vanadium-titanium ore powder with a particle size of less than 75 μm accounts for about 50% by weight and sent to a magnetic separator for rough separation. , Table 2 and Table 3. During roughing, the magnetic field strength is 2000Oe. After roughing, the vanadium-titanium ore is transported to the mine through a belt, and the water is dried to 4% for use. After roughing, the vanadium-titanium ore powder is transported to the fluidized Bed silo, the furnace material is fed from the middle of the fluidized bed to the preheated fluidized bed through a screw feeder, and the iron ore is preheated to 400°C and sent to the oxidation roasting fluidized bed at a roasting temperature of 1100°C to oxidize the iron in the iron ore It is trivalent iron, destroys the phase structure of vanadium-titanium magnetite, iron-containing black titanite and magnesium-containing black titanite, and roasts for 30 minutes. The oxidized and roas...

Embodiment 2

[0085] The raw ore is crushed and finely ground until the vanadium-titanium ore powder with a particle size of less than 75 μm accounts for about 40% by weight and sent to a magnetic separator for rough separation. , Table 2 and Table 3. During roughing, the magnetic field strength is 1800Oe. The vanadium-titanium ore after roughing is transported to the mine through a belt, and the water is dried to 4% for use. The vanadium-titanium ore powder after roughing is transported to the fluidized bed silo, the furnace material is fed from the middle of the fluidized bed to the preheated fluidized bed through a screw feeder, and the vanadium-titanium ore powder is preheated to 400°C and sent to the oxidation roasting fluidized bed at a roasting temperature of 900°C. The iron in the ore is oxidized to ferric iron, which destroys the phase structure of vanadium-titanium magnetite, iron-containing black titanite and magnesium-containing black titanite. The roasting time is 30 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com